Table of Contents

Advertisement

Quick Links

http://www.dropsa.com

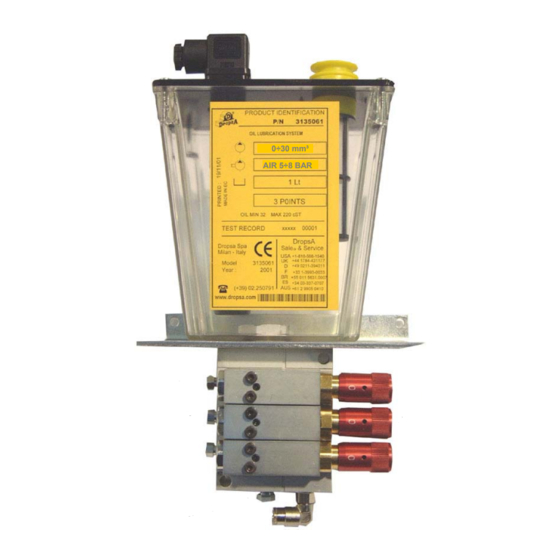

VIP4Tools/Oil Panel

Oil Lubrication System

User and

Maintenance Manual

Warranty information

TABLE OF CONTENTS

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

15.

16.

17.

18.

Manufacturer

Product

Year

Certification

Manual drafted in compliance with

EC Directive 98/37, Annex I, paragraph 1.7.4

DropsA SpA

VIP4Tools/Oil

2001

1

C2041IE- WK 23/04

Advertisement

Table of Contents

Summary of Contents for DROPSA VIP4Tools/Oil

-

Page 1: Table Of Contents

VIP4Tools/Oil Panel Oil Lubrication System User and Maintenance Manual Warranty information TABLE OF CONTENTS INTRODUCTION GENERAL DESCRIPTION PRODUCT-MACHINE IDENTIFICATION TECHNICAL CHARACTERISTICS MACHINE COMPONENTS UNPACKING AND INSTALLING THE PANEL MACHINE OPERATION TROUBLESHOOTING MAINTENANCE PROCEDURE DISPOSAL ORDERING INFORMATION DIMENSIONS HANDLING AND TRANSPORTATION... -

Page 2: Introduction

2. GENERAL DESCRIPTION VIP4Tools/Oil Panel can be used for dripping or brush applications on chains. It has been designed to guarantee high performance at low price and is characterised by compactness. The system consists in mini- pumps (from 1 to 4) pneumatically driven from sub-bases. -

Page 3: Machine Components

Mini-pumps (from 1 to 4) provided with a cap to adjust flowrate; SAMBA level sensor, which indicates lubricant minimum level via a N.O. electric contact. (To reverse N.O. to N.C., please contact Dropsa Eng. Dept.) 0÷30 mm³ AIR 5÷8 BAR... -

Page 4: Unpacking And Installing The Panel

6.6 ELECTRIC WIRING Samba level is the only electric connection for VIP4Tools/Oil (see the electric diagram below). At the end of all connecting operations, make sure that pipes and wires are safe from impacts and... -

Page 5: Machine Operation

1.5 (0.05) Cap totally unscrewed 8. TROUBLESHOOTING WARNING: This unit can be opened and repaired by Dropsa personnel only 9. MAINTENANCE PROCEDURE The machine does not require any special tool for check or maintenance tasks. However, it is recommended the use only of appropriate and in good conditions tooling, protective devices (gloves) and clothing (626/94 and DPR 547/55) to avoid injury to persons or damage to machine parts. -

Page 6: Disposal

Refer to local regulations in force in your area. When disposing of this unit, it is important to ensure that the identification label and all the other relative documents are also destroyed. 11. ORDERING INFORMATION 11.1 VIP4Tools/Oil VERSIONS SERIAL N° of mini-pumps N°... -

Page 7: Dimensions

12. DIMENSIONS N° Weight mini-pumps 10.4 1.85 11.2 2.55 12.8... -

Page 8: Handling And Transportation

WARNING: Empty the reservoir, before the replaicing of the mini-pumps. 15. PRECAUTIONS No particular operating hazards characterize VIP4Tools/Oil Panel, except for the following precautions: • Operator’s contact with fluid in case of piping breaking/opening or contact with oil during filling up/maintenance. -

Page 9: Warranty Information

Upon prepaid receipt of subject product to an authorized Dropsa Sales & Service location, we will then either repair or replace such product(s), at out option, and if determined to be a warranted defect, we will perform such necessary product repairs or replace such product(s) at our expense. -

Page 10: Declaration Of Compliance With Standards

02 – 250.791 Telephone Certifies that: The machine: VIP4Tools/Oil Panel Has been manufactured in conformance with the EUROPEAN COMMUNITY DIRECTIVE relating to machines (98/37/EC), low voltage (BT 73/23/EEC). Has been manufactured in conformance with the following technical harmonised standards and specification... -

Page 11: Dropsa Locations

18.DROPSA LOCATIONS Dropsa USA Inc. Dropsa France 50679 Wing Drive 23, Av. des. Morillons Utica, Michigan 48315 - USA Z.I. des Doucettes Tel: (+1) 586-566-1540 91140 - Garges Les Gonesse Fax: (+1) 586-566-1541 Tel: (+33) 01 39 93 00 33 E-mail: salesusa@dropsa.com...

Need help?

Do you have a question about the VIP4Tools/Oil and is the answer not in the manual?

Questions and answers