Table of Contents

Advertisement

Quick Links

KA01125F/00/EN/03.22-00

71575725

2022-08-01

Products

Brief Operating Instructions

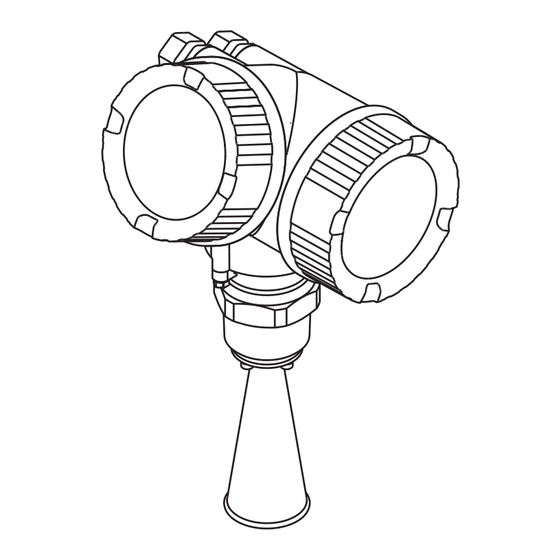

Micropilot FMR51, FMR52

FOUNDATION Fieldbus

Free space radar

These Instructions are Brief Operating Instructions; they are

not a substitute for the Operating Instructions pertaining to

the device.

Detailed information about the device can be found in the

Operating Instructions and the other documentation:

Available for all device versions via:

• Internet:

www.endress.com/deviceviewer

• Smart phone/tablet: Endress+Hauser Operations App

Solutions

Services

Advertisement

Table of Contents

Need help?

Do you have a question about the FOUNDATION Fieldbus Micropilot FMR51 and is the answer not in the manual?

Questions and answers