Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Andritz MC

- Page 1 Medium-consistency pump MC STANDARD, C-01-000000 Erection Work, Operating and Maintenance Instructions Centrifugal pump MC Machine: TRANSLATION OF ORIGINAL Issued: HPU-CP/ Revision: Checked: HPU-CP/ Checked: Rev. 0, 2010.02.09 Kap. , Seite 1 of 2 GRZ-2698563-v1-Title_page.FM...

- Page 2 STANDARD, C-01-000000 The operating manual is protected by copyright. All usual rights reserved. It must not be wholly or partly reproduced without authorization by Andritz AG. Contraventions shall entail damage claims and may have penal consequences. All rights shall also be reserved for any patents granted, registration of trade marks and technical modifications without prior notification.

- Page 3 Medium-consistency pump - MC STANDARD, C-01-000000 TABLE OF CONTENTS INTRODUCTION ......Use ..........

-

Page 4: Table Of Contents

Medium-consistency pump - MC STANDARD, C-01-000000 3.6.1 Applicable standards ..........13 3.6.2... - Page 5 Medium-consistency pump - MC STANDARD, C-01-000000 MAINTENANCE ........

- Page 6 Medium-consistency pump - MC STANDARD, C-01-000000 Rev. 0, 2010.02.09 TABLE OF CONTENTS Page 4 of 4 GRZ-2836263-v1-Table_of_contents.FM...

- Page 7 Medium-consistency pump MC STANDARD, C-01-000000 INTRODUCTION This manual is part of the Andritz AG technical documentation for the machine. It is intended as a supplement to supply the basic knowledge required for proper, safe and economical use of the equipment delivered by Andritz AG.

- Page 8 Medium-consistency pump MC STANDARD, C-01-000000 How to use the manual Presentation • Chapter and paragraph headings are printed in capitals in the continuous text. Chapter on SAFETY • Designations of indicating and handling elements are written in inverted commas in the continuous text.

- Page 9 Non-authorized structural changes to the machine/system. • Non-observance of the maintenance and upkeep instructions. In the event of a claim for repair under guarantee, ANDRITZ AG reserves the right to assess the damage to the machine/system. Rev. 0, 2010.02.09 INTRODUCTION Kap.1 , Seite 3 of 4...

- Page 10 Copyright The operating manual is protected by copyright. All usual rights reserved. It must not be wholly or partly reproduced without authorization by Andritz AG. Contraventions shall entail damage claims and may have penal consequences. All rights shall also be reserved for any patents granted, registration of trade marks and technical modifications without prior notification.

- Page 11 DANGER and WARNING SIGNS highlight these additional safety regulations in the operating instructions. Safety instructions on components not supplied by ANDRITZ AG are contained in the descriptions of these individual components ( /MEDIUM CONSISTENCY PUMP MC/ SUPPLIER DOCUMENTATION).

- Page 12 Any modifications to the scope of supply made without the agreement of Andritz AG are considered contrary to the designated use. The term designated use also covers adherence to the operating instructions, compliance with the operating, inspection and maintenance conditions and with the regulations on cleaning and upkeep.

- Page 13 Medium-consistency pump MC STANDARD, C-01-000000 User's obligations Designated use The user of the medium-consistency pump is responsible for its designated use. Work instructions In addition to the operating instructions, applicable legal stipulations in the user countries and other rules governing safety at work, health and environmental protection must be observed and personnel instructed in these matters.

- Page 14 Medium-consistency pump MC STANDARD, C-01-000000 Inspections The operator undertakes • to check at regular intervals whether the safety instructions and regulations governing work on the medium-consistency pump are observed. • to carry out regular training to confirm the level of knowledge of the operating and maintenance personnel.

- Page 15 Medium-consistency pump MC STANDARD, C-01-000000 General obligations of personnel To avoid personal and material damage, all persons working on the machine shall observe the following safety instructions: • Observe the safety instructions in the operating regulations and on the medium-consistency pump.

- Page 16 Medium-consistency pump MC STANDARD, C-01-000000 Safety devices The medium-consistency pump must not be operated without effective safety equipment. Safety equipment must not be circumvented, dismantled or made unserviceable during operations. The safety equipment is there to protect operating personnel. Safety equipment and access thereto must be kept clear.

- Page 17 Medium-consistency pump MC STANDARD, C-01-000000 Indicative, warning Indicative, warning and prohibiting signs must be observed. They must be and prohibiting checked regularly for legibility and completeness and they must not be signs removed or obstructed. The following indicative, warning and prohibiting signs are attached to the machine.

- Page 18 Medium-consistency pump MC STANDARD, C-01-000000 General protective Operating personnel must use and carry personal protective equipment apparel along with them in accordance with the national regulations or as specified by the plant operator. It should be compulsory to wear hard-toed boots throughout the entire mill premises.

- Page 19 Medium-consistency pump MC STANDARD, C-01-000000 Safety at the machine installation site Adequate lighting must be provided (industrial lighting). The foundations must be sized to withstand the loads caused by the medium-consistency pump. The customer will be provided with a load plan.

- Page 20 Medium-consistency pump MC STANDARD, C-01-000000 2.10.1 Noise Levels (dB) The sound power levels were detected according to ISO/DIS 9614, Part II. 1000 1500 2200 Tab. 2-3 Noise levels in respect of motor speed level It is impossible to measure all applications. That is why values have been calculated according to the Europump Guideline 001/30/E, Forecasting the Airborne Noise Emission of Centrifugal Pumps.

- Page 21 Medium-consistency pump MC STANDARD, C-01-000000 2.11 Electrical equipment All work on the electrical equipment, without exception, must be carried out by skilled electricians. Any form of contact with electrical equipment may cause fatal injuries. Before beginning any maintenance or repair work, the operator must disconnect the energy supply to all drives securely.

- Page 22 Medium-consistency pump MC STANDARD, C-01-000000 monitored by a second person outside the danger zone. It must always be possible to evacuate a worker from the danger zone without delay. Any leakage (e.g. at the shaft seal) of hazardous media (e.g. explosive, toxic, ...) as well as hot (more than 60°C) must be collected by the...

- Page 23 STANDARD, C-01-000000 2.13 Welding work In general, welding work is only permitted after consulting Andritz AG. Any welding work that is described in detail in the maintenance instructions is excluded from this ruling. When performing welding work, always observe the relevant safety regulations, as well as the appropriate safety regulations for work performed in enclosed and confined spaces.

- Page 24 Medium-consistency pump MC STANDARD, C-01-000000 • Hydrogen peroxide H • Caustic soda (sodium hydroxide) (NaOH) • Sodium dithionite Na • Sulphuric acid H These chemicals may irritate or causing burning to skin and mucous membranes, particularly the eyes, and can lead to inflammations in the respiratory tract.

- Page 25 Medium-consistency pump MC STANDARD, C-01-000000 Possible chemical inlet Abb. 2-2 Possible chemical inlet to the suction channel Reactions In reactions with other substances, these chemicals (NaOH) can lead to highly exothermic reactions, heat generation, danger of ignition or generating of inflammable gases or vapours, even to a risk of explosion.

- Page 26 --> If combustible liquids as solvents, petrol, alcohol..or installing the pump in an explosive area is planned, this first has to be conferred with Andritz AG. Low flash points of combustible liquids may cause danger of fire and explosion. Zone arrangement...

- Page 27 Medium-consistency pump MC STANDARD, C-01-000000 2.18 Work in enclosed vessels and in confined spaces Definition All operating equipment that is closed off towards the surrounding atmosphere is considered an enclosed vessel. This includes shafts, channels, pipework and cavities in machines.

- Page 28 Medium-consistency pump MC STANDARD, C-01-000000 Ventilation – The ventilation system must be sized such as to maintain the protective concentration of noxious substances below the maximum concentration breathing permitted in the work place and also to ensure that sufficient oxygen is equipment available.

- Page 29 Medium-consistency pump MC STANDARD, C-01-000000 Further Gas bottles regulations and It is forbidden to take gas bottles or liquid fuel (liquid gas) into an enclosed measures vessel. (e.g. welding equipment, lamps or soldering tools). Safety harness If it is necessary to enter an enclosed vessel in which there is a danger of...

- Page 30 Medium-consistency pump MC STANDARD, C-01-000000 2.19 Permit for work in enclosed / confined spaces Object / location / point at which work is performed: ....Type of work: ..........

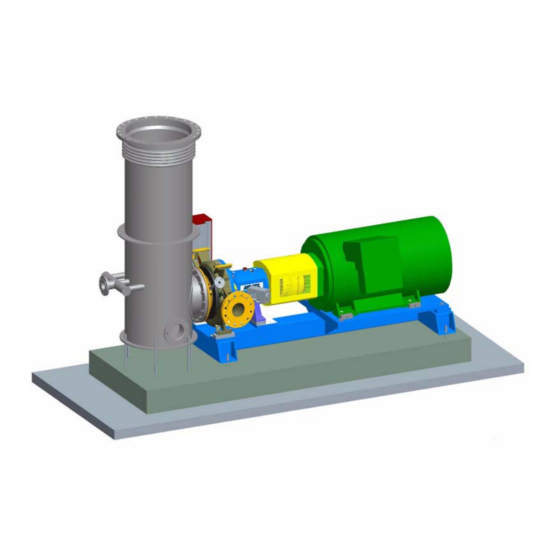

- Page 31 Medium-consistency pump MC STANDARD, C-01-000000 DESCRIPTION Field of application The medium-consistency pump is used to pump medium-consistency pulps in the pulp and paper industry. Fig. 3-1 Medium-consistency pump Rev. 0, 2010.02.09 DESCRIPTION Kap.3 , Seite 1 of 18 GRZ-2698568-v1-Description.FM...

- Page 32 Medium-consistency pump MC STANDARD, C-01-000000 Main components of the medium-consistency pump Standpipe Control box MC pump Fig. 3-2 Main components of the medium-consistency pump Rev. 0, 2010.02.09 DESCRIPTION Kap.3 , Seite 2 of 18 GRZ-2698568-v1-Description.FM...

- Page 33 Medium-consistency pump MC STANDARD, C-01-000000 Centrifugal pump Fig. 3-3 Centrifugal pump Item Component Item Component Spiral casing (102) Front wear lining (135.1) Pump shaft (211) Fluidizer (230.2) Impeller (230.1) Suction branch (153) Mechanical seal (433) Casing cover (161) Bearing unit (322)

- Page 34 Medium-consistency pump MC STANDARD, C-01-000000 Spiral casing (102) Function: Guiding the medium with a favorable flow pattern. Converting the speed energy into pressure energy. Design: • Pressure-sealed, single-flow pump casing with delivery and suction channel. • Suction and delivery flange.

- Page 35 Medium-consistency pump MC STANDARD, C-01-000000 • Acid-resistant flange – chemical application (optional) Tantalum Hastelloy Fig. 3-6 Acid-resistant flange – chemical application Pump shaft (211) Function: Holding the impeller, the fluidizer, the shaft seal, bearing assembly and coupling. Transmitting the drive energy to the impeller and thus, to the medium.

- Page 36 Medium-consistency pump MC STANDARD, C-01-000000 Design: Semi-open impeller 4 + 4 (main blades, intermediate blades) with high efficiency. Material: 1.4460, 1.4469 Fluidizer Function: Fluidizes the pulp, separates the air and builds up preliminary pressure in order to feed pulp to the pump.

- Page 37 Medium-consistency pump MC STANDARD, C-01-000000 Water off (730.9b) Water on (730.9a) Fig. 3-9 Sealing water connections Bearing support 421.1 421.2 Fig. 3-10 Bearing support Rev. 0, 2010.02.09 DESCRIPTION Kap.3 , Seite 7 of 18 GRZ-2698568-v1-Description.FM...

- Page 38 Medium-consistency pump MC STANDARD, C-01-000000 Fig. 3-11 Oil lubrication Item Component Item Component Rotary shaft seal ( Bearing housing 421.1, 421.2 Shaft Vent screw Roller bearing Oil level indicator Cylindrical roller bearing Tab. 3-3 Main components for the bearing support Rev.

- Page 39 Medium-consistency pump MC STANDARD, C-01-000000 Function: Interface between stationary and rotating parts. Absorption of axial and radial forces. Design: Impeller sideCylinder roller bearing ( ) with plastic cage (steel cage optional), Drive side Two angular contact ball bearings ( ) with plastic cage (steel cage optional).

- Page 40 Medium-consistency pump MC STANDARD, C-01-000000 Degasser/ Control cabinet Flow meter Degassing chamber Flow meter Differential pressure transmitter; measuring Flow meter position: Differential pressure transmitter; measuring position: Flow meter Suction branch Mechanical seal Differential pressure transmitter Fig. 3-12 Control box Flushing water connection...

- Page 41 Medium-consistency pump MC STANDARD, C-01-000000 Control valve at the degassing pipe Function: Shutting off the degassing pipe Design: Ball valve with pneumatic drive, with solenoid valve, including inference adapter and proximity switch. Acid-proof stainless steel. 1.4404 Flow meter for the mechanical seal Function: Monitoring the sealing water at the centrifugal pump.

- Page 42 Medium-consistency pump MC STANDARD, C-01-000000 Standpipe Function: Storage tank for centrifugal pump Design: Please refer to the assembly drawing for details. Components: • Level measurement • Connection Drainage • Connection Flushing • Overflow With or without Standpipe expansion joint Dilution water...

-

Page 43: Applicable Standards

....... DIN EN 1092-1 (PN16, PN25) 3.6.2 Model designation MC 125 - 450 - 440/460 - CL - 25 - 200 - 16 - 125 - D - F - 2v Flow sheet variante Connection suction flange to... - Page 44 Medium-consistency pump MC STANDARD, C-01-000000 Type plate Each medium-consistency pump has a type plate mounted on the spiral casing showing the main pump data. Q..Capacity (m H..Delivery head (m) P..Motor power (kW) n..Motor speed (rpm) C..Consistency (%) γ..spec. gravity (kg/m Fig.

-

Page 45: Application Limiting Values

Medium-consistency pump MC STANDARD, C-01-000000 Application limiting values The limit values shown for the medium-consistency pump stated in the present Chapter should not be exceeded under any circumstances. Pressure limit The permitted pressure limit value according to table (Tab. 3-4) must be value observed. - Page 46 6 l/min min. Tab. 3-7 Sealing water requirement Data on the limit values for the mechanical seal with regard to pressure and temperature can be found in the manufacturer's operating manual. /MEDIUM CONSISTENCY PUMP MC/ SUPPLIER DOCUMENTATION/.. Rev. 0, 2010.02.09 DESCRIPTION Kap.3 , Seite 16 of 18...

- Page 47 Medium-consistency pump MC STANDARD, C-01-000000 Permitted loads on The permitted loads on connecting branches according to the table connecting (Tab. 3-8) must be observed. branches • Force in N • Torque in Nm Type MC80-350 8500 2800 MC100-330 9000 3600...

-

Page 48: Technological Description

Medium-consistency pump MC STANDARD, C-01-000000 Technological description Path following by the air through the degassing plant Fig. 3-19 Function of the medium-consistency pump Centrifugal pump The medium-consistency pulp supplied from the fluidizer reaches the inlet section of the centrifugal pump impeller. -

Page 49: Erection Work And Transport

This chapter describes certain steps for transport, storage and installation of the medium-consistency pump which may be the responsibility of the user. Activities which are carried out by ANDRITZ AG, including works assembly, are not the subject of this description. Safety regulations Disregarding the safety regulations may cause a risk to life and limb. -

Page 50: Haulage

• In the event of transport damage or short supply, do not accept goods but notify forwarder and ANDRITZ AG's shipping department. • If there is a hidden defect or any damage, notify forwarder and ANDRITZ AG's shipping department within two weeks. - Page 51 Medium-consistency pump MC STANDARD, C-01-000000 Lifting the The complete medium-consistency pump should only be raised as follows medium-consisten after unpacking: cy pump The medium-consistency pump should not be raised until the lifting devices have been attached to the frame. The lifting devices must be short enough to prevent the medium-consistency pump from tilting (Abb.

- Page 52 Medium-consistency pump MC STANDARD, C-01-000000 Abb. 4-4 Haulage of the Exchange Unit Abb. 4-5 Haulage of the Spiral Casing During transport of the medium-consistency pump or loading/unloading (pump may fall). Disregarding the directives above may cause danger for life and...

-

Page 53: Storage

Medium-consistency pump MC STANDARD, C-01-000000 Storage Short-term storage If the pump is to be stored for less than three months before erection work begins, please observe the following storage instructions. • Store the medium-consistency pump in a dry place, with suitable protection against dirt and corrosion. -

Page 54: Erection Work

Packing lists for each individual consignment Space requirement for erection work, operation and maintenance will be defined together with the ANDRITZ AG representative in charge before the beginning of field installation work. Ambient temperature during field installation should not be less than 10-15°C. -

Page 55: Mounting The Medium-Consistency Pump

Medium-consistency pump MC STANDARD, C-01-000000 4.5.1 Mounting the medium-consistency pump Foundation The foundation should be made according to ANDRITZ AG's foundation plan. The following preparations have to be made prior to placing the medium-consistency pump on the foundation: • Mark axes and elevations on the foundation. - Page 56 After connecting up the pipes (acc. to Section 5.5.2), the pump unit is aligned accurately and/or centred in accordance with the coupling table /MEDIUM CONSISTENCY PUMP MC/SUPPLIER DOCUMENTATION/REXNORD A formal record must be made of pump alignment. When checking the sense of rotation, ensure that the mechanical seal is not damaged due to dry running (remove intermediate sleeve from coupling).

- Page 57 Medium-consistency pump MC STANDARD, C-01-000000 Final Grouting Base Grouting Abb. 4-8 Foundations L2 = L1 + (L3 - L1) + 250 mm (Final grouting) B2 = B1 + 2 x 200 mm Abb. 4-9 Drill and insert dowel pin Item...

-

Page 58: Pipework

Medium-consistency pump MC STANDARD, C-01-000000 Item Component Item Component Base frame Tab. 4-2 ... due to the medium-consistency pump falling or the medium-consistency pump components being dropped during transport to installation point. DANGER Raise medium-consistency pump according to the transport instructions in Chapter 4.3. -

Page 59: Cold Test

Medium-consistency pump MC STANDARD, C-01-000000 Cold test Prerequisites The following utilities must be available: • Electric power • Water Lubrication • First filling of lubricant and recording of all further lubrication procedures according to the section on "Lubrication" in the MAINTENANCE chapter. - Page 60 Medium-consistency pump MC STANDARD, C-01-000000 Rev. 0, 2010.02.09 ERECTION WORK and TRANSPORT Kap.4 , Seite 12 of 12 GRZ-2698569-v1-Erection.FM...

-

Page 61: Start-Up

DANGER All safety instructions in this section must be strictly observed. General safety Start-up shall be supervised by ANDRITZ AG's start-up manager or by the instructions buyer. All applicable accident prevention rules must be observed. -

Page 62: Prerequisites For Start-Up

Parts of the pump which are under pressure are not considered pressure vessels in terms of the official regulations on pressure vessels. The MC-Pump is constructed according to the EC directive for pressure devices No. 97/23/EGand bears the pressure. Sense of rotation Before start-up, check that the motors are rotating in the right direction. -

Page 63: Start-Up

Ensuring a proper shaft seal run, clean water with sufficient flow and sealing water pressure has to be provided. For specification of the sealing water please see: /MEDIUM CONSISTENCY PUMP MC/DESCRIPTION/Application limiting values Start-Up Machine may be damaged if incorrect start-up procedures are used. - Page 64 After start-up, the medium-consistency pump is handed over to the mill operator in a complete, reliable condition and ready for operation. The MC pump is designed for an operation against a closed slide. An automatic switch-off after 600s operation on closed slide has to be implemented.

- Page 65 • Start value = 0,7 bar (DEFAULT VALUE) recommended operation at low flow, i.e. 20% of optimum which is for MC 150-470 < 150m --> set correct value Low pump stability (instable flow/ pressure) --> set value too low; increase for 0,1 bar.

- Page 66 Medium-consistency pump MC STANDARD, C-01-000000 Diff. press. transm. Measurem. pt. 1 Measurem. pt. 2 Contr. valve Abb. 5-1 Flowsheet showing functionality of the differential pressure transmitter Degassed pulp Measurement position 2 Signal to control the Pulp in degassing valve Measurement position 1 Abb.

-

Page 67: Logs

Medium-consistency pump MC STANDARD, C-01-000000 Logs The following certificates must be completed and signed after start-up: • Start-up log: • Provisional acceptance log: Certificates: /ATTACHMENT/LOGS AND BLOCK DIAGRAMS Rev. 0, 2010.02.09 START-UP Kap.5 , Seite 7 of 8 GRZ-2698571-v1-Startup.FM... - Page 68 Medium-consistency pump MC STANDARD, C-01-000000 Rev. 0, 2010.02.09 START-UP Kap.5 , Seite 8 of 8 GRZ-2698571-v1-Startup.FM...

-

Page 69: Operation

Medium-consistency pump MC STANDARD, C-01-000000 OPERATION General This chapter describes the activities required for starting, operating and stopping the medium-consistency pump. Possible malfunctions and troubleshooting methods are also presented. Safety regulations Disregarding the safety regulations may cause a risk to life and limb. -

Page 70: Starting

Starting Prerequisites All preliminary requirements for start-up must be fulfilled before switching on the pump. See: /MEDIUM CONSISTENCY PUMP MC/START-UP/Prerequisites for start-up Before starting the medium-consistency pump, the following parameters must be fulfilled: • Stand pipe and pump casing must be filled with the medium. -

Page 71: Checks After Initial Start-Up

Medium-consistency pump MC STANDARD, C-01-000000 Checks after initial start-up The following items must be checked after initial start-up: • required amount of sealing water and required sealing water pressure to the shaft seal • bearing temperature and vibration (in continuous operation) •... -

Page 72: Limits Due To Temperature

(i.e. +/- 0,5%) Defoamer In case the MC pump is in use after a DD washer, it´s an obligation to the user to make sure the air content in the recirculation duct of the DD washer does not exceed the values in line with the industry standard. - Page 73 (standard air content in filtrate ~ 1%) Automatic control The entire control of the MC pump has to be carried out via automatic control. ANDRITZ AG does not issue guarantee, when the operating point is left without permission of ANDRITZ AG.

-

Page 74: Specification Of Medium-Consistency Pump (Delivery Head And Flow Rate)

Medium-consistency pump MC STANDARD, C-01-000000 Specification of medium-consistency pump (delivery head and flow rate) Sizing The pump sizing (delivery head/flow rate) refers to the values shown on the pump's type plate. The values stated for delivery head and flow rate relate to a specific impeller diameter and the specified operating speed. -

Page 75: Shutdown

Medium-consistency pump MC STANDARD, C-01-000000 Shutdown Automatic When using the group stop, all necessary steps are carried out shutdown automatically by the DCS. Manual shutdown Carry out the following steps for manual shutdown: • Shut the chemical inlet branch •... -

Page 76: Operating Malfunctions And Troubleshooting

Medium-consistency pump MC STANDARD, C-01-000000 Operating malfunctions and troubleshooting Malfunction Possible cause Remedy Pump is not pumping Filling level in stand pipe is too Correct filling level (increase) medium Suction pipe, suction valve or Check the suction pipe and impeller are clogged... - Page 77 Medium-consistency pump MC STANDARD, C-01-000000 Malfunction Possible cause Remedy Speed too high Check the motor speed High power loss Wrong direction of rotation Check the sense of rotation of the motor Flow resistance in the pipe is Check the resistance in the...

- Page 78 Medium-consistency pump MC STANDARD, C-01-000000 Malfunction Possible cause Remedy Unexpected air/gas content in Check the conditioner Excessive noise and/or pumping medium vibration Vortex formation in the stand Correct (increase) level in pipe stand pipe Impeller is clogged Check the entire centrifugal...

- Page 79 Medium-consistency pump MC STANDARD, C-01-000000 Malfunction Possible cause Remedy Pump and motor are not in Check pump/motor alignment Excessive wear on bearing true alignment or re-align Pump shaft broken or running Replace the pump shaft and off centre bearing Rotating objects or pump parts...

- Page 80 Medium-consistency pump MC STANDARD, C-01-000000 Rev. 0, 2010.02.09 OPERATION Kap.6 , Seite 12 of 12 GRZ-2698572-v1-Operation.FM...

-

Page 81: Maintenance

The ANDRITZ AG service department is at your disposal for troubleshooting, as well as for extensive maintenance and repair work. /MEDIUM CONSISTENCY PUMP MC/INTRODUCTION) Operators trained and authorized by Andritz AG may also carry out repairs on site after obtaining consent from AAG. Safety regulations Disregarding the safety regulations may cause a risk to life and limb. -

Page 82: Regular Maintenance

Medium-consistency pump MC STANDARD, C-01-000000 Lighting The operator shall ensure that adequate lighting is provided (with extra-low voltage bulbs) during service and repair work. Qualification of Maintenance and upkeep must be carried out by specially trained, skilled personnel personnel only. - Page 83 For these checks, the attached maintenance and upkeep instructions provided by the manufacturer must be observed. /MEDIUM CONSISTENCY PUMP MC/SUPPLIER DOCUMENTATION Malfunctions and inadmissible changes found during these checks must be rectified immediately.

-

Page 84: Maintenance Schedule

Maintenance schedule In addition to the work outlined below, personnel must also carry out maintenance and work required for normal operations /MEDIUM CONSISTENCY PUMP MC/ OPERATION/ NORMAL OPERATION). Monthly The following maintenance work is to be carried out at monthly intervals. -

Page 85: Fasteners

Pre-stressing forces and tightening torques in the table apply to normal screwed/bolted connections. Please contact Andritz AG if you have special requirements. The thread and screw head should be lubricated with an appropriate lubricant (for example Molyslide Plus from Loctite). -

Page 86: Lubrication

Tab. 7-6 Lubricating oil brands In case the surface temperature of the bearing housing rises above 60°C, Andritz AG should be consulted. WARNING Bearing damage may be caused by using the wrong oil! Use only oil grades according to Tab. 7-6. - Page 87 Medium-consistency pump MC STANDARD, C-01-000000 Required oil quantity, depending on bearing support size Bearing size Pump type Oil quantity (litres ) Size 42 MC80-350 Size 42 MC100-330 Size 75 MC125-450 Size 75 MC150-470 Size 90 MC200-550 Size 100 MC250-600 11,5 Tab.

-

Page 88: Aligning The Coupling

If the alignment changes during production, the pump can also be aligned at operating temperature. Aligning Permitted tolerances tolerances /MEDIUM CONSISTENCY PUMP MC/SUPPLIER DOCUMENTATION/REXNORD Rev. 0, 2010.02.09 MAINTENANCE Kap.7 , Seite 8 of 22 GRZ-2698573-v1-Maintenance.FM... -

Page 89: Centrifugal Pump

Medium-consistency pump MC STANDARD, C-01-000000 Centrifugal pump 7.8.1 Removing and installing the centrifugal pump Preparations The following parts must be prepared before starting to disassemble the centrifugal pump: • Tools • Lifting gear • Belts, ropes • Replacement parts The machine must be thoroughly cleaned before carrying out any maintenance work. - Page 90 Medium-consistency pump MC STANDARD, C-01-000000 Safety cover Abb. 7-2 Safety cover Abb. 7-3 Couplings Arpex ARS6 (left) and Rexnord VIVA (right) Rev. 0, 2010.02.09 MAINTENANCE Kap.7 , Seite 10 of 22 GRZ-2698573-v1-Maintenance.FM...

- Page 91 Medium-consistency pump MC STANDARD, C-01-000000 Removing the The pump unit comprises the impeller ( ), fluidisator (230.2), shaft 230.1 pump unit ), bearing assemblies, sealing unit, bearing housing ( ), bearing covers ( ) and the casing cover ( 360.1 , 360.2...

- Page 92 Medium-consistency pump MC STANDARD, C-01-000000 920.5 554.5 Push-off screw Abb. 7-5 Removing the centrifugal pump Abb. 7-6 Lifting the pump unit Rev. 0, 2010.02.09 MAINTENANCE Kap.7 , Seite 12 of 22 GRZ-2698573-v1-Maintenance.FM...

- Page 93 Mount measurement connection degassing line (Abb. 7-4) Mount dilution water connection degassing line (Abb. 7-4) Assemble the coupling according to the instructions issued by the coupling manufacturer. /MEDIUM CONSISTENCY PUMP MC/SUPPLIER DOCUMENTATION/REXNORD Tab. 7-12 Installing the pump unit Rev. 0, 2010.02.09 MAINTENANCE Kap.7 , Seite 13 of 22...

-

Page 94: Removing And Installing The Impeller, Fluidisator, Casing Cover And Mechanical Seal

Medium-consistency pump MC STANDARD, C-01-000000 7.8.2 Removing and installing the impeller, fluidisator, casing cover and mechanical seal Limbs can be trapped or crushed during disassembly work. DANGER of injury at the impeller and fluidisator! Impellers may have very sharp edges, particularly when they are worn. - Page 95 Medium-consistency pump MC STANDARD, C-01-000000 554.5 920.5 902.5 554.9 920.9 230.1 902.9 230.2 901.2 931.1 551.2 Abb. 7-7 Mounting and removing the impeller 551.3 135.1 1 +/- 0,3 mm 1 +/- 0,3 mm 554.3 920.3 902.3 230.1 Abb. 7-8 Impeller gap Rev.

- Page 96 Medium-consistency pump MC STANDARD, C-01-000000 Installation of the Preliminary requirements: impeller (230.1) • Pump shaft, impeller and fluidisator comply with the requirements in and fluidisator terms of measuring accuracy, roundness and true running. (230.2) Step Activity Clean pump shaft (...

-

Page 97: Changing The Anti-Friction Bearings With Oil Lubrication

Medium-consistency pump MC STANDARD, C-01-000000 Changing the anti-friction bearings with oil lubrication The anti-friction bearings are designed for continuous operation under full load for approximately 50000 operating hours. Higher bearing temperature and vibration at the bearing support are a sign of an impending bearing damage. - Page 98 Medium-consistency pump MC STANDARD, C-01-000000 Step Procedure Insert baffle plate ( 504.4 Insert the first outer ring of the angular contact ball bearing ) and the first anti-friction bearing cage. Place the second anti-friction bearing cage and the second outer ring on the shaft.

- Page 99 Medium-consistency pump MC STANDARD, C-01-000000 Detail X 412.1 421.2 360.1 360.2 507.2 507.1 504.3 504.4 421.1 931.1 412.2 504.2 504.1 Detail X 0,1-0,2 Abb. 7-10 Changing the anti-friction bearings Raised area and groove in 3 o'clock or 9 o'clock position Abb.

-

Page 100: Changing The Front Lining

Medium-consistency pump MC STANDARD, C-01-000000 7.9.1 Changing the front lining Limbs can be jammed or crushed during installation work. Wear your personal protective apparel. DANGER Changing Change the wear linings according to the following table: Step Activity Remove pump unit according to Section 7.8.1 Remove bearing as per Section 7.8.2... -

Page 101: Balancing The Impeller

Medium-consistency pump MC STANDARD, C-01-000000 7.9.2 Balancing the impeller Balancing the Proceed according to the following table when balancing the impeller: pump shaft with impeller Step Activity Clean all contact surfaces of the pump shaft carefully with the balancing machine. - Page 102 Medium-consistency pump MC STANDARD, C-01-000000 Rev. 0, 2010.02.09 MAINTENANCE Kap.7 , Seite 22 of 22 GRZ-2698573-v1-Maintenance.FM...

-

Page 103: Technical Data

Medium-consistency pump MC STANDARD, C-01-000000 TECHNICAL DATA • Data sheet • Characteristic curve See: /MEDIUM CONSISTENCY PUMP MC/Technical Data/... Rev. 0, 2010.02.09 TECHNICAL DATA Kap.8 , Seite 1 of 2 GRZ-2698574-v1-Technical_Data.FM... - Page 104 Medium-consistency pump MC STANDARD, C-01-000000 Rev. 0, 2010.02.09 TECHNICAL DATA Kap.8 , Seite 2 of 2 GRZ-2698574-v1-Technical_Data.FM...

-

Page 105: Supplier Documentation

Medium-consistency pump MC STANDARD, C-01-000000 SUPPLIER DOCUMENTATION 100 16 - Ball valves with actuator 9.1.1 Proximity switch Name of company KYTÖLÄ Type ........KY/ILKM18-AB 100 18 - Sealing water monitoring unit 9.2.1... -

Page 106: 700 00 - Coupling

Medium-consistency pump MC STANDARD, C-01-000000 700 00 - Coupling 9.4.1 Coupling Name of company REXNORD Technical data Type........VIVA365-250KUP Type.

Need help?

Do you have a question about the MC and is the answer not in the manual?

Questions and answers