Summary of Contents for Hainbuch MANDO Adapt T212

- Page 1 Operating instructions [incl. installation manual] MANDO Adapt T212 Size XXS - 4...

- Page 2 MANDO Adapt T212 Translation of the original operating instructions Order hotli ne + 49 7144.907-333 Order hotline +49 7144.907-333...

-

Page 3: Table Of Contents

MANDO Adapt T212 Contents General ........................ 7 1.1 Information about this manual ..............7 1.2 Key to symbols .................... 7 1.3 Definition of terms ..................8 1.3.1 Release setting ................8 1.3.2 Complete clamping reserve ............8 1.4 Limitation of liability ..................9 1.5 Copyright ..................... - Page 4 MANDO Adapt T212 5.2.3 Second limit [workpiece mass] ............ 30 5.2.4 Third limit [clamping length] ............30 5.2.5 Fourth limit [forces] ..............30 Transport, packaging, storage ................32 6.1 Safety, transport, packaging, storage ............32 6.2 Symbols on the packaging ................ 33 6.3 Transport inspection..................

- Page 5 MANDO Adapt T212 10.3.3 Removal of the variant with direct screw connection ....69 10.3.4 Removal of the central variant with axial screw connection ..70 10.4 Removal of the clamping element ............. 71 10.5 Removal of the product ................76 10.5.1 Removal of the adaptation clamping device ........

- Page 6 MANDO Adapt T212 Directory of tables Table 1: Technical data ................24 Table 2: Operating conditions ..............26 Table 3: Nomenclature application limits ............ 29 Table 4: Maximum workpiece mass ............30 Table 5: Screw tightening torques for adaptation clamping devices ... 39 Table 6: Screw tightening torques, metric control threads ......

-

Page 7: General

MANDO Adapt T212 General 1 General 1.1 Information about this manual This manual enables you to work safely and efficiently with the product. This manual is part of the product and must be kept in a lo- cation directly beside the product that is accessible to the personnel at all times. -

Page 8: Definition Of Terms

MANDO Adapt T212 General Tips and recommenda- INFORMATION tions … highlights useful tips and recommendations as well as information for efficient and problem-free opera- tion. … refers to other documents relating to personal and general safety. Warning symbols may appear on the product or its compo- nents. -

Page 9: Limitation Of Liability

MANDO Adapt T212 General 1.4 Limitation of liability All details and notices in this manual were compiled with due reference to applicable standards and specifications, state- of-the-art technology and our many years of expertise and experience. The manufacturer accepts no liability for damage arising... -

Page 10: Spare Parts And Accessories

MANDO Adapt T212 General 1.7 Spare parts and accessories WARNING Serious injuries can be caused by incorrect or de- fective spare parts! Always use genuine spare parts made by the orig- inal manufacturer. WARNING Serious injuries can be caused by incorrect or de-... -

Page 11: Warranty Terms

MANDO Adapt T212 General 1.8 Warranty terms The warranty terms are included in the manufacturer's Gen- eral Terms & Conditions of Business. Order hotline +49 7144.907-333... -

Page 12: Safety

No modifications must be made to the product. The operator is wholly and solely responsible for any resultant personal injury and/or damage to materials. Excepted from this are changing parts that HAINBUCH ap- proved explicitly for autonomous machining, but specified limits must never be exceeded. -

Page 13: Personnel Requirements

MANDO Adapt T212 Safety DANGER Serious injuries caused by parts being ejected centrifugally after defective setting of the ma- chine! Set up the end-stop requests by the machine tool on the product involved. On a regular basis, check the end-stop requests ... -

Page 14: Intended Use

MANDO Adapt T212 Safety Hydraulics specialist Hydraulics specialists are trained in the specific task profile for which they are employed, and are familiar with the rele- vant standards and legislative provisions. Due to their vocational training and experience, hydraulics specialists can work on hydraulic systems and can inde- pendently identify and avoid potential hazards. - Page 15 MANDO Adapt T212 Safety Never exceed the technical values stipulated for the product [see »General information« and »Operating conditions« chapters]. Furthermore, never exceed the limits for use of the product [see »Limits of use« chapter]. Maintain the product at regular intervals [see »Maintenance schedule«...

-

Page 16: Personal Protective Equipment

MANDO Adapt T212 Safety NOTE Damage to materials caused by incorrect use of the product! Only in a CE-compliant machine tool with a sepa- rating set of guards. Only use with compatible products. Only use for the type of use indicated [see »Use«... -

Page 17: Particular Hazards

MANDO Adapt T212 Safety Safety footwear To protect the wearer from any heavy items that may fall, and from losing their footing on slippery ground. Protective goggles To protect the eyes from projectile parts and liquid splashes. Hair net To protect long hair from getting snagged in rotating parts on the machine tool. - Page 18 MANDO Adapt T212 Safety Moving parts WARNING Serious injuries caused by touching rotating and/or moving parts! Do not open guards while the system is operating. During operation, do not reach for rotating and/or moving parts. Pay attention to the gap dimensions of moving ...

-

Page 19: Other Safety Instructions

MANDO Adapt T212 Safety Sharp-edged parts WARNING Serious cut injuries caused by sharp-edged parts and burrs! All installation of individual parts must be per- formed by skilled staff from the relevant specialist field. Also wear the following items of personal protec- ... - Page 20 MANDO Adapt T212 Safety WARNING Serious head injuries caused by bending into the working area of the machine! Only ever bend into the working area of the ma- chine if there are no cutting tools or sharp objects in it, or if these are covered.

- Page 21 MANDO Adapt T212 Safety CAUTION Cut injuries caused by sharp edges and burrs re- sulting from wear and/or repeated rework! Remove sharp edges and burrs. If necessary, replace worn components with gen- uine parts made by the manufacturer.

-

Page 22: Screws

MANDO Adapt T212 Safety 2.7 Screws WARNING Serious injuries caused by radially installed screws being ejected centrifugally if installed in- correctly / poor handling! Do not open the screws secured with sealing lac- quer. Screws and threaded pins fitted radially to the ... -

Page 23: Environmental Protection

MANDO Adapt T212 Safety 2.9 Environmental protection NOTE Substantial damage to the environment can result from non-compliant handling or incorrect dis- posal of environmentally hazardous substances! If environmentally hazardous substances enter the environment accidentally, take immediate re- medial action. -

Page 24: Technical Data

MANDO Adapt T212 Technical data 3 Technical data 3.1 General information XXS 215 8-13 1.5 0.3 Ø 130.0 x 200.5 6000 42 10/1 XS 215 13-18 1.5 0.4 Ø 130.0 x 198.5 5400 42 10/1 215 16-21 1.5 0.4 Ø 130.0 x 200.5... -

Page 25: Performance Values

MANDO Adapt T212 Technical data 3.2 Performance values NOTE Material damage to the products use and/or to the machine tool caused by exceeding the maximum performance values! Do not exceed the maximum performance values [see »General information« chapter]. On all products used, do not exceed the lowest of ... -

Page 26: Speed

MANDO Adapt T212 Technical data 3.4 Speed The product is authorized for rotational operation. The maximum speed is written on the product [maximum speed, see »General information« chapter]. DANGER Serious injuries caused by parts being ejected centrifugally due to a non-compliant combination... -

Page 27: Layout And Function

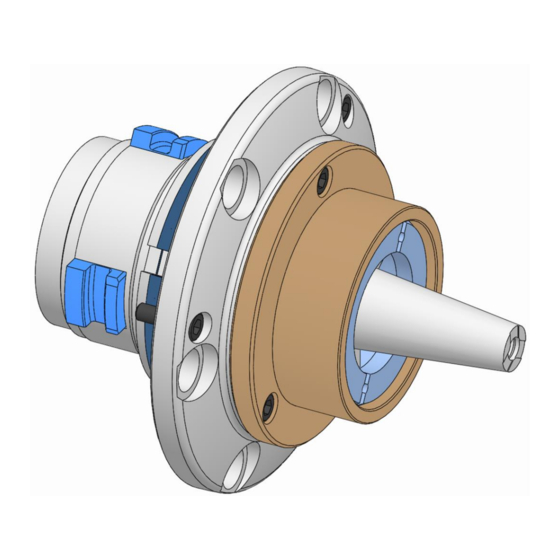

MANDO Adapt T212 Layout and function 4 Layout and function 4.1 Overview and brief description Basic clamping device Adaptation clamping de- vice Rotary extractor sleeve / workpiece end-stop Coupling ring Segmented clamping bushing [clamping ele- ment] The adaptation clamping device is intended to convert exter- nal into internal stresses. -

Page 28: Accessories Required

MANDO Adapt T212 Layout and function 4.2 Accessories required 4.2.1 Basic clamping device The basic clamping device supports the adaptation clamping device. 4.2.2 Segmented clamping bushing The segmented clamping bushing is manufactured with a customer-specified clamping diameter. 4.2.3 Workpiece end-stop The workpiece end-stop is produced with an end-stop di- mension that reflects customer wishes. -

Page 29: Use And Limits Of Use

The product can only be used in combination with a suitable basic clamping device from HAINBUCH. As well as for its general field of application, this product was designed and developed for use, when necessary, in a specific and documented application [see clamping situa- tion drawing or order confirmation]. -

Page 30: Second Limit [Workpiece Mass]

MANDO Adapt T212 Use and limits of use 5.2.3 Second limit [workpiece mass] The maximum mass of workpiece depends on the cutting cir- cle diameter of the mandrel tip on the product. Maximum workpiece Cutting circle diame- [ ���� ] mass ��... - Page 31 MANDO Adapt T212 Use and limits of use The clamping forces must be adapted to reflect the work- piece materials. The torque exerted on the clamping device during machining of the workpiece must never exceed the maximum level of transmissible torque resulting from the radial clamping force.

-

Page 32: Transport, Packaging, Storage

MANDO Adapt T212 Transport, packaging, storage 6 Transport, packaging, storage 6.1 Safety, transport, packaging, storage WARNING High level of physical strain due to the weight of the product or of its components if not trans- ported properly! From a weight of 10 kg, use appropriate transport ... -

Page 33: Symbols On The Packaging

MANDO Adapt T212 Transport, packaging, storage NOTE Damage to materials caused by falling parts if transported incorrectly! Ensure that the product cannot roll away or fall. Place on a non-slip surface. When using lifting gear, use appropriate load- ... -

Page 34: Unpacking And Internal Transportation

MANDO Adapt T212 Transport, packaging, storage 6.4 Unpacking and internal transportation The total weight of the product depends on its size. Depending on the weight involved, it may be necessary to use lifting gear to lift the product or its components out of the packaging safely, to transport them and to position and in- stall them in the machine tool or on the machine table. -

Page 35: Storage

MANDO Adapt T212 Transport, packaging, storage 6.6 Storage INFORMATION The packaged items may display information relating to storage and readmission to storage that extend be- yond the scope of these requirements. Pay attention to these notices. Store packaged items under the following conditions: Safe for storage. -

Page 36: Installation

MANDO Adapt T212 Installation 7 Installation 7.1 Installation safety WARNING Serious injuries caused by unskilled staff during installation / removal! Installation and removal must be performed by skilled staff from the relevant specialist field. WARNING Serious injuries can be caused if the machine tool starts up accidentally! Set the machine tool into set-up mode. -

Page 37: Preliminary Remarks

MANDO Adapt T212 Installation WARNING Serious head injuries caused by bending into the working area of the machine! Only ever bend into the working area of the ma- chine if there are no cutting tools or sharp objects in it, or if these are covered. -

Page 38: Screw Tightening Torques

Damage to materials caused by defective screw tightening torques! To secure the product to the machine, pay attention to the values specified by HAINBUCH and by the machine manufacturer for screw tightening torques. If the machine manufacturer stipulates different values, you must consult HAINBUCH. - Page 39 MANDO Adapt T212 Installation Tightening torque at screw quality [Nm] Thread desig- nation 10.9 12.9 Table 5: Screw tightening torques for adaptation clamping devices Metric control threads The following table contains the guide values in Nm for screw tightening torques for achieving the highest permitted pre- load for metric control threads.

-

Page 40: Preparation Of The Machine For Installation

MANDO Adapt T212 Installation 7.4 Preparation of the machine for installation Set the machine into set-up mode. Reduce the operating pressure to a minimum. Remove cutting tools and/or sharp objects from the working area of the machine, or cover them. - Page 41 MANDO Adapt T212 Installation Use the release key to release the release pin in the jaw. INFORMATION The release key cannot be removed in this position. Pull the jaw outwards to remove it from the groove. Order hotline +49 7144.907-333...

- Page 42 MANDO Adapt T212 Installation Install the chuck protector up to the marker line. Rotate the release key until the serrations on the jaw chuck mesh with those in the jaw. Remove the release key. Install the other chuck protectors as described.

-

Page 43: Installation Of The Product

MANDO Adapt T212 Installation Remove the integrated liner from the jaw chuck. 10. Clean the locating faces on the jaw chuck and the adap- tation clamping device. 7.6 Installation of the product Adaptation clamping device Fixing screws adaptation clamping device... -

Page 44: Compatibility Check

MANDO Adapt T212 Installation 7.6.1 Compatibility check Check the compatibility of the product and the connection point of the basic clamping device. For this, check that the connection point and the product share the same adaptation geometry. Also check if the actu- ating element / coupling element is suitable. -

Page 45: Installation Of The Adaptation Clamping Device

MANDO Adapt T212 Installation Open the coupling ring and remove it. 7.6.3 Installation of the adaptation clamping device Attach any lifting gear that may be required. If necessary, fit the mounting aid onto a vertically sus- pended spindle. Move the basic clamping device into its release position. - Page 46 MANDO Adapt T212 Installation Screw in the adaptation clamping device fixing screws and tighten to the specified tightening torque [see »Screw tightening torques« chapter]. Unfasten and remove any lifting gear that may have been required. Remove the mounting aid on a vertically suspended spindle if one was used.

- Page 47 MANDO Adapt T212 Installation WARNING Serious injuries caused by the coupling ring being ejected centrifugally after incorrect installation! The coupling ring must never be installed without the rotary extractor sleeve / the workpiece end- stop. If installation / removal work is interrupted, either ...

-

Page 48: Installation Of The Clamping Element

MANDO Adapt T212 Installation 10. Install the rotary extractor sleeve / the workpiece end- stop over the coupling ring on the product [see »Instal- lation of the changing parts« chapter]. 7.7 Installation of the clamping element Segmented clamping bushing [clamping element]... - Page 49 MANDO Adapt T212 Installation INFORMATION To install the clamping element, the rotary extractor sleeve / the workpiece end-stop and the coupling ring must be removed [see »Preparation of the product« chapter]. Move the clamping device into release position. Fit the segmented clamping bushing to the product and secure it to prevent it from falling out.

- Page 50 MANDO Adapt T212 Installation WARNING Serious injuries caused by the coupling ring being ejected centrifugally after incorrect installation! The coupling ring must never be installed without the rotary extractor sleeve / the workpiece end- stop. If installation / removal work is interrupted, either ...

- Page 51 MANDO Adapt T212 Installation Install the rotary extractor sleeve / the workpiece end- stop over the coupling ring on the product [see »Instal- lation of the changing parts« chapter]. Unfasten and remove the changing aid, which is used where necessary.

-

Page 52: Installation Of The Changing Parts

MANDO Adapt T212 Installation 7.8 Installation of the changing parts Changing part variant x-times axial screw connection Fixing screws changing part variant x-times axial screw connec- tion Changing part variant x-times axial screw connection bayonet Fixing screws changing part variant x-times axial screw connec- tion bayonet Order hotline +49 7144.907-333... - Page 53 MANDO Adapt T212 Installation Changing part variant direct screw connection Changing part variant, central, axial screw connection D1 Fixing screws, changing part variant, central, axial screw connec- tion DANGER Serious injuries caused by workpieces being ejected centrifugally if the coupling ring is not se-...

-

Page 54: Installation Of The Variant X-Times With Axial Screw Connection

MANDO Adapt T212 Installation INFORMATION If necessary, the changing part is positioned. Position- ing can for example be performed by marks, or a cy- lindrical pin and a bore or a groove. 7.8.1 Installation of the variant x-times with axial screw connection Place the changing part onto the product. -

Page 55: Installation Of The Variant X-Times With Bayonet Axial Screw Connection

MANDO Adapt T212 Installation 7.8.2 Installation of the variant x-times with bayonet axial screw connection INFORMATION Initial installation of the changing part with bayonet is in accordance with the variant with an x-times axial screw connection, see »Installation of x-times variant with axial screw connection«. -

Page 56: Installation Of The Variant, Screwed Directly

MANDO Adapt T212 Installation Screw in the changing part fixing screws and tighten to the specified tightening torque [see »Screw tightening torques« chapter]. 7.8.3 Installation of the variant, screwed directly Screw the changing part into the product using its thread, and tighten it down. -

Page 57: Installation Of The Central Variant With Axial Screw Connection

MANDO Adapt T212 Installation 7.8.4 Installation of the central variant with axial screw connection Place the changing part onto the product. Screw in the changing part fixing screw and tighten it to the specified tightening torque [see »Screw tightening torques« chapter]. -

Page 58: Commissioning

MANDO Adapt T212 Commissioning 8 Commissioning For commissioning purposes, set the operating pressure to the permitted, established machining value. The machine tool must not start up until full operating pres- sure has built up. 8.1 Commissioning safety DANGER Serious injuries caused by workpieces being... -

Page 59: Checking The Total Stroke

MANDO Adapt T212 Commissioning NOTE Damage to components caused by cooling lubri- cants with sufficient levels of corrosion inhibitor! The components made of steel materials must be protected before the usual oxidation process. Only ever use cooling lubricants with sufficient ... -

Page 60: Tests

MANDO Adapt T212 Commissioning Prior to commissioning, check the complete stroke to ensure that there is sufficient reserve stroke and opening stroke. For this, the same measurement of the moving part must be performed at fixed points in front and rear limit positions. -

Page 61: Workpiece

MANDO Adapt T212 Commissioning Conduct a clamping force measurement. 8.4 Workpiece DANGER Serious injuries caused by parts being ejected centrifugally if level of workpiece clamping is in- sufficient! Never utilize the full clamping reserve. Do not exceed the permitted maximum clamping ... -

Page 62: Activities After End Of Production

MANDO Adapt T212 Activities after end of production 9 Activities after end of production Move product into release position. Switch off machine tool and secure it to prevent it from being switched back on. Open the safety door / hood. -

Page 63: Removal

MANDO Adapt T212 Removal 10 Removal If a break in production occurs that lasts for more than three days, the product must be removed and stored safely in ac- cordance with manufacturer's stipulations [see »Transport, packaging, storage« chapter]. 10.1 Safe removal... - Page 64 MANDO Adapt T212 Removal WARNING Serious crushing injuries caused by improper ma- chine movement during installation or removal! Machine movements are only permitted in set-up mode during installation and removal. Never reach into a gap. Pay attention to the gap dimensions of moving ...

-

Page 65: Preparing The Machine For Removal

MANDO Adapt T212 Removal 10.2 Preparing the machine for removal Set the machine into set-up mode. Reduce the operating pressure to a minimum. Remove cutting tools and/or sharp objects from the working area of the machine, or cover them. Remove operating and auxiliary materials as well as re- maining processing materials and dispose of them in an environmentally responsible manner. - Page 66 MANDO Adapt T212 Removal Changing part variant direct screw connection Changing part variant, central, axial screw connection D1 Fixing screws, changing part variant, central, axial screw connec- tion DANGER Serious injuries caused by workpieces being ejected centrifugally if the coupling ring is not se-...

-

Page 67: Removal Of The Variant X-Times With Axial Screw Connection

MANDO Adapt T212 Removal 10.3.1 Removal of the variant x-times with axial screw connection Unfasten and remove the fixing screws on the changing part. Take the changing part off the product. Order hotline +49 7144.907-333... -

Page 68: Removal Of The Variant X-Times With Axial Screw Connection Bayonet

MANDO Adapt T212 Removal 10.3.2 Removal of the variant x-times with axial screw connection bayonet Unfasten the fixing screws on the changing body a few turns without removing them. Turn the changing part until the screw head on the changing part fixing screw fits through the bayonet opening. -

Page 69: Removal Of The Variant With Direct Screw Connection

MANDO Adapt T212 Removal Take the changing part off the product. 10.3.3 Removal of the variant with direct screw connection Unscrew the changing part from the product using its thread. Order hotline +49 7144.907-333... -

Page 70: Removal Of The Central Variant With Axial Screw Connection

MANDO Adapt T212 Removal 10.3.4 Removal of the central variant with axial screw connection Unfasten and remove the fixing screw on the changing part. Take the changing part off the product. Order hotline +49 7144.907-333... -

Page 71: Removal Of The Clamping Element

MANDO Adapt T212 Removal 10.4 Removal of the clamping element Segmented clamping bushing [clamping element] Coupling ring Rotary extractor sleeve / workpiece end-stop C1 Fixing screws on rotary extractor sleeve / workpiece end stop Changing aid Special aids needed: If necessary, use a changing aid [depending on size] ... - Page 72 MANDO Adapt T212 Removal CAUTION Injuries caused by falling clamping element when installed / removed incorrectly! Secure the clamping element to prevent it from falling out. If a changing aid is included in the scope of deliv- ery, use it to secure the clamping element.

- Page 73 MANDO Adapt T212 Removal WARNING Serious injuries caused by the coupling ring being ejected centrifugally after incorrect installation! The coupling ring must never be installed without the rotary extractor sleeve / the workpiece end- stop. If installation / removal work is interrupted, either ...

- Page 74 MANDO Adapt T212 Removal Unfasten and remove the changing aid, which is used where necessary, and secure the segmented clamping bushing to prevent it from falling out. Take the segmented clamping bushing off the product. If a different clamping element is to be installed, proceed with installation of the clamping element [see »Installation of the...

- Page 75 MANDO Adapt T212 Removal WARNING Serious injuries caused by the coupling ring being ejected centrifugally after incorrect installation! The coupling ring must never be installed without the rotary extractor sleeve / the workpiece end- stop. If installation / removal work is interrupted, either ...

-

Page 76: Removal Of The Product

MANDO Adapt T212 Removal Install the rotary extractor sleeve / the workpiece end- stop over the coupling ring on the product [see »Instal- lation of the changing parts« chapter]. 10.5 Removal of the product Adaptation clamping device Fixing screws adaptation clamping device... -

Page 77: Removal Of The Adaptation Clamping Device

MANDO Adapt T212 Removal 10.5.1 Removal of the adaptation clamping device INFORMATION To remove the product, the rotary extractor sleeve and the coupling ring must be removed [see »Removal of the clamping element« chapter]. Attach any lifting gear that may be required. - Page 78 MANDO Adapt T212 Removal WARNING Serious injuries caused by the coupling ring being ejected centrifugally after incorrect installation! The coupling ring must never be installed without the rotary extractor sleeve / the workpiece end- stop. If installation / removal work is interrupted, either ...

-

Page 79: Maintenance

MANDO Adapt T212 Maintenance 11 Maintenance 11.1 Maintenance safety WARNING Serious injuries caused by parts being ejected centrifugally after a loss of clamping power! Maintain the maintenance and cleaning intervals of the product at all times. It is essential to check the maintenance status of ... -

Page 80: Cleaning

MANDO Adapt T212 Maintenance Interval Maintenance work Clean the clamping element, clamping taper and coupling area [see »Cleaning« chapter] Completely clean the product [see »Cleaning« chapter] six-monthly or after 3000 operating hours* Lubricate the product [see »Lubricating the product« chapter] with storage See »Storage«... - Page 81 MANDO Adapt T212 Maintenance WARNING Eye injuries and cuts caused by failure to wear protective clothing during cleaning operation! Never use compressed air to clean the product. Also wear the following items of personal protec- tive equipment, in addition to the basic equip-...

-

Page 82: Visual Inspection

MANDO Adapt T212 Maintenance WARNING Serious injuries caused by imbalance resulting from incorrect reassembly! The product components must be installed back in the same position. If necessary, mark out the relative positions of components prior to disassembly. NOTE... -

Page 83: Lubricating The Product

For this, the following lubricants are recommended: Special grease GL 261 [see the HAINBUCH product catalogue] NOTE Malfunction of the product due to a combination of different greases! Never mix different greases with one another. -

Page 84: Disposal

MANDO Adapt T212 Disposal 12 Disposal If no agreement exists for return or disposal, send disman- tled components off for recycling. NOTE Substantial damage to the environment can result from incorrect disposal of environmentally haz- ardous substances! Lubricants, auxiliary materials and operating flu- ... -

Page 85: Faults

MANDO Adapt T212 Faults 13 Faults The following chapter describes possible causes for faults, and the work involved in remedial action. If multiple faults occur, shorten the maintenance intervals in accordance with actual load levels. Contact the manufacturer if faults occur that cannot be rem- edied by following these instructions [see »Contact«... -

Page 86: Fault Table

MANDO Adapt T212 Faults 13.2 Fault table Fault Possible cause Remedial action Remedied by Remove and clean the clamping Dirt in the parts in element and, if necessary, re- Defective axial the power flow move, dismantle and clean the ad-... -

Page 87: Commissioning After A Fault Has Been Remedied

MANDO Adapt T212 Faults Fault Possible cause Remedial action Remedied by Dirty clamping ta- Remove the clamping element and clean the clamping taper Geometry error on the workpiece due Use a suitable clamping element to incorrect type of clamping element... -

Page 88: Annex

Our experts are there for you around the clock: +49 7144. 907-444 For advice or help, you can contact the sales partners and service staff listed in www.hainbuch.com. 14.2 Manufacturer certification Manufacturer certification is supplied with the product and with this manual. - Page 89 MANDO Adapt T212 Annex Order hotline +49 7144.907-333...

- Page 90 MANDO Adapt T212 Index directory Accessories, needed Maintenance schedule ...... 79 Segmented clamping bushing ..28 Misuse ..........15 Accessories, required Basic clamping device ....28 Operating conditions ......26 Workpiece end-stop ...... 28 Accessories, special aids Packaging ......... 34 Changing aid ........

- Page 91 MANDO Adapt T212 Storage ..........35 Type designation ....... 26 Symbols on the packaging ....33 Unpacking ......... 34 Technical data........24 Use ............ 29 Tests ..........60 Transport inspection ......33 Warranty ..........11 Transportation, internal ..... 34 Order hotline +49 7144.907-333...

- Page 92 HAINBUCH GMBH SPANNENDE TECHNIK Postfach 1262 71667 Marbach / Erdmannhäuser Strasse 57 71672 Marbach Germany Tel. +49 7144.907-0 Fax +49 7144.18826 verkauf@hainbuch.de www.hainbuch.com 24 hour emergency phone line + 49 7144.907-444...

Need help?

Do you have a question about the MANDO Adapt T212 and is the answer not in the manual?

Questions and answers