Summary of Contents for Huawei FusionDC1000A40

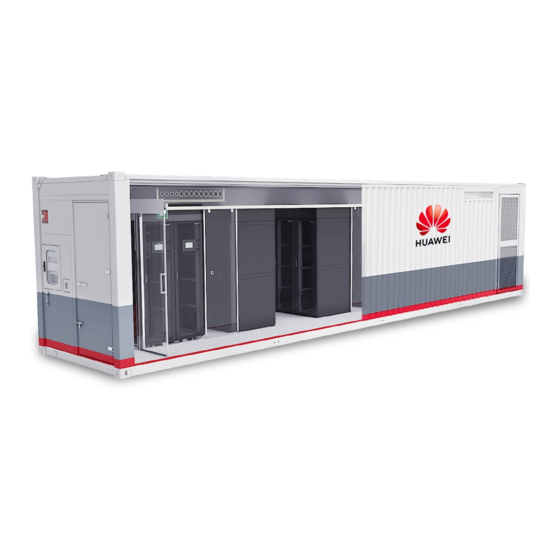

- Page 1 FusionDC1000A40 Prefabricated All-in-One Data Center Quick Guide (2021, Zambia, ZESCO) Issue Date 2021-06-18 HUAWEI TECHNOLOGIES CO., LTD.

- Page 2 Notice The purchased products, services and features are stipulated by the contract made between Huawei and the customer. All or part of the products, services and features described in this document may not be within the purchase scope or the usage scope. Unless otherwise specified in the contract, all statements, information, and recommendations in this document are provided "AS IS"...

-

Page 3: About This Document

Indicates a hazard with a medium level of risk which, if not avoided, could result in death or serious injury. Indicates a hazard with a low level of risk which, if not avoided, could result in minor or moderate injury. Issue 01 (2021-06-18) Copyright © Huawei Technologies Co., Ltd. - Page 4 Change History Changes between document issues are cumulative. The latest document issue contains all updates made in previous issues. Issue 01 (2021-06-18) This issue is the first official release. Issue 01 (2021-06-18) Copyright © Huawei Technologies Co., Ltd.

-

Page 5: Table Of Contents

Contents Contents About This Document........................ ii 1 Quick Guide Usage........................1 2 Installation Drawings......................3 3 Removing Transport Protection Materials................ 4 4 Initial Configuration Parameters..................5 A Common Torque Selection Table..................6 Issue 01 (2021-06-18) Copyright © Huawei Technologies Co., Ltd. -

Page 6: Quick Guide Usage

This chapter describes the notes for using the quick guide. ● Before the installation, check whether the materials are intact according to the packing list. If there is any problem, contact Huawei technical support. ● This document provides only the initial configuration parameters required for data center commissioning and O&M as well as the drawings and parameters... - Page 7 Do not perform operations such as arc welding, drilling, and cutting on the top of a pre-fab. module. Issue 01 (2021-06-18) Copyright © Huawei Technologies Co., Ltd.

-

Page 8: Installation Drawings

FusionDC1000A40 Prefabricated All-in-One Data Center Quick Guide (2021, Zambia, ZESCO) 2 Installation Drawings Installation Drawings Issue 01 (2021-06-18) Copyright © Huawei Technologies Co., Ltd. - Page 9 Checklist of Devices Installed Onsite Installation Sequence Subcategory Item Diagram ID Diagram Name Installing Pre-fab. Module Bases Installing Bases NO.S001 Pre-fab. Module Base Installation Position Diagram Installing Twistlocks Installing and Combining Pre-fab. Modules Removing the Transport Protection Cover Removing the Transport Protection Cover Grounding Pre-fab.

- Page 10 No.S001 Pre-fab. Module Base Installation Position Diagram 12,192 3,902.2 12,414 >=\ Single-capacity base Steel base Concrete platform Ground Concrete platform Note: 1. The concrete platform needs to support a pre-fab. module with the maximum weight of 25,000 kg. The recommended anti-seismic acceleration is 3g. Calculate the strength of the concrete platform based on the contact area (refer to the 1720 cm²...

- Page 11 No.S002 Pre-fab. Module Grounding Position Diagram 1,026 1,026 Note: 1. Four ground points are set for each pre-fab. module, among which two are located at the front wall and two at the rear wall. For details about the ground points, see the Drawing No.

- Page 12 No.S003 Eave Installation Position Diagram Eave 2 Eave 1 Eave component Rubber strip GB5783-2000_M16X40_S_ZNAL Note: Drawing No. Quantity Item Unit 1. The eaves are secured on the pre-fab. module using 3 PCS of Eave 1 DKBA68688294 Eave 2 YT63217430 GB5783-2000_M16X40_S_ZNAL screws with a torque of 40 N·m, as shown GB5783-2000_M16X40_S_ Screw in the figure.

- Page 13 No.S004 Electric Cable and ELV Signal Cable Outlet Position Diagram ELV signal cable outlet 1,470 Electric cable outlet (M50-38) 1,042.5 (M50-38)

- Page 14 No.S005 Air Conditioner and LCD Embedded Piece Installation Position Diagram 1,200 Air conditioner Air conditioner drainage port drainage port 1,200 Embedded piece Glass window Embedded pieces Floor inside the pre-fab. module Floor inside the pre-fab. module Front wall Rear wall...

- Page 15 No.S006 Suspended Ceiling-Aluminum Clip-in Panel Installation Position Diagram Lighting-1 Lighting-3 Lighting-5 Lighting-7 Lighting-9 Lighting-11 Front wall Rear wall Lighting-2 Lighting-4 Lighting-6 Lighting-8 Lighting-10 Lighting-12 11400 Hanging rod Hanger Hanging rod Connection nut Hook Bracket U50 main keel Aluminum top plate L-shaped slot Aluminum plate Triangular...

- Page 16 No.S007 Glass Window Installation Position Diagram 5+9A+5 hollow glass Outdoor Indoor Neutral black sealant Edge steel sheet Glazing bead Corner connector Frame Neutral sealant Foam glue 40*20*1.5 Thermal insulation layer galvanized steel square tube (different project) Wall M8*80 nylon expansion bolt After all windows are installed, install the glass bead and apply the glass cement.

- Page 17 No.M003 Monitoring Onsite Wiring Diagram Note: The customer provides network cables to connect to the network port connector on the signal cable feeder window. Power & Signal Feeder DDF-1 DDF-2 DDF-3 DDF-4 DDF-5 DDF-6 DDF-7 DDF-8 Window IE Socket-1 IE Socket-2 IE Socket-3 IE Socket-4 IE Socket-5...

- Page 18 Socket-12 Lighting Switch-1 WY-10A 1000mm*1000mm Cable Relation Table Terminal Relation Table INPUT OUTPUT Power System Huawei Part Description Terminal Spec From Part 1 Terminal Spec From Part 2 Cable No. Breaker Container From Device Container To Device Provide by customer...

-

Page 19: Removing Transport Protection Materials

Device Protection Materials to Be Removed Smart cooling product Transport fastener Light Securing tape Emergency light Securing tape Camera Securing tape Emergency door release Plastic cover button Issue 01 (2021-06-18) Copyright © Huawei Technologies Co., Ltd. -

Page 20: Initial Configuration Parameters

FusionDC1000A40 Prefabricated All-in-One Data Center Quick Guide (2021, Zambia, ZESCO) 4 Initial Configuration Parameters Initial Configuration Parameters Issue 01 (2021-06-18) Copyright © Huawei Technologies Co., Ltd. - Page 21 List of Initial Configuration Parameters Detailed Initial Configuration Category Diagram ID Diagram Name Parameters NO.P001 Power Supply and Distribution Device Layout Diagram Initial Configurations for the Power Supply and Distribution System NO.P002 Power Supply and Distribution System Diagram Initial Configurations for the Cooling System (Air Cooled) NO.C001 Cooling Device Layout Diagram Initial Configurations for the Management System...

- Page 22 No.P001 Power Supply and Distribution Device Layout Diagram Power & Signal Feeder Window Socket-2 Socket-3 Socket-4 Socket-5 Socket-6 Socket-7 Socket-8 Socket-9 Socket-10 Socket-11 Lighting PDB-1 Lighting PDB-2 WY-10A WY-10A WY-10A WY-10A WY-10A WY-10A WY-10A WY-10A WY-10A WY-10A Lighting-1 Lighting-3 Lighting-5 Lighting-7 Lighting-9 Lighting-11...

- Page 23 No.P002 Power Supply and Distribution System Diagram Customer Input Customer Input 32A/1P RCD 32A/1P RCD...

- Page 24 No.C001 Cooling Device Layout Diagram 1000mm*1000mm...

- Page 25 No.M001 Monitoring Device Layout Diagram Power & Signal Feeder DDF-1 DDF-2 DDF-3 DDF-4 DDF-5 DDF-6 DDF-7 DDF-8 Window IE Socket-1 IE Socket-2 IE Socket-3 IE Socket-4 IE Socket-5...

- Page 26 No.F001 Fire Extinguishing Device Layout Diagram (CE) Power & Signal Feeder Window Exit-1 Emergency Lighting-1 Emergency Lighting-2 EXIT Emergency Lighting Emergency Lighting...

- Page 27 No.F003 Emergency Exit Diagram Power & Signal Feeder Window...

-

Page 28: A Common Torque Selection Table

Block Battery (Commo Wiring n Steel Terminal Connecto Cross Electric recessed screwdriv small pan head screw assembly Cross Electric recessed screwdriv counters unk head screw; cross recessed pan head screw assembly Issue 01 (2021-06-18) Copyright © Huawei Technologies Co., Ltd. - Page 29 Cross Pneumati recessed counters screwdriv unk head screw Hexagon Torque head wrench screw assembly Hexagon Torque head wrench screw assembly Common Torque 1600 1200 bolt wrench Issue 01 (2021-06-18) Copyright © Huawei Technologies Co., Ltd.

- Page 30 50 (for recessed checking, hexagon screwdriv not for flange tightenin self- drilling tapping screw G1/2'' 1/2'' pipe Torque connecto wrench G3/4'' 3/4'' pipe Torque connecto wrench G1'' 1'' pipe Torque connecto wrench Issue 01 (2021-06-18) Copyright © Huawei Technologies Co., Ltd.

Need help?

Do you have a question about the FusionDC1000A40 and is the answer not in the manual?

Questions and answers