Summary of Contents for eta EEP 50

- Page 1 2017-10-04 0000000242 V.004 X.35.4, X.39.1 93530-001 Precipitator EEP 50, EEP 90, EEP 130 Service manual...

- Page 2 ETA Heiztechnik Gewerbepark 1 A-4716 Hofkirchen an der Trattnach Tel: +43 (0) 7734 / 22 88 -0 Fax: +43 (0) 7734 / 22 88 -22 info@eta.co.at www.eta.co.at...

- Page 3 "www.eta.co.at". Copyright All contents of this document are property of ETA Heiztechnik GmbH and are protected by copyright. Any reproduction, transfer to third parties or use for other purposes is prohibited without written permission...

- Page 4 Use glue to adhere the seals, for example. boiler and precipitator. Also clean the flue gas recircu- lator if one is installed. Do not use compressed air to clean the components. www.eta.co.at...

- Page 5 Cleaning and maintenance Maintenance notes Do not use cleaning brushes to clean the components.

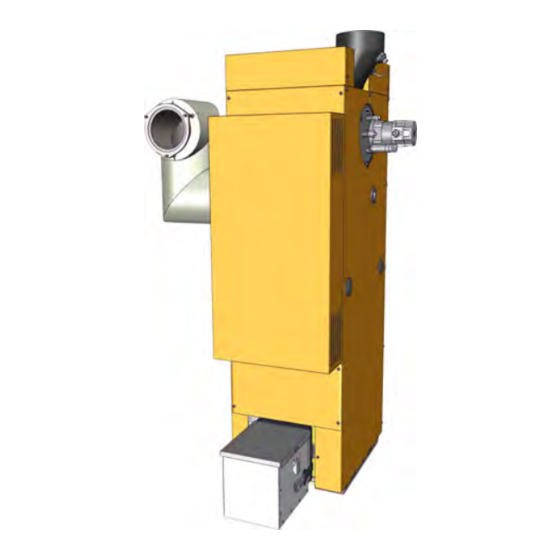

- Page 6 Maintenance cover Position switch for the electrode dedusting Drive chain for the electrode dedusting Position switch for the sliding rake Drive chain for the sliding rake and ash screw Draught fan Ash box seal Ash box position switch www.eta.co.at...

- Page 7 Cleaning and maintenance Maintenance openings Maintenance cover for optional flue gas recircula- tion Flue gas temperature sensor Maintenance cover for the piping between boiler and precipitator Maintenance cover for optional flue gas recircula- tion...

-

Page 8: Table Of Contents

• Check the drive chain and the sliding rake position switch Clean the draught fan Specialist Clean the temperature sensor Specialist Check the ash box position switch Specialist Check the safety switch for the maintenance cover Specialist www.eta.co.at... -

Page 9: Empty The Ash Box X Xx

Cleaning and maintenance Regular maintenance Regular maintenance Inspect the seal on the ash box cover to ensure it is in good order, and replace it if necessary. 2.4.1 Empty the ash box End heating mode End the boiler's heating mode with the On/Off switch in the boiler overview window. - Page 10 Cleaning and maintenance Switch the boiler on via the mains switch and start de-ashing Restore the boiler's power supply from the mains switch. Start de-ashing, so that the boiler can perform de-ashing. Switch the boiler back on with the On/Off switch. www.eta.co.at...

-

Page 11: Clean The Piping

Cleaning and maintenance Cleaning (customer) Cleaning (customer) 2.5.2 Clean piping Clean the piping between boiler and precipitator 2.5.1 Preparation Open the maintenance cover in the piping. End heating mode End the boiler's heating mode with the On/Off switch in the boiler overview window. The boiler performs an ember burnout and then changes to the [Switched off] operating mode. -

Page 12: Clean The Flue Tube From The Precipitator To The Chimney

Fig. 2-11: Maintenance cover Brush out the pipes with a cleaning brush and remove the ash with a vacuum. Fig. 2-9: Flue tube Brush the ash into the chimney and not the pre- cipitator. Fig. 2-12: Clean pipes www.eta.co.at... -

Page 13: Clean The Precipitator

Cleaning and maintenance Cleaning (customer) 2.5.4 Clean precipitator Remove maintenance cover and panels Remove the panel from the top and remove the insulating cover. Fig. 2-13: Clean pipes Then re-install all maintenance covers and the seals. Fig. 2-14: Panels and insulating cover Remove the maintenance cover. -

Page 14: Check And Remove Ash Accumulations

Fig. 2-16: Ash accumulations Use the cleaning brush to carefully scrape the ash ac- cumulations from the inner walls. Especially the area above the sliding rake. Fig. 2-19: Clean the inner walls Fig. 2-17: Clean the inner walls www.eta.co.at... -

Page 15: Clean The Flushing Air Opening

Vacuum out the opening for the electrode flushing air flushing air openings. If cracks or small holes can be on the isolator on the inside of the precipitator. "felt" there is damage. In this case, contact ETA Customer Support. Check the alignment of the electrodes The electrode must be in the centre of the precipitator so that the flue gas can be optimally cleaned. -

Page 16: Check Maintenance Cover Seal

Otherwise, leak air is sucked in, disturbing the combustion process and causing increased wear. Always replace seals immediately when they are damaged. Re-attach maintenance cover and panels Place the maintenance cover and tighten the screws evenly and cross-wise. Fig. 2-25: Maintenance cover www.eta.co.at... - Page 17 Cleaning and maintenance Cleaning (customer) 2.5.5 Establish operational readiness Switch the boiler on via the mains switch and start de-ashing Restore the boiler's power supply from the mains switch. Start de-ashing, so that the boiler can perform de-ashing. Switch the boiler back on with the On/Off switch.

-

Page 18: Check Idle Position

Therefore, switch off the boiler at the mains switch and ensure that it cannot be switched back on before starting work. Then establish additional earthing between the electrode on the inside and the housing of the precipitator. www.eta.co.at... -

Page 19: Check Idle Position Of The Electrode Dedusting

Cleaning and maintenance Maintenance (expert) Removing the side panel Through the maintenance opening on the top, inspect whether the lever gear teeth can support Remove the side panel from the precipitator. the striking weight in idle position. The gap must be 3 mm. -

Page 20: Check De-Ashing

2 cm without effort. Tension the chain by shifting the motor. Lubricate the drive chain with chain spray. Fig. 2-33: Idle position Fig. 2-34: Electrode dedusting drive chain Check whether the position switch is actuated. Fig. 2-35: Position switch www.eta.co.at... -

Page 21: Check The Drive Chain And The Sliding Rake Position Switch

Cleaning and maintenance Maintenance (expert) Check the drive chain and the sliding rake position Install the side panels switch Re-install the side panels of the precipitator. Check the chain tension. The chain may sag by 1 - 2 cm without effort. Tension the chain by shifting the motor. -

Page 22: Clean The Draught Fan

Carefully clean the impeller of the draught fan with a soft brush (not a wire brush) or with compressed air, so that the impeller does not move out of balance. Replace the seal on the draught fan. Fig. 2-41: Clean impeller; replace seal www.eta.co.at... - Page 23 Cleaning and maintenance Maintenance (expert) 2.6.5 Clean temperature sensor 2.6.6 Check ash box position switch Clean flue gas temperature sensor Check the ash box position switch To clean, loosen the screw and pull out the flue gas Inspect the function of the ash box position switch. It temperature sensor.

- Page 24 Otherwise, leak air is sucked in, disturbing the combustion process and causing increased wear. Always replace seals immediately when they are damaged. Fig. 2-44: Panel Check safety switch Check the function of the safety switch for the maintenance cover. Fig. 2-45: Safety switch www.eta.co.at...

- Page 25 Cleaning and maintenance Maintenance (expert) Install panels Finally, place the insulating cover and re-attach the panels. Reattach the panel on the front. Fig. 2-49: Panels and insulating cover Fig. 2-47: Panel Re-attach maintenance cover and panels Place the maintenance cover and tighten the screws evenly and cross-wise.

- Page 26 Establish operational readiness Switch the boiler on via the mains switch and start de-ashing Restore the boiler's power supply from the mains switch. Start de-ashing, so that the boiler can perform de-ashing. Switch the boiler back on with the On/Off switch. www.eta.co.at...

- Page 27 Cleaning and maintenance Maintenance (expert)

- Page 28 Clean the precipitator • Check and remove ash accumulations • Clean the flushing air opening • Clean and inspect the electrode holder • Check the alignment of the electrodes • Check maintenance cover seal performed on: _________________________ performed by: _________________________ Comments: www.eta.co.at...

- Page 29 Records Cleaning (customer) Cleaning (customer) Cleaning must be carried out at least once a year or when requested by the control system. Tasks Notes Empty the ash box • Empty the ash box • Check the seals Clean the piping •...

-

Page 30: Clean The Temperature Sensor

Check the drive chain and the sliding rake position switch Clean the draught fan Clean the temperature sensor Check the ash box position switch Check the safety switch for the maintenance cover performed on: _________________________ performed by: _________________________ Comments: www.eta.co.at... - Page 31 Records Cleaning (customer) Cleaning (customer) Cleaning must be carried out at least once a year or when requested by the control system. Tasks Notes Empty the ash box • Empty the ash box • Check the seals Clean the piping •...

- Page 32 Clean the precipitator • Check and remove ash accumulations • Clean the flushing air opening • Clean and inspect the electrode holder • Check the alignment of the electrodes • Check maintenance cover seal performed on: _________________________ performed by: _________________________ Comments: www.eta.co.at...

- Page 33 Records Maintenance (expert) Maintenance (expert) Maintenance is necessary at least every 3 years, or when requested by the control system. We recommend you perform maintenance annually. Tasks Notes Empty the ash box • Empty the ash box • Check the seals Clean the piping •...

- Page 34 Clean the precipitator • Check and remove ash accumulations • Clean the flushing air opening • Clean and inspect the electrode holder • Check the alignment of the electrodes • Check maintenance cover seal performed on: _________________________ performed by: _________________________ Comments: www.eta.co.at...

- Page 35 Records Cleaning (customer) Cleaning (customer) Cleaning must be carried out at least once a year or when requested by the control system. Tasks Notes Empty the ash box • Empty the ash box • Check the seals Clean the piping •...

- Page 36 Check the drive chain and the sliding rake position switch Clean the draught fan Clean the temperature sensor Check the ash box position switch Check the safety switch for the maintenance cover performed on: _________________________ performed by: _________________________ Comments: www.eta.co.at...

- Page 37 Records Cleaning (customer) 3.10 Cleaning (customer) Cleaning must be carried out at least once a year or when requested by the control system. Tasks Notes Empty the ash box • Empty the ash box • Check the seals Clean the piping •...

- Page 38 Clean the precipitator • Check and remove ash accumulations • Clean the flushing air opening • Clean and inspect the electrode holder • Check the alignment of the electrodes • Check maintenance cover seal performed on: _________________________ performed by: _________________________ Comments: www.eta.co.at...

- Page 39 Records Maintenance (expert) 3.12 Maintenance (expert) Maintenance is necessary at least every 3 years, or when requested by the control system. We recommend you perform maintenance annually. Tasks Notes Empty the ash box • Empty the ash box • Check the seals Clean the piping •...

- Page 40 Clean the precipitator • Check and remove ash accumulations • Clean the flushing air opening • Clean and inspect the electrode holder • Check the alignment of the electrodes • Check maintenance cover seal performed on: _________________________ performed by: _________________________ Comments: www.eta.co.at...

- Page 41 Records Cleaning (customer) 3.14 Cleaning (customer) Cleaning must be carried out at least once a year or when requested by the control system. Tasks Notes Empty the ash box • Empty the ash box • Check the seals Clean the piping •...

- Page 42 Check the drive chain and the sliding rake position switch Clean the draught fan Clean the temperature sensor Check the ash box position switch Check the safety switch for the maintenance cover performed on: _________________________ performed by: _________________________ Comments: www.eta.co.at...

- Page 43 Records Cleaning (customer) 3.16 Cleaning (customer) Cleaning must be carried out at least once a year or when requested by the control system. Tasks Notes Empty the ash box • Empty the ash box • Check the seals Clean the piping •...

- Page 44 Clean the precipitator • Check and remove ash accumulations • Clean the flushing air opening • Clean and inspect the electrode holder • Check the alignment of the electrodes • Check maintenance cover seal performed on: _________________________ performed by: _________________________ Comments: www.eta.co.at...

- Page 45 Records Maintenance (expert) 3.18 Maintenance (expert) Maintenance is necessary at least every 3 years, or when requested by the control system. We recommend you perform maintenance annually. Tasks Notes Empty the ash box • Empty the ash box • Check the seals Clean the piping •...

- Page 46 Clean the precipitator • Check and remove ash accumulations • Clean the flushing air opening • Clean and inspect the electrode holder • Check the alignment of the electrodes • Check maintenance cover seal performed on: _________________________ performed by: _________________________ Comments: www.eta.co.at...

- Page 47 Records Cleaning (customer) 3.20 Cleaning (customer) Cleaning must be carried out at least once a year or when requested by the control system. Tasks Notes Empty the ash box • Empty the ash box • Check the seals Clean the piping •...

- Page 48 Check the drive chain and the sliding rake position switch Clean the draught fan Clean the temperature sensor Check the ash box position switch Check the safety switch for the maintenance cover performed on: _________________________ performed by: _________________________ Comments: www.eta.co.at...

- Page 50 www.eta.co.at...

- Page 52 DOWNLOAD www.eta.co.at...

Need help?

Do you have a question about the EEP 50 and is the answer not in the manual?

Questions and answers