Wilden Original Series Engineering, Operation & Maintenance

Metal pumps

Hide thumbs

Also See for Original Series:

- Engineering, operation & maintenance (43 pages) ,

- Operation & maintenance manual (39 pages) ,

- Operation & maintenance manual (23 pages)

Subscribe to Our Youtube Channel

Summary of Contents for Wilden Original Series

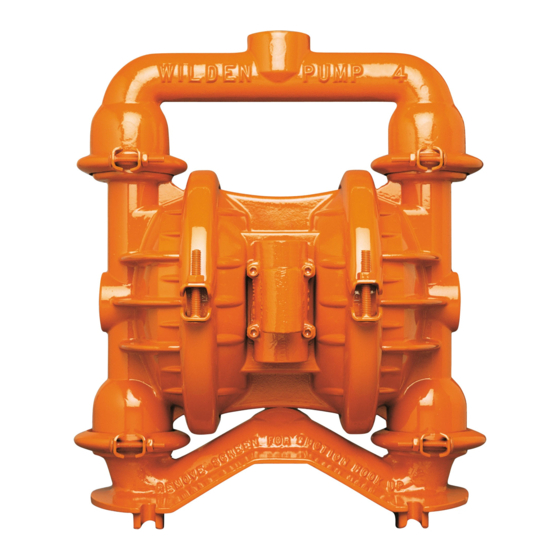

- Page 1 E n g i n e e r i n g O p e r a t i o n & ™ Original Series METAL Pumps M a i n t e n a n c e S i m p l i f y y o u r p r o c e s s WIL-10262-E-01 WIL-10262-E-01...

-

Page 2: Table Of Contents

..........1 SECTION 2 WILDEN PUMP DESIGNATION SYSTEM ....... . .2 SECTION 3 HOW IT WORKS—PUMP &... -

Page 3: Cautions-Read First

Pump, NOTE: All non lube-free air-operated pumps must be valves, and containers must be properly grounded when lubricated. Wilden suggests an arctic 5 weight oil (ISO handling flammable fluids and whenever discharge of grade 15). Do not over-lubricate pump. Over-lubrica- static electricity is a hazard. -

Page 4: Wilden Pump Designation System

, internals, spark free, BSPT 0231 Stallion ® , externals (screen) 0233 Stallion ® , externals (screen), BSPT NOTE: MOST ELASTOMERIC MATERIALS USE COLORED DOTS FOR IDENTIFICATION. ® Viton is a registered trademarks of DuPont Dow Elastomers. WILDEN PUMP & ENGINEERING, LLC WIL-10262-E-01... - Page 5 H O W I T W O R K S — P U M P The Wilden diaphragm pump is an air-operated, positive displacement, self-priming pump. These drawings show the flow pattern through the pump upon its initial stroke. It is assumed the pump has no fluid in it prior to its initial stroke.

-

Page 6: Dimensional Drawings

32 mm (1-1/4") BSP/ DIMENSIONS FNPT LIQUID DISCHARGE ITEM METRIC (mm) STANDARD (inch) 15.4 13 mm (1/2") BSP/ 17.7 FNPT AIR INLET 11.2 Ø14 Ø 0.6 BSP threads available. 38 mm (1-1/2") BSP/ FNPT LIQUID INLET WILDEN PUMP & ENGINEERING, LLC WIL-10262-E-01... -

Page 7: Rubber-Fitted

For optimum life and performance, pumps should be specified so that daily operation parameters 25.5 Nm /h (15 scfm) air consumption. (See will fall in the center of the pump performance curve. dot on chart.) Caution: Do not exceed 8.6 bar (125 psig) air supply pressure. WIL-10262-E-01 WILDEN PUMP & ENGINEERING, LLC... -

Page 8: Ptfe-Fitted

For optimum life and performance, pumps should be specified so that daily operation parameters Caution: Do not exceed 8.6 bar (125 psig) air will fall in the center of the pump performance curve. supply pressure. WILDEN PUMP & ENGINEERING, LLC WIL-10262-E-01... -

Page 9: Suction Lift Curves

(atmospheric pressure) and pipe friction loss all affect the amount of suction lift your pump will attain. PTFE Diaphragms [0.7] [1.4] [2.0] [2.7] [3.4] [4.1] [4.8] [5.5] [6.2] [6.9] WIL-10262-E-01 WILDEN PUMP & ENGINEERING, LLC... - Page 10 S e c t i o n 4 N O T E S WILDEN PUMP & ENGINEERING, LLC WIL-10262-E-01...

- Page 11 ATTACHING TO PUMP TO MAKE SURE ALL PIPE LINE be eliminated. In addition, pump efficiency can be adversely DEBRIS IS CLEAR. ALWAYS USE AN IN-LINE AIR affected if proper attention is not given to elevation (see pump FILTER. performance chart). WIL-10262-E-01 WILDEN PUMP & ENGINEERING, LLC...

- Page 12 The pump ness of process fluid all affect the parts life of a Wilden pump. has reached a “deadhead” situation and can be restarted...

- Page 13 Use only Wilden Glyd™ rings as they are of special construction and ISO 15-5 wt oil with arctic char- Air bubbles in pump discharge.

-

Page 14: Assembly / Disassembly

Be aware of any hazardous effects of contact with your process fluid. The Wilden T4 has a 38 mm (1-1/2") inlet and 32 mm (1-1/4") outlet and is designed for flows up to 81 gpm (307 lpm). The model T4 is available in aluminum, cast iron, or 316 stainless steel wetted parts. - Page 15 Remove the two small clamp bands, which fasten the intake chambers and inspect for nicks, gouges, chemical attack or manifold to the liquid chambers. Lift liquid chambers and abrasive wear. Replace worn parts with genuine Wilden parts center section from intake manifold to expose intake valve for reliable performance.

- Page 16 Inspect diaphragm bly from shaft. assembly and shaft for signs of wear or chemical attack. Replace all worn parts with genuine Wilden parts for reliable performance. WILDEN PUMP & ENGINEERING, LLC WIL-10262-E-01...

-

Page 17: Air Valve/Center Block Disassembly/Reassembly

It is reliable and simple to maintain. The bushing in the center block, along with the diaphragm shaft, provides the “trigger” to tell the air valve to shift. The following procedure will ensure that the air valve on your Wilden pump will provide long trouble-free service. AIR VALVE ASSEMBLY AND DISASSEMBLY:... - Page 18 Grooves In Bushing Which Contain Glyd™ Rings (Front View) CENTER AIR VALVE BLOCK INLET PISTON FILTER SCREEN P/N 04-3800-09-07 P/N 04-3100-01-225 Figure E END CAP Figure H *Refer to Section 8 for torque specifications. WILDEN PUMP & ENGINEERING, LLC WIL-10262-E-01...

-

Page 19: Reassembly Hints & Tips

3.4 N·m [30 in-lbs] Large Clamp Band (Rubber-Fitted) 10.7 N·m [95 in-lbs] Large Clamp Band (PTFE-Fitted) 13.5 N·m [120 in-lbs] Center Block Assembly 8.5 N·m [75 in-lbs] Polyurethane Screen Base 2.3 N·m [20 in-lbs] WIL-10262-E-01 WILDEN PUMP & ENGINEERING, LLC... -

Page 20: Gasket Kit Installation

G A S K E T K I T I N S T A L L A T I O N The Wilden T4 cast iron pumps require PTFE gasket tape on the liquid chambers (P/N 04-9502-99). Other pump types may use PTFE gasket kits for additional sealing character- istics. - Page 21 N O T E S WIL-10262-E-01 WILDEN PUMP & ENGINEERING, LLC...

-

Page 22: Exploded View & Parts Listing

E X P L O D E D V I E W & P A R T S L I S T I N G T4 METAL R u bber / T P E - F i t t ed E X P L O D E D V I E W WILDEN PUMP & ENGINEERING, LLC WIL-10262-E-01... - Page 23 (P/N 04-5660-01) and one bolt (P/N 08-6140-03). See exploded view on page 26 for details. NOTE: Cast iron pumps require a reinforcing washer (P/N 04-6800-08) between the outer piston (P/N 04-4550-08) and bolt (P/N 04-6090-08). All boldface items are primary wear parts. WIL-10262-E-01 WILDEN PUMP & ENGINEERING, LLC...

-

Page 24: Ptfe-Fitted

E X P L O D E D V I E W & P A R T S L I S T I N G T4 METAL P T F E - F i t t ed E X P L O D E D V I E W PTFE Assembly WILDEN PUMP & ENGINEERING, LLC WIL-10262-E-01... - Page 25 * Back-up Diaphragm for PTFE-fi tted pump: P/N 04-1060-51. Sanifl ex™ Back-up Diaphragm, P/N 04-1060-56, is available upon request for PTFE-fi tted pumps. Please consult your local distributor. All PTFE fi tted cast iron pumps require 1/2" gasket tape P/N 04-9502-99 BSP threads available. All boldface items are primary wear parts. WIL-10262-E-01 WILDEN PUMP & ENGINEERING, LLC...

-

Page 26: Elastomer Options

E L A S T O M E R O P T I O N S – S T A L L I O N T4 Metal STALLION Pumps Diaphragms (2) VALVE BALLS (4) VALVE SEATS (4) MATERIAL Neoprene 04-1020-51 04-1080-51-50 04-1120-51-50 Buna-N 04-1020-52 04-1080-52-50 04-1120-52-50 EPDM 04-1020-54 04-1080-54-50 04-1120-54-50 Viton ® 04-1020-53 04-1080-53-50 04-1120-53-50 WILDEN PUMP & ENGINEERING, LLC WIL-10262-E-01... - Page 27 Since the use of Wilden pumps and parts is beyond our control, we cannot guarantee the suitability of any pump or part for a particular application and Wilden Pump and Engineering, LLC shall not be liable for any consequential damage or expense arising from the use or misuse of its products on any application.

Need help?

Do you have a question about the Original Series and is the answer not in the manual?

Questions and answers