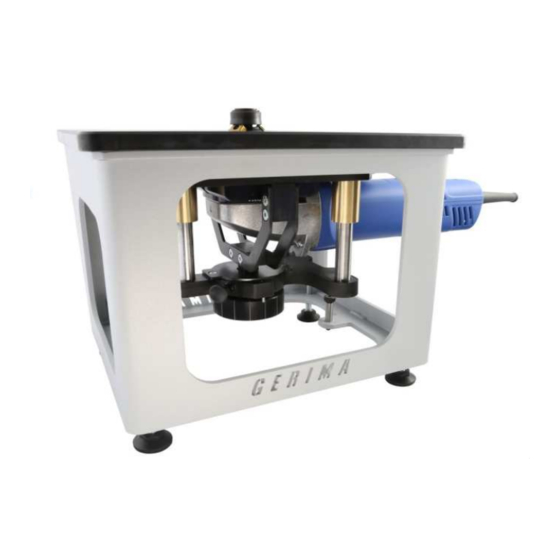

Summary of Contents for Gerima SMT 30 AER-24.G1

- Page 1 © Operating manual Table beveling machine SMT 30 AER-24.G1 SMT 30 AER-14.G1 Operating manual...

-

Page 2: Imprint

All rights, including translation, are reserved. No part of this manual may be reproduced in any form (print, photocopy, microfilm or any other process) without the written permission of GERIMA GmbH, St. Wendel, reproduced or distributed using electronic systems, duplicated or distributed. -

Page 3: Table Of Contents

© Directory Preface…….…………………………………………. Imprint…...………………………………………….… 2 Foreword……………………………………………... Signs and symbols ..……………………………….. Technical specification………………….………… 6 Technical data….…………………………………….. 6 Shipment….………………………….……………….. 6 Noise emission value…..………………………….… 7 Power-on time…………..………………………….… 7 Safety instructions……….………………………… 8 Basic safety instructions…………….………………. 8 Intended use………………………...……………….. 14 Settings………………...……………………..……… 15 Replacing guiding bearing………..………………... 15 Replacing carbide inserts……...…………………... -

Page 4: Preface

Our specialist retailers are also the people to please always have the identification number of contact if you wish to purchase additional your GERIMA SMT 30 AER-24.G1 / SMT 30 AER- GERIMA machine. 14.G1 available. The machine identification number is engraved on the gear box (see red arrow in diagram shown at top right of page). -

Page 5: Signs And Symbols

© Signs and symbols Please read the manual before using machine ! The information in this manual are indentified as follows: This manual has been created so that you can work with your device quickly and safely. Here is a Danger! brief guide on how you should read this manual: Warning of person, machinery or... -

Page 6: Technical Specification

Motor Speed control Locking handwheel (7) Handwheel setting bevel width / radius Spindle lock ON-OFF-switch Shipment 1x Basic machine SMT 30 AER-24.G1 Basic machine SMT 30 AER-14.G1 1x Manual 1x Torx wrench T15 1x Hexagon screwdriver SW5... -

Page 7: Noise Emission Value

© Technical manual Noise emission values in accordance with the DIN Power-on time (POT): EN 60745-1 standard: To avoid damaging the machine, it is essential to be monitor how long the machine has been Noise emission [dB (A)] Value operating continuously (‘power-on time’). certainty Emission sound pressure All electric brushed motors generate large amounts... -

Page 8: Safety Instructions

© Basic safety instructions Duties of the operator The following instructions must be The SMT 30 AER-24.G1 and SMT 30 read carefully in order to avoid ac- AER-14.G1 was designed and built cidents to persons and / or property taking into account a risk analysis and... - Page 9 © Basic safety instructions Operator qualifications and protection of ma- Protective clothing: chine operators: When working on/with the machine always wear: The term ‘operator’ is used here to mean any per- son who operates, adjusts, services and/or repairs the machine. The employer is obliged to inform the operator ear protectors, about security relevant standards and to verify...

- Page 10 Do not lay the cable over sharp edges. • Servicing: The machine may only be serviced by appropriately qualified technical staff or by the • Always use genuine GERIMA spare parts and acces- manufacturer’s service personnel. sories. • Repair: The machine may only be repaired by appropriately qualified technical staff or by the manufacturer’s service personnel.

- Page 11 © Basic safety instructions Risk of electric shock! Regular pre-start safety precautions Warning of physical injury by electricity Perform the following pre-start proce- dures each time you plan to use the • All work on the machine’s electrical machine: systems must be performed only by qualified •...

- Page 12 © Basic safety instructions Maintenance: Maintenance or service work must • If protective guards or other safety devices have only be performed once the machi- to be removed for servicing or maintenance work, ne’s moving parts have come to they must be reinstalled immediately after the rest.

- Page 13 • The machine is covered to prevent the risk of Any alterations to the machine contact with moving parts. must have been approved by GERIMA GmbH. • However residual risks still exist. This also applies to the welding of the component parts.

-

Page 14: Intended Use

‚intended use‘. Do not use the machine to work on materials containing asbestos! The SMT 30 AER-24.G1 and SMT 30 AER-14.G1 is a stationary, electrically powered beveling ma- chine intended: • For machining workpieces made of steel,... -

Page 15: Settings

© Settings Replacing guide wheel / carbide inserts / milling bo- Adjusting the 8-fold bevel- and radius carbide inserts (type KX and KXR): The bevel- and radius-carbide inserts of type KX and KXR Before replacing always disconnect the have 8 cuttings. By rotation and turning it is possible to machine from the power supply by re- use the inserts 8 times. -

Page 16: Setting The Bevel Length

© Settings Setting the bevel length: Adjusting radius: The procedure for setting the radius and bevel is identi- a leg length = bevel length a cally. b leg length = bevel length b Please note that only the position of the lower edge of C bevel width the radius can be adjusted by rotating the hand wheel α... -

Page 17: Operating Mode

© Operating mode General: Handling: To became acquainted with the Damages caused by wrong power machine, you must start by machining a supply! small bevel with a width of no more than • Check the supply voltage. The supply 2 mm and remember to advance the voltage must correspondend with the machine slowly first. -

Page 18: Maintenance

! • Wear protective gloves when changing or readjusting the carbide inserts! Repair must only be carried out by a GERIMA trained technician! Improperly repaired machines are hazzard! • Increased risk of injury • Machine does not function correctly! Hot carbide inserts and milling head! •... -

Page 19: Disposal

© Disposal Disposal of components removed from the ma- chine: All machine parts, operating and auxiliary materials must be dis- posed of in accordance with the applicable statutory provisions. -

Page 20: Technical Documentation

© Technical documentation SMT 30 AER-24.G1 / SMT 30 AER-14.G1 0202-24-01-00-00-06 order-nr. name of part 0101.992.16-00001 Frame 0101.992.18-00001 Lever 0101.992.18-00002 Holder 0101.992.16-00022 Cover 0101.992.16-00018 Knob 0101.992.16-00017 Threaded bolt 0101.992.16-00016 Locking piece 0101.992.16-00015 Bush 0101.992.16-00014 Plate 0101.992.16-00013 Guide 0101.992.16-00011 Brass insert 0101.992.16-00010... - Page 21 © Technical documentation SMT 30 AER-24.G1 / SMT 30 AER-14.G1 0202-21-08-00-00-03 order-nr. name of part 0101.462.19-00005 Bevel gear 0101.372.19-00001 Shaft 0101.992.16-00019 Gearbox 0101.372.15-00004 Belleville spring washer 0101.203.09-00013 Internal thread M5x10 0000.022.15-00005 Locking ring 35x1 0000.022.15-00276 Locking ring 11x1 0000.042.15-00028 O-ring 0101.112.15-00013...

- Page 22 © Technical documentation SMT 30 AER-24.G1 / SMT 30 AER-14.G1 0202-24-01-00-00-05 order-nr. (230V) order-nr. (120V) name of part 0101.362.18-00001 0101.362.18-00001 Motor housing 0101.362.18-00002 0101.362.18-00025 Stator 0101.112.17-00001 0101.112.17-00001 Switch 0101.392.18-00002 0101.392.18-00001 Elektronic 0101.112.18-00001 0101.112.18-00001 Shift rod 0101.112.18-00002 0101.112.18-00002 Swich slide 0101.112.16-00025 0101.112.16-00035...

-

Page 23: Terms Of Guarantee

GERIMA or by one of its authorized specialist retailer or representatives. Guarantee claims can be made only for genuine GERIMA parts and if the machine was used for its intended purpose. The guarantee does not cover, in particular: operational wear and tear; improper use;... -

Page 24: Ec Declaration Of Conformity

Weimarer Straße 12 66606 St. Wendel Germany Product SMT 30 AER-24.G1, 21-250-*****, 00001-99999, 2021 Product SMT 30 AER-14.G1, 21-251-*****, 00001-99999, 2021 We hereby declare that the above mentioned product complies with all relevant provisions of the Machinery Directive 2006/42/EC. The above product fulfills the relevant requirements of the following guidelines: ►...

Need help?

Do you have a question about the SMT 30 AER-24.G1 and is the answer not in the manual?

Questions and answers