Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Bartec MAK TIGER 3003

- Page 1 MAK 3003 Measuring system TIGER / LYNX Operating Instructions Software MAK 3003 2.35 BA 190130 BARTEC BENKE GmbH Schulstrasse 30 D-94239 Gotteszell Tel. +49(0)9929)-301-0 Fax +49(0)9929)-301-112 E-mail: gotteszell@bartec.com Internet: www.bartec.de...

- Page 2 All rights reserved. Subject to change without prior notice. Copyright © 2022 by No part of this document may be reproduced, processed or distributed BARTEC BENKE in any form or by any means without the prior written permission of BARTEC Schulstraße 30 BENKE. D-94239 Gotteszell...

-

Page 3: Table Of Contents

Contents Table of Contents About this manual ........................... 5 Safety Precautions .......................... 6 Basics 7 Compact Controller ....................... 7 3.1.1 Keypad .......................... 7 3.1.2 Display .......................... 7 Operating Concept ......................8 3.2.1 The software user interface ..................8 3.2.2 Info line ......................... 8 3.2.3 Softkeys ........................ - Page 4 Contents 12.8 Activate pre-sample....................63 12.9 Pre-sample switched off ..................... 63 12.10 Long-term memory ..................... 64 12.11 Unloading unmeasured ....................65 12.12 Driver number input ....................66 12.13 Tank segment levels ....................66 12.14 Tank segment quality ....................67 13 Shortcut keys ..........................68 13.1 Intake data of the last supplier ...................

- Page 5 No liability shall be accepted for consequential damage as a general rule. EU-Declaration of conformity We BARTEC BENKE GmbH, Schulstraße 30, D-94239 Gotteszell, hereby declare, that this product is in compliance with the essential re- quirements of the relevant EU-directives.

- Page 6 Contents MAK 3003 Measuring system TIGER / LYNX Operating Instructions, Software version 2.35, BA 190130 (11.07.2022)

-

Page 7: About This Manual

They cannot always be transferred unchanged and may differ slightly from the actual design of the device. BARTEC GmbH reserves the right to make technical changes at any time. BARTEC GmbH is under no circumstances responsible or liable for any indi- rect or consequential damages resulting from the use, operation or application of this user manual. -

Page 8: Safety Precautions

Safety Precautions Safety Precautions The system operator is responsible for all complying with all regulations appli- cable to the storage, transport and handling of the food product "milk". All regulations and provisions remain in full force when operating the system with MAK devices. -

Page 9: Basics

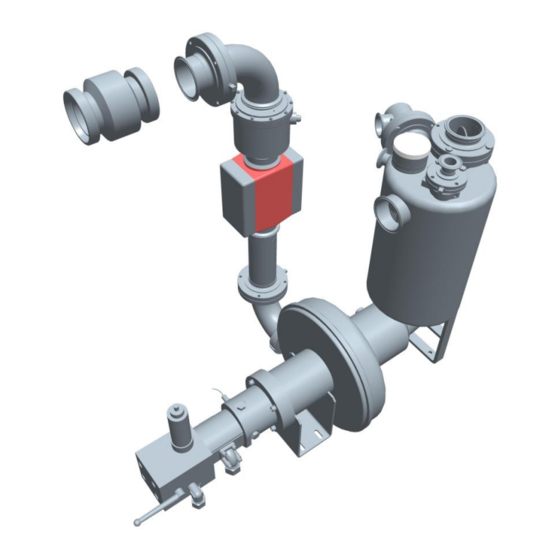

Basics Basics With the MAK 3003 system, all processes and operating steps required for the loading and unloading of milk collection and transport vehicles can be rec- orded and controlled. The TIGER 3003 version is used to control milk intake and record the data entered during that process. -

Page 10: Operating Concept

Basics Operating Concept The software user interface 3.2.1 After starting the system, the main screen appears on the display. You can call up different screens or operating modes using the soft keys to the left and right of the display. Corresponding to the installed measuring equipment type (TIGER, LYNX HLW, ABO Magyar, V3003, Optimate, ROMEX, V plus or E-TIGER) differ the start screen and the main menu. -

Page 11: Hidden Softkeys

Basics Hidden softkeys 3.2.4 In various operating situations, the current assignment of soft keys is not shown on the display. In such instances, the keys to the left or right of the display will not be marked. In this case, you have to touch any soft key in this row of keys. -

Page 12: Event Display

Basics Event display 3.2.5 Important error or malfunction messages are shown right on the display. The event screen is called up using the hidden softkey EVENTS . This displays all operating statuses and malfunctions. To exit the event screen, touch the same softkey again. MAK 3003 Measuring system TIGER / LYNX Operating Instructions, Software version 2.35, BA 190130 (11.07.2022) -

Page 13: Overview Of Functions

Overview of functions Overview of functions The operating sequence and scope during the round of sampling depend on the respective equipment and the configuration of the software. All functions that are available during and outside of a tour are described be- low. - Page 14 Overview of functions Special functions in the tour During the tour, various functions are available via the tour menu (e.g., acti- vation or deactivation of functions, discharge and transfer processes, clean- ing) (chapter 12). Shortcut keys During the tour, you can call up various displays directly using one-touch keys (chapter 13).

-

Page 15: Tour Start And Tour End

Tour start and tour end Tour start and tour end Switching on the system Switch on the system according to the installation on the vehicle (usually a separate switch). When the system is switched on, the controller executes a start-up program. The start screen is then shown on the display. -

Page 16: Ending The Tour

Tour start and tour end Ending the tour ● To end the current tour, touch the soft key END TOUR . ● Then enter the number of the destination dairy and the current mileage. ● Confirm the entries with the soft key CONFIRM ; the "Tour log record" is printed. -

Page 17: Enter Supplier Number

Enter supplier number Enter supplier number To perform an intake, a supplier number must be entered. Manual input ● Touch the soft key INTAKE . The window for entering the intake data opens. ● If the "Supplier ID" line is selected, touch the soft key CHANGE or enter the number directly using the numeric keys. -

Page 18: Supplier Recording With Gps

Enter supplier number Supplier recording with GPS If the vehicle stops at a position within a tour for which supplier data are stored in the database, these data are automatically displayed. The requirement for this is that an intake has already been carried out at this location with the corresponding supplier number. - Page 19 Enter supplier number New supplier If the intake is not to take place at any of the suppliers displayed, and instead a new supplier is to be entered under the current position, you must first enter this supplier manually. ● Touch one of the soft keys to the right of the display to display the hidden softkeys.

-

Page 20: Milk Intake

Milk intake Milk intake After confirming the manually entered supplier number, or after displaying a supplier number from the database, you can start the intake. ● Touch the START button on the controller or press the start button on the remote control. - Page 21 Milk intake If there is no more milk flow, the pump switches off. The intake can be ended in different ways depending on the configuration: The intake is ended manually by the driver ( INTAKE END soft Manual: key or Finished button on the remote control). GPS Speed The intake is automatically ended via the measured speed (termination also possible via the Finished button).

-

Page 22: Sampling

Sampling Sampling The measuring system can be configured so that a single sample, tour sample or Belgium sample are automatically activated at the start of the tour. If there is no automatic activation, you can also activate the sampling manu- ally. -

Page 23: Single Sample

Sampling Single sample ® If you work with the ULTRASAMPLER sampling system, you must enter or confirm a preset quantity in addition to the supplier number. From the preset quantity and the configured pump capacity, the controller calculates the flow ®... -

Page 24: Tour Sample

Sampling ● Enter the new preset quantity and confirm it with ENTER . The sample bottles are automatically brought into the filling position and the sample bottle number is read. If a fault is displayed even though the bottle is in the filling position, clean the reading window of the barcode reader. -

Page 25: Belgium Sample

Sampling Belgium sample The Belgium sample can only be activated if output 88 is configured. The WAVE box 100S must be configured to read and write tags. Procedure 8.3.1 ● Move a sample bottle to the filling position. ● Start the intake. If the sample is active, the system checks whether a sample bottle with a blank tag is in the filling position when an intake is started. - Page 26 Sampling The sample bottle with empty tag is in position. The intake has started. The intake can be started. The intake is complete. The tag is written. ● Wait until the display shows that the tag has been written. MAK 3003 Measuring system TIGER / LYNX Operating Instructions, Software version 2.35, BA 190130 (11.07.2022)

- Page 27 Sampling If a tag could not be detected continuously during the intake, the correspond- ing messages are displayed. If an error occurs during writing after intake, have the option to repeat write process. Cancel Repeat write operation MAK 3003 Measuring system TIGER / LYNX Operating Instructions, Software version 2.35, BA 190130 (11.07.2022)

-

Page 28: Belgium Sample Menu

Sampling Belgium Sample menu 8.3.2 The Belgium Sample menu allows you to write additional information to the tag. ● To display the hidden soft keys, touch one of the soft keys to the left of the display. ● Then open the BELGIUM SAMPLE MENU. Four categories are then displayed, from which the further selection takes place. -

Page 29: Sampler Errors

Sampling 8.3.2.1 Sampler errors If sampler errors occur, you can select the appropriate information here. Information Explanatory notes No Info No applicable information available Second tank Two tanks available System is not working properly Sampler error Storage sample not OK Malfunction of the sample cassette Bottle broken Sample bottle broken... -

Page 30: Additional Analysis Of Tank

Sampling 8.3.2.2 Additional Analysis of Tank If an additional analysis is to be performed for the currently taken sample, you can write this information to the tag. ● From the list, select which additional analysis should be performed on the sample. -

Page 31: Additional Sample

Sampling 8.3.2.3 Additional Sample In addition to the normal sample, additional filled sample bottles can be pro- vided. Number of additional samples ● Select the menu item "Additional Samples". ● Enter the number of additional samples. MAK 3003 Measuring system TIGER / LYNX Operating Instructions, Software version 2.35, BA 190130 (11.07.2022) - Page 32 Sampling Additional analyses ● Select the menu item "Additional Analysis". ● Select from the list (see section 8.3.2.2) which additional analysis should be performed on the sample. ● Press the "Confirm" soft key to confirm your selection. You can also make the selection directly by touching the corresponding num- ber key(s).

-

Page 33: Manual Sample

Sampling 8.3.2.4 Manual sample You can fill a sample manually in case of a malfunction of the automatic sam- pling. ● Then place the filled sample bottle in the reading position of the tag reader. ● Select the appropriate reason for manual sampling from the list under "Manual Sample". -

Page 34: Smv4 Sample

Sampling SMV4 sample The SMV4 probe can only be activated if outputs 90 and 92 are configured. To read and write tags, Tag Scanner NL-TAG Manuel must be configured. Procedure 8.4.1 ● Select the sample type "NL Sample" at tour start. When the SMV4 sample is activated, this symbol is displayed in the intake window. - Page 35 Sampling ● Move a sample bottle to the filling position. ● Start the intake. If the sample is active, the system checks whether a sample bottle with a blank tag is in the filling position when an intake is started. The sample bottle with empty tag is in position.

- Page 36 Sampling If no sample bottle with empty tag was detected, the intake cannot be started. A corresponding message appears on the display. The tag of the cur- rent sample bottle is already written. Replace the sam- ple bottle. The tag could not recognised.

- Page 37 Sampling The tag was successfully written. The intake has started. When the intake is finished, you will be prompted to remove the sample bottle. The intake is complete. Remove the sample bottle when the request to do so is displayed. The pipe is purged after the sample bottle has been removed.

-

Page 38: Additional Sample

Sampling Additional sample 8.4.2 In addition to the normal sample, you can fill another sample bottle. ● Touch the soft key ADD SAMPLE during the intake. This soft key is only active during the intake. When the intake is finished and the purging has been completed, you will be prompted to describe the additional sample. - Page 39 Sampling ● From the list, select which additional analysis should be performed on the sample. ● Press the "Confirm" soft key to confirm your selection. You can also make the selection directly by touching the corresponding num- ber key(s). Only one additional analysis can be selected for the sample at a time.

- Page 40 Sampling When the tag is recognized, the additional sample information is written to the tag. If a write error occurs, you can repeat the write operation or cancel the oper- ation. Cancel additional sample Repeat writing MAK 3003 Measuring system TIGER / LYNX Operating Instructions, Software version 2.35, BA 190130 (11.07.2022)

-

Page 41: Tank Segment Monitoring

Tank segment monitoring Tank segment monitoring The configurable tank segment monitoring makes it possible to fill the milk spe- cifically into individual tank segments. If a segment sequence is defined in the configuration, you can only fill the seg- ments in this sequence. An arrow above the segment number indicates which segment must be opened. - Page 42 Tank segment monitoring When the configured segment capacity is reached, a message is output and the intake is interrupted. If an overfill quantity is configured, you can continue to fill the segment after each confirmation of the message until the configured overfill quantity is reached.

- Page 43 Tank segment monitoring The intake is running in Segment 2. The intake is finished and can be completed. If the configuration does not specify a sequence for the segments, you can fill them in any sequence. You can check the fill level of the tank segments outside an intake via the tour menu (see section 12.13) or with the numeric shortcut key 5 (see section 13.2).

-

Page 44: Raw Milk Separation

Raw milk separation Raw milk separation During intake, the milk can be filled into separate tank segments according to its quality. Qualities from 1 (good) to 8 (bad) are possible. The quality level of the milk is taken either from the quantity memory, transferred with the default data or the driver must manually enter the quality level on the basis of the avail- able supplier data. - Page 45 Raw milk separation Confirm the assignment of the tank segment qualities with CONFIRM . If no quality is applied by default or from the quantity memory, the quality of the milk to be collected must be entered. If automatic compartment selection is configured, the tank segment config- ured for this quality is automatically selected after the quality has been entered.

- Page 46 Raw milk separation Milk quality worse than the quality level of the segment the quality level of the segment is downgraded. Milk quality better than the quality level of the segment the quality of the collected milk is downgraded.

- Page 47 Raw milk separation ● Confirm the segment selection, intake will be continued. If no free tank segment is available for the quality of the milk currently to be No segment is available with collected, you have the option of selecting another segment. the required quality MAK 3003 Measuring system TIGER / LYNX Operating Instructions, Software version 2.35, BA 190130 (11.07.2022)

- Page 48 Raw milk separation In the example, milk of quality 2 is to be accepted into segment 3. This will downgrade the quality level of segment 3 from 1 to 2. If you want to collect milk whose quality is not configured, you can select any Milk quality is not configured segment for the intake.

- Page 49 Raw milk separation Segment 3 is selected for the intake. When the intake occurs, the quality level of the segment is downgraded from 2 to 4. Reserve capacity If an intake is interrupted shortly before its end because the segment is full, you can keep the previously active segment.

- Page 50 Raw milk separation Possible messages for raw milk separation The quality of the milk to be collected is better than the quality level of the se- lected segment. If the segment is empty, the quality level is upgraded to the quality of the milk to be collected.

-

Page 51: Data Transfer To The Office

Data transfer to the office Data transfer to the office The recorded data are transferred via an internet connection using the config- ured FTP server. You can start the data transfer in the main menu (see also section 14.1). The disk symbol at the bottom left of the display indicates that the vehicle has data to send. -

Page 52: Tour Menu

Tour menu Tour menu During the tour you can use the soft key MENU to access a number of special functions. Which functions are available via this soft key depends on the current operat- ing status, the type of collection truck and the configuration of the system. The following special functions may be available: Function Section... -

Page 53: Intake

Tour menu Intake 12.1 To change intake data, you can call up the intake dialogue manually. Pump over measured 12.2 During the tour it may be necessary to pump milk, e.g., over to a trailer to get free tank capacity for further intakes. The pumping over can be measured or unmeasured (see section 12.5). - Page 54 Tour menu You can stop and resume pumping over using the buttons STOP and START on the controller or with the remote control. During the pump-over you can adjust the pump-over power to various config- urable flow rates using the soft key LOW POWER or HIGH POWER . This may be necessary, for example, to fill a tank to its capacity limit or to reduce foam formation.

-

Page 55: Pump Over Segment

Tour menu Pump over segment 12.3 The contents of a tank segment can be pumped over if necessary. Logic output 16 must be configured for this. The menu item "Segment overpump" is displayed in the tour menu. ● Select the menu item "Segment overpump". Pump Over ID ●... - Page 56 Tour menu Preset quantity ● Optionally, you can enter a preset quantity at which the pumping over is automatically stopped. Source segment ● Enter the number of the segment from which the milk is to be pumped. MAK 3003 Measuring system TIGER / LYNX Operating Instructions, Software version 2.35, BA 190130 (11.07.2022)

- Page 57 Tour menu Target segment ● Enter the number of the target segment into which the milk is to be pumped. Raw milk separation If raw milk separation is active, the system checks whether the quality level of the milk in the target segment matches the quality level in the source segment. If this is not the case, the system issues a corresponding message.

- Page 58 Tour menu The pumping-over process starts when the entries have been confirmed. The pumped quantity is measured and the process is recorded. MAK 3003 Measuring system TIGER / LYNX Operating Instructions, Software version 2.35, BA 190130 (11.07.2022)

-

Page 59: Drain The Measuring System

Tour menu Drain the measuring system 12.4 When this menu item is confirmed, the milk in the measuring system is forced into the tank with compressed air. This may be necessary, e.g., before unloading to ensure that no milk remains in the measuring system. -

Page 60: Pump Over Unmeasured

Tour menu Pump over unmeasured 12.5 Pump over unmeasured is only possible if additional piping with valve 13 (see technical description TIGER 3003) is available and logic output 13 is config- ured. If you do not want the quantity to be recorded during the pump-over, select "Pump over unmeasured"... - Page 61 Tour menu During the pump-over you can adjust the pump-over power to various config- urable flow rates using the soft key LOW POWER or HIGH POWER . This may be necessary, for example, to fill a tank to its capacity limit or to reduce foam formation.

-

Page 62: Manual Cleaning

Tour menu Manual cleaning 12.6 The collection truck must be cleaned at the end of the tour in accordance with the operating instructions in force at the respective dairy plant. If no cleaning ID is entered in the configuration, you must enter the cleaning The cleaning ID does not need to be entered if it is specified in the configura- tion. - Page 63 Tour menu ● The cleaning process starts and the cleaning data appear on the display. As soon as the flow rate reaches 0 L/min., the soft key CLEAR SYSTEM is displayed. Depending on the regulations applicable to the dairy, you can now empty the air separator when changing the cleaning me- dium.

-

Page 64: Automatic Cleaning

Tour menu Automatic cleaning 12.7 Automatic cleaning is started in the same way as manual cleaning (see sec- tion 12.6). The system is automatically emptied (e.g., triggered by a compressed air sig- nal from the dairy). After the air separa- tor is emptied at the end of the cleaning process, a prompt... -

Page 65: Activate Pre-Sample

Tour menu Activate pre-sample 12.8 If "Presample" is configured, you can manually activate or deactivate the pre- sample (see section 12.9). The configured number of additional pre-samples is taken before the next in- take with sampling. Pre-sample switched off 12.9 If "Presample"... -

Page 66: Long-Term Memory

Tour menu Long-term memory 12.10 Collection and tour data from the past three months are stored in the long- term memory. You can view both tour data and single data. The long-term memory can also be viewed in the main menu (see section 14.2). -

Page 67: Unloading Unmeasured

Tour menu Unloading unmeasured 12.11 To carry out unloading in a dairy during the tour, select "Unload unmeasured" in the tour menu. ● Enter the unloading ID (configuration-dependent). ● Start the unloading by confirming the Unload ID with CONFIRM . MAK 3003 Measuring system TIGER / LYNX Operating Instructions, Software version 2.35, BA 190130 (11.07.2022) -

Page 68: Driver Number Input

Tour menu Driver number input 12.12 If there is a change in driver during the tour, the new driver number must be entered. The change in driver is logged in the database. Tank segment levels 12.13 You can check the fill level of the tank segments outside the intake. Touch the soft key ... -

Page 69: Tank Segment Quality

Tour menu Tank segment quality 12.14 During intake, the milk can be filled into separate tank segments according to its quality. Qualities from 1 (good) to 8 (bad) are possible. If you want to change the current quality assignment, select the "Tank seg. quality"... -

Page 70: Shortcut Keys

Shortcut keys Shortcut keys During the tour, you can call up various displays directly using the numeric keys. Intake data of the last supplier 13.1 Key 1 Tank segment levels 13.2 Key 5 MAK 3003 Measuring system TIGER / LYNX Operating Instructions, Software version 2.35, BA 190130 (11.07.2022) -

Page 71: Main Menu

Main Menu Main Menu When the home screen is displayed, you can use the soft key MENU to call up the main menu. It contains submenus which are used to con- figure the equipment and to access various functions. The configuration menus and service menu are write-protected by password. Only the menus and functions to which you have access without entering a password or after entering the driver password are described here. -

Page 72: Data Transfer

Main Menu Data transfer 14.1 Data transfer to the dairy is launched in this menu. All as yet not transferred tour data are transferred to the designated server. The data are processed there in the format specified for the dairy and made available for the dairy to collect. - Page 73 Main Menu Single data Enter the desired search criteria in the search form. Touch CONFIRM to start the search. If you touch a soft key next to the display, additional functions are displayed. You can print the located data, start a new search or exit the screen. MAK 3003 Measuring system TIGER / LYNX Operating Instructions, Software version 2.35, BA 190130 (11.07.2022)

- Page 74 Main Menu Tour data To view tour data, proceed as for displaying single data. Only the supplier number is omitted from the search box. If you touch a soft key next to the display, additional functions are displayed. You can send the tour data, print the located data, start a new search or exit the screen.

-

Page 75: Password Level

Main Menu Password level 14.3 The software configuration is protected by passwords which allow access to various configuration options. You can access the configuration menus without a password but you cannot make any changes. After entering the driver password, you can change the time in the controller display. - Page 76 Main Menu Once you have finished entering the password, touch the " " soft key. The password level (D) is then displayed, to which access is possible. You can use the soft key to reopen the window to enter the password (driver, user or service password).

-

Page 77: Databases

Main Menu Databases 14.4 Location info database The GPS positions of the various suppliers are recorded in the location info database. Here the supplier ID, type (intake, cleaning, pump over), average amount, GPS position "long" and "lat" and quality are displayed. Access to other functions in the Databases menu is not possible at the driver password level. -

Page 78: Configuration

Main Menu Configuration 14.5 You can open the submenus in the "Configuration" menu without entering a password, but you cannot make any changes. The configuration is described in the configuration manual ("MAK 3003 Meas- uring system TIGER, Configuration"). MAK 3003 Measuring system TIGER / LYNX Operating Instructions, Software version 2.35, BA 190130 (11.07.2022) -

Page 79: Service Menu

Main Menu Service menu 14.6 Logfile Browser 14.6.1 The logfile browser allows you to view all saved log entries. The information about the various operations is displayed in text format and can be read di- rectly on the screen. Update Log: Log entries about updates and update attempts Audit Log: Log entries about all parameter changes... -

Page 80: Activate Bluetooth

Main Menu Within the log window, you can move the displayed content to the left, right, up or down using the arrow softkeys. You close the log window with the STOP key. Activate Bluetooth 14.6.2 If a Bluetooth receiver is configured, you can activate the Bluetooth interface here after entering the driver password to allow service personnel access to the software. - Page 81 Main Menu If the Bluetooth interface is activated, this is indicated by a symbol. With the BARTEC Service Tool, a Bluetooth connection can be established and the software can be accessed. Once the connection is established, this symbol is displayed.

-

Page 82: Language

Main Menu Language 14.7 You can change the language setting without entering a password. Language Select language de (German) for the display screens en (English) pt (Portuguese) fr (French) cs (Czech) nl (Dutch) pl (Polish) If you change the language setting, the system will automatically be rebooted. MAK 3003 Measuring system TIGER / LYNX Operating Instructions, Software version 2.35, BA 190130 (11.07.2022) -

Page 83: Cleaning

Main Menu Cleaning 14.8 For the vehicle types "LYNX", “LYNX Digital“, "TIGER", "E-TIGER" and "V 3003", the cleaning functions are also available outside of a tour. Manual cleaning ("cleaning") or automatic cleaning ("cleaning automatic") can be selected depending on the configuration. These functions are operated as described in the Tour menu;... -

Page 84: Special Functions Hlw

Main Menu Special functions HLW 14.9 The main menu contains additional functions to activate outputs for the "HLW" measuring system type. Pump over 14.9.1 The controller activates the pump-over output. MAK 3003 Measuring system TIGER / LYNX Operating Instructions, Software version 2.35, BA 190130 (11.07.2022) -

Page 85: Cleaning

Main Menu Cleaning 14.9.2 The controller activates the cleaning output. Emptying system 14.9.3 The controller activates the output for purging the air separator. Control is carried out by HLW. The outputs are deactivated when closing the screens. MAK 3003 Measuring system TIGER / LYNX Operating Instructions, Software version 2.35, BA 190130 (11.07.2022) - Page 86 Main Menu MAK 3003 Measuring system TIGER / LYNX Operating Instructions, Software version 2.35, BA 190130 (11.07.2022)

- Page 87 MAK 3003 Measuring system TIGER / LYNX Operating Instructions, Software version 2.35, BA 190130 (11.07.2022)

Need help?

Do you have a question about the MAK TIGER 3003 and is the answer not in the manual?

Questions and answers