Advertisement

Quick Links

WARNING

NOTICE:

TECHNICAL SPECIFICATIONS - ASSEMBLY PROCEDURE

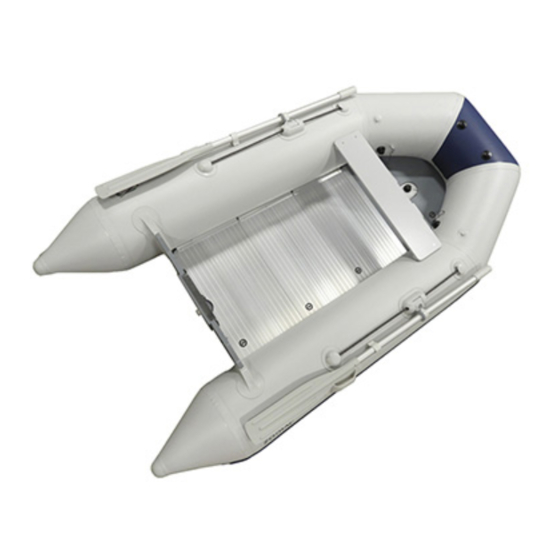

WAVE 275 Roll Up – WAVE 275 Aero

WAVE 310 HD – WAVE 310 Aero – WAVE 310 Compact

Assembly procedure

Check on unpacking

Assembly

Inflation system

Inflation

CAREFULLY READ THIS MANUAL BEFORE OPERATING YOUR

BOAT.

THIS OWNER'S MANUAL IS IN TWO VOLUMES THAT MUST BE

KEPT TOGETHER.

THE OWNER'S MANUAL IS IN TWO VOLUMES:

- VOLUME 1

DEALS

WITH

OPERATING

RECOMMENDATIONS THAT MUST BE OBSERVED.

- VOLUME 2

DEALS WITH TECHNICAL SPECIFICATIONS AND ASSEMBLY

PROCEDURE OF THE BOAT AND ITS EQUIPMENT.

VOLUME 2

CONTENTS

Page

3

3

4-6

7

8-9

1 / 12

PRECAUTIONS

AND

Pressure

Assembly of equipment

Deflation - folding the boat

General description

E

N

G

L

I

S

H

SAFETY

Page

10

11

12

I -VI

Advertisement

Need help?

Do you have a question about the WAVE 275 Roll Up and is the answer not in the manual?

Questions and answers