Table of Contents

Advertisement

Quick Links

Operating Instructions

®

ProMinent

Metering Pumps

ProMinent

Makro/ 5 HK

Makro/ 5 HMH

Two operating instruction manuals are required for the safe and correct use of ProMinent

This product-specific Makro/5 operating instruction manual and the "General Operating Instructions"

®

for ProMinent

Motor-Driven Metering Pumps and Hydraulic Accessories" applies only when read in conjunction

Please read through operating instruction manual carefully! Do not discard!

Part no. 987441

Teile Nr. 987442

ProMinent

®

Makro/ 5

Please affix nameplate here!

The guarantee is void in the event of damage caused by misuse!

ProMinentGroup.ir

ProMinent Dosiertechnik GmbH · 69123 Heidelberg · Germany

ProMinent Dosiertechnik GmbH · 69123 Heidelberg · Germany

Makro/ 5 HM

with the other!

®

Makro/5 metering pumps:

BA MAK 002 02/02 GB

BA MAK 003 01/02 G

Page 1

Advertisement

Table of Contents

Summary of Contents for ProMinent Makro/ 5 HK

- Page 1 Makro/ 5 HK Makro/ 5 HM Makro/ 5 HMH Please affix nameplate here! Two operating instruction manuals are required for the safe and correct use of ProMinent ® Makro/5 metering pumps: This product-specific Makro/5 operating instruction manual and the “General Operating Instructions”...

- Page 2 Publishing details Publishing details: Operating Instruction Manual for ProMinent ® Makro/ 5 © ProMinent Dosiertechnik GmbH, 2001 ProMinent Dosiertechnik GmbH Im Schuhmachergewann 5-11 69123 Heidelberg Postfach 101760 · 69007 Heidelberg Germany info@prominent.de www.prominent.de Subject to revision Printed in the F.R. Germany ProMinentGroup.ir...

-

Page 3: Table Of Contents

11.1 Diaphragm liquid end ............. 25 11.2 Hydraulic diaphragm liquid end ........26 11.3 Piston liquid end ............28 11.4 Valve servicing ............... 31 12 Troubleshooting ..............35 13 Decommissioning and disposal ........35 14 Technical data ..............37 Appendix ProMinentGroup.ir ProMinent ® Page 3... -

Page 4: Type Code

Please give the order number and the serial number, which you will find on the nameplate of the pump itself, in the event of any enquiry or spare part order. This will facilitate identification of the pump type. Makro ProMinent ® Makro/ 5... -

Page 5: General User Instructions

NOTICE Describes a potentially damaging situation. If not avoided. could cause damage to property. Please also note the guidelines in “General Operating Instruction Manual for ProMinent ® Motor- Driven Metering Pumps and Hydraulic Accessories”! The nameplates affixed to the title page are identical to those on the pump supplied to enable a clear allocation of the correct operating instruction manual to the pump. -

Page 6: About This Pump

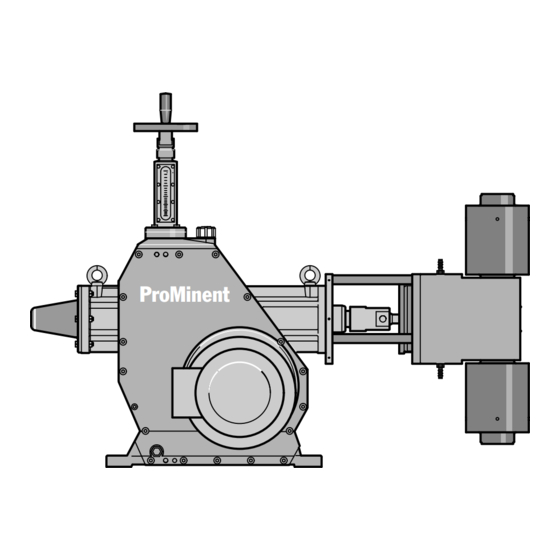

• It is prohibited to assemble and install ProMinent metering pumps with parts which have not been approved or recommended by ProMinent. Damage to persons and property may ensue. • When metering aggressive media, check the resistance of the pump materials ®... - Page 7 Fig. 1 Makro/5 HK with AK add-on power end Protective equipment: 1 Protective cover (piston and diaphragm version) 2 Cover plate (add-on power end only) 3 Flange cover 4 Cap (single-head version only) Fig. 2 Safety relief valve (*) on HMH liquid end ProMinentGroup.ir ProMinent ® Page 7...

-

Page 8: Storage. Transport. Unpacking

Device overview, controls A Power end C Liquid end 1 Lifting eye 2 Manual adjustment wheel 3 Dial 4 Motor 5 Oil drain plug Fig. 3 Makro/5 HK 6 Vent screw 7 Oil inspection window ProMinentGroup.ir ProMinent ® Page 8... - Page 9 Fig. 4 Makro/5 HK A Power end C Liquid end 1 Lifting eye 2 Manual adjustment wheel 3 Dial 4 Motor 5 Oil drain plug 6 Vent screw 7 Oil inspection window Fig. 5 Makro/5 HKD ProMinentGroup.ir ProMinent ® Page 9...

- Page 10 Device overview, controls Fig. 6 Makro/5 HKD 1 Discharge valve 2 Liquid end 3 Suction valve 4 Hose nozzle for leakage fluid 5 Protective cover Fig.7 Diaphragm liquid end (for HM) ProMinentGroup.ir ProMinent ® Page 10...

- Page 11 6 Filler opening, feed tank 7 Overpressure sensor terminal 8 Bleed valve 9 Bleed hose 10 Pressure relief valve 11 Oil inspection window – hydraulic oil 12 Diaphragm rupture sensor terminal Fig. 9 Hydraulic diaphragm liquid end (for HMH) ProMinentGroup.ir ProMinent ® Page 11...

- Page 12 Device overview, controls 1 Discharge valve 2 Liquid end 3 Suction valve Fig. 10 Piston liquid end (for HK) 4 Support bracket 5 Protective cover 6 Hose nozzle for leakage/ flushing connector ProMinentGroup.ir ProMinent ® Page 12...

-

Page 13: Function Description

Liquid ends can be attached to both ends of the push rod. They will then operate according to the Boxer principle (counter-cycle). Fig. 11 1 Cam shaft 2 Connecting rod 3 Sliding block 4 Oscillating crank 5 Fork 6 Spindle 7 Manual adjustment wheel 8 Push rod ProMinentGroup.ir ProMinent ® Page 13... - Page 14 (1) closes due to the negative pressure in the liquid end and fresh feed chemical flows into the liquid end via the suction valve (4). Fig. 12 1 Discharge valve 2 Discharge valve 3 Pump diaphragm 4 Suction valve ProMinentGroup.ir ProMinent ® Page 14...

- Page 15 1 Discharge valve 2 Composite diaphragm Fig. 13 HMH function 3 Liquid end 4 Suction valve 5 Diaphragm position sensor 6 Compensation valve (snifting valve) 7 Piston 8 Feed tank 9 Overpressure sensor 10 Bleed valve ProMinentGroup.ir ProMinent ® Page 15...

- Page 16 (to be carried out by the customer! ). The composite diaphragm also prevents feed chemical from mixing with hydraulic oil in the event of a diaphragm rupture. Section A - A (enlarged) Fig. 14 HMH diaphragm rupture system function ProMinentGroup.ir ProMinent ® Page 16...

- Page 17 (4). The flushing collar (3) enables the user to rinse the piston sealing surface or drain off leakage fluid. 1 Discharge valve 2 Piston Fig. 15 3 Flushing collar 4 Packing collar 5 Suction valve ProMinentGroup.ir ProMinent ® Page 17...

-

Page 18: Assembly

Bolt the pump to the base with four bolts (M12) through the four holes in the sub frame. Installation NOTICE ® • Also note “General Operating Instruction Manual for ProMinent Motor-Driven Metering pumps and Hydraulic Accessories”! Installation, hydraulic Liquid end WARNING •... -

Page 19: Installation, Electrical

The wiring diagram is in the terminal box. You will find guidelines for connecting the motor in “General Operating Instruction Manual for ® ProMinent Motor-Driven Metering Pumps and Hydraulic Accessories”! Stroke sensor (optional) 5 - 25 V DC. Namur type and/or DIN 19234, zero volt connection. -

Page 20: Commissioning

• The pump is designed to meter liquid media within the stated capacity limits. • Note the limitations regarding high viscosity or density of the medium. • Ensure that the liquid end materials are resistant to the feed chemical. (See ProMinent ® resistance list in the Product Catalogue or on our Homepage) •... -

Page 21: Operation

• Metering pumps and their periphery must be maintained by qualified or authorised personnel. • Read the safety guidelines in the operating instruction manual before working on the motor. ProMinentGroup.ir ProMinent ® Page 21... - Page 22 Shorter intervals are recommended if subject to heavy use (e.g. continuous operation). (30 Nm) (25 Nm) 1 Liquid end screws Fig. 17 Makro/5 diaphragm liquid end (HM) 2 Power end flange screws 3 Hose nozzle ProMinentGroup.ir ProMinent ® Page 22...

- Page 23 Fig. 19 Makro/5 piston liquid end (HK) After approx. 5000 operating hours: Change gear oil. Gear oil Mobilgear 634 VG 460. ProMinent part no.. 1006248 (20 l oil canister). Oil quantity: 16. 5 l Draining gear oil Unscrew bleed screw (1)

- Page 24 Start the pump Slowly pour gear oil into the bleed screw opening (1) until the upper oil inspection window (3) is partly covered Run the pump for a further 1-2 min Screw in bleed screw (1) ProMinentGroup.ir ProMinent ® Page 24...

-

Page 25: Repair

(rinse thoroughly in the case of hazardous media). 1 Liquid end 2 Diaphragm 3 Armour plate 4 Screw 5 Protective cover 6 Top plate 7 Shock absorber 8 Push rod 9 Hose nozzle Fig. 22 ProMinentGroup.ir ProMinent ® Page 25... -

Page 26: Hydraulic Diaphragm Liquid End

(is the cut-out on the side of the liquid end located on the side of the diaphragm rupture warning system?) Check that the diaphragm contact is resting easily in the diaphragm rupture warning system housing ProMinentGroup.ir ProMinent ® Page 26... - Page 27 Screw the housing back on (is the O-ring seated correctly beneath?) Tighten the union nut on the PG threaded connector (must be sealed. ) Fig. 23 Diaphragm rupture sensor (*) ProMinentGroup.ir ProMinent ® Page 27...

-

Page 28: Piston Liquid End

Remove the guide sleeves (6) and the guide bands (5), the packing collars (8) and the flushing collar (7) Clean the sealing area thoroughly Clean the piston (1), the guide sleeves (6) and the flushing collar (7) Dispose of the packing rings and the guide bands Insert the piston (1) ProMinentGroup.ir ProMinent ® Page 28... - Page 29 Place a sling around the liquid end and attach to a crane. WARNING • A helper should steady the liquid end by hand. It could slip out of the sling if allowed to swing freely. • Ensure that the pistons cannot fall out! ProMinentGroup.ir ProMinent ® Page 29...

- Page 30 The feed chemical can no longer penetrate through the packing collars – the liquid lubrication is suppressed. The piston is not lubricated. The packing collars will burn and the piston will be damaged. Leakage will increase sharply. Packing collar Feed chemical- Tensioning screw- pressure pressure Fig. 27 Piston ProMinentGroup.ir ProMinent ® Page 30...

-

Page 31: Valve Servicing

(where applicable: slide the second spring (6) into the valve seat’s spring guide (2)) the second ball one seal (5) and the third valve seat (direction!) and one further seal (5) place the insert disc (7) onto the packing with the bowed side up ProMinentGroup.ir ProMinent ® Page 31... - Page 32 (2). ) 1 Valve body 2 Valve seat 3 Valve ball 4 Valve housing 5 Seal 6 Spring (optional) 7 Insert disc 8 Seal (liquid end) Fig. 29 ProMinentGroup.ir ProMinent ® Page 32...

- Page 33 Screw in the valve cover (5). 1 Seal 2 Valve body 3 Valve ball 4 Valve seat 5 Valve cover Fig. 30 NOTICE Note the flow direction for the discharge and suction connections when installing the valve. ProMinentGroup.ir ProMinent ® Page 33...

- Page 34 • Note the flow direction for the discharge and suction connections when installing the valve. • only HMH . . . 130 P, PP, PTFE: Tighten the nuts for the valve mounting flange on the liquid end crosswise (12 Nm). ProMinentGroup.ir ProMinent ® Page 34...

-

Page 35: Troubleshooting

• Always depressurise the suction and discharge lines before working on the pump! • Always wear suitable protective equipment to work on the liquid end when the pump has been used with hazardous or unknown media. ProMinentGroup.ir ProMinent ® Page 35... - Page 36 -10 °C to 50 °C humidity max. 95 % rel. humidity, non-condensing Disposal NOTICE Observe all currently applicable local directives! (particularly with regard to oils) Germany: spent parts can be taken to municipal and regional collection points. ProMinentGroup.ir ProMinent ® Page 36...

-

Page 37: Technical Data

G 2 1/4-40 Component materials Liquid end size 1st. and 2nd digits ratio, 09 = 9:1 Type (H = main pump. MH =diaphragm - hydraulic liquid end) Max. piston stroke (hydraulic piston) Gearbox type - Makro/ 5 ProMinentGroup.ir ProMinent ® Page 37... - Page 38 G 2 1/4-40 Component materials Liquid end size 1st. and 2nd digits ratio, 09 = 9:1 Type (H = main pump. MH =diaphragm - hydraulic liquid end) Max. piston stroke (hydraulic piston) Gearbox type - Makro/ 5 ProMinentGroup.ir ProMinent ® Page 38...

- Page 39 G2 1/2-DN65 Component materials Liquid end size 1st. and 2nd digits ratio, 09 = 9:1 Type (H = main pump. MH =diaphragm - hydraulic liquid end) Max. piston stroke (hydraulic piston) Gearbox type - Makro/ 5 ProMinentGroup.ir ProMinent ® Page 39...

- Page 40 Makro 5/50 HK 14-130 S 3896 4652 1232 G 2 1/2- 65 Makro 5/50 HK 11-130 S 5031 6014 1593 G 2 1/2- 65 Makro 5/50 HK 09-130 S 6000 – – – – G 2 1/2- 65 ProMinentGroup.ir ProMinent ® Page 40...

- Page 41 200 mPa s - valves without valve springs 500 mPa s - valves with valve springs 1000 mPa s - correspondingly designed installation 1000 mPa s - correspondingly designed installation and after consultation with ProMinent Component materials - diaphragm liquid ends (HM and HMH) Liquid end...

- Page 42 60 °C 60 °C 100 °C 90 °C 120 °C PTFE 90 °C 120 °C Stainless steel Piston liquid ends (HK) Material long term at max. back pressure 150 °C PTFE 150 °C Stainless steel ProMinentGroup.ir ProMinent ® Page 42...

- Page 43 FM 4000 T 1008173 FM 4000 S (no valve set ) 1008174 PTFE pump diaphragm ProMinent ® DEVELOPAN ® EPDM pump diaphragm with large surface area and fabric insert, vulcanised aluminium core and PTFE Teflon coating on the side in contact with chemicals.

- Page 44 FMH 130-50 S 1008264 FMH 130-50 S (also with 2 valve sets ) 1008265 PTFE pump diaphragm ProMinent ® DEVELOPAN ® EPDM pump diaphragm with large surface area and fabric insert, vulcanised aluminium core and PTFE Teflon coating on the side in contact with chemicals.

-

Page 45: Appendix

Appendix Technical specification Makro/ 5/20 HM Main power end DN50 G 2 3/4 Ø 15.5 Ø 16 61_03-101_00_04_74_1 Dimensions - Makro/ 5/20 HM (in mm) HM xx-4000 S HM xx-4000 PP, P, T ProMinentGroup.ir ProMinent ® Page 45... - Page 46 Technical specification Makro/ 5/20 HM Main power end with add-on power end DN50 G 2 3/4 U 100 Ø 15.5 Ø 16 1135 61_03-101_00_04_74_2 Dimensions - Makro/ 5/20 HM (in mm) HM..-4000 S HM..-4000 PP, P, T ProMinentGroup.ir ProMinent ® Page 46...

- Page 47 Appendix Technical specification Makro/ 5/20 HMD Double head version DN50 G 2 3/4 Ø 15.5 Ø 16 61_03_101_00_04_74_3 Dimensions - Makro/ 5/20 HMD (in mm) HM..-4000 S HM..-4000 PP, P, T ProMinentGroup.ir ProMinent ® Page 47...

- Page 48 G2 1/4 A HMH...-100/50 S* DN50 G2 3/4 A HMH...-100/50 P, PP, T* DN50 G2 3/4 A 1008 HMH...-130/50 S* DN65 G2 1/2 A 1003 HMH...-130/50 P, PP, T* DN65 flange DN65 1032 (pipe d75) ProMinentGroup.ir ProMinent ® Page 48...

- Page 49 G2 1/4 A HMH...-100/50 S* DN50 G2 3/4 A HMH...-100/50 P, PP, T* DN50 G2 3/4 A 1008 HMH...-130/50 S* DN65 G2 1/2 A 1003 HMH...-130/50 P, PP, T* DN65 flange DN65 1032 (pipe d75) ProMinentGroup.ir ProMinent ® Page 49...

- Page 50 G2 1/4 A 1117 HMH...-100/50 S* DN50 G2 3/4 A 1223 HMH...-100/50 P, PP, T* DN50 G2 3/4 A 1247 HMH...-130/50 S* DN65 G2 1/2 A 1237 HMH...-130/50 P, PP, T* DN65 flange DN65 1294 (pipe d75) ProMinentGroup.ir ProMinent ® Page 50...

- Page 51 DN 40G 2 1/4 A 1059 HK 85/50 DN40 DN40G 2 1/4 A 1085 HK 85/50 DN50 DN50G 2 3/4 A 1085 HK 100/50 DN50G 2 3/4 A 1090 HK 130/50 DN65G 2 1/2 A 1120 ProMinentGroup.ir ProMinent ® Page 51...

- Page 52 DN 40G 2 1/4 A 1059 HK 85/50 DN40 DN40G 2 1/4 A 1085 HK 85/50 DN50 DN50G 2 3/4 A 1085 HK 100/50 DN50G 2 3/4 A 1090 HK 130/50 DN65G 2 1/2 A 1120 ProMinentGroup.ir ProMinent ® Page 52...

- Page 53 HK 30/50 DN15 1273 HK 30/50 DN20 1273 HK 40/50 DN20 1301 HK 40/50 DN25 1301 HK 50/50 DN25 1295 HK 60/50 DN25 1295 HK 60/50 DN32 1295 HK 70/50 DN32 1297 HK 70/50 DN40 1297 ProMinentGroup.ir ProMinent ® Page 53...

- Page 54 Technical specification Makro/ 5/50 HKD 85-130 Double head version U100 Ø 16 417.5 417.5 Dimensions - Makro/ 5/50 HKD 85-130 (in mm) Type HK 85/50 DN40 1341 HK 85/50 DN50 1351 HK 100/50 1371 HK 130/50 1417 ProMinentGroup.ir ProMinent ® Page 54...

- Page 55 Getriebemotor / Übersetzung (Hübe/min) comments 1005481 / 9:1 (ca. 156) observation 1005482 / 11:1 (ca. 133) 1005483 / 14:1 (ca. 103) 1005484 / 19:1 (ca. 75) 1005485 / 23:1 (ca. 60) Nr./no. ProMinent MD-1005481 Pumpentyp: Makro/ 5_ _ Datum/Date 08.08.2000 ProMinentGroup.ir ProMinent ®...

- Page 56 Appendix ProMinentGroup.ir ProMinent ® Page 56...

- Page 57 Appendix ProMinentGroup.ir ProMinent ® Page 57...

- Page 58 Appendix ProMinentGroup.ir ProMinent ® Page 58...

- Page 59 Appendix ProMinentGroup.ir ProMinent ® Page 59...

- Page 60 Appendix ProMinentGroup.ir ProMinent ® Page 60...

- Page 61 Appendix ProMinentGroup.ir ProMinent ® Page 61...

- Page 62 Appendix ProMinentGroup.ir ProMinent ® Page 62...

- Page 63 Appendix ProMinentGroup.ir ProMinent ® Page 63...

- Page 64 Appendix ProMinentGroup.ir ProMinent ® Page 64...

- Page 65 Appendix ProMinentGroup.ir ProMinent ® Page 65...

- Page 66 ProMinentGroup.ir ProMinent ® Page 66...

- Page 67 ProMinentGroup.ir ProMinent ® Page 67...

- Page 68 ProMinentGroup.ir ProMinent ® Page 68...

Need help?

Do you have a question about the Makro/ 5 HK and is the answer not in the manual?

Questions and answers