Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Tatu Marchesan 9009T DODH-F

- Page 1 IN STR UC TIONS M ANUA L 9009T DODH-F...

- Page 2 IDENTIFICATION Dealer: Owner: Firm / Farm: City: State: No. of the Certificate of Guarantee: Serial / No.: Date: Invoice No.: Product: Notes:...

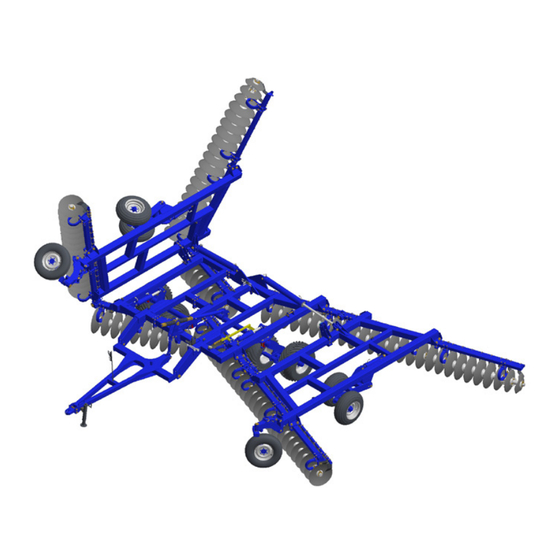

- Page 3 Introduction The DODH-F 9009T disk harrow was specially designed to prepare the soil over long areas, break the clods and level the soil after the harrowing. Equipped with bearings bathed in oil, reagreasable roller bearings and duo-cone seals; they provide a greater durability. The bearings have protection covers to protect them from the wear.

-

Page 4: Table Of Contents

Table of contents 1. To the owner 2. To the operator 04 to 09 3. Data sheet 4. Components 5. Assembly 12 to 24 Using the set of wrenches / Disc gangs assembly Assembly of bearings and spacer spools 13 & 14 Disc gangs assembly sequence 15 &... -

Page 5: To The Owner

To the owner The acquisition of any Tatu product assures to the original purchaser the following rights: • Warranty certificate; • Instructions manual; • Technical assistance by the dealer on equipment delivery. However, the owner must check the condition of the equipment on delivery, as well as knowing the warranty terms. -

Page 6: To The Operator

To the operator Be careful with the environment Dear user! Respect the ecology. Do not throw trash away. This gesture of goodwill helps to protect our environment. Products such as oil, fuel, filters, batteries and others are spilled to the soil and can penetrate to the underground layers, compromising nature. - Page 7 To the operator Never use your bare hands to check hydraulic leaks, the high pressure can cause several injuries. Never attempt to change the adjustments, clean or lubricate the equipment when the same is switched on or in movement. Be careful while driving on slopes. Risk of overturn. Prevent that chemical products (i.e.: fertilizers, treated seeds) make any contact with your skin or clothes.

- Page 8 To the operator • Only trained and qualified personnel is allowed to operate the equipment. • While working or during transportation, only the presence of the operator is allowed on the tractor. • Do not allow children to play near or over the equipment while it is operating, during transportation or storage.

- Page 9 To the operator Truck or trailer transportation Marchesan does not advise the equipment traffic on highways, because this practice involves serious security risks in addition to being prohibited by the current existing traffic law. The transportation for long distances should be done on truck, trailer or others by following these safety guidelines: •...

- Page 10 To the operator Safety stickers The safety stickers warn about the equipment points that require more attention and they should be kept in good repair. If these stickers become damaged or illegible, replace them. Marchesan provide stickers, upon request and indication of the respective serial number.

- Page 11 To the operator ADVERTÊNCIA / WARNING / ADVERTENCIA Para evitar acidentes, instale as travas dos cilindros antes do transporte ou antes de efetuar serviços no equipamento. In order to avoid accidents activate cylinder locks before transportation or carrying out any service on the equipment.

-

Page 12: Data Sheet

Data sheet Type: ..................Double Offset Disk Harrow Model: .....................DODH-F 9009T Number of disc blades: ................88, 96 and 104 Spacing between disc blades: ................230 mm Discs dimension - Plain disc blade: ............Ø 24" x 6 mm - Plain disc blade: ............Ø 22" x 6 mm - Plain disc blade: ............Ø... -

Page 13: Components

Components 01 - Central frame 08 - Front disc gang 02 - Lateral frames 09 - Rear disc gang 03 - Drawbar 10 - Central wheelset 04 - Hitch 11 - Lateral wheelset 05 - Hose support 12 - Front wheelset 06 - Jack 13 - Shock absorber 07 - Hydraulic cylinders... -

Page 14: Assembly

Assembly First of all, put the parts in a clean place to identify them easier. Check the parts using the list that comes inside the packing box. Using the set of wrenches Use two box end wrenches (A) to tighten the nuts of the disc gangs, one to hold the axle nut on one side while the other tight the nut to the other end, thereby preventing the axle from rotating. -

Page 15: Assembly Of Bearings And Spacer Spools

Assembly Assembly of bearings and spacer spools DODH-F 9009T 88 disc blades 26 bearings 50 spacer spools DODH-F 9009T 96 disc blades 26 bearings 58 spacer spools DODH-F 9009T Marchesan Implementos e Máquinas Agrícolas “TATU” S.A. - Page 16 Assembly Assembly of bearings and spacer spools DODH-F 9009T 104 disc blades 26 bearings 66 spacer spools Bearing Spacer spool Furrow filler DODH-F 9009T Marchesan Implementos e Máquinas Agrícolas “TATU” S.A.

-

Page 17: Disc Gangs Assembly Sequence

Assembly Disc gangs assembly sequence Place the outer lock (A) along with the axle (B). Then, place the lock nut (C) and nut (D). Place the disc blades (E), bearings (F) and spacer spools (G), following the instructions on pages 13 and Place the bolt (H), along with a spring washer and nut. - Page 18 Assembly Axle torque Axle diameter Ft. - lbs. 1.1/2" 2670 1.5/8" 2890 2.1/8" 3300 NOTE 2.1/2" 3500 Consult torque table on page 38. DODH-F 9009T Marchesan Implementos e Máquinas Agrícolas “TATU” S.A.

-

Page 19: Assembly Of The Disc Gangs On The Frame

Assembly Assembly of the disc gangs on the frame The rear gang turns dirt to the left and the front gang turns dirt to IMPORTANT the right. In the gang assembly to the carriers, the bearing hangers should remain facing the disc blades concavity. -

Page 20: Scrapers Assembly

Assembly Scrapers assembly Note the fixing point of the scrapers with the end facing the concave side of the disc blades. Assemble the scrapers (A) using clamps (B), which are placed over the bar (C); lock it using a flat washer and nut. The scrapers feature an adjustment to approach or distance them from the NOTE disc blades, on a range from 5 to 10 mm. -

Page 21: Assembly Of The Disc Carrier To The Frame

Assembly Assembly of the disc carrier to the frame Fasten the front and rear disc carriers to the frame (A) using bolts (B), flat washers, spring washers and nuts. Note that the bolts (B) are placed from the bottom up. Tires assembly Couple the hubs (A) to the wheelset arms (B) using bolts (C), pressure washers and nuts. - Page 22 Assembly Couple the hubs (A) to the wheelset arms (B) using bolts (C), pressure washers and nuts. Then, couple the tires (D) to the hubs (A) and fasten using nuts (E). Lateral wheelset Couple the tires (F) to the hubs (A) and fasten using nuts (G).

-

Page 23: Drawbar Assembly

Assembly Drawbar assembly Couple the drawbar (A) to the arms of the frame (B). T h e n , a s s e m b l e t h e extensor (C) to the drawbar using junction axles, castle nuts and cotter pin; also locks the rocker arm (D) using an axle and cotter pin. -

Page 24: Engraved Information On The Disc Gang Carriers

Assembly Engraved information on the disc gang carriers DODH-F 9009T 104 disc blades Number of Model disc blades 3720 3719 3718 3717 8460 8461 8462 8463 (DLD) (DLE) (TLD) (TLE) (DCE) (DCD) (TCE) (TCD) DODH-F 8465 8464 8466 8467 8460 8461 8462 8463... -

Page 25: Folding Disc Gangs Carriers Assembly

Assembly Folding disc gang carriers assembly Approach the folding disc carrier (A) to the central disc c a r r i e r ( B ) a n d c h e c k t h e i r identification according to the previous page. -

Page 26: Hydraulic Circuit

Assembly Hydraulic circuit Item Description Quantity 3/8 X 7500 TR -TC hose 3/8 X 6320 TC -TC hose 3/8 X 600 TR -TC hose 3/8 X 6800 TR - TM hose 3/8 X 4200 TC-TM hose 3/8 X 3900 TC - TC hose 3/8 X 870 TR-TC hose 3/8 X 2100 TR-TC hose Male quick coupler... -

Page 27: Working Preparation

Working preparation The following instructions must be carefully observed in order to get the best working performance. Tractor preparation The addition of ballast water in the tires and a set of weights on the front part and rear wheels of the tractor are the most used ways to increase the soil traction and give greater stability to the tractor. -

Page 28: Important Recommendations

Working preparation Important recommendations • The traction bar of the tractor must remain fixed during working and transportation. • Always relieve the control valve pressure in order to remove the hoses. • Before starting working, make sure nuts and bolts of all parts are properly tightened, especially the ones on the disc blade gangs, otherwise the axle and other components may be damaged. -

Page 29: Adjustments And Operations

Adjustments and operations Adjusting the wheelset bearings T h e D O D H - F d i s k h a r r o w h a v e adjustments on the semi-bearings of the central wheelsets by its slots (A). This adjustment can be used to centralize the wheelsets with the harrow structure and to eliminate lateral clearances between the... -

Page 30: Locking The Frames For Transportation

Adjustments and operations Locking the frames for transportation It is necessary to articulate the lateral frames (A) to transport the harrow. To do so, activate the hydraulic cylinders and remove the safety lock (B) found on the shock absorber (C), changing from working to transport position, thus locking the lateral frames (A) on the central frames (D). - Page 31 Adjustments and operations Ways to start the harrowing DODH-F works in a continuous way. Entrance Direction of the maneuvers As described in the foregoing adjustments, the DODH-F harrow provides several working angles to operate properly in all types o f s o i l . H o w e v e r, t h i s h a r r o w requires certain precautions during operations, like never make m a n e u v e r s t o t h e r i g h t ,...

-

Page 32: Operations - Important Points

Adjustments and operations Operations - Important points • Retighten nuts and bolts after the first day of work and check the conditions of all pins and cotter pins. Then, retighten every 24 working hours. • Special attention should be given to the disc gangs, retightening daily during the first week of use. -

Page 33: Maintenance

Maintenance Lubrication To reduce the wear caused by the friction on the moving parts of the equipment, carry out a proper lubrication, according to the instructions below. 1) Every 24 working hours, lubricate the articulations through the grease fittings in the following way: •... -

Page 34: Lubrication / Lubrication Points

Maintenance Lubrication points Lubricate every 24 working hours. DODH-F 9009T Marchesan Implementos e Máquinas Agrícolas “TATU” S.A. - Page 35 Maintenance Lubrication points Lubricate every 24 working hours. Lubricate the points shown above and NOTE all grease fittings as well. DODH-F 9009T Marchesan Implementos e Máquinas Agrícolas “TATU” S.A.

- Page 36 Maintenance Harrow maintenance In disuse period wash the harrow, repair the missing painting and protect the disc blades with oil; lubricate all grease fittings and store the harrow in a covered and dry location, avoiding contact with the soil. The disc blades should be replaced as soon as you notice a low-income, characterized mainly by the reduction in diameter, cut loss and other damages to which they are subjected during working.

-

Page 37: Lifting Points

Maintenance Lifting points The DODH-F 9009T harrow has adequate lifting points. When lifting with a hoist, it is essential to hitch the cables at the suitable points for lifting. Use the adequate points for lifting and check if the equipment is safe. Avoid accidents. -

Page 38: Important Data

V = Average income of the tractor (meters per hour); E = Efficiency = 0.90; X = Hectare value = 10,000 m Example using a 9009T DODH-F (88 disc blades): R = ? L = 10.15 m V = 6,000 m/h (6 km/h) E = 0.90... -

Page 39: Average Income Table

Important data Average income table Number of Cutting Hourly Daily income Model disc blades width (m) income (ha) (ha) 10.15 5.48 49.33 DODH - F 10.79 5.83 52.44 9009T 11.65 6.29 56.62 NOTE An average speed of 6 km/h was assumed to prepare the table above. To know how many hours will be spent to work a certain previously known area, it is necessary to divide the value of the area by the hourly income. -

Page 40: Torque Table

Important data Torque table TORQUE VALUES CHART Grade 2 Grade 5 Grade 8 Bolt Diameter Coarse Fine Coarse Fine Coarse Fine 1/4” 50 In. Lbs. 56 In. Lbs. 76 In. Lbs. 87 In. Lbs. 9 Ft. Lbs. 10 Ft. Lbs. 5/16”... -

Page 41: Important

Important MARCHESAN S/A reserves the right at any time to make improvements ATTENTION in the design, material or specifications of machinery, equipment or parts without thereby becoming liable to make similar changes in machinery, equipment or parts previously sold. Images are for illustration purposes only. Some illustrations in this manual appear without the safety devices, removed to allow a better view and detailed instructions. -

Page 42: Notes

Notes DODH-F 9009T Marchesan Implementos e Máquinas Agrícolas “TATU” S.A.

Need help?

Do you have a question about the 9009T DODH-F and is the answer not in the manual?

Questions and answers