Summary of Contents for Huazheng HZKS-N3

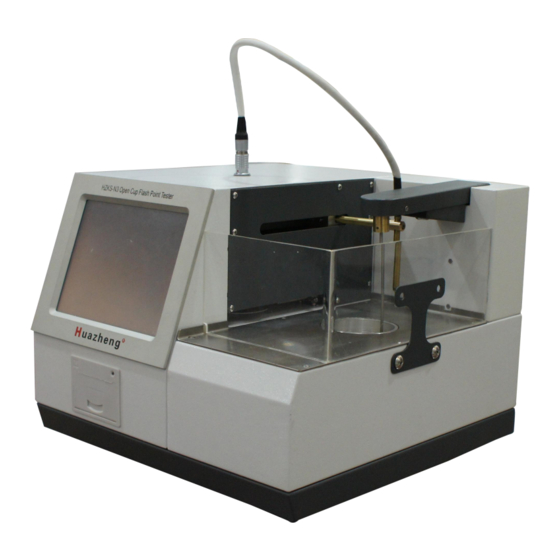

- Page 1 HZKS-N3 Open Cup Flash Point Tester Huazheng Electric Manufacturing (Baoding) Co., Ltd...

- Page 2 (0312) 6775656 to tell you to ser ve you at all times- Baoding Huazheng Elect ric Manufact uring Co. , Lt d. , our company will def initely make you satisf ied !

-

Page 3: Table Of Contents

Contents 1 Overview ........................1 1.1 Instructions for use ....................1 1.2 Safety precautions ....................1 1.3 Technical parameter ....................2 1.4 Instrument feature ....................2 2 Instrument structure and components ................2 2.1 Flash point detection system .................. 4 2.2 Sample temperature sensor ..................5 2.3 Heating system ......................5 2.4 Fire extinguishing device .................. -

Page 4: Overview

I Summary 1.Instructions for use Dear user, thank you for purchasing the automatic open flash point tester produced by our company. This manual describes the safety and correct use of the series of products related matters. Please refer to this manual carefully and use it after understanding before use. ... -

Page 5: Technical Parameter

The temperature of the heating furnace is high in the process of measuring this instrument, and it needs to be attended by someone. 3.Technical parameter Applicable standards: gb/t 3536-2008, gb/t 267-88 and other standards Working power supply: AC220V 10% 50Hz ... - Page 6 1 Touch screen: 8-inch 800 * 600 true color touch screen 2 Lifting mechanism 3 Fire sweeping mechanism 4 L-type armored platinum resistor 5 Ignition platinum wire 6 Test cup 7 Printer...

-

Page 7: Flash Point Detection System

Instrument rear view 1 Serial communication port, RS 232 Level 2 Fan outlet 3 Electric furnace fan outlet 4 Power cord 5 Safety seat 6 Power switch Lifting mechanism Stepper motor drive, automatic control mechanism lifting. 1.Flash point detection system The ignition wire of platinum alloy is controlled by the program of small voltage and ... -

Page 8: Sample Temperature Sensor

high current. The fire sweeping mechanism is driven by a stepping motor and swept through the test cup in a straight line. The flash fire detection sensor adopts optical sensitive sensor to detect the flash point in a non-contact manner. 2.Sample temperature sensor The sample temperature sensor adopts armored L-type PT100 to measure the ... -

Page 9: Instrument Operation Instructions

Main interface The main interface operation interface is shown in the following figure: 1. Product Name: automatic open flash point tester 2. Instrument model: hzks-n3 3. Component control switch and button: cooling fan, ignition, mechanism lifting and fire sweeping once 4. - Page 10 5. Sample related parameters: sample temperature and hot bath temperature 6. Atmospheric pressure and temperature in the cabinet Component control Under the main interface, the control of components can be divided into cooling fan, mechanism lifting, fire sweeping once and ignition. Manual start or stop of cooling fan: press the cooling fan to start and then press the ...

-

Page 11: System Setup

thermometer Hot bath temperature: the current temperature of the heated bath body 2.System settings The system settings interface is as follows: Screen correction: click this button to complete the screen calibration Operation password: the user can set the password at will, which is convenient for ... - Page 12 1Method of establishment Press the new button, enter the method name in the pop-up interface to confirm the following parameters are added and saved Delete method Select the method to delete, press the delete button, and press OK in the pop-up interface to delete Implementation standards ...

-

Page 13: Historical Data

Save and exit If the parameters in the method are modified, please save before exiting.If you do not modify the parameters in the method, you can exit directly. 4.Historical data The historical data interface is shown in the following figure: Query historical data: click the list box on the left to query historical data arbitrarily Printing: printing the current displayed historical data Exit button: press exit button to return to main interface... -

Page 14: Instrument Calibration

Lifting mechanism: control the lifting or stopping of the lifting mechanism Fire sweeping mechanism: control the fire sweeping mechanism to sweep or stop Flash point detection: click the "flash point test stop" switch to convert the switch text into "flash point test start", and then close the fire source to the experimental cup, and the instrument will give a beep.Click the "flash point test start"... -

Page 15: Analysis Interface

1.Temperature correction Temperature correction must be careful and careful, any careless correction method will affect the accuracy of instrument data. Input the real temperature of the environment where the current temperature sensor is placed at the temperature correction. Click the temperature correction button. ... -

Page 16: Preparatory Work

Start or stop switching: when the experiment starts, it shows that the experiment has started, otherwise it shows that the experiment has stopped Print: you can print the latest set of experimental data. This function is disabled when starting the experiment. -

Page 17: End Of Experiment

Click the analysis interface button to enter the analysis interface. Click the experiment stopped switch in the analysis interface to change the switch text into experiment started and experiment test started. After the experiment is started, the instrument controls the whole experiment process according to the parameters set by the method, and the user monitoring is not required.

Need help?

Do you have a question about the HZKS-N3 and is the answer not in the manual?

Questions and answers