Subscribe to Our Youtube Channel

Summary of Contents for Fluke 7 Series

- Page 1 ® 7 Series Meters Service Manual PN 602730 August 1996 © 1996 Fluke Corporation, All rights reserved. Printed in U.S.A. All product names are trademarks of their respective companies.

- Page 2 Fluke authorized resellers shall extend this warranty on new and unused products to end-user customers only but have no authority to extend a greater or different warranty on behalf of Fluke. Warranty support is available if product is purchased through a Fluke authorized sales outlet or Buyer has paid the applicable international price.

-

Page 3: Table Of Contents

Table of Contents Chapter Title Page Introduction and Specifications............1-1 Introduction ....................... 1-1 Specifications ....................1-1 Theory of Operation................2-1 Introduction ....................... 2-1 Analog Measurement IC (U1) ................2-1 Microcomputer IC (U2)..................2-3 Automatic Selection Input Resistance............... 2-3 Maintenance ..................3-1 Introduction ....................... - Page 4 12/18/7 Service Service Manual...

- Page 5 List of Tables Table Title Page 1-1. Specifications......................1-2 2-1. Electrical Components on Main PCA..............2-2 2-2. U1 Pinout Table..................... 2-4 3-1. Required Equipment ....................3-6 3-2. Performance Tests for Models 7-300 and 7-600 ........... 3-7 3-3. Performance Tests for Models 12B and 18 ............3-8 4-1.

- Page 6 12/18/7 Service Service Manual...

- Page 7 List of Figures Figure Title Page 2-1. Typical Automatic Selection Input Resistance with DC Volts Function Selected 2-3 3-1. Models 12B and 18 Disassembled Unit..............3-3 3-2. Models 7-300 and 7-600 Disassembled Unit............3-4 3-3. Removing and Reinserting the Printed Circuit Assembly ........3-5 3-4.

- Page 8 12/18/7 Service Service Manual...

- Page 9 MULTIMETER SAFETY The Fluke 7-300, 7-600, 12B, and 18 Meters have been designed and tested according to IEC Publication 1010, Safety Requirements for Electronic Measuring Apparatus. This manual contains information and warnings that must be followed to ensure safe operation and keep the meter in safe condition.

-

Page 10: Introduction And Specifications

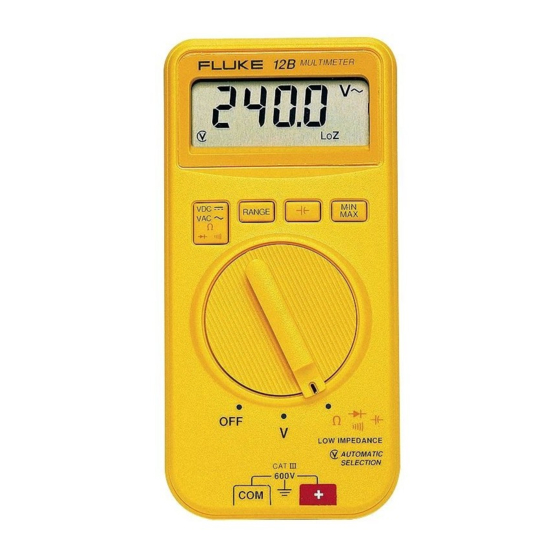

To avoid electric shock, perform only those service procedures described in this manual. The 12B, 18, 7 Series Service Manual provides the information necessary to service the Fluke Model 12B, Model 18, and Models 7-300 and 7-600 meters. This manual provides the following information: •... - Page 11 12B/18/7 Series Service Manual Accuracy specifications are given as follows: ±([% of reading] + [number of least significant digits]) Table 1-1. Specifications Maximum Voltage Between any 600V ac rms or dc Terminal and Earth Ground (excludes 10% tolerance) Display 3-3/4-digits, 4000 counts, updates 4/sec Operating Temperature -10°C to 50°C...

- Page 12 Introduction and Specifications Specifications Table 1-1. Specifications (continued) Accuracy (50 to 400 Hz) Function Range Resolution 7-300 7-600 12B/18 4000 mV 1 mV ±(1.9%+3) 4.000V 0.001V ±(1.9%+3) 40.00V 0.01V ±(2.9%+3) ±(2.9%+3) ±(1.9%+3) 300.0V 0.1V ±(2.9%+3) 400.0V 0.1V ±(2.9%+3) ±(1.9%+3) 600.0V ±(2.9%+3) ±(1.9%+3) 4000 mV...

- Page 13 12B/18/7 Series Service Manual Table 1-1. Specifications (continued) Common Mode Rejection Ratio Overload Input (1 kΩ Normal Mode Function Protection Impedance Unbalanced) Rejection (Nominal) 600V rms or dc >60 dB at dc 50 or >5 MΩ <100pF 60 Hz Automatic Selection and LoZ = >2 kΩ...

-

Page 14: Theory Of Operation

Chapter 2 Theory of Operation Introduction Chapter 2 provides a basic theory of operation for the Models 7, 12B, and 18 Meters. Electrical components on the printed circuit assembly (A1 Main PCA) are listed in Table 2-1. Refer to Figure 4-3 for the location of these components and Figures 4-4 through 4-7 for the schematic diagrams. - Page 15 12B/18/7 Series Service Manual Table 2-1. Electrical Components on Main PCA Circuit and Function Component Designator(s) Analog Measurement IC Microcomputer IC Input Divider and Ohms Reference Resistor Network Input Divider AC Coupling Capacitor J2 Input Receptacle Voltage Sense Resistor J1 Input Receptacle Voltage Sense Resistor...

-

Page 16: Microcomputer Ic (U2)

Theory of Operation Microcomputer IC (U2) Finally, digital circuitry interfaces with U2 via a parallel address and bidirectional data bus. Voltage is measured using a ratio comparison of the unknown voltage to the reference voltage (REFI pin). Resistance is calculated using a ratio comparison of the voltage across the unknown resistor to the voltage across a precision reference resistor, with the same current in both. - Page 17 Common input sense line. No current flow (analog ground). CLAMP Op amp output voltage for Q2 clamp transistor base drive AMPS Shunt resistor sense pin. Unused in Fluke Model 18. ISRC Current source pin for continuity, ohms, and capacitance Slide-switch position sense pin. Internal pull down.

- Page 18 Theory of Operation Automatic Selection Input Resistance Table 2-2 U1 Pinout Table (continued) Pin No. Pin Name Description APV0 DC volts input pin from 10 MΩ resistor DIVLO Input divider (Z1) common (low) pin APV1 10-to-1 voltage divider and 1 MΩ reference resistor input APV2 100-to-1 voltage divider and 100 kΩ...

- Page 19 12B/18/7 Series Service Manual...

- Page 20 A Message From Fluke Corporation Some semiconductors and custom IC's can be damaged by electrostatic discharge during handling. This notice explains how you can minimize the chances of destroying such devices 1. Knowing that there is a problem.

- Page 21 8. WHEN REMOVING PLUG-IN ASSEMBLIES 5. USE STATIC SHIELDING CONTAINERS FOR HANDLE ONLY BY NON-CONDUCTIVE HANDLING AND TRANSPORT. EDGES AND NEVER TOUCH OPEN EDGE CONNECTOR EXCEPT AT STATIC-FREE WORK STATION. PLACING SHORTING STRIPS ON EDGE CONNECTOR HELPS PROTECT INSTALLED S.S. DEVICES. 6.

-

Page 22: Maintenance

Chapter 3 Maintenance Introduction Chapter 3 covers the following: • Disassembly and reassembly • Cleaning • Performance tests • Calibration Disassembly and Reassembly P Warning To avoid electrical shock, remove test leads and any input signals before opening the case. Caution To avoid contamination from the fingers, handle the pca by the edges or wear gloves. - Page 23 12B/18/7 Series Service Manual Referring to Figures 3-1 and 3-2 as necessary, disassemble the meter as follows. A Phillips-head screwdriver and small flat-blade screwdriver are required. 1. Remove the test leads and set the slide switch or rotary knob to OFF.

- Page 24 Maintenance Disassembly and Reassembly Case, Top Conn. Elastomeric Conn. Elastomeric LCD to PCA Switch Assembly Actuator, Switch Support, Switch Assembly Battery Shock Absorber Main PCA Case, Bottom Shield, Bottom Screw, THD Form, PH.P.STL, 5-14 x .750 Foot as07f.eps Figure 3-1. Models 12B and 18 Disassembled Unit...

- Page 25 12B/18/7 Series Service Manual Case, Top Conn. Elastomeric LCD to PCA Actuator Switch Support, Switch Assembly Main PCA Shock Absorber Battery Shield, Bottom Case, Bottom Screw, THD Form, PH.P.STL, Foot 5-14 x .750 as10f.eps Figure 3-2. Models 7-300 and 7-600 Disassembled Unit...

- Page 26 Maintenance Disassembly and Reassembly Snap Snaps Snap as04f.eps Figure 3-3. Removing and Reinserting the Printed Circuit Assembly...

-

Page 27: Cleaning

1. Connect the calibrator to the [+] and COM jacks on the meter. 2. Referring to Table 3-2 for the Fluke 7-300 or 7-600, or Table 3-3 for the Fluke 12B or 18, put the meter in the function and range shown for Test 1. - Page 28 Maintenance Performance Tests Table 3-2. Performance Tests for Models 7-300 and 7-600 Test No. Applicable Meter Input To Display Display Model(s) Range Meter Minimum Maximum 7-300/7-600 40.00V ac 4.40V, 50 Hz 4.24 4.56 7-300/7-600 40.00V ac 35V, 50 Hz 33.95 36.05 7-300/7-600 40.00V ac...

- Page 29 12B/18/7 Series Service Manual Table 3-3. Performance Tests for Models 12B and 18 Test Meter Range Input To Switch Display Display Meter Position Minimum Maximum (Automatic Selection 12B Only) 4.000V ac Center 0.000 0.003 4.000V ac, MIN MAX Center 0.000 0.040...

-

Page 30: Calibration Adjustments For Models 12B And 18

Maintenance Calibration Adjustments for Models 12B and 18 Calibration Adjustments for Models 12B and 18 To ensure that the meter performs to specifications, make calibration adjustments annually using the following procedure: 1. Set the calibrator for 0V dc. Put the meter in the 4.000V dc range. 2. -

Page 31: Calibration Adjustments For Models 7-300 And 7-600

12B/18/7 Series Service Manual Clip to Base Contacts Input Receptacles BATTERY Adjust R4 for 3.997-4.003V DC as05f.eps Figure 3-4. Calibration Adjustment Calibration Adjustments for Models 7-300 and 7-600 To ensure that the meter performs to specifications, make calibration adjustments annually using the following procedure: 1. - Page 32 Maintenance Calibration Adjustments for Models 7-300 and 7-600 5. Connect the calibrator to the [+] and COM input jacks on the meter. Defeat the 50Ω divider on the calibrator (if any). 6. Apply an input of 3.500V dc ±0.25%. Wait at least 3 seconds. 7.

- Page 33 12B/18/7 Series Service Manual 3-12...

-

Page 34: Parts And Schematics

Electrical components may be ordered directly from the manufacturer by using the manufacturers part number, or from the Fluke Corporation and its authorized representatives by using the part number under the heading FLUKE STOCK NO. In the U.S., order directly from the Fluke Parts Dept. by calling 1-800-526-4731. Parts price information is available from the Fluke Corporation or its representatives. -

Page 35: Manual Status Information

This instrument may contain a Nickel-Cadmium battery. Do not mix with the solid waste stream. Spent batteries should be disposed of by a qualified recycler or hazardous materials handler. Contact your authorized Fluke service center for recycling information. P Warning To avoid fire or explosion, replace the fusible resistor only with Fluke PN 867361. - Page 36 Parts and Schematics Parts Lists, Drawings, and Schematics Table 4-2. Models 12B, 18, and 18/AL Final Assembly Reference Fluke Stock Total Designator Description Number Quantity MAIN PCA (MODEL 12B) 879002 MAIN PCA (MODEL 18) 878991 BATTERY, 9V, 0-15MA 696534 H1-4 SCREW, PH, P, AM THD FORM, STL, 5-14, .750...

- Page 37 12B/18/7 Series Service Manual MP10 H1-4 MP11 FLUKE 12B, FLUKE 18, FLUKE 18/AL T&B as06f.eps Figure 4-1. Models 12B and 18 Final Assembly...

- Page 38 CASE TOP, (PAD XFER & WINDOW, MODEL 7-300) 614922 ACTUATOR, SWITCH 203452 SUPPORT, SWITCH ASSEMBLY 879031 CASE, BOTTOM, YELLOW 614864 SHIELD, BOTTOM 878277 MP10 SHOCK ABSORBER 878983 MP11 FOOT, NON-SKID 885884 MP12 TEST LEADS 855742 LCD, 3.5 DIGIT, MULTIPLEXED 855226 INSTRUCTION SHEET, FLUKE 7 602018...

- Page 39 12B/18/7 Series Service Manual MP10 H1-4 MP11 FLUKE 7-300, FLUKE 7-600 T&B as09f.eps Figure 4-2. Models 7-300 and 7-600 Final Assembly...

- Page 40 Parts and Schematics Parts Lists, Drawings, and Schematics Table 4-4. A1 Main PCA Fluke Stock Total Quantity Reference Designator Description Number 7-300 7-600 CAP, TA, 0.47 µF, ±20%, 35V 655035 CAP, POLYES, 0.022 µF, ±10%, 50V C2, C5-7 715268 CAP, POLYES, 0.022 µF, ±10%, 50V...

- Page 41 12B/18/7 Series Service Manual Table 4-4. A1 Main PCA (cont) Fluke Stock Reference Total Quantity Designator Description Number 7-300 7-600 RES, CERM, 100K, ±1%, .125W, 100 PPM, 1206 769802 RES, CERM, 0, +.05 MAX, .125W, 1206 810747 THERM, POS 1.1K, ±20%, 25C...

- Page 42 Parts and Schematics Parts Lists, Drawings, and Schematics FLUKE 12-1601 as11f.eps Figure 4-3. Models 12B, 18, 7-300, and 7-600 Main PCA Components...

- Page 43 12B/18/7 Series Service Manual as20f.eps Figure 4-4. Model 12B Schematic 4-10...

- Page 44 Parts and Schematics Parts Lists, Drawings, and Schematics as21f.eps Figure 4-4. Model 12B Schematic (cont) 4-11...

- Page 45 12B/18/7 Series Service Manual as16f.eps Figure 4-5. Model 18 Schematic 4-12...

- Page 46 Parts and Schematics Parts Lists, Drawings, and Schematics as17f.eps Figure 4-5. Model 18 Schematic (cont) 4-13...

- Page 47 12B/18/7 Series Service Manual as12f.eps Figure 4-6. Model 7-300 Schematic 4-14...

- Page 48 Parts and Schematics Parts Lists, Drawings, and Schematics as13f.eps Figure 4-6. Model 7-300 Schematic (cont) 4-15...

- Page 49 12B/18/7 Series Service Manual as18f.eps Figure 4-7. Model 7-600 Schematic 4-16...

- Page 50 Parts and Schematics Parts Lists, Drawings, and Schematics as19f.eps Figure 4-7. Model 7-600 Schematic (cont) 4-17...

- Page 51 12B/18/7 Series Service Manual 4-18...

- Page 52 Service Centers PN 850941 2/96...

- Page 53 Service Centers (cont) 2/96...

Need help?

Do you have a question about the 7 Series and is the answer not in the manual?

Questions and answers