Summary of Contents for Rice Lake RoughDeck CC Caster Cargo

- Page 1 RoughDeck ® Caster Cargo Scale with EZ Mount Load Cell Kits and a TuffSeal Junction Box ® Installation Manual PN 203881 Rev B September 20, 2021...

- Page 2 All information contained within this publication is, to the best of our knowledge, complete and accurate at the time of publication. Rice Lake Weighing Systems reserves the right to make changes to the technology, features, specifications and design of the equipment without notice.

-

Page 3: Table Of Contents

7.2 TuffSeal JB4SS Junction Box ........16 Technical training seminars are available through Rice Lake Weighing Systems. - Page 4 RoughDeck CC Rice Lake continually offers web-based video training on a growing selection of product-related topics at no cost. Visit www.ricelake.com/webinars. Visit our website www.RiceLake.com...

-

Page 5: Introduction

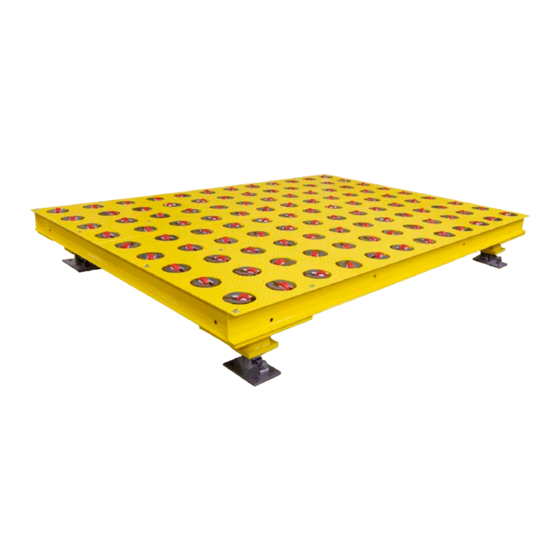

Warranty information can be found on the website at www.ricelake.com/warranties The RoughDeck CC Caster Cargo Scale has a 20,000 lb capacity with a powder coat surface for durability. Load and unload the caster deck scale in all directions with 360 degree swivel casters (108 Kalpar Casters model DL55014893). -

Page 6: Safety

General Safety Do not operate or work on this equipment unless this manual has been read and all instructions are understood. Contact any Rice Lake Weighing Systems dealer for replacement manuals. WARNING Failure to heed may result in serious injury or death. -

Page 7: Mechanical Installation

The load on each mount assembly should vary by no more than 20%. Add shims where necessary to achieve correct load distribution. Note During installation, avoid overload damage to the load cells. WARNING © Rice Lake Weighing Systems ● All Rights Reserved... -

Page 8: Mount Installation

RoughDeck CC Mount Installation Secure an EZ Mount assembly to the riser mount plate in each corner of the caster deck. The access panel top plate and corner caster plate need to be removed to access the mounting holes to secure the EZ Mount assemblies. Access Panel Top Plate Mount Riser... - Page 9 Top Plate Loading Bracket Load Cell Bolt Load Pin Washer Cotter Pin Load Cell Locating Pin Load Bar Base Plate Figure 2-4. EZ Mount Parts Illustration © Rice Lake Weighing Systems ● All Rights Reserved...

-

Page 10: Load Cell Wiring

RoughDeck CC Load Cell Wiring This section provides an overview of load cell wiring information. 1. Route the load cell cables so they will not be damaged or cut. Cable should not be routed near heat sources greater than 150°F. Do not shorten any load cell cable. The load cell is temperature compensated with the supplied length of cable. -

Page 11: Tuffseal Junction Box

The RoughDeck CC comes with the TuffSeal stainless steel junction box. The TuffSeal JB4SS is a signal trim junction box that can accommodate four load cells. Manuals and additional resources are available on the Rice Lake Weighing Systems Note website at www.ricelake.com. Refer to the Load Cell and Weigh Module Handbook (PN 22054) for additional system calibration details. -

Page 12: Dimensions

Class III, Division 1 and 2 173044 for hazardous locations. T4, Ta = 50˚C 230 W. Coleman St. • Rice Lake, WI 54868 • (715) 234-9171 • www.ricelake.com Figure 4-3. Junction Box Mounting Location Load cell output is temperature compensated for the supplied cable length. -

Page 13: Junction Box Wiring

5. Insert the appropriate wire into the exposed wire opening. 6. Release the screwdriver to allow the spring-loaded gate to close and lock the wire in place. The spring-loaded terminals will accommodate 12-28 gauge wire. Note © Rice Lake Weighing Systems ● All Rights Reserved... -

Page 14: Connect Indicator

RoughDeck CC 4.3.1 Connect Indicator The indicator terminal strip is used to connect the main cable to an indicator. This equipment was examined and approved for the connection to a single indicator only. 1. Determine the indicator’s load cell input connections from the indicator manual. 2. -

Page 15: Trimming Procedure

Refer to Handbook 44 Field Manual, published by NIST (National Institute of Note Standards and Technology, for weight recommendations. For a four cell platform, it’s 25% of scale capacity is recommended. © Rice Lake Weighing Systems ● All Rights Reserved... - Page 16 RoughDeck CC 6. Record the value displayed on the indicator once test weight is placed on each corner, directly over the load cell. Do not allow weight to overhang the sides. 7. Allow scale to return to zero each time to check for friction or other mechanical problems. 8.

-

Page 17: Calibration

(Section 4.4 on page 11). Rice Lake Weighing Systems recommends using weights greater than 20% of the scale’s rated capacity and that the weights be evenly distributed when calibration is performed. The greater the weight used to perform calibration the more linear the scale will be. -

Page 18: Troubleshooting

RoughDeck CC Troubleshooting This section provides an overview of troubleshooting information. Issues associated with load cells are often non-load cell related. Ensure all parts of the device are properly connected and secured prior to troubleshooting: 1. Check load cell mount for debris restricting load cell movement or debris between scale and structure. -

Page 19: Replacement Parts

Top Plate Weldment, EZ Mount 1, 5K/20K SST 191645 Quick Release Pin, 3/16 DIA x 1-5/8 Usable Length Not Shown 208534 Shim Kit Table 7-1. EZ Mount Stainless Steel Replacement Parts List © Rice Lake Weighing Systems ● All Rights Reserved... -

Page 20: Tuffseal Jb4Ss Junction Box

Class III, Division 1 and 2 173044 for hazardous locations. T4, Ta = 50˚C 230 W. Coleman St. • Rice Lake, WI 54868 • (715) 234-9171 • www.ricelake.com Figure 7-2. TuffSeal JB4SS Replacement Parts Diagram PG11 Cord Grip Nuts to be tightened to 33 in-lb... - Page 21 FEM END Untapped No. 6 14839 Screw, Mach 6-32NC x 1/4 SEMS Steel Zinc Plated 92266 Label, TuffSeal Large Metallic Adhesive 190009 Label, FM Junction Box JB4SS Enclosure Table 7-2. TuffSeal JB4SS Replacement Parts List © Rice Lake Weighing Systems ● All Rights Reserved...

- Page 22 RoughDeck CC Visit our website www.RiceLake.com...

- Page 24 Specifications subject to change without notice. Rice Lake Weighing Systems is an ISO 9001 registered company. 230 W. Coleman St. • Rice Lake, WI 54868 • USA U.S. 800-472-6703 • Canada/Mexico 800-321-6703 • International 715-234-9171 • Europe +31 (0)26 472 1319...

Need help?

Do you have a question about the RoughDeck CC Caster Cargo and is the answer not in the manual?

Questions and answers