Table of Contents

Advertisement

Advertisement

Table of Contents

Summary of Contents for Toshiba B-EV4T SERIES

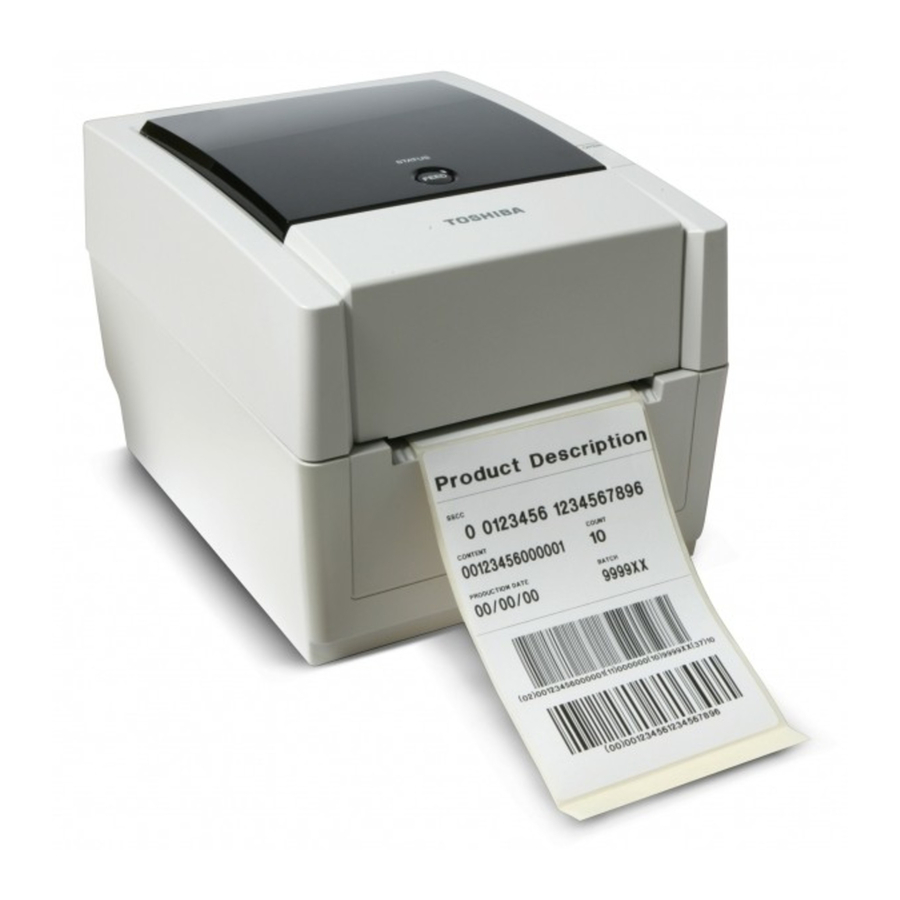

- Page 1 TOSHIBA Barcode Printer B-EV4T SERIES Owner’s Manual...

- Page 2 “Cet appareil numérique de la classe B respecte toutes les exigences du Règlement sur le matériel brouilleur du Canada.” The EA10953 AC adapter should be exclusively used for the B-EV4T Series printer. The B-EV4T Series printer must be powered by the EA10953 AC adapter.

-

Page 3: Safety Summary

Do not attempt to effect repairs or modifications to this equipment. If a fault occurs that cannot be rectified using the procedures described in this manual, turn off the power, unplug the machine, then contact your authorised TOSHIBA TEC representative for assistance. Meanings of Each Symbol This symbol indicates warning items (including cautions). - Page 4 • Utilize our maintenance services. After purchasing the machine, contact your authorised TOSHIBA TEC representative for assistance once a year to have the inside of the machine cleaned. Otherwise, dust will build up inside the machines and may cause a fire or a malfunction. Cleaning is particularly effective before humid rainy seasons.

-

Page 5: Table Of Contents

PRODUCT OVERVIEW... E1-1 Introduction... E1-1 Features ... E1-1 Unpacking... E1-1 Accessories ... E1-1 Appearance ... E1-3 1.5.1 Dimensions...E1-3 1.5.2 Front View ...E1-3 1.5.3 Rear View ...E1-3 1.5.4 Interior ...E1-4 1.5.5 Button and Indicator Lamp ...E1-5 PRINTER SETUP ... E2-1 Precautions... E2-1 Procedure before Operation ... -

Page 6: English Version

GLOSSARIES CAUTION! 1. This manual may not be copied in whole or in part without prior written permission of TOSHIBA TEC. 2. The contents of this manual may be changed without notification. 3. Please refer to your local Authorized Service representative with regard to any queries you may have in this manual. -

Page 7: Product Overview

1. Unpack the printer. 2. Check for damage or scratches on the printer. However, please note that TOSHIBA TEC shall have no liability for any damage of any kind sustained during transportation of the product. 3. Keep the cartons and pads for future transportation of the printer. - Page 8 When purchasing the power cord Since the power cord set is not enclosed in this unit, please purchase an approved one that meets the following standard from your authorized TOSHIBA TEC representative. Certification Country Agency mark Australia Austria Belgium CEBEC...

-

Page 9: Appearance

1. PRODUCT OVERVIEW 1.5 Appearance 1.5.1 Dimensions 1.5.2 Front View Ribbon Access Cover 1.5.3 Rear View The names of the parts or units introduced in this section are used in the following chapters. 258 (10.2) FEED Button Media Outlet Fanfold Paper Slot Ethernet Interface USB Interface Connector... -

Page 10: Interior

1. PRODUCT OVERVIEW 1.5.4 Interior WARNING! Do not touch the print head or around it just after printing. You may get burned as the print head becomes very hot during printing. Feed Gap Sensor Media Holder Lock Switch Cover Open Sensor Ribbon Rewind Gear Print Head (Receiver) -

Page 11: Button And Indicator Lamp

1. PRODUCT OVERVIEW 1.5.5 Button and Indicator Lamp The [FEED] button operates as FEED button or PAUSE button depending on the printer statuses. • Pressing this button when the printer is in online As the FEED state causes a media feed. •... -

Page 12: Printer Setup

• For best results, and longer printer life, use only TOSHIBA TEC recommended media and ribbon. (Refer to the Supply Manual.) • Store the media and ribbon in accordance with the specifications. -

Page 13: Procedure Before Operation

Windows application. The printer can also be controlled with its own programming commands. For details, please contact your TOSHIBA TEC representative. 2.3 Turning the Printer ON/OFF 2.3.1 Turning ON the Printer CAUTION! Use the power switch to turn the printer on/off. -

Page 14: Turning Off The Printer

2.3.2 Turning OFF the Printer CAUTION! 1. Do not turn off the printer power while the media is being printed as this may cause a paper jam or damage to the printer. 2. Do not turn off the printer power while the Green Indicator Lamp is flashing as this may cause damage to the data being... -

Page 15: Connecting The Cables To The Printer

2.4 Connecting the Cables to the Printer CAUTION! Be sure to connect the serial or parallel cable while the printer and the host computer are power-off states. Failure to do this may cause electric shock, short-circuit, or breakdown of the printer. NOTE: For the specifications of the serial interface cable, refer to... -

Page 16: Connecting The Power Adapter And The Power Cord

1-2. 2. The EA10953 AC adapter should be exclusively used for the B-EV4T Series printer. The B-EV4T Series printer must be powered by the EA10953 AC adapter. 2.5 Connecting the Power Adapter and the Power Cord 1. -

Page 17: Opening/Closing The Top Cover

2.6 Opening/Closing the Top Cover WARNING! To avoid injury, be careful not to trap your fingers while opening or closing the cover. CAUTION! 1. Be careful not to touch the Print Head Element when opening the Top Cover. Failure to do this may cause missing dots by static electricity or other print quality problems. - Page 18 This section describes how to load a media in the printer. This printer accepts label rolls, tag rolls, and fanfold paper stocks. Please use TOSHIBA TEC approved media. NOTES: 1. Please perform a media sensor calibration whenever you change the media type.

- Page 19 2. PRINTER SETUP 2.7 Loading the Media (Cont.) NOTE: Media path Feed Gap Sensor Platen Black mark sensor NOTES: 1. Refer to the Supply Path Label attached inside of the Top Cover. 2. Make sure that the print side faces up. 3.

- Page 20 2. PRINTER SETUP 2.7 Loading the Media (Cont.) NOTES: 1. The sensor type used in the last print job has been selected. To change the sensor type, refer to Section 2.9.1 Media Sensor Calibration. 2. The Feed Gap Sensor is positioned 6.35 mm right from the media centre.

- Page 21 2. PRINTER SETUP 2.7 Loading the Media (Cont.) CAUTION! To separate the printed media from the media roll in batch mode, be sure to tear off the media at the Media Outlet or cut the media past the Strip Plate. If you tear off the media at the Print Head by mistake, be sure to feed one label (10 mm or...

- Page 22 2. PRINTER SETUP 2.7 Loading the Media (Cont.) NOTES: 1. When issuing labels without removing them from the backing paper, it is not necessary to pass the media through the Strip Block. 2. When the media is correctly set, the backing paper is supposed to be pinched by the Platen and the Strip Feed Roller as shown below.

-

Page 23: Loading The Media

2.7 Loading the Media (Cont.) WARNING! HAZARDOUS MOVING PARTS KEEP FINGERS AND OTHER BODY PARTS AWAY The cutter is sharp, so care must be taken not to injure yourself when handling the cutter. CAUTION! 1. Be sure to cut the backing paper of the label. - Page 24 2.7 Loading the Media (Cont.) When a media roll has an outside diameter exceeding 127 mm (5”) and the inner core diameter of 76.2 mm (3”), the optional External Media Roll Hanger is required. 1. Fit the protrusions on the bottom of the printer into the holes in the External Media Roll Hanger.

-

Page 25: Loading The Ribbon

2.8 Loading the Ribbon WARNING! 1. Do not touch any moving parts. To reduce the risk of fingers, jewellery, clothing, etc. being drawn into the moving parts, be sure to load the media once the printer has stopped moving completely. 2. - Page 26 2.8 Loading the Ribbon (Cont.) NOTE: Ribbon Path Print Head Ribbon Take-up Core Ribbon Supply Roll 3. Push up the Ribbon Access Cover by the portions indicated by arrows A and fully open it supporting the Print Head Block. Print Head Block 4.

- Page 27 2.8 Loading the Ribbon (Cont.) 6. Close the Ribbon Access Cover until it clicks. Print Head Block 7. Again, turn the Ribbon Rewind Gear to remove any slack of the ribbon. Ribbon Rewind Gear 8. Close the Top Cover gently and push down the front part of the Top Cover until they click.

-

Page 28: Media Sensor Calibration, Self Print Test, And Dump Mode Utilities

2.9 Media Sensor Calibration, Self Print Test, and Dump Mode Utilities 2.9.1 Media Sensor Calibration NOTE: The sensor type used in the last print job has been selected. The factory default is the Feed Gap Sensor. 2.9 Media Sensor Calibration, Self Print Test, and Dump Mode Utilities This utility is used to calibrate the sensitivity of the Feed Gap/Black Mark Sensor. -

Page 29: Self Print Test And Dump Mode

2.9.2 Self Print Test and Dump Mode NOTE: The following commands should not affect the test print issue. D, AX, XS, Z2;1, Z2;2 (without 2.9 Media Sensor Calibration, Self Print Test, and Dump Mode Utilities 1. Turn off the printer power and install a media roll on the printer. 2. - Page 30 2.9.2 Self Print Test and Dump Mode (Cont.) 2.9 Media Sensor Calibration, Self Print Test, and Dump Mode Utilities The test print contents should be changed by the following commands and parameters: PROGRAM VERSION: VX.XX XXXX --- Firmware version and checksum TONE ADJUST: +XX ------------------------- Print tone fine adjustment value FEED ADJUST: +XX.Xmm ------------------ Print position fine adjustment value CUT POSITION ADJUST: +XX.Xmm ----- Cut position fine adjustment value...

-

Page 31: How To Use An Sd Card

This printer enables you to save print formats, writable characters, True Type fonts, etc. in commercially available SD cards. For available SD card types, please ask the nearest TOSHIBA TEC representative. For how to save data in an SD card, please refer to the External Equipment Interface Specification stored in the CD-ROM. -

Page 32: Maintenance

NOTE: Please purchase the Print Head Cleaner from the authorised TOSHIBA TEC service representative. This chapter describes how to perform routine maintenance. To ensure the continuous high quality operation of your printer, you should perform a regular maintenance routine. For high throughput it should be done on a daily basis. -

Page 33: Platen/Sensors

3.1.2 Platen/Sensors 3.1.3 Cover CAUTION! Do not use any volatile solvents including thinner and benzene, as this may cause discoloration or distortion of the cover. 3.1.4 Media Housing 1. Wipe the Platen with a soft cloth moistened with absolute ethyl alcohol. -

Page 34: Strip Sensor/Strip Roller (Option)

3.1.5 Strip Sensor/Strip Roller (Option) 3.2 Care/Handling of the Media and Ribbon CAUTION! Be sure to carefully review and understand the Supply Manual. Use only media and ribbon which meet specified requirements. Use of non- specified media or ribbon may shorten the head life and result in problems with bar code readability or print quality. -

Page 35: Troubleshooting

4. TROUBLESHOOTING If a problem cannot be solved by taking actions described in this chapter, do not attempt to repair the printer. Turn off and unplug the printer. Then contact an authorised TOSHIBA TEC service representative for assistance. 4.1 Troubleshooting Guide... -

Page 36: Status Lamp

Clean the print head. (⇒ Section 3.1.1) When the missing dots affect printouts, turn off the printer and contact the nearest TOSHIBA TEC representative to ask for replacement of the print head. Replace the media with TOSHIBA TEC approved one. -

Page 37: Removing Jammed Media

Flashing speed of the LED Status Flashing slowly Flashing at medium speed Flashing fast 4.3 Removing Jammed Media This section describes in detail how to remove jammed media from the printer. CAUTION! Do not use any tool that may damage the print head. 1. -

Page 38: Appendix 1 Specifications

• QR Code is a trademark of DENSO CORPORATION. • Maxi Code is a trademark of United Parcel Service of America, Inc., U.S. • Please use TOSHIBA TEC recommended SD cards. The SD Cards are available from your nearest TOSHIBA TEC representative or TOSHIBA TEC Head Quarters. - Page 39 • QR Code is a trademark of DENSO CORPORATION. • Maxi Code is a trademark of United Parcel Service of America, Inc., U.S. • Please use TOSHIBA TEC recommended SD cards. The SD Cards are available from your nearest TOSHIBA TEC representative or TOSHIBA TEC Head Quarters. B-EV4T-TS14-QM-R AC100 to 240V, 50/60 Hz 100 to 120V: 2.3A, 55.2W maximum, 200 to 240V: 2.29A, 55.0W maximum...

-

Page 40: A1.2 Options

The above options are available from your nearest TOSHIBA TEC representative or TOSHIBA TEC Head Quarters. A1.3 Media Please make sure that the media to be used is approved by TOSHIBA TEC. The warranties do not apply to problems caused by using media that is not approved by TOSHIBA TEC. -

Page 41: A1.3.2 Detection Area Of The Transmissive Sensor

Inner core diameter NOTES: 1. To ensure print quality and print head life use only TOSHIBA TEC approved media. 2. When using a media roll of 76.2-mm (3”) inner core diameter, the 3”-Diameter Media Shaft included in the optional External Media Roll Hanger is required. -

Page 42: A1.3.3 Detection Area Of The Reflective Sensor

APPENDIX 1 SPECIFICATIONS A1.3.3 Detection Area of the Reflective Sensor The Reflective Sensor is movable within the full range of the media width. The reflection factor of the Black Mark must be 10% or lower with a waveform length of 950 nm. The Reflective Sensor should be aligned with the centre of the Black Mark. -

Page 43: A1.4 Ribbon

5. Line weight should be 3 to 12 dots. A1.4 Ribbon Please make sure that the ribbon being used is approved by TOSHIBA TEC. The warranty does not apply to any problem caused by using non-approved ribbons. For information regarding TOSHIBA TEC approved ribbon, please contact a TOSHIBA TEC service representative. -

Page 44: Appendix 2 Interface

APPENDIX 2 INTERFACE Interface Cables To prevent radiation and reception of electrical noise, the interface cables must meet the following requirements: • Fully shielded and fitted with metal or metallized connector housings. • Keep as short as possible. • Should not be bundled tightly with power cords. •... -

Page 45: Printer Driver

GLOSSARIES Bar code A code which represents alphanumeric characters by using a series of black and white stripes in different widths. Bar codes are used in various industrial fields: Manufacturing, Libraries, Retail, Transportation, Warehousing, etc. Reading bar codes is a fast and accurate means of capturing data while keyboard entry tends to be slow and inaccurate. - Page 46 GLOSSARIES ENGLISH VERSION EO1-33087 GLOSSARIES Supply Media and ribbon A type of media having no adhesive backing but black marks to indicate the print area. Usually tags are made of cardboard or other durable material. Thermal print head A print head using thermal transfer or thermal direct printing method.

- Page 48 EO1-33087...

Need help?

Do you have a question about the B-EV4T SERIES and is the answer not in the manual?

Questions and answers

How to change the ink roll? label maker MODEL NUMBER B-EVAT-GS14QM-R