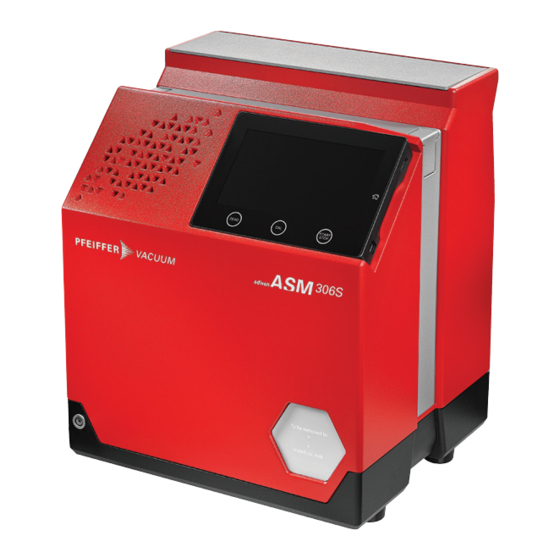

Pfeiffer Vacuum ASM 306S Additional Installation, Operation And Maintenance Instructions

Leak detector

Hide thumbs

Also See for ASM 306S:

- Operating instructions manual (68 pages) ,

- Operating instructions manual (48 pages) ,

- Condensed manual (2 pages)

Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Pfeiffer Vacuum ASM 306S

- Page 1 MAINTENANCE INSTRUCTIONS Translation of the Original ASM 306S Leak detector...

- Page 2 These operating instructions describe all models and variants of your product. Note that your product may not be equipped with all features described in this document. Pfeiffer Vacuum constantly adapts its products to the latest state of the art without prior notice. Please take into account that online operating instructions can deviate from the printed operating instructions supplied with your product.

-

Page 3: Table Of Contents

5.10 Solenoid valve replacement Decommissioning Shutting down for longer periods Disposal 6.2.1 Restriction of Hazardous Substances (RoHS) 6.2.2 Electrical and Electronic Equipment (EEE) Malfunctions Operation monitoring Fault display Service solutions by Pfeiffer Vacuum Spare parts Tools Accessories Leak detector spare parts 3/30... -

Page 4: About This Manual

Keep the manual for future consultation. 1.1 Validity This Maintenance manual is intended for Pfeiffer Vacuum customers. It describes the product mainte- nance operations which can be performed by the customer on the product concerned. This documen- tation must be used with the Operating Instructions of the product of the same name. -

Page 5: User Target Group

About this manual 1.2.2 User target group This maintenance manual is intended for all persons responsible for product maintenance, for the fol- lowing operations: ● disassembly ● maintenance ● cleaning The work described in this document must only be carried out by persons with suitable technical train- ing (e.g. -

Page 6: Abbreviations

About this manual Product rating plate. 98 avenue de Brogny F-74000 ANNECY Weight Part Number Made in France Operating voltage Description Operating frequency Serial number P/N : Maximum power consumption Date of manufacture S/N : This label indicates that the product is subject to regulations for the treatment of electrical and electronic equipment waste (see the EC declaration of product conformity). -

Page 7: Safety

Safety 2 Safety 2.1 General safety information The following 4 risk levels and 1 information level are taken into account in this document. DANGER Immediately pending danger Indicates an immediately pending danger that will result in death or serious injury if not observed. ►... -

Page 8: Precautions

Safety WARNING Risk of serious injury due to falling objects When transporting parts/items by hand, there is a danger of loads slipping and falling down. ► Carry small and medium-size parts/items with two hands. ► Wear safety shoes with steel toe according to directive EN 347. WARNING Risk of burns in case of contact with hot surfaces For the operator’s safety, the products are designed to avoid thermal risk. - Page 9 Safety Infringement of conformity due to modifications to the product The Declaration of Conformity from the manufacturer is no longer valid if the operator changes the original product or installs additional equipment. ● Following the installation into a system, the operator is required to check and re-evalu- ate the conformity of the overall system in the context of the relevant European Direc- tives, before commissioning that system.

-

Page 10: General Information

(see chap- ter “Spare parts”, page 28). ● To identify the product and communicate with Pfeiffer Vacuum look at the product's rat- ing plate. 3.2 Preparatory work The detector does not require any maintenance at the customer’s premises, except for the sub-assem- bly maintenance described in this manual. -

Page 11: Maintenance Intervals And Responsibilities

Maintenance intervals and responsibilities 4 Maintenance intervals and responsibilities Maintenance operations for levels 1 and 2 of the interval table are described in this manual. Level 3 overhaul operations require a technician from the Pfeiffer Vacuum Service network. Operation Number of hours in use... -

Page 12: Service - Maintenance

Service - Maintenance 5 Service - Maintenance 5.1 Cleaning ► Clean the cover using a clean, lint-free cloth and a product that will not damage the screen-printed surfaces or adhesive labels. 5.2 Powering off The detector is installed on a horizontal work surface. 5.3 Cover disassembly/reassembly Disassembly ►... -

Page 13: Calibrated Leak Replacement (Accessory)

Service - Maintenance The cover can be removed without disconnecting the control panel, the cable is long enough. To fully release the cover, disconnect the cable and remove the control panel con- nector. Reassembly ► Follow the disassembly steps in reverse. 5.4 Calibrated leak replacement (accessory) ►... -

Page 14: Analyzer Cell Maintenance

Service - Maintenance Example of calibrated leak rating plate PFEIFFER VACUUM F-74000 ANNECY Made in USA S/N:FC20001345 P/N:119678 1,33E-07 Value..: mbar.l/s ± 10 % 1,33E-08 Pa.m /s ± 10 % Leak code....... : 4437GKIK04 : 4He Gaz......... Calibration date....: 20-Jul-2020 Loss per year (1st year). - Page 15 The use of an analysis cell different from the original component requires adjustments. Without these settings, the measurements made by the product are not correct. Only a Pfeiffer Vacuum service center can make these adjustments. It is mandatory to reassemble the original analysis cell.

-

Page 16: Seal Replacement

Service - Maintenance 5.5.2 Seal replacement 1 Seals 1. Remove the detector analyzer cell (see chapter “Disassembly/reassembly of the analyzer cell”). 2. Check the condition of the seals: change them if necessary. 3. Replace the 2 seals. Never lubricate the seals. 5.5.3 Filament replacement NOTICE Distortion of product performance due to damaged filament... -

Page 17: Fan Maintenance

Service - Maintenance Reassembly F1 Filament 1 Connectors Fixing screw and washer Centering stops Filament strip The connectors are perpendicular to the supporting surface and parallel to each other. 1. Place the new filament on its housing against both centering stops. Fix it with the screw and washer provided with the filament. -

Page 18: Fan Replacement

Service - Maintenance 5.6.2 Fan replacement Disassembly 1. Power off the leak detector (see chapter “Powering Off”). 2. Remove the cover (see chapter “Cover disassembly/reassembly.”) 18/30... -

Page 19: Sniffer Probe Maintenance (Accessory)

Service - Maintenance Reassembly The fan propels air from the exterior to the interior of the detector. ► Follow the disassembly steps in reverse. 5.7 Sniffer probe maintenance (accessory) 1 Tip filter Probe body 2 Rod Sleeve 3 Intermediate filter for small particles (See chapter “Accessory spare parts”). -

Page 20: Replacement Of Tc 110 Electronic Unit Of The Turbomolecular Pump

Service - Maintenance 5.8 Replacement of TC 110 electronic unit of the turbomolecular pump Disassembly 1. Create an air inlet on the analyzer cell from the menu [Maintenance] [Maintenance turbo pump & cell] [Stop and vent] (see chapter “Maintenance turbo pump & cell” in the operating manual). 2. -

Page 21: Solenoid Valve Replacement

Service - Maintenance Reassembly 1. Follow the disassembly steps in reverse. 2. Update the diaphragm pump maintenance counter from the menu [Maintenance] [Information] [Backing Pump] [Reset timer] (see chapter “Information” of the operating manual). Diaphragm replacement ► See the diaphragm pump Operating Instructions (see chapter “Applicable Documents”). 5.10 Solenoid valve replacement Disassembly 1. - Page 22 Service - Maintenance Remontage 0.6 N·m The o-ring must stay in the valve groove. Be careful not to pinch the o-ring when reassembling the solenoid valve on the vacuum block. 22/30...

-

Page 23: Decommissioning

This product bears the identification logo because it is subject to regulations on the management of Waste from EEE. The manufacturer shall only be required to take back EEE marked Pfeiffer Vacuum sold by Pfeiffer Vac- uum: ● EEE subject to applicable regulations for recycling end-of-life products;... - Page 24 To find out more about the collection solutions, contact ecosystem who will inform you of the best col- lection solution for your needs: www.ecosystem.eco For further details, consult the General Conditions of Sale available in French on the Pfeiffer Vacuum website. Product on sale outside of France...

-

Page 25: Malfunctions

Malfunctions 7 Malfunctions 7.1 Operation monitoring During operation, the user is notified of an incident on the detector control panel and on the sniffer probe. Type of fault Control panel Sniffer probe Warning Press i Next pictograph to dis- ‘Standby’ mode play the fault. ●... -

Page 26: Service Solutions By Pfeiffer Vacuum

We are always focused on perfecting our core competence – servicing of vacuum components. Once you have purchased a product from Pfeiffer Vacuum, our service is far from over. This is often exactly where service begins. Obviously, in proven Pfeiffer Vacuum quality. - Page 27 Service solutions by Pfeiffer Vacuum 5. Prepare the product for transport in accordance with the provisions in the contamination declaration. a) Neutralize the product with nitrogen or dry air. b) Seal all openings with blind flanges, so that they are airtight.

-

Page 28: Spare Parts

Spare parts 9 Spare parts 9.1 Tools Description Part Number The maintenance set contains: 114718 Box-shank nut spinner Screwdriver for TORX ® 6x35 screws CHC M4x80 screws CHC M4x12 screws M4 washer CHC M3x6 screws M3 washer 2.5 mm male hex wrench 3 mm male hex wrench 4 mm male hex wrench 5 mm male hex wrench... -

Page 29: Leak Detector Spare Parts

Description Part Number Control panel (without cable) - ASM 306S 127325S 5 m RJ9 cable 123909 Equipped cover set (without probe sheath) - ASM 306S 127298 2 m mono A/J power cable 103567 2 m Europe power cable 103566 Filament - analyzer cell...

Need help?

Do you have a question about the ASM 306S and is the answer not in the manual?

Questions and answers