Table of Contents

Advertisement

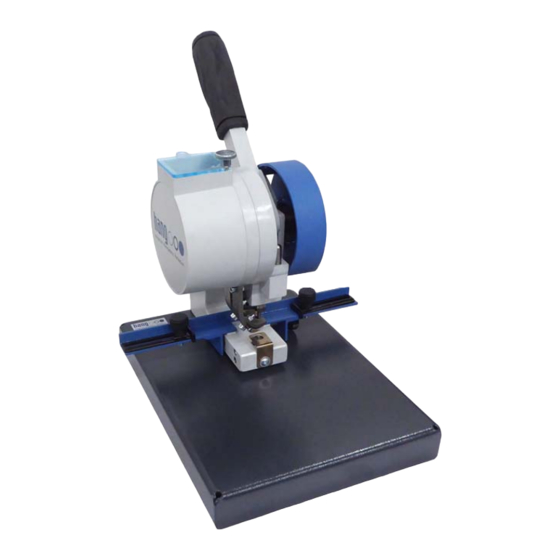

Operating Instruction Eyeleter

Model

102 - 00

Part no.

701 - 0060

Eyelet

24 / 25

For future use, take note

and keep on hand with

the Eyeleter.

Maschinen - Produktion GmbH

Jahnstraße 82

D - 73037 Göppingen

Telefon +49 (0) 7161 / 6005-0

Telefax +49 (0) 7161 / 6005-78

https://www.hang.de

https://www.hang-shop.de

info@hang.de

Advertisement

Table of Contents

Summary of Contents for HANG 102-00

- Page 1 Maschinen - Produktion GmbH Eyelet 24 / 25 Jahnstraße 82 D - 73037 Göppingen For future use, take note and keep on hand with Telefon +49 (0) 7161 / 6005-0 Telefax +49 (0) 7161 / 6005-78 the Eyeleter. https://www.hang.de https://www.hang-shop.de info@hang.de...

-

Page 2: Table Of Contents

Recommended lubricants ......................8 Servicing ..........................8 © 2018 Constantin Hang, Maschinen - Produktion GmbH Jahnstraße 82, D-73037 Göppingen All rights reserved Reproduction, in whole or in part, is permissible only with the prior consent of the manufacturer. -

Page 3: Introduction

Eyeleter 102-00 Introduction By purchasing this Eyeleter, you have chosen a robust, reliable, proven model from Hang. We constantly strive to improve Hang products. This also includes the operating manual. Please notify us of any deficiencies, errors or ambiguities you notice in our products. -

Page 4: Commissioning

Operating manual Eyeleter 102-00 Commissioning The Eyeleter is delivered in stable packing. Keep the packing for possible return dispatch for reconditioning purposes. Put the Eyeleter in a stationary position on a stable surface according to the purpose of use. Work surface, desk, etc. -

Page 5: Setting The Side Stop

Operating manual Eyeleter 102-00 Setting the side stop Loosen the knurled screw [4] and set the distance by sliding the side stop [5]. Then tighten the knurled screw [4]. Figure B. Figure B Setting the rear stop ... -

Page 6: Pressure Setting (Eyelet Pressure)

Operating manual Eyeleter 102-00 Pressure setting (eyelet pressure) If you wish the eyelets to be pressed harder or if the eyelets are being pressed too hard, you must regulate the pressure by moving the lower stamp [11]. Figure E. ... -

Page 7: Replacing The Upper Stamp

Operating manual Eyeleter 102-00 Replacing the upper stamp Press the eyelet channel to the side to allow easier handling. Screw out the upper stamp [18] using the (size 12) open-ended spanner provided. If the catch pin [19] also has to be replaced, user pliers to pull it down and out. -

Page 8: Replacing The Bristle Disk

Operating manual Eyeleter 102-00 Replacing the bristle disk Caution: The worm spring is pre-tensioned! There will also be malfunctions if the bristles on the bristle disk are worn. Loosen and remove the screw [20]. Remove the cover [21]. -

Page 9: Maintenance And Servicing

Operating manual Eyeleter 102-00 Remove the eyelet container [23] by pulling it off to the left. Figure K. Figure K Loosen the screw [24]. Pull off the bristle disk [25]. Figure L. Install in the opposite sequence. -

Page 10: Lubrication

Operating manual Eyeleter 102-00 Lubrication If the Eyeleter machine is used daily, oil it once a week. Carefully use an oil can to put one drop of oil at each location [26]. Figure M. Wipe up excess oil with a rag. - Page 11 Form for Operating Personnel The knowledge of the operating personnel has been checked by a competent person (e.g. supervisor, safety representative) prior to the start of work. It is recommended that the test be repeated every six months. I herewith confirm that I have read and understood Chapters ..and Chapter 1 „Safety Precautions“...

Need help?

Do you have a question about the 102-00 and is the answer not in the manual?

Questions and answers