Summary of Contents for LPKF ProtoMat M60

- Page 1 Manual ProtoMat M60 English, version 1.0 LPKF Laser & Electronics AG Osteriede 7 D-30827 Garbsen Telefon : ++ 49 - 51 31 - 70 95 - 0 Telefax : ++ 49 - 51 31 - 70 95 - 90 eMail : lpkf@lpkf.de...

- Page 2 Copyright (c) 2000 LPKF AG Distribution or reproduction of this manual and use of its content permitted only with the written approval of LPKF AG. Right to make modifications reserved. No liability is accepted for the content. In particular, we accept no liability for damage caused by information given, information absent, or erroneous information.

- Page 3 LPKF. We have taken great trouble to ensure the accuracy and completeness of the information in this document. However, LPKF accepts no liability for the use of the document, including breach of copyright or other infringement against third parties which may arise from this.

- Page 4 Danger! This symbol is used to highlight danger to life or health. Caution! This symbol is used to identify hazards which may cause damage. Note: This symbol is used for notes intended to help you avoid faults in operation or to help you improve your procedures. ProtoMat M60...

- Page 5 : special foil for cutting aperatures for the connections to be soldered BoardMaster : Machine control software CurcuitCAM : Software for data preparation IV. Target Group This manual is written for people with basic knowledge in PCB production. ProtoMat M60...

-

Page 6: Table Of Contents

2.0 Introduction......10 2.1 Characteristics of the ProtoMat M60 ...10 3.0 General Information . - Page 7 7.10 Milling of solder mask foils ....37 7.11 Drilling with the micrometer screw ... .37 ProtoMat M60...

- Page 8 8.8 Fuses, commuting the device voltage ..45 8.9 The LPKF ProtoMat M60 Commands ..48 8.9.1 Command structure ..... . . 48 8.9.2 HP-GL standard commands.

-

Page 9: Safety Notes

Ask your supplier of the materials. • Always work with the vacuum device! • When using chemicals please take note of the safety notes on the containers or separate security sheets delivered with them! • Keep the workplace tidy. ProtoMat M60... -

Page 10: Introduction

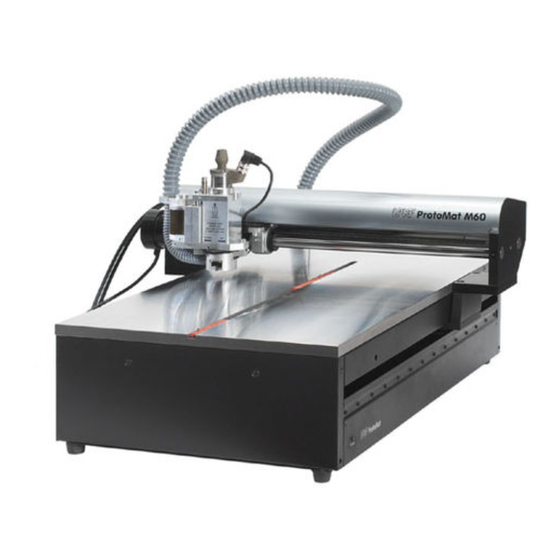

Introduction 2.0 Introduction The LPKF ProtoMat M60 mill/drill unit is a circuit board plotter which can be used to produce prototype PCBs and gravure films, and for engraving aluminum or plastic. Familiarity with the BoardMaster driver program of the LPKF ProtoMat M60 is essential for operation of the machine. -

Page 11: General Information

• Inserting tool for alignment pins • This manual 3.2 Optional accessories The following accessories can be supplied for the LPKF ProtoMat M60: • Vacuum system with fine filter. The fine filter is essential in particular when handling materials containing glass fiber, such as for FR4 base material. -

Page 12: Installation

› Set up the circuit board plotter so that the connecting cables to the electronic unit can move freely. › Connect the LPKF ProtoMat M60 to the computer with the null modem cable supplied with the system (COM1 or COM2). -

Page 13: Computer-Controlled Functions

(PC). The second interface (SERIAL 2) is an OUTPUT and is provided for future applications. The LPKF ProtoMat M60 control unit's SERIAL 1 is connected to a serial interface on the computer with the RS232 cable supplied. The RS232 cable (null modem) for the LPKF ProtoMat M60 circuit board plotter is wired as follows: The cable shield ground is connected only on the PC side (port). -

Page 14: Machine Orientation

Computer-controlled functions 4.2 Machine orientation Description of the main machine positions: fig. 2: LPKF ProtoMat M60: the x- axis is the longer direction of movement 1- PAUSE position: The machine will move to this point to load or turn the material to be machined. -

Page 15: Displays And Connections

Computer-controlled functions 4.3 Displays and connections Description of the front panel: fig. 3: Front LPKF ProtoMat M60 1- Operating display of the integrated machine control SMCU 2- X motor 3- High-speedcycle spindle motor 4- Working depth limiter ProtoMat M60... -

Page 16: Use Of Boardmaster

All LPKF circuit board plotters are driven via an asynchronous interface (RS232C). In the case of the LPKF ProtoMat M60, it is operated at 9600 baud, 1 stop bit, 8 data bits, no parity and hardware handshake. The configuration of the computer’s serial interface has to be accordingly set... -

Page 17: Setup

5.2 Turning the system on The following switching on order is useful, but not essential: 1. Computer 2. LPKF ProtoMat M60 3. Start the BoardMaster program If for some reason it should be necessary to switch the machine off and on again, then change to the MACHINE/SETTINGS window of the BoardMaster program and click on OK. -

Page 18: Changing A Tool

For changing a tool there is to be considered, that the tool after the opening is introduced up to the plot in the tool clamp, before the tool clamp is closed again. Befor handling the tool clamp you must read chapters „Switch-on instructions for high-speedcycle spindles“ on page 17. ProtoMat M60... -

Page 19: After Switching On

› switch off the motor, to click of › move the head manually using the cursor keys on the BoardMaster function bar. If the equipment does not move, check the interface configuration, the connecting cable as well as the PC interface. ProtoMat M60... -

Page 20: Home-Position And Two-Pin System

The home position needs to be programmed on new equipment and when the system has been moved. The HOME position of the LPKF ProtoMat M60 must be precisely on the mirror (X) axis (the two-pin system with the red plastic slides) for machining double-sided base-material. -

Page 21: Checking And Correcting The Home Position

HOME position. › Mill a channel over the hole manually in the X direction, without moving in the Y direction. › Check visually that the milled channel passes precisely through the center point of the hole. ProtoMat M60... -

Page 22: Making A New Two-Pin System

› Move the mill/drill head to the side. Insert two alignment pins in the holes now made in the two-pin strip. Check that the pins are firmly inserted as any play affects alignment accuracy. › Mark old holes with a felt pen so they cannot be confused with the new ones. ProtoMat M60... -

Page 23: Producing A Pcb With Boardmaster

› Switch on AUTO-MOTOR-ON ( ) (motor key on right in BoardMaster). › Press START . BoardMaster requests the tool needed for the machining phase by traveling to the tool change position and then switching the motor off automatically. ProtoMat M60... - Page 24 › Select and carry out the MILLINGTOP mill phase. › If required, select the CUTTING mill phase and machine with a contour milling cutter. › Move to the pause position, remove the PCB and proceed as described in the section „Cleaning the PCB“ on page 37. ProtoMat M60...

-

Page 25: Tools And Accessories

6.0 Tools and accessories 6.1 Tools The tools for the LPKF ProtoMat M60 come in two different lengths. Tools used to machine the material surface (milling and engraving) are 36 mm long for 1/8" and tools used for drilling or contour milling are 38 mm long for 1/8"... -

Page 26: Materials Used For Machining

Tools and accessories 6.2 Materials used for machining In general all base materials supplied by LPKF can be used for machining. You are free to machine all other materials at your own risk. Take into consideration the notes of the manufacturers. - Page 27 FR4-material : engraving, drilling, milling Engraving film: engraving Material suitable for machining but not yet supplied by LPKF: Different HF applications: engraving, drilling, milling Danger! Keep from overheating, hazardous gases may be produced! Danger! When working with materials containing glass fibers there might be produced cancerogenous dusts.

-

Page 28: Milling And Drilling

It is important that there is no dirt (adhesive tape remains, drilling or milling chips) between the individual layers so that the base material can be laid absolutely flat. Small particles under the base material would adversely affect milling depth uniformity. ProtoMat M60... -

Page 29: The Mechanical Working Depth Limiter

Danger! Keep your fingers away from the movement area of the machine during operation! When milling isolation channels in PCB materials, it is extremely important to keep a constant milling depth. With the LPKF ProtoMat M60, this done by the mechanical working depth limiter. This provides the following benefits: •... -

Page 30: Functional Elements On The Mill/Drill Head

(Attention! Do not move!) 4- Working depth limiter 10- Adjustment screw for working depth limiter 5- Knob for manual clamping 11- Base plate for high-speedcycle spindle 6- Connector for high-speedcycle spindle 12- Setting screw for knurled nut (Attention! Do not move!) ProtoMat M60... -

Page 31: Drilling

Only one PCB can be drilled at a time. It is not possible to stack PCBs one on top of the other. No drill cover plate is needed. All drills are 38 mm long. For further notes see „Practical tips“ on page 38. ProtoMat M60... -

Page 32: Isolation Milling

Caution! Before milling make sure that the PCB is positioned tightly! Switch on the vacuum system! Before milling, it must be ensured that sharp LPKF universal milling cutters (36 mm long) are used. The milling width is set to between 0.2 and 0.5 mm depending on component thickness. -

Page 33: Contour Milling In Pcb Material

After machining, the PCB has to be cleaned. This can be carried out either in a brush machine or alternatively manually with board cleaners (LPKF accessories). In either case, the PCB must be rinsed thoroughly with water to remove any copper dust produced by brushing. -

Page 34: Milling Wide Isolation Channels

The milling depth must be set such that when the copper is removed, only minimal burring results. The 3 mm double chamfered cutter is particularly well suited for milling very wide isolation channels (VDE regulations). 7.8 Front plate engraving fig. 17: Universal cutter ProtoMat M60... -

Page 35: Milling Layout Films

Use an LPKF universal milling cutter or LPKF double chamfered cutter. Danger! Use extractor when engraving, too! The LPKF ProtoMat can be used for milling through 3 mm thick aluminium front panels. 7.9 Milling layout films fig. -

Page 36: Correction Agents

30 minutes. Any coating remains must be removed with a fine hand brush. This method is cheaper and more environmentally friendly. The film can be left in the water bath as long as you want. ProtoMat M60... -

Page 37: Milling Of Solder Mask Foils

If cleaning by hand, the PCB is placed on a flat support. The board is brushed in the direction of the conductor paths with wet board cleaner (e.g. LPKF board cleaner PAD). The purpose of the brushing is on the one hand to remove the layer of oxidation and on the other to remove swarf in the isolation channels. -

Page 38: Practical Tips

The solution lies in selecting the right milling direction. When isolating conductor paths with LPKF isolate, the solder side should be mirrored before isolating as the isolation algorithm itself works in a clockwise direction. The standard postprocessing is already designed for this. - Page 39 If the film is secured with elastic adhesive tape, waves may form in the film after a while. It is particularly important here that the milling base should be level (LPKF film engraving base). • Burrs are produced when milling films either because the tool is blunt or milling was too deep.

-

Page 40: Appendix

• In rooms with a high air humidity, wipe down with a lightly oiled cloth from time to time. • Keep transport spindles oiled and clean. Caution! Do not oil bearings! Please use LPKF plastic lubrication. fig. 19: ProtoMat M60... - Page 41 At an insufficient distance the device can no longer drill through the workpiece. › At last tighten the screws again (3) and put the connector again on the spindle. Check the distance when mounting the high-speedcycle spindle ProtoMat M60...

-

Page 42: Lubricating The Carriage Guide Wipers

Appendix fig. 20: 8.2 Lubricating the carriage guide wipers You must make sure that the carriage guide wipers on the LPKF ProtoMat M60 are always well lubricated. 8.2.1 Carriage guide wipers of the X-axis The wipers (4 in total) are located on both sides of the carriage both in front of and behind the guide cheeks. -

Page 43: Oiling The Rear Wipers

PC by activating the DTR signal. The SERIAL 1 transmission speed is programmed with DIL switches 1 and 2. Switch 1 Switch 2 Baud rate 4800 baud 9600 baud 19200 baud SERIAL 1 settings: Signal Meaning Transmit data Receive data Request to send Clear to send ProtoMat M60... -

Page 44: Serial Port Serial 2

The position of the sockets is described in the section see „Displays and connections“ on page 15. Another 5-pole cable is used to supply the high-speedcycle spindle with power. Caution! Never confuse the stepper motor and the mill/drill head cables! ProtoMat M60... -

Page 45: Mill Head Connection

8.7 EPROMs The software for the control unit is in 2 EPROMs. If the EPROMs need to be replaced (updates), the LPKF ProtoMat M60 has to be partially dismantled, so follow the procedure described in the section „Fuses, commuting the device voltage“ on page 45 and change the EPROMs, ensuring that the EPROMs are correctly aligned and positioned. - Page 46 23:Position of screws for removing the electronics from the mechanical part of an LPKF ProtoMat M60 Caution! Be sure the power cable is removed! › Remove the cover with the x limit switches. The control unit thus released is constructed as Fig. 24 on page 47.

- Page 47 Appendix fig. 24: View of the PCB of the LPKF ProtoMat M60 PCB A- Power filter I- DIL switches for baud rate setting (with default setting) B- Transformer J- Power packs C- Transformer connection K- Processor D- Power pack for mill/drill head...

-

Page 48: The Lpkf Protomat M60 Commands

The fuses should be medium semi-time lag: • 230V fused with 3.15A/T • 115V fused with 3.15A/T 8.9 The LPKF ProtoMat M60 Commands 8.9.1 Command structure The SMCU (Signal Processor Control Unit) control unit of the machine interprets the HP-GL commands described below and converts them into set reactions. -

Page 49: Hp-Gl Standard Commands

If additional pairs of coordinates are sent, the command word PA is not necessary. All pairs of coordinates without a command word are taken to relate to the last PA or PR commands sent and are carried out accordingly. ProtoMat M60... -

Page 50: Special Commands

Switches the mill/drill motor on (n=1) or off (n=0). !ES (n){;} Enable stop Release (n=1) and block (n=0) the external stop function. After switching on, the external stop function is blocked. !FP {;} Full power Switches the motors of the XYZ axis to full power. ProtoMat M60... - Page 51 Carries out a physical movement from the current position to the relative coordinate (x,y,z). !TS (t){;} Time to stabilize Sets a stabilization time t=[ms] between the individual commands. !TW (t){;} Time to wait The following command is only carried out after a wait t=[ms]. ProtoMat M60...

-

Page 52: Special Command For The High-Speedcycle Spindle52

Deletes all commands from the command buffer. !GO{;} Go on Removes the stop command and continues the command implementation. !RC{;} Repeat command Repeats the last command carried out. !ST{;} Stop Interrupts command processing when the current command is completed. ProtoMat M60... -

Page 53: Inventory Of Available Tools

The step size is 7.9375 µm/step (0.0003125 inch/step). 8.10 Inventory of available tools Tools shaded gray cannot be used for the LPKF ProtoMat M60. Name Diameter. Length... -

Page 54: Concluding Remarks

LPKF is not responsible for damage following the operation and handling of the LPKF ProtoMat M60. This also applies to the case of these damage having been referred to. ProtoMat M60... -

Page 55: Declaration Of Conformity

Osteriede 7 D-30827 Garbsen Germany 2. The machine designated as LPKF ProtoMat M60 is a circuit board plotter, suitable for the production of circuit boards-prototypes and engraving films, as well as for the engraving of aluminum or plastics. The series number of the above-mentioned machine is 1P....... -

Page 56: Konformitätserklärung

Appendix 8.13 Konformitätserklärung 1. Hersteller der mit LPKF ProtoMat M60 bezeichneten Maschine ist die Firma: LPKF Laser & Electronics AG Osteriede 7 D-30827 Garbsen 2. Bei der mit LPKF ProtoMat M60 bezeichneten Maschine handelt es sich um einen Fräsbohrplotter, der zum Erstellen von Leiterplattenprototypen und Gravurfilmen, sowie zum Gravieren von Aluminium oder Kunststoff geeignet ist. -

Page 57: Index

....................26 FR 3 ............................ 26 FR 4 ............................ 26 Fuses ..........................45 gravure films ........................10 guarantee ........................10 HF and microwave applications ................27 high-speedcycle spindle ..................17 HOME position ......................20 Humidity ........................... 10 ProtoMat M60... - Page 58 .......................19 Serial port ........................43, 44 sound ..........................11 symbols ..........................4 Teflon ..........................26 Temperature ........................10 tips ............................38 tools .............................25 transport safety ......................12 two-pin system ......................20 Vitrification of the drilled hole .................39 Voltage ..........................10 Weight ..........................10 working depth limiter ....................29 ProtoMat M60...

Need help?

Do you have a question about the ProtoMat M60 and is the answer not in the manual?

Questions and answers