Summary of Contents for LPKF ProtoMat S64

- Page 1 ProtoMat S64/S104 Basic reference to the detailed documentation Order code: 10073612 Version: 1.0...

- Page 2 Publisher LPKF Laser & Electronics AG Osteriede 7 30827 Garbsen Germany Phone: +49 5131-7095-0 Fax: +49 5131-7095-90 Email: info@lpkf.com Date of issue 13.03.2019 Copyright © 2019 LPKF AG This document and its contents in whole and in parts are subject to copyright.

- Page 3 PCs running Microsoft Windows® are required. LPKF Laser & Electronics AG (abbreviated to LPKF in the following) reserves the right to make changes in respect to the content of this document. The figures in this document serve as basic understanding and can differ from the actual state of the system/product.

- Page 4 Courier New highlighting buttons of software user interfaces highlighting keys 4/54 LPKF Laser & Electronics AG | V. 1.0...

- Page 5 This symbol indicates an intermediate result. This symbol indicates a final result. Registered Trademarks Product and brand names are trademarks of LPKF Laser & Electronics AG, registered among others at the US Patent and Trademark Office: LPKF and the company logo, ®...

- Page 6 By now, new versions of the documentation as well as new software versions might be available. For all the latest news and updates visit the support area of our homepage: http://www.lpkf.com/support. 6/54 LPKF Laser & Electronics AG | V. 1.0...

-

Page 7: Table Of Contents

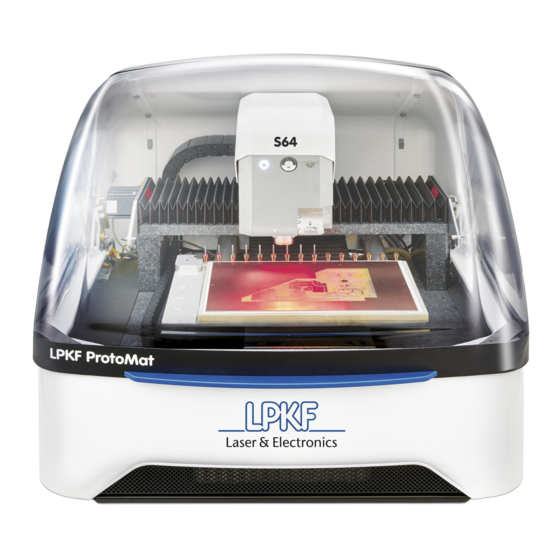

Dummy tool ................... 48 5.5 Software ...................... 49 5.6 Reading the user manual ................50 Appendix ......................51 6.1 List of figures ....................51 6.2 List of tables ....................51 6.3 Index ......................52 V. 1.0 | LPKF Laser & Electronics AG 7/54... - Page 8 ProtoMat S64/S104 Scope of this basic reference This document describes systems that resemble each other. ProtoMat S64 and ProtoMat S104 are identically constructed, differing only in a few characteristics. The following always describes the system. For comprehensibility and practicability of the instruction steps, it does not matter which of the two systems is described.

-

Page 9: Scope Of This Basic Reference

How-to guide CircuitPro PM First steps, practical tips and basics of the system software CircuitPro PM Unpacking instructions Instructions for unpacking the system Table 2: Overview of the documentation on the data medium V. 1.0 | LPKF Laser & Electronics AG 9/54... -

Page 10: Safety

Always ensure that there is no unintended escape of compressed air. Defective components that are under pressure when operating the system have to be replaced immediately by sufficiently qualified personnel. 10/54 LPKF Laser & Electronics AG | V. 1.0... -

Page 11: Electrical Hazards

Hoses and cables are routed to the system. If the hoses and cables are laid inappropriately they pose a tripping hazard for the operating personnel. Always ensure that the hoses and cables do not pose a tripping hazard. V. 1.0 | LPKF Laser & Electronics AG 11/54... -

Page 12: Personnel Requirements

The maintenance personnel has been trained for the special field where he/she works and knows the relevant standards and regulations. Service personnel Service personnel are persons who are authorized by the manufacturer LPKF for servicing the system/product. These tasks may only be performed by the LPKF Service. -

Page 13: Personal Protective Equipment

Safety shoes protect the feet against crushing injuries, falling objects and from slipping on slippery surfaces. Protective gloves Protective gloves protect the hands against friction, abrasions, puncture hazards and deep cuts as well as when touching hot surfaces. V. 1.0 | LPKF Laser & Electronics AG 13/54... -

Page 14: Intended Use

LPKF recommends the LPKF extraction system with integrated HEPA filter and activated carbon filter. In case of doubt contact the LPKF Service to receive more information on alternative materials or processing procedures. - Page 15 The system must not be used for processing highly combustible materials like e.g. paper or wood, sealed containers, hollow parts, textiles, or food. Do not use the system with a different or modified software. V. 1.0 | LPKF Laser & Electronics AG 15/54...

-

Page 16: System Description

The ProtoMat S64/S104 is a circuit board plotter for structuring single-layer and multi- layer circuit boards. The tool magazine can accommodate up to 20 different drilling and milling tools (ProtoMat S104 only, 15 tools for ProtoMat S64) that can realize among others the following applications: ... -

Page 17: Technical Data

Pneumatic data Data Value Unit min. 6 Pressure Standard volume flow 40 l/min @ 6 bar Nl/min Compressed-air purity acc. to ISO 8573-1:2010-04 Data Value Unit Solid particles Class Water Class Class V. 1.0 | LPKF Laser & Electronics AG 17/54... - Page 18 < 70 dB (A) EMC emission class – Extraction system Data Value Unit Extraction air flow at least 186 Extraction fitting (Ø) Separation efficiency > 98 (≙ filter class: at least E12) 18/54 LPKF Laser & Electronics AG | V. 1.0...

-

Page 19: Type Label

The type label is located at the housing of the system. For information on identifying the system and the relevant equipment, specify the system model and the serial number on the type label when you contact the LPKF Service. Fig. 1:... -

Page 20: Scope Of Delivery

2× USB cable for ProtoMat, plug A-B 3 m with snap-on ferrite bead 1× PVC hose connector for extraction system, ProtoMat S64/ S104 and ProConduct, PVC soft, black 1× Unit for compressed-air connection, pneumatic tube 6 mm with 1/8"... -

Page 21: Ec Declaration Of Conformity

ProtoMat S64/S104 System description EC Declaration of conformity Fig. 2: Declaration of conformity (German) V. 1.0 | LPKF Laser & Electronics AG 21/54... - Page 22 System description ProtoMat S64/S104 Fig. 3: Declaration of conformity (English) 22/54 LPKF Laser & Electronics AG | V. 1.0...

-

Page 23: Transport And Storage

Dispose of the packaging material environmentally friendly. Observe the local disposal regulations and hire a specialized company for the disposal, if necessary. The system may only be shipped in the original packaging of LPKF. Contact the LPKF Service if you need the packaging. -

Page 24: Unpacking The System

Incorrect transport using the enclosed lifting device can cause serious injuries. The lifting device serves only for lifting and putting down the system. Transport the system only with a sufficiently load-bearing means of transport. 24/54 LPKF Laser & Electronics AG | V. 1.0... - Page 25 Ensure that the following prerequisites are fulfilled before performing the described tasks: Prerequisites Spare parts and auxiliaries Wear protective gloves Safety cutter Wear safety shoes Lifting device Work in a group of four. V. 1.0 | LPKF Laser & Electronics AG 25/54...

- Page 26 1. Cut the black polyester straps that secure the transport box using a safety cutter and remove them. Fig. 5: Polyester straps removed 2. Open the transport box. Fig. 6: Transport box opened 3. Remove the sheet of cardboard. 26/54 LPKF Laser & Electronics AG | V. 1.0...

- Page 27 ProtoMat S64/S104 Transport and storage Fig. 7: Removing the sheet of cardboard 4. Remove the two steel rods for lifting the system. Fig. 8: Removing the steel rods V. 1.0 | LPKF Laser & Electronics AG 27/54...

- Page 28 5. With the help of another person, pull the transport box upwards. Put the transport box aside. Now, the padding material at the sides is accessible: Fig. 10: Padding material 6. Remove the padding material at the sides successively. 28/54 LPKF Laser & Electronics AG | V. 1.0...

- Page 29 Transport and storage Fig. 11: Removing the padding material on the left side Fig. 12: Removing the padding material on the right side Now, the system is accessible from both sides: V. 1.0 | LPKF Laser & Electronics AG 29/54...

- Page 30 7. Pull out the four transport slings of the system. Fig. 14: Transport sling pulled out 8. Push the steel rod through the foam damper and through both of the transport slings on the left side of the system. 30/54 LPKF Laser & Electronics AG | V. 1.0...

- Page 31 Always wear the recommended safety shoes and protective gloves. 10. Lift the system in a group of four, with each person holding one end of the rods. Fig. 16: System lifted by a group of four V. 1.0 | LPKF Laser & Electronics AG 31/54...

- Page 32 The system can be transported over short distances (e.g. within a room or a building) using a table trolley. Make sure that the table trolley has an appropriate load-bearing capacity. The system has been unpacked. 32/54 LPKF Laser & Electronics AG | V. 1.0...

-

Page 33: Transporting The System

For transport over short distances, the transport lock does not have to be installed and the system does not have to be packed. The system has been prepared for transport. V. 1.0 | LPKF Laser & Electronics AG 33/54... -

Page 34: Storage

When putting the system out of operation and into storage over a longer period, ensure that the storage room is clean, almost dust-free, and has a sufficient loadbearing capacity. 34/54 LPKF Laser & Electronics AG | V. 1.0... -

Page 35: First Startup

Climatic conditions Data Value Unit Temperature range (operation) 20 to 25 (68 to 77) °C (°F) Temperature range (storage, transport) -10 to 40 (14 to 104) °C (°F) Max. humidity, non-condensing V. 1.0 | LPKF Laser & Electronics AG 35/54... -

Page 36: Minimum Required Space

In front of the system, at least 400 mm (15.8 in) of space should be available for operation and movement. Fig. 18: Minimum required space Extraction system PC (recommended position for desk and PC) System 36/54 LPKF Laser & Electronics AG | V. 1.0... -

Page 37: Workplace Of The Operating Personnel

Ensure that the floor has a sufficient load-bearing capacity for the system and is even. The floor has to be leveled and antistatic and has to have a sufficient load-bearing capacity for the total weight of the system (95 kg, ~209.4 lbs). V. 1.0 | LPKF Laser & Electronics AG 37/54... -

Page 38: The System's Center Of Gravity

Pneumatic data Data Value Unit min. 6 Pressure Standard volume flow 40 l/min @ 6 bar Nl/min Compressed-air purity acc. to ISO 8573-1:2010-04 Data Value Unit Solid particles Class Water Class Class 38/54 LPKF Laser & Electronics AG | V. 1.0... -

Page 39: Preparations

First startup Preparations Before the system is installed, you have to consider and ensure the following: A suitable extraction system has to be provided. LPKF recommends using the JetStream iSeries AX079-25 extraction system. This is optionally available at LPKF. ... -

Page 40: Connecting The Extraction System

Do not block the air flow. 5.4.1 Connecting the extraction system The extraction system is an optional accessory that can be ordered at LPKF. The following describes the required steps for connecting the JetStream iSeries AX079-25: Material The following material is required: Fig. - Page 41 Extraction hose connected to the system 3. Connect the other end of the extraction hose with the extraction system. Fig. 27: Connecting the extraction hose 4. Connect the male 25-pin D-sub connector with the system. V. 1.0 | LPKF Laser & Electronics AG 41/54...

- Page 42 The extraction system has been connected. LPKF recommends to set the extraction system to 70 %. You can adapt the run-down time of the extraction system according to your requirements. For further information refer to the user manual of the extraction system.

-

Page 43: Connecting The Compressed-Air Supply

1. Connect the pneumatic tube to the compressed-air connector G 1/4". Fig. 32: Connecting the pneumatic tube to the system 2. Connect the pneumatic tube with the compressed-air supply (maximum pressure: 6 bar). The compressed-air supply has been connected. V. 1.0 | LPKF Laser & Electronics AG 43/54... -

Page 44: Establishing A Connection Between The Camera And The Pc

2. Connect the A cable of the provided USB cable to the slot of the PC. Fig. 34: Connecting the USB cable for the camera Extending the USB cable can interfere with the camera image. The camera has been connected to the PC. 44/54 LPKF Laser & Electronics AG | V. 1.0... -

Page 45: Establishing A Connection Between The System And The Pc

Connecting the USB cable to the system 2. Connect the A cable of the provided USB cable to the slot of the PC. Extending the USB cable causes transmission problems. The maximum cable length is 3 meters. V. 1.0 | LPKF Laser & Electronics AG 45/54... - Page 46 First startup ProtoMat S64/S104 Fig. 37: Connecting the USB cable to the PC The USB cable has been connected. 46/54 LPKF Laser & Electronics AG | V. 1.0...

-

Page 47: Connecting The System To The Mains Power Supply

1. Connect the mains cable to the system. 2. Connect the mains cable to the earthed wall socket. Ensure that the earthed wall socket is always accessible! The mains cable has been connected. V. 1.0 | LPKF Laser & Electronics AG 47/54... -

Page 48: Connecting The Pc To The Mains Power Supply

Once the system and the corresponding software are ready for operation, the dummy tool is ejected automatically when a processing job is started. Fig. 40: Dummy tool 48/54 LPKF Laser & Electronics AG | V. 1.0... -

Page 49: Software

The following system requirements have to be met in order to install CircuitPro PM successfully: Component Minimum system requirements 2 GHz LPKF discourages the use of the following CPU because it causes problems: Intel Xeon 2 GB Memory requirements... -

Page 50: Reading The User Manual

PCs with Intel Core i3/i5 or i7 processor of the 6th generation (Skylake) do not fully support the USB 2.0 interface of the installed camera. If problems arise while transmitting the camera image, LPKF recommends to use a USB 3.0 camera. Reading the user manual 50/54 LPKF Laser &... -

Page 51: Appendix

Table 2: Overview of the documentation on the data medium ........9 Table 3: Type label S64/S104 .................. 19 Table 4: Minimum system requirements ..............49 Table 5: Recommended system configuration ............49 V. 1.0 | LPKF Laser & Electronics AG 51/54... -

Page 52: Index

........13 mechanical data ....... 17 service personnel ......12 operating personnel ......13 technical data general .......... 17 transporting the system ....33 packaging symbols on the packaging .... 24 52/54 LPKF Laser & Electronics AG | V. 1.0...

Need help?

Do you have a question about the ProtoMat S64 and is the answer not in the manual?

Questions and answers