Table of Contents

Advertisement

Quick Links

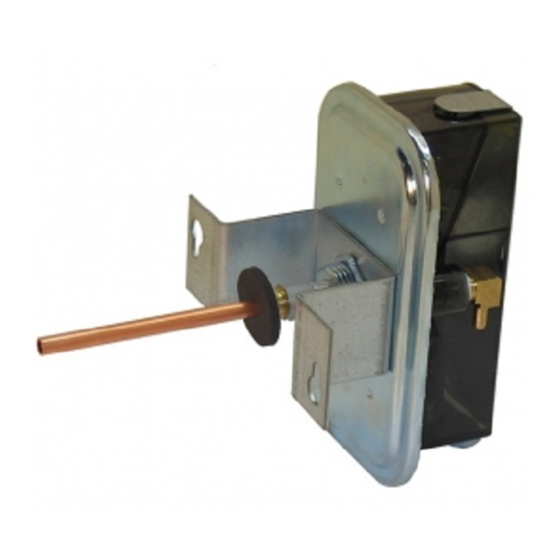

P32 Series Sensitive Differential Pressure Switch

Installation Guide

Figure 1: P32AC Differential Pressure Switch with

U mounting bracket and direct mounted sensing

probe assembled.

Application

This differential pressure switch is used to sense

the flow of air in ducts. When used with electric

strip heaters, the switch can be wired to open the

control circuit and de-energize the heaters when

air flow stops.

Important: P32 Series pressure switches are

intended to control equipment under normal

operating conditions. Where failure or malfunction

of a P32 pressure switch could lead to an abnormal

operating condition that could cause personal

injury or damage to the equipment or other

property, other devices (limit or safety controls) or

systems (alarm or supervisory) intended to warn

of or protect against failure or malfunction of the

P32 pressure switch must be incorporated into and

maintained as part of the control system.

Typical applications include:

•

Air flow proving with electric duct heaters

•

maximum air flow controller for variable air

Volume systems

•

Clogged filter detection

•

Detection of icing of air conditioning coils

and initiation of defrost cycle

For a P32 sensitive differential pressure switch

for combustion air applications, refer to P32

Series Sensitive Differential Pressure Switch For

Combustion Air Applications ( LIT-125430) at

https://docs.johnsoncontrols.com/bas/.

Operation

This differential pressure switch senses a change

in the differential pressure (either velocity pressure

or pressure drop across a fixed restriction in

the duct) as air flow in the duct changes. This

differential pressure, as sensed by the two sensing

ports, is applied to the two sides of a diaphragm in

the pressure switch.

The spring-loaded diaphragm moves and actuates

the switch when the air pressure difference

reaches the setpoint.

This switch can also be used to detect small

positive gauge pressure by using only the high

pressure connection and leaving the low pressure

connector open, or to detect a vacuum by using

only the low pressure connection and leaving the

high pressure connector open to ambient pressure.

Installation

Follow equipment manufacturer's instructions.

Locating

Select a location on or near the duct where

vibrations are minimal and the terminal screws

and adjusting screw are accessible. Ambient

temperature should be within the range of -40 to

167°F (-40 to 75°C) to avoid physical damage to

the control. The factory setting of the P32 is made

at room temperature. Ensure mounting locations

are as close to room temperature as possible.

Otherwise, for best performance, set switches

in the field in their mounted position and at the

normal ambient temperature for that application.

Mounting

The switch is normally mounted with the

diaphragm in a vertical position. It may be

fastened directly to the duct, heater, or panel as

long as the mounting surface has minimal or no

vibration.

Note: The switch is factory set with the

diaphragm in a vertical position. If it is mounted

in a horizontal position with the steel housing

(high pressure connector) down, the setpoint

will increase by about 0.07 in W.C. (.017 kPa). If

mounted with the steel housing up, the switch

may be inoperative at minimum setting. Adjustable

models can be readjusted for this mounting

position and minimum setpoint as follows:

1.

Mount the switch securely.

2.

Make sure no pressure is applied to either

connector.

3.

Turn the adjusting screw clockwise until the

switch operates and at least an additional 1/3

turn.

Important: When turning the fitting into the

plastic low pressure port, do not overtighten

and crack the threaded boss. Turn fitting in

finger-tight, then an additional 1 to 1 1/2 turns

(approximately 15 to 20 in.lb). Sealing compound

or tape is not required for the plastic low pressure

port.

Figure 2: Interior view of the P32AA Differential

Pressure Switch.

Part No. 996-100, Rev. F

Issue Date: May 2022

Figure 3: Direct mounting a P32 using the L

bracket as a mounting flange

Figure 4: Typical installation for a P32 Switch on

duct using Part No. BKT229-1R bracket and direct

mounting probe

Mounting for direct duct or heater

1.

Cut or drill a 7/8 in. (22 mm) diameter hole.

2.

Install tubing in the 1/8 in. NPT high pressure

(metal) connector, if required.

3.

Place the metal connector in the hole.

4.

Use a 1/2 in. conduit lock nut on the

connector and secure in place.

Advertisement

Table of Contents

Summary of Contents for Penn P32 Series

- Page 1 P32 Series Sensitive Differential Pressure Switch Part No. 996-100, Rev. F Installation Guide Issue Date: May 2022 for combustion air applications, refer to P32 Note: The switch is factory set with the Series Sensitive Differential Pressure Switch For diaphragm in a vertical position. If it is mounted...

- Page 2 CHINA www.penncontrols.com ® Johnson Controls and Penn are registered trademarks of Johnson Controls in the United States of America and/or other countries. All other trademarks used herein are the property of their respective owners. © Copyright 2022 by Johnson Controls.

Need help?

Do you have a question about the P32 Series and is the answer not in the manual?

Questions and answers