EnerSys PRO Series Owner's Manual

Hide thumbs

Also See for PRO Series:

- Owner's manual (16 pages) ,

- Owner's manual (19 pages) ,

- Owner's manual (9 pages)

Summary of Contents for EnerSys PRO Series

- Page 1 PRO S PRO Series eries® BATTERY HANDLING EQUIPMENT BATTERY HANDLING EQUIPMENT UNI-TUGGER OWNER’S MANUAL OPERATOR’S MANUAL / PARTS MANUAL BATTERY HANDLING EQUIPMENT...

- Page 2 Carney Battery Handling is prohibited. OWNER’S MANUAL OPERATOR’S MANUAL / PARTS MANUAL BATTERY HANDLING SOLUTIONS EnerSys EMEA Motive Power - Working in partnership with Carney Battery Handling Ltd. ENERSYS EMEA EH Europe GmbH Baarerstrasse 18...

- Page 3 – From chain, gear or Pinch Point Hazard pulley. Crush Hazard From Crush Hazard – Keep Falling Load Feet Clear Eye Protection Safety Shoes Required Required Heavy Object – Do not Slip Hazard exceed recommended load weight. Protective Clothing Rubber Gloves Required Required www.enersys.com...

- Page 4 BATTERY HANDLING EQUIPMENT DANGERS, WARNINGS, AND CAUTIONS LABELS Labels, languages, and symbols shown below may be different than the ones on the unit. Check the unit for actual labels www.enersys.com...

- Page 5 BATTERY HANDLING EQUIPMENT www.enersys.com...

- Page 6 BATTERY HANDLING EQUIPMENT www.enersys.com...

-

Page 7: Table Of Contents

Battery Tugger Quick Clamp (Figure – 4)................20 Battery Tugger Quick Clamp (Figure – 4.1)................21 Electromagnet Maintenance (Figure – 6)................22 Drive Mechanism Maintenance (Figure – 7)...............23 Slider Strip Maintenance (Figure – 8)...................24 STATEMENT OF WARRANTY....................26 Pacemaker and Magnet information..................27 HOW TO PLACE AN ORDER FOR PARTS................28 www.enersys.com... -

Page 8: General Information

(THIS WILL NOT BE COVERED UNDER WARRANTY) Note: If your Tugger is equipped with an emergency stop button and it is activated, you must wait 20 seconds before pulling the button back up (This is required for the controller to re-boot itself) www.enersys.com... -

Page 9: Pallet Truck Front Mounting (Figure - 1A)

BATTERY HANDLING EQUIPMENT Pallet Truck Front Mounting (Figure – 1a) Fork Truck Front Mounting (Figure – 1b) UNI-Tugger / Lift Truck positioning (Figure – 2) Example Showing Extraction Using Pallet Truck www.enersys.com... -

Page 10: Operating Instructions

• Engage the parking brake. • Remove any protective covers. • Unplug the battery and position the connector plug And cable so as to prevent snagging or pinching during the battery removal process. • Remove the battery retaining gate. www.enersys.com... -

Page 11: Extraction From The Lift Truck

The magnet on/ off control does not require the activation of the two-handed operation button. www.enersys.com... -

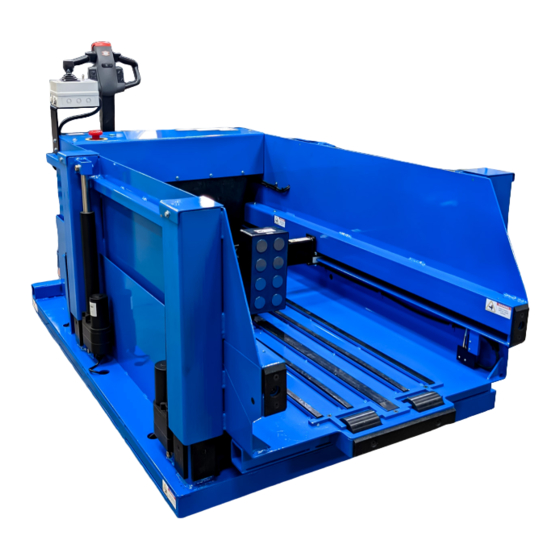

Page 12: Uni-Tugger Battery Handling Equipment Assembly With 24V Dc Vsj (Figure - A)

BATTERY HANDLING EQUIPMENT UNI-Tugger Battery Handling Equipment Assembly with 24V DC VSJ (Figure – A) www.enersys.com... -

Page 13: Uni-Tugger Battery Handling Equipment Assembly (Figure - B)

BATTERY HANDLING EQUIPMENT UNI-Tugger Battery Handling Equipment Assembly (Figure – B) www.enersys.com... -

Page 14: Battery Tugger Assembly (Figure - C)

BATTERY HANDLING EQUIPMENT Battery Tugger Assembly (Figure – C) www.enersys.com... -

Page 15: Battery Tugger Assembly (Figure - D)

BATTERY HANDLING EQUIPMENT Battery Tugger Assembly (Figure – D) www.enersys.com... -

Page 16: Battery Tugger 24V Dc Vsj Assembly (Figure - E)

BATTERY HANDLING EQUIPMENT Battery Tugger 24V DC VSJ Assembly (Figure – E) www.enersys.com... -

Page 17: Joystick Control Switch Assembly (Figure - F)

BATTERY HANDLING EQUIPMENT Joystick Control Switch Assembly (Figure – F) www.enersys.com... -

Page 18: Electrical Schematic 24V Vsj Control (Figure -3.1)

14 Nov. 2014 J.B. Change 50A fuse to 60A Circuit Breaker 3 Nov. 2014 J.B. TITLE: BTE 24V CURTIS CONTROLLER JOYSTICK VARIABLE SPEED Rev. Description Date Approved BTE 24V CURTIS CONTROLLER VSJ 3.3-R4 DRAWN BY: M.W. 24/07/2017 CAD File: www.enersys.com... -

Page 19: Electrical Schematic 24V Linear Actuators (Figure -3.2)

BATTERY HANDLING EQUIPMENT Electrical Schematic 24V Linear Actuators (Figure –3.2) www.enersys.com... -

Page 20: Battery Tugger Quick Clamp (Figure - 4)

BATTERY HANDLING EQUIPMENT Battery Tugger Quick Clamp (Figure – 4) BT-QC www.enersys.com... -

Page 21: Battery Tugger Quick Clamp (Figure - 4.1)

BATTERY HANDLING EQUIPMENT Battery Tugger Quick Clamp (Figure – 4.1) www.enersys.com... -

Page 22: Electromagnet Maintenance (Figure - 6)

If the face is heavily worn, lightly surface grind a few thousandths off the face to clean up the pulling surface. Never try to remove the electrical wires mounted in the magnet. Should you do this you will destroy the magnet and it will require rebuilding or replacement. www.enersys.com... -

Page 23: Drive Mechanism Maintenance (Figure - 7)

Check the drive chain tension. There should be no more than ½” of deflection. See ‘Drive Chain Tension Adjustment’ inset. If excessively slack, remove one full link or ½ link and reset tension. If chain is badly worn or stretched, replace it. TITLE: Drive Mechanism Maintenance DESIGNED: 04/03/02 CAD File: btmanualdrawings.dwg www.enersys.com... -

Page 24: Slider Strip Maintenance (Figure - 8)

If the slider strips are heavily worn, replace them. To do this remove front slider stop (item 2) and slide the plastic Slider Strip out. Slide the new Slider Strip into the Slider Strip Channel and replace front slider stop (item 2). TITLE: Slider Strip Maintenance DESIGNED: CAD File: 04/03/02 btmanualdrawings.dwg www.enersys.com... - Page 25 BATTERY HANDLING EQUIPMENT www.enersys.com...

-

Page 26: Statement Of Warranty

EnerSys Inc. The right to repair or replace, as set forth herein is the sole and exclusive remedy for breach of the above warranty, and EnerSys Inc. shall not be liable... -

Page 27: Pacemaker And Magnet Information

However, it is the employee’s responsibility to ensure that the pacemaker they have is a current model that is shielded and uses Bipolar leads. Please contact you’re a Carney Battery Handling representative should you have any further questions. Sincerely, Roland Mark, P.Eng. Engineering Manager, Carney Battery Handling www.enersys.com... -

Page 28: How To Place An Order For Parts

Failure to provide this information will only delay or prevent the processing of your order. To order parts or for assistance in ordering parts, you may contact us by: For Sales and Service: +41 (0)44 215 74 10 Fax: +41 (0)44 215 74 11 Notes: www.enersys.com... - Page 29 BATTERY HANDLING EQUIPMENT BATTERY HANDLING SOLUTIONS EnerSys EMEA Motive Power - Working in partnership with Carney Battery Handling Ltd. ENERSYS EMEA EH Europe GmbH Baarerstrasse 18 6300 Zug Switzerland Phone: +41 (0)44 215 74 10 • Fax: +41 (0)44 215 74 11 Email: info@enersys-hawker.com...

- Page 30 OUR EXCLUSIVE PARTNERSHIP WITH CARNEY BATTERY HANDLING LTD Since 1984, Carney Battery Handling Ltd has globally provided EnerSys® with turn-key battery room solutions, sharing our mission to innovate, design, and create quality critical battery room solutions as dedicated partners. Our dependable alliance allows us to provide dedicated support, delivering tailored engineering and design individualized for every customer.

- Page 31 Please refer to the website address for details of your nearest EnerSys office: www.enersys.com © 2022 EnerSys. All rights reserved. Trademarks and logos are the property of EnerSys and its affiliates unless otherwise noted. Subject to revisions without prior notice. E.&O.E.

Need help?

Do you have a question about the PRO Series and is the answer not in the manual?

Questions and answers