Summary of Contents for Wilden P2 series

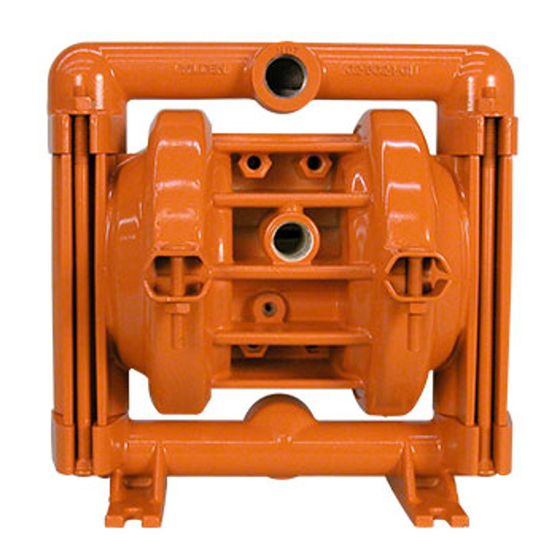

- Page 1 Engineering Operation & Maintenance Original Series ™ Metal Pump W h e r e I n n o v a t i o n F l o w s www.wildenpump.com WIL-10181-E-05 WIL-10181-E REPLACES WIL-10181-E-04...

-

Page 2: Table Of Contents

SECTION 2 WILDEN PUMP DESIGNATION SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 SECTION 3 HOW IT WORKS—PUMP &... -

Page 3: Cautions-Read First

CAUTION: Maximum temperature limits are based upon CAUTION: Tighten all hardware prior to installation. mechanical stress only. Certain chemicals will significantly reduce maximum safe operating temperatures. Consult Chemical Resistance Guide (E4) for chemical compatibility and temperature limits. WILDEN PUMP & ENGINEERING, LLC WIL-10181-E-05... -

Page 4: Wilden Pump Designation System

2103 Wil-Gard 220V 2480 Pump Cycle Monitor (sensor & wires) 2483 Pump Cycle Monitor (module, sensor & wires) NOTE: Most elastomers use colored dots for identification. Not all models are available with all material options. WILDEN PUMP & ENGINEERING, LLC WIL-10181-E-05... - Page 5 H O W I T W O R K S The Wilden diaphragm pump is an air-operated, positive displacement, self-priming pump. These drawings show fl ow pattern through the pump upon its initial stroke. It is assumed the pump has no fl uid in it prior to its initial stroke.

-

Page 6: Dimensional Drawings

D I M E N S I O N A L D R A W I N G S P 2 METAL DIMENSIONS ITEM METRIC (mm) STANDARD (inch) 10.8 10.0 10.8 11.9 REV. A P 2 METAL S A NIFLO DIMENSIONS ITEM METRIC (mm) STANDARD (inch) 10.8 10.0 11.2 12.2 REV. A WILDEN PUMP & ENGINEERING, LLC WIL-10181-E-05... -

Page 7: Rubber-Fitted

For optimum life and performance, pumps should be specified so that daily operation parameters will fall in the center of the pump's performance curve. CAUTION: Do not exceed 8.6 bar (125 psig) air supply pressure. WILDEN PUMP & ENGINEERING, LLC WIL-10181-E-05... -

Page 8: Reduced-Stroke Ptfe-Fitted

For optimum life and performance, pumps should be specified so that daily operation parameters consumption. (See dot on chart.) will fall in the center of the pump's performance curve. CAUTION: Do not exceed 8.6 bar (125 psig) air supply pressure. WILDEN PUMP & ENGINEERING, LLC WIL-10181-E-05... -

Page 9: Suction-Lift Curves

Suction-lift curves are calibrated for pumps operating at and discharge elbows, viscosity of pumping fluid, elevation 305 m (1,000’) above sea level. This chart is meant to be (atmospheric pressure) and pipe friction loss all affect the a guide only. There are many variables that can affect your amount of suction lift your pump will attain. pump’s operating characteristics. The number of intake WILDEN PUMP & ENGINEERING, LLC WIL-10181-E-05... - Page 10 The suction pipe size should be at least the equivalent or larger until the piping challenges of each possible location have been than the diameter size of the suction inlet on your Wilden pump . evaluated . The impact of current and future installations should be...

- Page 11 AIR-OPERATED PUMPS: To stop the pump from operating in an emergency situation, simply close the in an emergency situation . WILDEN PUMP & ENGINEERING, LLC WIL-10181-E-05...

-

Page 12: Assembly / Disassembly

ASSEMBLY/DISASSEMBLY INSTRUCTIONS . the parts life of a Wilden pump . Periodic inspections Pump discharge rate can be controlled by limiting the have been found to offer the best means for preventing volume and/or pressure of the air supply to the pump . - Page 13 . liquid chambers and air chamber to discharge manifolds to the center assist with proper alignment during section assembly . reassembly . WILDEN PUMP & ENGINEERING, LLC WIL-10181-E-05...

- Page 14 . shaft is not nicked, scratched, or gouged . Using an adjustable wrench, remove the diaphragm assembly from shaft . Inspect all parts for wear and replace with genuine Wilden parts, if necessary . WILDEN PUMP & ENGINEERING, LLC WIL-10181-E-05...

-

Page 15: Air Valve/Center Section Assembly

Remove air valve end cap to expose loosen the air valve bolts . plate from the center section . air valve spool . NOTE: The end cap cannot be removed until removing air valve bolts . WILDEN PUMP & ENGINEERING, LLC WIL-10181-E-05... - Page 16 “notched” end side first, this end incorporates the urethane O-ring and will be damaged as it slides over the ports cut in the pilot spool sleeve . WILDEN PUMP & ENGINEERING, LLC WIL-10181-E-05...

-

Page 17: Reassembly Hints & Tips

Description of Part Max. Torque Air Valve, Pro-Flo 3.1 N.m (27 in-lb) Air Inlet, Reducer Bushing 10.9 N.m (8 ft-lb) Outer Piston, Rubber and PTFE-fitted 40.7 N.m (30 ft-lb) Vertical Bolts 31.1 N.m (23 ft-lb) WILDEN PUMP & ENGINEERING, LLC WIL-10181-E-05... -

Page 18: P2 Metal

R U B B E R / T P E - F I T T E D E X P L O D E D V I E W FULL-STROKE PTFE-FITTED FULL-STROKE IPD SANIFLO FDA MANIFOLDS REDUCED-STROKE PTFE-FITTED REDUCED-STROKE IPD WILDEN PUMP & ENGINEERING, LLC WIL-10181-E-05... - Page 19 Air Valve Assembly includes items 2 and 3. Large Clamp Band Assembly for SANIFLO™ FDA pumps include items 17, 18 and 20. Center Section Assembly includes items 10 and 11. All boldface items are primary wear parts. WILDEN PUMP & ENGINEERING, LLC WIL-10181-E-05...

-

Page 20: P2 Metal Saniflo™ 1935/2004/Ec

1 9 3 5 / 2 0 0 4 / E C E X P L O D E D V I E W FULL-STROKE PTFE FULL-STROKE IPD REDUCED-STROKE PTFE REDUCED-STROKE IPD LW0094, Rev. A WILDEN PUMP & ENGINEERING, LLC WIL-10181-E-05... - Page 21 Air Valve Assembly includes items 2 and 3. Center Section Assembly includes items 12 and 14. Large Clamp Band Assembly for SANIFLO™ FDA pumps include items 17, 18 and 20. All boldface items are primary wear parts. WILDEN PUMP & ENGINEERING, LLC WIL-10181-E-05...

-

Page 22: Elastomer Options

DIAPHRAGMS DIAPHRAGMS DIAPHRAGMS BALLS O-RINGS FDA BUNA-N 02-1010-69E ® FDA EPDM 02-1010-74E 02-1060-54E SANIFLEX™ 02-1010-56E 02-1060-56E 02-1065-56E 02-1080-56E 02-1200-56E FDA WIL-FLEX™ 02-1010-57E 02-1065-57E 02-1031-57E PTFE 02-1010-55E 02-1040-55E 02-1010-72-85E 02-1060-55-85E 02-1080-55E 02-1200-55E LW0083, Rev. B WILDEN PUMP & ENGINEERING, LLC WIL-10181-E-05... - Page 23 8) Metal and Alloy 10) Plastics ® Compliance is subject to material and equipment storage, handling and usage recommended by Wilden in the engineering operation and maintenance manual and supplemental technical publications. This declaration is based on the following information: Statements of raw material suppliers ®...

- Page 24 N O T E S...

- Page 25 N O T E S...

- Page 26 N O T E S...

- Page 27 Since the use of Wilden pumps and parts is beyond our control, we cannot guarantee the suitability of any pump or part for a particular application and Wilden Pump and Engineering, LLC shall not be liable for any consequential damage or expense arising from the use or misuse of its products on any application.

- Page 28 SCREW PUMPS redscrewpump.com CENTRIFUGAL PUMPS griswoldpump.com SYSTEM ONE ® MAAG CENTRIFUGAL PUMPS FILTRATION blackmer.com PLASTIC MANUFACTURING & PROCESSING FILTRATION WILDEN ® maag.com AIR-OPERATED DOUBLE-DIAPHRAGM PUMPS MAAG wildenpump.com INDUSTRIAL PUMPS GEAR & SCREW PUMPS maag.com Where Innovation Flows 22069 Van Buren Street, reserves the right to modify the information and illustrations contained in this document without prior notice.

Need help?

Do you have a question about the P2 series and is the answer not in the manual?

Questions and answers