Table of Contents

Advertisement

Advertisement

Table of Contents

Summary of Contents for Andritz FP Series

- Page 1 Fan Pump, FP series Erection Work, Operating and Maintenance Instructions Erection Work, Operating and Maintenance Instructions Fan Pump, FP series Machine: Issued: PFe/Subosits, 2002-01 Revision: Checked: HPp/Hartl Checked: Rev.0, Printed: 2002.03.04 TITLE PAGE #455857 v1 - DECKBLATT...

- Page 2 Fan Pump, FP series Erection Work, Operating and Maintenance Instructions Table of contents INTRODUCTION ..... . . Use ......... .

-

Page 3: Table Of Contents

Fan Pump, FP series Erection Work, Operating and Maintenance Instructions DESCRIPTION ......Field of application ...... - Page 4 Fan Pump, FP series Erection Work, Operating and Maintenance Instructions MAINTENANCE ......General ........

- Page 5 Fan Pump, FP series Erection Work, Operating and Maintenance Instructions TABLE OF CONTENTS Page 4 of 4 Rev.0, Printed: 2002.03.04 #455856 v1 - INHALTSVERZEICHNIS...

- Page 6 Erection Work, Operating and Maintenance Instructions INTRODUCTION This manual is part of the technical documentation of Andritz AG. It is intended as a supplement to the training provided, to supply the basic knowledge required for proper, safe and economical use of the plant and machinery delivered by Andritz AG.

- Page 7 Fan Pump, FP series Erection Work, Operating and Maintenance Instructions How to use the manual Presentation • Chapter and paragraph headings are printed in capitals in the continuous text. SAFETY • Designations of indicating and handling elements are written in inverted commas in the continuous text.

- Page 8 Non-authorized structural changes to the machine/system. • Non-observance of the maintenance and upkeep instructions. In the event of a claim for repair under guarantee, ANDRITZ AG reserves the right to assess the damage to the machine/system. Rev.0, Printed: 2002.03.04 INTRODUCTION Chapter 1, Page 3 of 4 #704713 v1 - EINF‹HRUNG...

- Page 9 Copyright The operating manual is protected by copyright. All usual rights reserved. It must not be wholly or partly reproduced without authorization by Andritz AG. Contraventions shall entail damage claims and may have penal consequences. All rights shall also be reserved for any patents granted, registration of trade marks and technical modifications without prior notification.

- Page 10 In addition, the chapters in the operating manual contain further safety regulations. These are marked by DANGER SIGNS. Safety instructions on components not supplied by Andritz AG are contained in the descriptions of the components ( /FAN PUMP/SUPPLIER DOCUMENTATION).

- Page 11 Any modifications to the scope of supply made without the agreement of Andritz AG are considered contrary to the designated use. The term designated use shall also include adherence to the operating instructions, observance of the operating, inspection and maintenance conditions and of the regulations on cleaning and upkeep.

- Page 12 Fan Pump, FP series Erection Work, Operating and Maintenance Instructions User’s obligations Designated use The user of the fan pump is responsible for its designated use. Work instructions In addition to the operating instructions, applicable legal stipulations and other rules governing the safety at work, health and environmental protection must be observed and personnel instructed in them.

- Page 13 Fan Pump, FP series Erection Work, Operating and Maintenance Instructions Inspections The operator undertakes • to check at regular intervals whether the safety instructions and regulations governing work on the fan pump are observed. • to carry out regular training to confirm the level of knowledge of the operating and maintenance personnel.

- Page 14 Fan Pump, FP series Erection Work, Operating and Maintenance Instructions General obligations of personnel To avoid personal and material damage anybody working on the machine shall • observe the safety instructions in the operating regulations and on the fan pump.

- Page 15 Fan Pump, FP series Erection Work, Operating and Maintenance Instructions Safety devices The fan pump must not be operated without effective safety equipment. Safety equipment must not be circumvented, dismantled or made unserviceable. The safety equipment is here to protect operating personnel.

- Page 16 Fan Pump, FP series Erection Work, Operating and Maintenance Instructions Personal protective apparel General safety equipment The following must always be worn when performing work on the fan pump: • protective clothing to prevent the pulp from coming into contact with the skin.

- Page 17 Fan Pump, FP series Erection Work, Operating and Maintenance Instructions The machine is designed such that no operator is required in the immediate vicinity of the machine. Appropriate hearing protection should be worn throughout maintenance and adjusting work while the machine is running.

- Page 18 Fan Pump, FP series Erection Work, Operating and Maintenance Instructions TECHNICAL DATA Data sheet Characteristic curve Dimensioned drawing Principal section Parts list Rev.0, Printed: 2002.03.04 TECHNICAL DATA Chapter 3, Page 1 of 2 #455860 v1 - TECHNISCHE DATEN...

- Page 19 Fan Pump, FP series Erection Work, Operating and Maintenance Instructions Rev.0, Printed: 2002.03.04 TECHNICAL DATA Chapter 3, Page 2 of 2 #455860 v1 - TECHNISCHE DATEN...

-

Page 20: Description

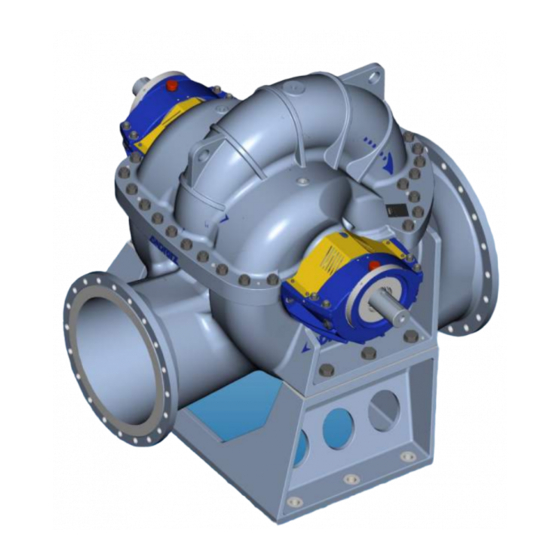

Fan Pump, FP series Erection Work, Operating and Maintenance Instructions DESCRIPTION Field of application The fan pump is used in continuous operation to pump clean liquids and various pulps in the paper industry. Fig. 4-1 Fan pump Rev.0, Printed: 2002.03.04... -

Page 21: Main Components Of Fan Pump

Fan Pump, FP series Erection Work, Operating and Maintenance Instructions Main components of fan pump Fig. 4-2 Main components of fan pump Item Component Item Component Volute casing – upper part ( Shaft seal 102.2 Volute casing – lower part ( Bearing 102.1... - Page 22 Fan Pump, FP series Erection Work, Operating and Maintenance Instructions Volute casing – Function: Guiding the medium with a favourable flow pattern. Converting upper part ( the speed energy into pressure energy. 102.2 and lower part Design: 102.1 • Pressure-sealed, double-flow pump casing with delivery and suction channels.

- Page 23 Fan Pump, FP series Erection Work, Operating and Maintenance Instructions Wear ring ( Function: Choke betwen suction and delivery side of the impeller. Design: Hydraulically optimised ring made of acidproof stainless steel. Fig. 4-5 Wear ring Shaft seal Function: Seal between medium (suction side) and the atmosphere.

- Page 24 Fan Pump, FP series Erection Work, Operating and Maintenance Instructions Design: Two-way mechanical seal with sealing water connection 433.2 433.1 Atmosphere Medium Fig. 4-7 Two-way mechanical seal Item Component Item Component 433.1 Mechanical seal coming 433.2 Mechanical seal coming into...

- Page 25 Fan Pump, FP series Erection Work, Operating and Maintenance Instructions Bearing Function: Interface between stationary and rotating parts. Absorption of axial and radial forces. Design: Self-aligning roller bearing with steel cage. Designed as fixed and movable bearing, suitable for grease or oil lubrication.

-

Page 26: Type Specification

Fan Pump, FP series Erection Work, Operating and Maintenance Instructions Type specification 4.3.1 Applicable standards Dimensions........ISO 2858 Design . -

Page 27: Application Limiting Values

Fan Pump, FP series Erection Work, Operating and Maintenance Instructions Application limiting values The limit values shown for the fan pump in the present Chapter should not be exceeded under any circumstances. Pressure and The permitted pressure and temperature limit values according to table temperature limits (Tab. - Page 28 Fan Pump, FP series Erection Work, Operating and Maintenance Instructions Type Sealing water - Sealing water - Sealing water - pressure (inlet) pressure (outlet) quantity FP40-400 2 bar min./3 bar 2 bar min./3 bar min.2x1.5 l/min max. max. FP40-500 2 bar min./3 bar 2 bar min./3 bar...

- Page 29 Fan Pump, FP series Erection Work, Operating and Maintenance Instructions Permitted load on The permitted loads on supports according to table (Tab. 4-8) must be supports observed. • Force in kN • Torque in kNm types 40-400 40-500 40-700 40-900...

- Page 30 Fan Pump, FP series Erection Work, Operating and Maintenance Instructions Relation between The relation between output and speed according to table Tab. 4-9 must output and speed be observed. Pump Shaft material 1.4462 Type Relation between output and speed P(kW) / n(rpm)/...

-

Page 31: Technological Description

Fan Pump, FP series Erection Work, Operating and Maintenance Instructions Technological Description Definition The fan pump is used in continuous operation to pump clean liquids and various pulps used in the paper industry, with the aim of obtaining well mixed medium and of increasing the pressure. -

Page 32: Erection Work And Transport

This chapter describes certain steps for transport, storage and installation of the fan pump which may be the responsibility of the user. Activities which are carried out by ANDRITZ AG, including works assembly, are not the subject of this description. -

Page 33: Haulage

In the event of transport damage or short supply, do not accept goods but notify forwarder and ANDRITZ AG’s shipping department. • If there is a hidden defect, notify forwarder and ANDRITZ AG's shipping department within two weeks. Rev.0, Printed: 2002.03.04... - Page 34 Fan Pump, FP series Erection Work, Operating and Maintenance Instructions Lifting the entire The complete fan pump should only be raised as follows after unpacking: fan pump The complete fan pump should only be raised if the lifting devices have been attached under the suction and delivery flanges.

- Page 35 Fan Pump, FP series Erection Work, Operating and Maintenance Instructions Lifting the Individual pump components should only be raised as follows: pump • The upper part of the volute case can be raised at the points marked components (lugs) with the aid of shackles Fig. 5-2.

-

Page 36: Storage

Fan Pump, FP series Erection Work, Operating and Maintenance Instructions Storage Short-term storage If the pump is to be stored for less than three months before erection work begins, please observe the following storage instructions. • Store the fan pump in a dry place, with suitable protection against dirt and corrosion. -

Page 37: Installation

Space requirement for erection work, operation and maintenance will be defined together with the ANDRITZ AG representative in charge before the beginning of erection work. Ambient temperature during erection work should not be less than 10-15°C. -

Page 38: Erection Of The Fan Pump

Erection Work, Operating and Maintenance Instructions 5.5.1 Erection of the fan pump Foundation The foundation should be made according to ANDRITZ AG's foundation plan. The following preparations have to be made prior to placing the fan pump on the foundation: •... - Page 39 Fan Pump, FP series Erection Work, Operating and Maintenance Instructions Anchor bolt Grouting compound Foundation Fig. 5-5 Fundation work without pedestal Due to the fan pump or components of the fan pump falling during transport on installation site. Raise fan pump according to the transport instructions in DANGER Chapter 5.3.

-

Page 40: Pipework

Fan Pump, FP series Erection Work, Operating and Maintenance Instructions 5.5.2 Pipework If pipework is not mounted professionally. This can result in risks to life and limb and in damage to the machine. DANGER Under no circumstances should the fan pump be used to support a... -

Page 41: Instruments

(if included in scope of supply) Instructions on installation and operation of the flow meter can be found in the enclosed description from the manufacturer. This device must be adjusted under the supervision of Andritz personnel. Rev.0, Printed: 2002.03.04 ERECTION WORK and TRANSPORT... -

Page 42: Cold Test

Fan Pump, FP series Erection Work, Operating and Maintenance Instructions Cold test Prerequisites The following utilities must be available: • Electric power • Water Lubrication • First filling of lubricant and recording of all further lubrication procedures according to the section headed "Lubrication" in the MAINTENANCE chapter. - Page 43 Fan Pump, FP series Erection Work, Operating and Maintenance Instructions Rev.0, Printed: 2002.03.04 ERECTION WORK and TRANSPORT Chapter 5, Page 12 of 12 #762848 v1 - MONTAGE...

-

Page 44: Start-Up

DANGER All safety instructions in this Chapter must be strictly observed. General safety Start-up shall be carried out under the control of ANDRITZ AG’s start-up instructions supervisor or by the Buyer. All applicable accident prevention rules must be observed. -

Page 45: Prerequisites For Start-Up

Fan Pump, FP series Erection Work, Operating and Maintenance Instructions Prerequisites for start-up The following must be checked before start-up: Motor may be started up unintentionally. Risk to life and limb and risk of damaging the machine or its components. - Page 46 Fan Pump, FP series Erection Work, Operating and Maintenance Instructions Aligning the A further check should be performed to ensure that the coupling is coupling properly aligned. Coupling alignment should then be verified in writing. For assembly and disassembly of the coupling, as well as the tolerances...

-

Page 47: Start-Up

Fan Pump, FP series Erection Work, Operating and Maintenance Instructions Start-up Machine may be damaged by inappropriate starting. All electric interlocks must be functional and checked. CAUTION Starting up the fan If all preliminary requirements (see Chapter 6.3) have been fulfilled, the... -

Page 48: Certificates

Fan Pump, FP series Erection Work, Operating and Maintenance Instructions First trial run Functioning of the pump must be monitored carefully during the first few hours in operation. Particular attention must be paid to the following: • temperature of the shaft seal •... - Page 49 Fan Pump, FP series Erection Work, Operating and Maintenance Instructions Rev.0, Printed: 2002.03.04 START-UP Chapter 6, Page 6 of 6 #762849 v1 - INBETRIEBNAHME...

-

Page 50: Operation

Fan Pump, FP series Erection Work, Operating and Maintenance Instructions OPERATION General This chapter describes the activities required for starting, operating and stopping the fan pump. Possible malfunctions and troubleshooting methods are also presented. Safety regulations Disregarding the safety regulations may cause a risk to life and limb. -

Page 51: Control Via Dcs

Fan Pump, FP series Erection Work, Operating and Maintenance Instructions Control via DCS The fan pump can be started up and operated entirely from the DCS. Starting Prerequisites All preliminary requirements for start-up must be fulfilled before switching on the pump. -

Page 52: Checks After Initial Start-Up

Fan Pump, FP series Erection Work, Operating and Maintenance Instructions Automatic starting All the necessary steps are performed automatically by the distributed control system during start-up. Manual start Carry out the following steps for manual start. Step Activity Operating device... -

Page 53: Normal Operation

Fan Pump, FP series Erection Work, Operating and Maintenance Instructions Normal operation Do not operate without all safety devices ON. DANGER While the pump is in operation the operating personnel should record the relevant data (shift record and data sheets). -

Page 54: Fan Pump Requirements (Delivery Head And Flow Rate)

Fan Pump, FP series Erection Work, Operating and Maintenance Instructions Fan pump requirements (delivery head and flow rate) Sizing The pump sizing (delivery head/flow rate) refers to the values shown on the pump's type plate. The values obtainable for head and flow rate can be read off the impeller diameter and the defined operating speed is shown in the performance diagram. -

Page 55: Stopping

Fan Pump, FP series Erection Work, Operating and Maintenance Instructions Stopping Automatic stop When using the group stop, all necessary steps are carried out automatically with the DCS. Manual stop Carry out the following steps for manual stop. • Stop the pump motor •... -

Page 56: Operating Malfunctions And Troubleshooting

Fan Pump, FP series Erection Work, Operating and Maintenance Instructions Operating malfunctions and troubleshooting Malfunction Possible cause Remedy Pump is not pumping Insufficient pre-filling of pump Repeat pre-filling of the pump medium Steam bubbles forming in and suction pipe suction pipe (NPSH... - Page 57 Fan Pump, FP series Erection Work, Operating and Maintenance Instructions Malfunction Possible cause Remedy Steam bubbles forming in the Repeat pre-filling of the pump Inadequate or irregular flow suction pipe and suction pipe rate Wrong direction of rotation Change sense of rotation of...

- Page 58 Fan Pump, FP series Erection Work, Operating and Maintenance Instructions Malfunction Possible cause Remedy Pressure difference between Check the suction pipe Excessive noise and/or NPSH and NPSH vibration plant pump too low Unexpected air/gas content in Contact Andritz AG for further...

- Page 59 Fan Pump, FP series Erection Work, Operating and Maintenance Instructions Malfunction Possible cause Remedy Pump and motor are not in Check pump/motor alignment Excessive wear on bearing true alignment or re-align Broken or eccentric pump Replace the pump shaft and...

-

Page 60: Maintenance

The ANDRITZ AG service department is at your disposal for troubleshooting, as well as for extensive maintenance and repair work. /FAN PUMP/INTRODUCTION) Workers trained and authorized by Andritz AG may also carry out repairs on site after obtaining consent from AAG. Safety regulations Disregarding the safety regulations may cause a risk to life and limb. -

Page 61: Regular Maintenance

Fan Pump, FP series Erection Work, Operating and Maintenance Instructions Work on the electrical equipment must be carried out without exception by skilled electricians. Personal The following protective equipment must be worn when carrying out protective apparel cleaning and maintenance: •... - Page 62 Fan Pump, FP series Erection Work, Operating and Maintenance Instructions In the course of general machine checks all additional units should also be checked to guarantee that the entire plant functions satisfactorily. For these checks, the attached manufacturer's maintenance and upkeep instructions must be observed.

-

Page 63: Maintenance Schedule

Fan Pump, FP series Erection Work, Operating and Maintenance Instructions Maintenance schedule In addition to the work outlined below, maintenance and work required for normal operations ( /FAN PUMP/OPERATION/NORMAL OPERATION) must also be carried out. monthly The following maintenance work is to be carried out at monthly intervals. -

Page 64: Fasteners

Prestressing forces and tightening torques in the table apply to normal screw connections. Please contact Andritz AG in the event of special requirements. The thread and screw head should be lubricated with an appropriate lubricant (for example Molyslide Plus from Loctite). -

Page 65: Lubrication

Fan Pump, FP series Erection Work, Operating and Maintenance Instructions Lubrication 8.6.1 Oil lubrication Bearing housings are supplied without oil filling. Fill bearing with a suitable lubricating oil before start-up. WARNING The first oil change should be carried out after 100 operating hours. - Page 66 Fan Pump, FP series Erection Work, Operating and Maintenance Instructions Oil change The first oil change should be carried out after 100 operating hours. After this oil changes should be performed according to Tab. 8-6. Oil change interval 1 year...

-

Page 67: Grease Lubrication

Fan Pump, FP series Erection Work, Operating and Maintenance Instructions Oil quantities The following oil quantities are required, depending on the pump size: Pump type Oil content (in litres)/bearing FP40-400 FP40-500 FP40-700 FP40-900 FP60-500 FP80-600 FP80-800 Tab. 8-8 Oil quantities The oil level may drop during operation. - Page 68 Fan Pump, FP series Erection Work, Operating and Maintenance Instructions Pump type Lubricating point First filling Relubricate Lubricating Lubricating interval interval at 1000 rpm at 1500 rpm per bearing housing FP40-400 Bearing FP40-500 Bearing FP40-700 Bearing FP40-900 Bearing FP60-500 Bearing...

- Page 69 Fan Pump, FP series Erection Work, Operating and Maintenance Instructions Grease change The old grease should be cleaned off the bearing housing each time the rotor unit is removed (annual service). After re-assembly the bearing should be given a filling of fresh grease.

-

Page 70: Aligning The Coupling

Fan Pump, FP series Erection Work, Operating and Maintenance Instructions Aligning the coupling The coupling alignment must be checked after each of the following assembly steps and corrected if necessary. In particular: • after mounting and before grouting in the pump •... -

Page 71: Removing And Installing The Rotor Unit

Fan Pump, FP series Erection Work, Operating and Maintenance Instructions Removing and installing the rotor unit Preparations The following parts must be prepared before starting to disassemble the rotor unit: • Tools • Lifting gear • Belts, ropes • Replacement parts The machine must be thoroughly cleaned before carrying out any maintenance work. - Page 72 Fan Pump, FP series Erection Work, Operating and Maintenance Instructions 360.1(360.2) 914.2 901.2 Raising the upper part of 920.2 102.2 the volute casing 560.1 560.4 920.2 920.1 Fig. 8-5 Removing and installing the rotor unit Rev.0, Printed: 2002.03.04 MAINTENANCE Chapter 8, Page 13 of 28...

- Page 73 Fan Pump, FP series Erection Work, Operating and Maintenance Instructions Removing the The rotor unit comprises the impeller ( ), the shaft ( ), the 232,233 rotor unit bearings, and the sealing units. Remove the rotor unit according to the following table: The activities listed in the table are to be carried out on both sides of the pump.

- Page 74 Fan Pump, FP series Erection Work, Operating and Maintenance Instructions Installation of the Proceed according to the following table when installing the rotor unit rotor unit Step Activity Replace O-rings ( ) and lift the rotor unit into 412.7 412.6 the lower part of the volute casing( ) according to Fig.

-

Page 75: Changing The Bearing Assembly

Fan Pump, FP series Erection Work, Operating and Maintenance Instructions Changing the bearing assembly In order to avoid damage to the bearing it is essential to observe the lubrication intervals indicated in section 8.6 - Lubrication, as well as to use... - Page 76 Fan Pump, FP series Erection Work, Operating and Maintenance Instructions Removing the Proceed according to the following table when changing the bearing: bearing Step Procedure Remove rotor unit as per section 8.8. Remove the feather key ( 940.2 Remove the fastening screw ( ) for the sleeve ( 904.2...

- Page 77 Fan Pump, FP series Erection Work, Operating and Maintenance Instructions Installing the Proceed according to the following table when installing the bearing: bearing Step Procedure Loosen the fastening screw ( ) for the splash ring ( 904.4 and push the splash ring towards the centre of the shaft.

-

Page 78: Changing The Stuffing Box Packing

Fan Pump, FP series Erection Work, Operating and Maintenance Instructions 8.10 Changing the stuffing box packing Removing the Proceed according to the following table when removing the stuffing box: packing Step Procedure Remove the cover ( 683.1 Loosen the hexagon nuts ( ) and remove the bipartite 920.3... - Page 79 Fan Pump, FP series Erection Work, Operating and Maintenance Instructions Installation Proceed according to the following table when installing the stuffing box: Step Procedure Mark packing (see Fig. 8-12) and cut to the appropriate length. Keep packing clean, do not stretch or squash when measuring and cutting.

- Page 80 Fan Pump, FP series Erection Work, Operating and Maintenance Instructions Setting the The following settings must be observed: stuffing box • Never tighten the stuffing box gland so far that drainage of sealing water is brought to a complete halt.

-

Page 81: Changing The Mechanical Seal

Fan Pump, FP series Erection Work, Operating and Maintenance Instructions 8.11 Changing the mechanical seal Changing Change the mechanical seal according to the following table: Step Procedure Remove rotor unit as per section 8.8. Remove bearing as per section 8.9. -

Page 82: Removing And Installing The Impeller

Fan Pump, FP series Erection Work, Operating and Maintenance Instructions 8.12 Removing and installing the impeller Limbs can be trapped or crushed during disassembly work. Do not touch the shaft with your hands while pushing the impeller off! DANGER Injury at the impeller! Impellers may have very sharp edges, particularly when they are worn. - Page 83 Fan Pump, FP series Erection Work, Operating and Maintenance Instructions Pushing off the Proceed according to the following table when pushing the impeller off: impeller Step Activity Remove both wear rings ( ) from the impeller. Turn hexagon socket pipe plug ( ) out of the impeller half 903.1...

- Page 84 Fan Pump, FP series Erection Work, Operating and Maintenance Instructions Installation of the Preliminary requirements: impeller • Clean room with no draft, temperature +20°C • Lifting device, e.g. crane, for manipulating the shaft • Ring bolt for manipulating the shaft •...

- Page 85 Fan Pump, FP series Erection Work, Operating and Maintenance Instructions High temperatures occur during this work. Take care when working with hot surfaces. Appropriate fire extinguishing equipment must be available. WARNING Personal protective clothing must be worn! 562.1 spacer plate Fig.

-

Page 86: Turning And Balancing The Impeller

Fan Pump, FP series Erection Work, Operating and Maintenance Instructions 8.13 Turning and balancing the impeller Turning the The impellers are manufactured in standard diameters at intervals of impeller 5 mm. Since the output (characteristic curve) of the pump depends on the diameter of the impeller, the characteristic curve for the appropriate impeller diameter is shown in the performance diagram. - Page 87 Fan Pump, FP series Erection Work, Operating and Maintenance Instructions Balancing the All impellers must be balanced dynamically together with the shafts and pump shaft with shaft protection sleeves according to ISO 1940/1 G6.3. impeller Proceed according to the following table when balancing the impeller:...

Need help?

Do you have a question about the FP Series and is the answer not in the manual?

Questions and answers