Table of Contents

Advertisement

Quick Links

Product description

Ԏ

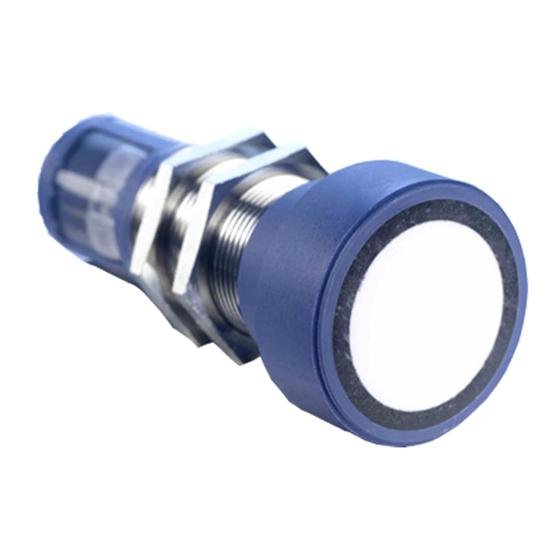

The mic+ sensor with one switching

Product description

Product description

output measures the distance to an

Ԏ

Ԏ

The mic+ sensor with one switching

The mic+ sensor with one switching

object within the detection zone

output measures the distance to an

contactless. Depending on the ad-

output measures the distance to an

object within the detection zone

justed detect distance the switching

object within the detection zone

contactless. Depending on the ad-

output is set.

contactless. Depending on the ad-

Ԏ

justed detect distance the switching

justed detect distance the switching

All settings are done with two push-

output is set.

output is set.

buttons and a three-digit LED-dis-

Ԏ

Ԏ

All settings are done with two push-

All settings are done with two push-

play (TouchControl).

buttons and a three-digit LED-dis-

Ԏ

Three-colour LEDs indicate the swit-

buttons and a three-digit LED-dis-

play (TouchControl).

ching status.

play (TouchControl).

Ԏ

Ԏ

Ԏ

Three-colour LEDs indicate the swit-

Three-colour LEDs indicate the swit-

The output functions are changea-

ching status.

ching status.

ble from NOC to NCC.

Ԏ

Ԏ

The output functions are changea-

The output functions are changea-

Ԏ

The sensors are adjustable manually

Operating Manual

ble from NOC to NCC.

ble from NOC to NCC.

via TouchControl or via Teach-in

Ԏ

Ԏ

The sensors are adjustable manually

mic+ Ultrasonic Sensors with

procedure.

The sensors are adjustable manually

Operating Manual

Operating Manual

one switching output an IO-Link

Ԏ

via TouchControl or via Teach-in

via TouchControl or via Teach-in

Useful additional functions are set

mic+ Ultrasonic Sensors with

mic+ Ultrasonic Sensors with

Operating Manual

procedure.

procedure.

in the Add-on-menu.

mic+25/F/TC

one switching output an IO-Link

one switching output an IO-Link

Ԏ

Ԏ

Useful additional functions are set

Useful additional functions are set

Ԏ

Using the LinkControl adapter (op-

mic+35/F/TC

mic+ Ultrasonic Sensors with

mic+130/F/TC

in the Add-on-menu.

in the Add-on-menu.

tional accessory) all TouchControl

one switching output an IO-Link

mic+25/F/TC

mic+25/F/TC

mic+340/F/TC

Ԏ

Ԏ

Using the LinkControl adapter (op-

Using the LinkControl adapter (op-

mic+35/F/TC

mic+35/F/TC

and additional sensor parameter

mic+25/F/TC

mic+600/F/TC

mic+35/F/TC

mic+130/F/TC

mic+130/F/TC

tional accessory) all TouchControl

tional accessory) all TouchControl

mic+130/F/TC

mic+340/F/TC

mic+340/F/TC

and additional sensor parameter

and additional sensor parameter

mic+340/F/TC

Diagram 1: Set sensor parameters numerically using LED display

mic+600/F/TC

mic+600/F/TC

mic+600/F/TC

Diagram 1: Set sensor parameters numerically using LED display

Diagram 1: Set sensor parameters numerically using LED display

Diagram 1: Set sensor parameters numerically using LED display

Start here

T1 + T2

Start here

Start here

Contact

T1 + T2

T1 + T2

Sensor Partners BV

Set switching output

James Wattlaan 15

Set switching output

T1

5151 DP Drunen

Set switching output

Set switching output

The Netherlands

T1

T1

T1 + T2

+31 (0)416 - 37 82 39

T1 + T2

T1 + T2

info@sensorpartners.com

T1

sensorpartners.com

T1

1

T1

T1 + T2

1

T1 + T2

1

T1 + T2

For single switching

point press T2

Sensor Partners BVBA

T2

– – –

until »

« is

For single switching

For single switching

displayed.

Z.1 Researchpark 310

point press T2

point press T2

T2

T2

– – –

until »

– – –

« is

until »

« is

B-1731, Zellik

displayed.

T1 + T2

displayed.

Belgium

T1 + T2

T1 + T2

T1

+32 (0)2 - 464 96 90

info@sensorpartners.com

T1

T1 + T2

T1

sensorpartners.com

T1 + T2

T1 + T2

T2

T2

T2

T1 + T2

Ready

T1 + T2

T1 + T2

Ready

Ready

settings can be adjusted by a Win-

dows

Software.

®

settings can be adjusted by a Win-

settings can be adjusted by a Win-

IO-Link

dows

dows

®

Software.

Software.

®

The mic+ sensors are IO-Link-capable

IO-Link

in accordance with IO-Link specifica-

IO-Link

The mic+ sensors are IO-Link-capable

The mic+ sensors are IO-Link-capable

tion V1.1 and support Smart Sensor

in accordance with IO-Link specifica-

in accordance with IO-Link specifica-

Product description

Profile like Digital Measuring Sensor.

settings can be adjusted by a Win-

Ԏ

The mic+ sensor with one switching

dows

Software.

tion V1.1 and support Smart Sensor

tion V1.1 and support Smart Sensor

®

The mic+ sensors have a blind zone

output measures the distance to an

Profile like Digital Measuring Sensor.

IO-Link

Profile like Digital Measuring Sensor.

in which distance measurement is not

object within the detection zone

The mic+ sensors are IO-Link-capable

contactless. Depending on the ad-

The mic+ sensors have a blind zone

The mic+ sensors have a blind zone

possible. The operating range indi-

in accordance with IO-Link specifica-

justed detect distance the switching

in which distance measurement is not

in which distance measurement is not

cates the distance of the sensor that

tion V1.1 and support Smart Sensor

output is set.

Profile like Digital Measuring Sensor.

possible. The operating range indi-

possible. The operating range indi-

can be applied with normal reflectors

Ԏ

All settings are done with two push-

cates the distance of the sensor that

The mic+ sensors have a blind zone

with sufficient function reserve. When

cates the distance of the sensor that

buttons and a three-digit LED-dis-

in which distance measurement is not

play (TouchControl).

can be applied with normal reflectors

can be applied with normal reflectors

using good reflectors, such as a calm

possible. The operating range indi-

Ԏ

Three-colour LEDs indicate the swit-

with sufficient function reserve. When

with sufficient function reserve. When

water surface, the sensor can also be

cates the distance of the sensor that

ching status.

using good reflectors, such as a calm

using good reflectors, such as a calm

used up to its maximum range. Ob-

can be applied with normal reflectors

Ԏ

The output functions are changea-

water surface, the sensor can also be

water surface, the sensor can also be

with sufficient function reserve. When

jects that strongly absorb (e.g. plastic

ble from NOC to NCC.

using good reflectors, such as a calm

used up to its maximum range. Ob-

used up to its maximum range. Ob-

Ԏ

The sensors are adjustable manually

foam) or diffusely reflect sound (e.g.

water surface, the sensor can also be

via TouchControl or via Teach-in

jects that strongly absorb (e.g. plastic

jects that strongly absorb (e.g. plastic

pebble stones) can also reduce the

used up to its maximum range. Ob-

procedure.

foam) or diffusely reflect sound (e.g.

foam) or diffusely reflect sound (e.g.

defined operating range.

jects that strongly absorb (e.g. plastic

Ԏ

Useful additional functions are set

pebble stones) can also reduce the

pebble stones) can also reduce the

foam) or diffusely reflect sound (e.g.

in the Add-on-menu.

pebble stones) can also reduce the

defined operating range.

defined operating range.

Ԏ

Using the LinkControl adapter (op-

defined operating range.

tional accessory) all TouchControl

and additional sensor parameter

Start here

T1 + T2

Press T1 and T2 simultaneously for about

3 s until welcome message has passed.

Press T1 and T2 simultaneously for about

3 s until welcome message has passed.

Press T1 and T2 simultaneously for about

Press T1 and T2 simultaneously for about

3 s until welcome message has passed.

3 s until welcome message has passed.

T1

T2

T2

T1 + T2

T2

T2

Set detect distance in

T1

T2

mm or cm.

Set detect distance in

T2

mm or cm.

1

T1 + T2

1

2

Set detect distance in

Set detect distance in

T2

T2

1

2

mm or cm.

mm or cm.

For single switching

For window mode

point press T2

operation set far

T2

T1

T2

– – –

until »

« is

switching point in

1

2

1

2

displayed.

mm or cm.

For window mode

operation set far

T2

T1

T1 + T2

switching point in

For window mode

For window mode

mm or cm.

operation set far

operation set far

Choose »

« for NCC or

T1

T2

T1

T2

switching point in

T1

T2

switching point in

»

« for NOC.

mm or cm.

mm or cm.

T1 + T2

Choose »

« for NCC or

T2

»

« for NOC.

Choose »

« for NCC or

Choose »

« for NCC or

T2

T1

T2

T2

»

« for NOC.

»

« for NOC.

T1 + T2

Ready

T1

T1

T1

SENSORPARTNERS.COM

Safety Notes

Installation

Ԏ

Read the operating instructions

Assemble the sensor at the installa-

Î

Safety Notes

Installation

Safety Notes

prior to start-up.

Installation

tion location.

Ԏ

Ԏ

Ԏ

Connection, installation and ad-

Read the operating instructions

Read the operating instructions

Assemble the sensor at the installa-

Assemble the sensor at the installa-

Î

Plug in the connector cable to the

Î

Î

prior to start-up.

prior to start-up.

tion location.

justment works may only be car-

tion location.

M12 connector, see Fig. 2.

Ԏ

Connection, installation and ad-

Plug in the connector cable to the

Ԏ

ried out by expert personnel.

Connection, installation and ad-

Î

Plug in the connector cable to the

Î

justment works may only be car-

M12 connector, see Fig. 2.

Ԏ

No safety component in ac-

justment works may only be car-

M12 connector, see Fig. 2.

2

Safety Notes

Installation

ried out by expert personnel.

cordance with the EU Machine

ried out by expert personnel.

Ԏ

Read the operating instructions

Assemble the sensor at the installa-

3

5

Î

Ԏ

Ԏ

No safety component in ac-

No safety component in ac-

prior to start-up.

tion location.

2

2

Directive, use in the area of per-

1

Ԏ

Connection, installation and ad-

Plug in the connector cable to the

cordance with the EU Machine

cordance with the EU Machine

Î

sonal and machine protection

3

3

5

5

justment works may only be car-

M12 connector, see Fig. 2.

3

Directive, use in the area of per-

Directive, use in the area of per-

not permitted

ried out by expert personnel.

4

1

1

sonal and machine protection

sonal and machine protection

Ԏ

No safety component in ac-

2

1

2

Proper Use

3

3

not permitted

not permitted

cordance with the EU Machine

5

3

5

4

mic+ ultrasonic sensors are used for

4

4

Directive, use in the area of per-

2

2

Proper Use

Proper Use

non-contact detection of objects.

Fig. 2: Pin assignment with view onto sensor

1

sonal and machine protection

plug and colour coding of the microso-

5

5

3

mic+ ultrasonic sensors are used for

mic+ ultrasonic sensors are used for

not permitted

Synchronisation

4

nic connection cable

Fig. 2: Pin assignment with view onto sensor

Fig. 2: Pin assignment with view onto sensor

non-contact detection of objects.

non-contact detection of objects.

2

Proper Use

If the assembly distances shown in

Start-up

plug and colour coding of the microso-

plug and colour coding of the microso-

5

mic+ ultrasonic sensors are used for

Synchronisation

Synchronisation

Fig. 1 for two or more sensors are ex-

nic connection cable

nic connection cable

Fig. 2: Pin assignment with view onto sensor

Connect the power supply.

non-contact detection of objects.

Î

If the assembly distances shown in

If the assembly distances shown in

ceeded the integrated synchronisation

plug and colour coding of the microso-

Start-up

Start-up

Set the parameters of the sensor

Î

Synchronisation

nic connection cable

Fig. 1 for two or more sensors are ex-

Fig. 1 for two or more sensors are ex-

should be used. Connect Sync/Com-

Connect the power supply.

Connect the power supply.

If the assembly distances shown in

Î

Î

manually via TouchControl (see

Start-up

ceeded the integrated synchronisation

ceeded the integrated synchronisation

channels (pin 5 at the units receptable)

Fig. 1 for two or more sensors are ex-

Set the parameters of the sensor

Set the parameters of the sensor

Î

Î

Fig. 3 and Diagram 1)

Connect the power supply.

Î

should be used. Connect Sync/Com-

should be used. Connect Sync/Com-

ceeded the integrated synchronisation

of all sensors (10 maximum).

manually via TouchControl (see

Set the parameters of the sensor

Î

manually via TouchControl (see

or use the Teach-in procedure to

Î

should be used. Connect Sync/Com-

channels (pin 5 at the units receptable)

channels (pin 5 at the units receptable)

manually via TouchControl (see

Fig. 3 and Diagram 1)

Fig. 3 and Diagram 1)

adjust the detect points (see Dia-

channels (pin 5 at the units receptable)

of all sensors (10 maximum).

Fig. 3 and Diagram 1)

of all sensors (10 maximum).

or use the Teach-in procedure to

or use the Teach-in procedure to

of all sensors (10 maximum).

Î

Î

gram 2).

or use the Teach-in procedure to

Î

adjust the detect points (see Dia-

adjust the detect points (see Dia-

adjust the detect points (see Dia-

cm mm %

gram 2).

gram 2).

gram 2).

mic+25...

≥0.35 m

≥2.50 m

cm mm %

cm mm %

cm mm %

mic+35...

≥0.40 m

≥2.50 m

mic+25...

≥0.35 m

≥2.50 m

mic+25...

mic+25...

≥0.35 m

≥0.35 m

≥2.50 m

≥2.50 m

mic+35...

≥0.40 m

≥2.50 m

mic+130...

≥1.10 m

≥8.00 m

mic+35...

mic+35...

≥0.40 m

≥0.40 m

≥2.50 m

≥2.50 m

mic+130...

≥1.10 m

≥8.00 m

T1

D1D2

mic+340...

≥2.00 m

≥18.00 m

T1

D1D2

T2

mic+130...

≥1.10 m

≥8.00 m

mic+130...

≥1.10 m

≥8.00 m

mic+340...

≥2.00 m

≥18.00 m

Fig. 3: TouchControl/LED display

Fig. 3: TouchControl/LED display

mic+600...

≥4.00 m

≥30.00 m

T1

D1D2

T1

D1D2

mic+600...

≥4.00 m

≥30.00 m

mic+340...

≥2.00 m

≥18.00 m

mic+340...

≥2.00 m

≥18.00 m

Factory setting

Factory setting

Fig. 3: TouchControl/LED display

Fig. 3: TouchControl/LED display

Fig. 1: Assembly distances, indicating synchro-

Fig. 1: Assembly distances, indicating synchro-

mic+ sensors are delivered factory

mic+600...

mic+600...

≥4.00 m

≥4.00 m

≥30.00 m

≥30.00 m

mic+ sensors are delivered factory

nisation/multiplex

nisation/multiplex

Factory setting

Factory setting

made with the following settings:

made with the following settings:

Fig. 1: Assembly distances, indicating synchro-

Multiplex mode

Fig. 1: Assembly distances, indicating synchro-

Multiplex mode

Ԏ

Switching output on NOC

mic+ sensors are delivered factory

Ԏ

mic+ sensors are delivered factory

Switching output on NOC

nisation/multiplex

nisation/multiplex

The Add-on-menu allows to assign an

Ԏ

Detecting distance at operating ran-

The Add-on-menu allows to assign an

made with the following settings:

made with the following settings:

individual address »01« to »10« to

Ԏ

Detecting distance at operating ran-

ge

Multiplex mode

Multiplex mode

individual address »01« to »10« to

each sensor connected via the Sync/

Ԏ

Switching output on NOC

Ԏ

Switching output on NOC

ge

Ԏ

Measurement range set to maxi-

The Add-on-menu allows to assign an

The Add-on-menu allows to assign an

each sensor connected via the Sync/

Com-channel (Pin5). The sensors per-

Ԏ

Detecting distance at operating ran-

Ԏ

Detecting distance at operating ran-

mum range

Ԏ

Measurement range set to maxi-

individual address »01« to »10« to

form the ultrasonic measurement se-

individual address »01« to »10« to

Com-channel (Pin5). The sensors per-

ge

Maintenance

ge

mum range

quentially from low to high address.

each sensor connected via the Sync/

each sensor connected via the Sync/

form the ultrasonic measurement se-

Ԏ

mic+ sensors work maintenance free.

Measurement range set to maxi-

Ԏ

Measurement range set to maxi-

Therefore any influence between the

Maintenance

Com-channel (Pin5). The sensors per-

Com-channel (Pin5). The sensors per-

Small amounts of dirt on the surface

quentially from low to high address.

sensors is rejected.

mum range

mum range

mic+ sensors work maintenance free.

do not influence function. Thick layers

form the ultrasonic measurement se-

form the ultrasonic measurement se-

Therefore any influence between the

The address »00« is reserved to syn-

Maintenance

Maintenance

of dirt and caked-on dirt affect sensor

Small amounts of dirt on the surface

quentially from low to high address.

chronisation mode and deactivates the

quentially from low to high address.

sensors is rejected.

function and therefore must be remo-

mic+ sensors work maintenance free.

multiplex mode. To use synchronised

mic+ sensors work maintenance free.

do not influence function. Thick layers

Therefore any influence between the

Therefore any influence between the

The address »00« is reserved to syn-

ved.

mode all sensors must be set to

Small amounts of dirt on the surface

Small amounts of dirt on the surface

of dirt and caked-on dirt affect sensor

sensors is rejected.

sensors is rejected.

chronisation mode and deactivates the

address »00«.

do not influence function. Thick layers

do not influence function. Thick layers

function and therefore must be remo-

The address »00« is reserved to syn-

The address »00« is reserved to syn-

multiplex mode. To use synchronised

of dirt and caked-on dirt affect sensor

of dirt and caked-on dirt affect sensor

ved.

chronisation mode and deactivates the

chronisation mode and deactivates the

mode all sensors must be set to

function and therefore must be remo-

function and therefore must be remo-

multiplex mode. To use synchronised

multiplex mode. To use synchronised

address »00«.

ved.

ved.

mode all sensors must be set to

mode all sensors must be set to

address »00«.

address »00«.

Notes

Ԏ

mic+ sensors have internal tempe-

Notes

Notes

rature compensation. Because the

Ԏ

Ԏ

mic+ sensors have internal tempe-

mic+ sensors have internal tempe-

sensors heat up on their own, the

rature compensation. Because the

rature compensation. Because the

temperature compensation reaches

sensors heat up on their own, the

sensors heat up on their own, the

its optimum working point after

temperature compensation reaches

1

temperature compensation reaches

approx. 30 minutes of operation.

Notes

Ԏ

its optimum working point after

its optimum working point after

During normal operating mode, a

4

Ԏ

mic+ sensors have internal tempe-

1

1

colour

rature compensation. Because the

approx. 30 minutes of operation.

approx. 30 minutes of operation.

yellow LED D2 signals that the swit-

+U

brown

sensors heat up on their own, the

Ԏ

Ԏ

During normal operating mode, a

During normal operating mode, a

4

ching output has connected.

4

B

–U

blue

temperature compensation reaches

colour

B

colour

yellow LED D2 signals that the swit-

Ԏ

yellow LED D2 signals that the swit-

During normal operating mode, the

F

black

its optimum working point after

+U

+U

brown

brown

ching output has connected.

B

B

ching output has connected.

measured distance value is dis-

approx. 30 minutes of operation.

–

white

–U

–U

blue

blue

B

B

Ԏ

Ԏ

Ԏ

During normal operating mode, the

During normal operating mode, the

Sync/Com

grey

During normal operating mode, a

played on the LED-indicator in mm

F

F

black

black

colour

yellow LED D2 signals that the swit-

measured distance value is dis-

measured distance value is dis-

(up to 999 mm) or cm (from

–

–

white

white

+U

brown

ching output has connected.

B

played on the LED-indicator in mm

played on the LED-indicator in mm

Sync/Com

Sync/Com

grey

grey

100 cm). Scale switches automati-

–U

blue

B

Ԏ

During normal operating mode, the

F

black

(up to 999 mm) or cm (from

(up to 999 mm) or cm (from

cally and is indicated by a point on

measured distance value is dis-

–

white

100 cm). Scale switches automati-

100 cm). Scale switches automati-

top of the digits.

Sync/Com

grey

played on the LED-indicator in mm

(up to 999 mm) or cm (from

Ԏ

cally and is indicated by a point on

cally and is indicated by a point on

During Teach-in mode, the hystere-

100 cm). Scale switches automati-

top of the digits.

top of the digits.

sis loops are set back to factory set-

cally and is indicated by a point on

Ԏ

Ԏ

During Teach-in mode, the hystere-

During Teach-in mode, the hystere-

tings.

top of the digits.

sis loops are set back to factory set-

sis loops are set back to factory set-

Ԏ

If no objects are placed within the

Ԏ

During Teach-in mode, the hystere-

sis loops are set back to factory set-

tings.

tings.

detection zone the LED-indicator

tings.

Ԏ

Ԏ

If no objects are placed within the

If no objects are placed within the

shows »– – –«.

Ԏ

If no objects are placed within the

detection zone the LED-indicator

detection zone the LED-indicator

Ԏ

If no push-buttons are pressed for

detection zone the LED-indicator

shows »– – –«.

shows »– – –«.

20 seconds during parameter set-

shows »– – –«.

Measuring Range

Ԏ

If no push-buttons are pressed for

Ԏ

Ԏ

If no push-buttons are pressed for

If no push-buttons are pressed for

ting mode the made changes are

3-digit

20 seconds during parameter set-

20 seconds during parameter set-

20 seconds during parameter set-

Measuring Range

stored and the sensor returns to

LED-display

Measuring Range

Measuring Range

ting mode the made changes are

3-digit

ting mode the made changes are

ting mode the made changes are

LED D1 and D2

normal operating mode.

3-digit

3-digit

stored and the sensor returns to

LED-display

stored and the sensor returns to

stored and the sensor returns to

LED-display

LED-display

Ԏ

The sensor can be reset to its facto-

LED D1 and D2

normal operating mode.

Push-buttons T1 and T2

T2

LED D1 and D2

LED D1 and D2

Ԏ

The sensor can be reset to its facto-

normal operating mode.

normal operating mode.

ry setting, see »Key lock and facto-

Push-buttons T1 and T2

ry setting, see »Key lock and facto-

Ԏ

Ԏ

The sensor can be reset to its facto-

The sensor can be reset to its facto-

ry setting«, Diagram 3.

Push-buttons T1 and T2

Push-buttons T1 and T2

ry setting«, Diagram 3.

T2

T2

ry setting, see »Key lock and facto-

Ԏ

ry setting, see »Key lock and facto-

The latest IODD file and informa-

Ԏ

The latest IODD file and informa-

ry setting«, Diagram 3.

ry setting«, Diagram 3.

tions about start-up and configura-

tions about start-up and configura-

Ԏ

The latest IODD file and informa-

tion of pico+ sensors with IO-Link,

Ԏ

The latest IODD file and informa-

tion of pico+ sensors with IO-Link,

you will find online at

tions about start-up and configura-

tions about start-up and configura-

you will find online at

www.microsonic.de/en/mic+.

tion of pico+ sensors with IO-Link,

tion of pico+ sensors with IO-Link,

www.microsonic.de/en/mic+.

Show parameters

you will find online at

you will find online at

Show parameters

In normal operating mode shortly

Î

www.microsonic.de/en/mic+.

www.microsonic.de/en/mic+.

push T1. The LED display shows

In normal operating mode shortly

Î

»PAr.«

Show parameters

Show parameters

push T1. The LED display shows

Each time you tap push-button T1 the

In normal operating mode shortly

Î

In normal operating mode shortly

Î

»PAr.«

actual settings of the analogue output

push T1. The LED display shows

push T1. The LED display shows

Each time you tap push-button T1 the

are shown.

»PAr.«

»PAr.«

actual settings of the analogue output

Each time you tap push-button T1 the

Each time you tap push-button T1 the

are shown.

actual settings of the analogue output

actual settings of the analogue output

are shown.

are shown.

Advertisement

Table of Contents

Summary of Contents for Microsonic mic+ Series

- Page 1 Ԏ mic+ sensors are delivered factory Switching output on NOC nisation/multiplex nisation/multiplex The Add-on-menu allows to assign an www.microsonic.de/en/mic+. The Netherlands T1 + T2 Ԏ Detecting distance at operating ran- tion of pico+ sensors with IO-Link, tion of pico+ sensors with IO-Link, The Add-on-menu allows to assign an www.microsonic.de/en/mic+.

- Page 2 Diagram 2: Set sensor parameters via Teach-in procedure Diagram 3: Key lock and factory setting Teach-in switching output Activate/deactivate Reset to factory setting TouchControl Turn supply voltage OFF. Turn supply voltage OFF. Set switching point Set window limits Set two way reflective barrier Set NOC/NCC While pressing T1 turn While pressing T1 turn...

- Page 3 32 Vdc, minimum 290 mA, in Approved on microsonic GmbH / Phoenixseestraße 7 / 44263 Dortmund / Germany / T +49 231 975151-0 / F +49 231 975151-51 / E info@microsonic.de / W microsonic.de the final installation. June 25th, 2019 MV-DO-187552-761752 The content of this document is subject to technical changes.

Need help?

Do you have a question about the mic+ Series and is the answer not in the manual?

Questions and answers