Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for nord MAXXDRIVE B 1050

- Page 1 B 1050 – en Industrial gear units Manual with installation instructions...

- Page 2 Industrial gear units – Manual with installation instructions B 1050 en-3921...

- Page 3 Please also note the following documents: • Gear unit catalogues, • Documentation for the electric motor, • Documentation for equipment which is attached or provided. Please contact Getriebebau NORD GmbH & Co. KG if you require further information. B 1050 en-3921...

- Page 4 Industrial gear units – Manual with installation instructions Documentation B 1050 Designation: 6052902 Part No.: Series: Gear units and geared motors Type series: SK 5207 to SK 15507, SK 5217 to SK 11217 and SK xx319 Gear unit types: Industrial gear units Version list Title, Order number /...

-

Page 5: Table 1: Version List B 1050

Version list Title, Order number / Remarks Version Date Internal code B 1050, 6052902 / 4620 • Descriptions for Options DB and VL/KL 2/3/4/6 added November • Revision of tables for lubricant oil and minimum starting temperatures 2020 • General corrections and amendments B 1050, 6052902 / 3921 •... - Page 6 Any editing or amendment or other utilisation of the document is prohibited. Publisher Getriebebau NORD GmbH & Co. KG Getriebebau-Nord-Straße 1 • 22941 Bargteheide, Germany • http://www.nord.com Fon +49 (0) 45 32 / 289-0 • Fax +49 (0) 45 32 / 289-2253 Member of the NORD DRIVESYSTEMS Group...

- Page 7 Publisher B 1050 en-3921...

-

Page 8: Table Of Contents

Industrial gear units – Manual with installation instructions Table of Contents Safety information ............................. 13 Intended use ............................ 13 Do not make any modifications......................13 Performing inspection and maintenance work ................. 13 Personnel qualification ........................13 Safety for particular activities ......................14 1.5.1 Check for transport damage .................... - Page 9 Table of Contents 3.16.1 Dog coupling........................52 3.16.2 Turbo coupling ........................52 3.16.3 Dog coupling........................53 3.17 Installing the output coupling ......................53 3.18 Installation of the internal cooling system (Option: CC)..............54 3.19 Installation of an external cooling system (Option: CS1-X, CS2-X) ..........55 3.20 Installing a fan (Option: FAN-A, FAN-R) ..................

- Page 10 Industrial gear units – Manual with installation instructions 5.2.14 Re-lubrication of bearings in the gear unit ................86 5.2.15 Re-lubricating the bearing in the output flange (Option: VL2/3/4/6, KL2/3/4/6) ....87 5.2.16 Re-greasing the Taconite seal .................... 88 5.2.17 Checking v-belts (belt drives) ..................... 89 5.2.18 Inspection cover .........................

- Page 11 List of illustrations List of illustrations ® Figure 1: MAXXDRIVE XT 2-stage helical bevel gear unit .................. 17 Figure 2: Name plate ............................. 20 Figure 3: Transport of standard gear unit ......................22 Figure 4: Transport of gear units with motor adapter ..................... 23 Figure 5: Transport of gear units with auxiliary drives or first stage gear units ............

- Page 12 Industrial gear units – Manual with installation instructions List of tables Table 1: Version list B 1050 ............................. 5 Table 2: Type designations and gear unit types ....................16 Table 3: Versions and options ..........................19 Table 4: Permissible machine shaft tolerances ..................... 39 Table 5: IEC and NEMA motor weights .........................

-

Page 13: Safety Information

The gear units may only be used according to the information in the technical documentation from Getriebebau NORD GmbH & Co. KG. Damage to the gear unit may result if the gear unit is not used as intended and according to the information in the operating and assembly manual. This may also result in personal injury. -

Page 14: Safety For Particular Activities

Industrial gear units – Manual with installation instructions 1.5 Safety for particular activities 1.5.1 Check for transport damage Transport damage may cause malfunctions of the gear unit, which may cause personal injury. Oil which escapes due to leaks may cause a slipping hazard. •... -

Page 15: Danger On Entry

1 Safety information 1.6.3 Danger on entry Persons may fall and be seriously injured when standing on the gear unit. • Only stand on the gear unit for maintenance and repair work and only when the gear unit is at a standstill. -

Page 16: Description Of Gear Units

Industrial gear units – Manual with installation instructions 2 Description of gear units 2.1 Type designations and gear unit types Gear unit types/ Type designations Parallel gear units 2-stage 3-stage SK 5207 SK 5307 SK 6207 SK 6307 SK 7207 SK 7307 SK 8207 SK 8307... -

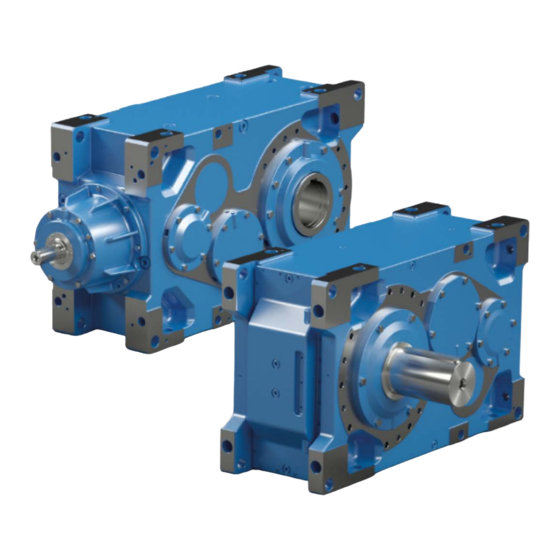

Page 17: Figure 1: Maxxdrive Xt 2-Stage Helical Bevel Gear Unit

2 Description of gear units ® Figure 1: MAXXDRIVE XT 2-stage helical bevel gear unit B 1050 en-3921... - Page 18 Industrial gear units – Manual with installation instructions Description Hollow output shaft Fastening element Cooling coil CS1-X Cooling system oil/water CS2-X Cooling system oil/air Torque support Drying agent filter Additional measures against oil leak for mounting position M5 (True Drywell) with standard bearings Splined hollow output shaft Elastic torque arm (details on name plate D)

-

Page 19: Table 3: Versions And Options

2 Description of gear units Description Oil gauge Oil level indicator Oil level tank PT100 Temperature sensor Back stop Shrink disc Solid output shaft Reinforced bearings Agitator version - Reinforced bearings Agitator version - Reinforced bearings - Drywell Agitator version - Reinforced bearings - True Drywell Extruder flange version... -

Page 20: Name Plate

2.2 Name plate The name plate must be firmly attached to the gear unit and must not be subjected to permanent soiling. Please contact the NORD service department if the name plate is illegible or damaged. Figure 2: Name plate... -

Page 21: Transport, Storage, Assembly

3 Transport, storage, assembly 3 Transport, storage, assembly 3.1 Transporting the gear unit WARNING Hazard due to falling loads • Do not use the eye bolts on a mounted motor to lift the unit. • Note the centre of gravity of the gear unit. Transport the gear unit with care. -

Page 22: Transport Of Standard Gear Units

Industrial gear units – Manual with installation instructions 3.1.1 Transport of standard gear units Legend 1: Lifting strap 2: Shackle : Not permissible : Permissible Figure 3: Transport of standard gear unit B 1050 en-3921... -

Page 23: Transport Of Gear Units With Motor Adapter

3 Transport, storage, assembly 3.1.2 Transport of gear units with motor adapter The ring bolts on the motor must not be used for transportation. Legend 1: Lifting strap 2: Shackle : Not permissible : Permissible Figure 4: Transport of gear units with motor adapter B 1050 en-3921... -

Page 24: Transport Of Gear Units With Auxiliary Drives Or First Stage Gear Units (Option: Wg, Wx)

Industrial gear units – Manual with installation instructions 3.1.3 Transport of gear units with auxiliary drives or first stage gear units (Option: WG, WX) The eyebolts on the auxiliary drive, on the first stage gear unit or on the motor must not be used for transportation. -

Page 25: Transport Of Gear Units With V-Belt Drives

3 Transport, storage, assembly 3.1.4 Transport of gear units with V-belt drives The ring bolts on the motor and the motor bracket must not be used for transportation. Legend 1: Lifting strap 2: Shackle : Not permissible : Permissible Figure 6: Transport of gear units with V-belt drives B 1050 en-3921... -

Page 26: Transport Of Agitator Version Gear Units

Industrial gear units – Manual with installation instructions 3.1.5 Transport of agitator version gear units The ring bolts on the motor must not be used for transportation. Special lifting gear must be used to ensure correct transport if the shackle holes cannot be used due to the IEC attachment. -

Page 27: Transport Of Gear Unit With Motor Swing Base Or Base Frame

3 Transport, storage, assembly 3.1.6 Transport of gear unit with motor swing base or base frame Motors with a motor swing base or base frame may only be transported with shackles and lifting straps or chains which are vertically aligned. Only use the attachment points on the motor swing base or on the base frame. -

Page 28: Storage And Downtimes

Industrial gear units – Manual with installation instructions 3.2 Storage and downtimes 3.2.1 General measures • Store the gear unit in a dry space, relative humidity less than 60%. • Store the gear unit at a temperature in the range of – 5 °C to + 50 °C without severe temperature fluctuations. -

Page 29: Preparing For Installation

(PG oils). If PG oils are used, the VCI concentrate must be removed from the gear unit. When using VCI additive, only use the oil types which are specified on the name plate and are approved by Getriebebau NORD (see chapter 7.3.2 "Gear oils"). -

Page 30: Check Rotational Direction

Do not allow dust to accumulate in the area of the gear unit Please contact NORD if the conditions stated above cannot be met. The base on which the gear unit is fitted must be vibration-free, torsionally rigid and flat. The flatness of the bolting surface on the base must be of the requested precision (see chapter 7.5 "Tolerances for... -

Page 31: Installation Of A Hub On Solid Shaft (Option: V, L)

3 Transport, storage, assembly Precisely align the gear unit with the drive shaft of the machine in order to prevent additional forces from being imposed on the gear unit due to distortion. The service life of shafts, bearings and couplings depends on the precision of alignment of the shaft. Therefore, zero deviation should always be aimed for in alignment. -

Page 32: Figure 10: Permissible Application Of Force To Drive And Driven Shafts

Industrial gear units – Manual with installation instructions Additional loads due to unbalanced hubs are not permitted. The transverse force must be applied as closely as possible to the gear unit. For drive shafts with free shaft ends (Option W), the maximum permissible transverse force F applies for the application of the transverse force to the centre of the free shaft journal. -

Page 33: Assembly Of Gear Unit With Hollow Shaft (Option: A, Ea)

Assembly and subsequent dismantling is facilitated by applying an anti-corrosive lubricant to the shaft before fitting (e.g. NORD Anti-Corrosion Part No. 089 00099). Excess lubricant may escape after fitting and may drip off. Thoroughly clean these points on the output shaft after a running-in time of approx. -

Page 34: Fitting A Hollow Shaft With Fastening Element (Option: B)

Industrial gear units – Manual with installation instructions 3.6.1 Fitting a hollow shaft with fastening element (Option: B) The gear unit can be fitted to shafts with and without a shoulder using the fastening element (Option B). Tighten the fastening element bolt with the correct torque (see chapter 7.4 "Screw tightening torques"). -

Page 35: Fitting A Hollow Shaft With Shrink Disc (Option: S)

Do not tighten the tensioning bolts if the solid shaft is not installed. This would permanently deform the hollow shaft. Hollow shafts with shrink discs must be protected from dust, dirt and moisture. NORD recommends option H/H66 (see chapter 3.14 "Installing the cover cap, air baffle (Option: H, H66, FAN, MF.., MS…)"). -

Page 36: Figure 14: Machine Shaft Assembly For Special Hollow Shafts With Shrink Discs

Industrial gear units – Manual with installation instructions Prerequisites • The hollow shaft must be completely free of grease. • The standard solid shaft of the machine must be completely free of grease. • Unless otherwise stated in the specific dimension sheet for the order, the external diameter of the solid shaft must be within the tolerance h6 if the diameter is up to and including 160 mm or g6 for larger diameters. -

Page 37: Figure 15: Fitted Shrink Disc

3 Transport, storage, assembly 7. After tightening the tensioning bolts the face of the inner ring on the screw side must be flush with the face of the outer ring. The shrink disc must be checked visually for distortion (Figure 15). Figure 15: Fitted shrink disc 8. -

Page 38: Fitting A Hollow Shaft With Gripmaxx™ (Option: M)

Industrial gear units – Manual with installation instructions 3.7 Fitting a hollow shaft with GRIPMAXX™ (Option: M) NOTICE Damage to the gear unit due to incorrect installation • Do not tighten the tensioning bolts of the shrink disc until the solid shaft and the torque bush are in the correct position. -

Page 39: Table 4: Permissible Machine Shaft Tolerances

3 Transport, storage, assembly Metric machine shafts Imperial machine shafts ISO 286-2 ISO 286-2 From From Tolerance h11(-) Tolerance h11(-) Ø [mm] Ø [mm] [mm] Ø [in] Ø [in] [in] -0.11 0.4375 0.6875 -0.004 -0.13 0.7500 1.0625 -0.005 -0.16 1.1250 1.9375 -0.006 -0.19... - Page 40 Industrial gear units – Manual with installation instructions Dismantling procedure WARNING Danger of injury due to sudden mechanical release The elements of the shrink disc are under great mechanical tension. Sudden release of the outer rings produces high separating forces and can result in uncontrolled detachment of shrink disc components.

-

Page 41: Installing A Flange Version Gear Unit (Option: F, Fk, Vl2/3/4/5, Kl2/3/4)

3 Transport, storage, assembly 3.8 Installing a flange version gear unit (Option: F, FK, VL2/3/4/5, KL2/3/4) NOTICE Risk of gear unit damage from distortion • Flange version gear units must only be bolted to the flange of the driven machine. The bolting surface of the driven machine must comply with the tolerances in Section 7.5 "Tolerances for bolting surfaces". -

Page 42: Agitator Version With True Drywell (Option: Vl4, Kl4)

Industrial gear units – Manual with installation instructions There is also and additional seal to the atmosphere below the bottom bearing. This design is known as Drywell. It enables detection of leaks before oil escapes outside of the gear unit. For leak indication, there is an oil inspection glass on the flange. -

Page 43: Agitator Version With True Drywell And Foot Mounting (Option: Vl6, Kl6)

3 Transport, storage, assembly 3.8.5 Agitator version with True Drywell and foot mounting (Option: VL6, KL6) These options include the entire internal elements of Option VL4 or KL4 (see 3.8.3 Agitator version with True Drywell (Option: VL4, KL4)). The elements are installed in a bolt-on housing without a flange. -

Page 44: True Drywell Version Gear Units (Option: Vl4, Kl4, Vl6, Kl6, Dry)

Industrial gear units – Manual with installation instructions 3.9 True Drywell version gear units (Option: VL4, KL4, VL6, KL6, DRY) NOTICE The grease-lubricated drive bearing is protected against oil by the oil level tube. Too much oil may flood the oil level tube. To prevent an oil leak on the bottom output bearing, the oil level in the gear unit is reduced. -

Page 45: Motor Base Frame (Option: Mf)

3 Transport, storage, assembly 3.10 Motor base frame (Option: MF) A motor base frame is a steel structure for pre-assembled drive packages in a horizontal position. This is used to mount the gear unit, (hydro) coupling, motor, and where applicable, a mechanical brake. It also includes the necessary protective devices (e.g. -

Page 46: Motor Swing Base (Option: Ms)

Industrial gear units – Manual with installation instructions 3.11 Motor swing base (Option: MS) A motor swing base is a steel structure for pre-assembled drive packages in a horizontal position. This is used to mount the gear unit, (hydro) coupling, motor, and where applicable, a mechanical brake. It also comes with the necessary protective devices (e.g. -

Page 47: Motor Mount (Option: Mt)

Excessive, or too little contact pressure increases losses due to friction and may result in an interruption of torque transfer. The belt tension can be checked with the aid of various measuring devices. NORD recommends that the check is made with the aid of a non-contact frequency measuring device, which enables quick, simple and reliable testing even in inaccessible areas. -

Page 48: Figure 21: V-Belt Pulley (Disassembled/Assembled)

Industrial gear units – Manual with installation instructions 8. Evenly tighten the studs or cap screws with an Allen key. Tightening torques can be provided on request. 9. Place on the belts in sequence. Roughly pre-adjust the tension by increasing the gap between the axles. -

Page 49: Figure 22: Axle Alignment (Belt Drives)

3 Transport, storage, assembly Legend 1: Axle (shaft) 2: Belt 3: Belt pulley I: Aligned pulleys on axially parallel shafts II: Axial displacement of the pulleys III: Horizontal angular displacement of axles : Not permissible : Permissible Figure 22: Axle alignment (belt drives) B 1050 en-3921... -

Page 50: Installing The Cover Cap, Air Baffle (Option: H, H66, Fan, Mf

• Protection of gear unit components (e.g. seals) with high dust concentrations (Option: H66) NORD fan covers and air baffles ensure a correct supply of air for the gear unit (Option FAN) NOTICE Risk of gear unit damage due to incorrect installation •... -

Page 51: Figure 23: Centre Of Gravity Of Motor

1500 Weight [kg] see Figure 23 for dimension X max Table 6: Transnorm motor weights Getriebebau NORD must be consulted if the values stated in the table are exceeded. Legend Centre of gravity of motor Figure 23: Centre of gravity of motor Fitting a motor with standard dog couplings (Rotex®) -

Page 52: Installing The Drive Coupling

Industrial gear units – Manual with installation instructions Figure 24: Fitting the coupling to the motor shaft 4. Coat the setscrew with securing adhesive (e.g. Loctite 242 or Loxeal 54-03) and secure the half- coupling with the setscrew. Tighten the setscrew with the correct tightening torque (see chapter 7.4 "Screw tightening torques"). -

Page 53: Dog Coupling

3 Transport, storage, assembly The quantity of oil in the coupling can be obtained from the manufacturer's documentation. An oil tray is installed as standard for gear units on a motor swing base or base frame which are combined with a turbo coupling. -

Page 54: Installation Of The Internal Cooling System (Option: Cc)

Industrial gear units – Manual with installation instructions 3.18 Installation of the internal cooling system (Option: CC) WARNING Risk of injury due to pressure discharge • Ensure that the pressure is released from the cooling circuit before carrying out any work on the gear unit. -

Page 55: Installation Of An External Cooling System (Option: Cs1-X, Cs2-X)

Connect the cooling system as shown in Figure 27. Do not modify any of the pre-assembled hoses without having consulted NORD beforehand. Further information about the cooling system and control information should be obtained from the manufacturer’s instructions for the cooling system. The technical limit values in the manufacturer's documentation have priority. -

Page 56: Installing A Fan (Option: Fan-A, Fan-R)

Industrial gear units – Manual with installation instructions Legend Gear unit intake connection Pump/cooling system intake connection Cooling system pressure connection Gear unit pressure connection PT100 temperature monitoring (optional/recommended) Cooling water connection Figure 27: Industrial gear unit with CS1-X and CS2-X cooling systems Legend Intake connection Pump... -

Page 57: Installation Of The Lubricant Circulation (Option: Lc, Lcx)

3 Transport, storage, assembly 3.21 Installation of the lubricant circulation (Option: LC, LCX) For gear units with lubricant circulation, either a flange-pump or a motor pump is used. A flange pump is driven by the drive shaft of the gear unit. The motor pump has a separate drive. The pump is already installed on the gear unit on delivery. -

Page 58: Figure 29: Permissible Installation Tolerances Of The Torque Arm (Option D And Ed) (Schematic Diagram)

Industrial gear units – Manual with installation instructions Legend Fork head with bolt Threaded bolt Maintenance-free joint head Fork plate with bolt Figure 29: Permissible installation tolerances of the torque arm (Option D and ED) (schematic diagram) The length of the torque support (Option: D) can be adjusted within a certain range. 1. -

Page 59: Connecting The Oil Heater (Option: Oh)

3 Transport, storage, assembly 3.24 Connecting the oil heater (Option: OH) WARNING Risk of fire due to exposed heater bars • Ensure that the heater bars are fully immersed in the oil bath before switching them on and during heating operation. The oil heater is already installed prior to delivery. -

Page 60: Limit Switch To Indicate The Brake Lining Wear (Option Slw)

Industrial gear units – Manual with installation instructions 3.25.2 Limit switch to indicate the brake lining wear (option SLW) While being operated, the brake lining of a mechanical brake is subject to wear. The option SLW indicates when the wear limit is reached and the brake lining must be replaced. 3.25.3 Connecting the NC/NO contacts (Option: SO/SC) The Option SO/SC comprises limit switches that make it possible to report the switching state of the mechanical brake (open/closed). -

Page 61: Commissioning

4 Commissioning 4 Commissioning 4.1 Checking the oil level Check the oil level before commissioning (see chapter 5.2 "Service and maintenance work"). The following table shows the usual oil filling state of oil spaces on delivery: Oil filling Oil space with without Industrial gear units... -

Page 62: Taconite Seal/Labyrinth Seal

Industrial gear units – Manual with installation instructions The connecting flange between the industrial gear unit and the auxiliary gear unit is always equipped with a pressure venting device. This device, as well as the pressure venting device on the industrial gear unit (only for ATEX-certified gear units) must be unlocked as shown in Figure 30. -

Page 63: Heated Output Hollow Shaft

Otherwise, the roller bearings may be damaged. This type of operation is a special case and must be taken into account by Getriebebau NORD during the gear unit planning. In case of changes to process parameters or a subsequent conversion to this application case, verification must be made by Getriebebau NORD. - Page 64 Industrial gear units – Manual with installation instructions NOTICE Risk of gear unit overheating from insufficient air flow • Check the contact guard for warping and damage. Repair possible damage prior to commissioning. • An adequate supply of air must be ensured by means of a minimum free space of 30° ahead of the air intakes.

-

Page 65: Cooling Coil (Option: Cc)

The coolant inlet temperature must not exceed 20 °C. The coolant inlet temperature may only be higher in individual cases according to the order documentation. In case of other coolant inlet temperatures, observe the special documentation provided by Getriebebau NORD or contact Getriebebau NORD. -

Page 66: External Cooling System (Option: Cs1-X, Cs2-X)

The maximum permissible cooling water inlet temperature is defined during the planning phase and can be found in the order data. The maximum ambient temperature is 40 °C. If higher ambient temperatures may occur, verification must be made by Getriebebau NORD prior to commissioning. -

Page 67: Oil / Air Coolers (Option: Cs2-X)

The oil heater is equipped with a temperature sensor and a thermostat. The heater is pre-set to a switch-off temperature of 20 °C. This means that the heater is in operation as long as an oil temperature of 20 °C has not been reached. Please contact Getriebebau NORD for other switch-off temperatures. -

Page 68: Backstop/Auxiliary Drive (Option: R, Wx)

Industrial gear units – Manual with installation instructions 4.11 Backstop/Auxiliary drive (Option: R, WX) NOTICE! Gear unit damage through overheating • The auxiliary drive must be secured or monitored to prevent it from idling. • Operation below the lift-off speed according to the following tables results in a considerable reduction of the service life of the back stop bearing. -

Page 69: Figure 32: Industrial Gear Unit With Back Stop (Schematic Diagram)

4 Commissioning Figure 32: Industrial gear unit with back stop (schematic diagram) Nominal gear ratio i Lift-off speed Gear unit Stages [rpm] From SK 5207 SK 5307 SK 5407 1088 1759 SK 5507 2740 SK 6207 SK 6307 31.5 SK 6407 1088 1759 SK 6507... -

Page 70: Table 8: Back Stop Lift-Off Speeds Sk 5..07 - Sk 10..07

Industrial gear units – Manual with installation instructions Nominal gear ratio i Lift-off speed Gear unit Stages [rpm] From SK 9207 SK 9307 SK 9407 1309 SK 9507 1636 SK 10207 SK 10307 31.5 SK 10407 31.5 1309 SK 10507 1636 Table 8: Back stop lift-off speeds SK 5..07 –... -

Page 71: Test Run

4 Commissioning Nominal gear ratio i Lift-off speed Gear unit Stages [rpm] From SK 15207 SK 15307 22.4 12.5 SK 15407 31.5 SK 15507 Table 9: Back stop lift-off speeds SK 11..07 – SK 15..07 Nominal gear ratio i Lift-off speed Gear unit Stages From... -

Page 72: Checklist

Industrial gear units – Manual with installation instructions Information Taconite seals have a grease filling to seal the gear unit against dirt and other contaminants. During continuous operation of the gear unit and the associated heating, grease may drip from the area of the Taconite seal. -

Page 73: Optional

4 Commissioning 4.13.2 Optional Checklist Date Information Item to be checked of check: see Section Option R, WX, FAN: 4.11, 4.6 Is the direction of rotation specified and checked? Option D and ED: 3.23 Is the torque arm installed correctly? Option S, FAN: 3.14 Are rotating parts covered with a contact guard? -

Page 74: Service And Maintenance

Industrial gear units – Manual with installation instructions 5 Service and maintenance 5.1 Inspection and maintenance intervals Inspection and Information Inspection and maintenance work maintenance intervals see Section According to • Option PT100: Check the function and measurement manufacturer's details accuracy;... -

Page 75: Table 13: Inspection And Maintenance Intervals

5 Service and maintenance Inspection and Information Inspection and maintenance work maintenance intervals see Section Every 2500 operating • Visual inspection of shaft sealing ring 5.2.1 hours, at least every six • Check the oil level and oil condition 5.2.5 months •... -

Page 76: Service And Maintenance Work

5.2.2 Check for running noises If the gear unit produces unusual running noises or vibrations, this could indicate damage to the gear unit. In this case the gear unit must be repaired immediately. Please contact the NORD Service department. 5.2.3 Check fan and spaces between the ribs (Maxxdrie XT) (Option: FAN-A, FAN-R) Keep the inlet and outlet on the fan cover and the fan wheel free from dirt. -

Page 77: Cleaning The Heat Exchanger (Option: Cs2-X)

5 Service and maintenance 5.2.4 Cleaning the heat exchanger (Option: CS2-X) Clean the heat exchanger of the oil/air cooler (Option: CS2-X) regularly in order to maintain the efficiency. Pay attention to the operating instructions of the oil/air cooler. 5.2.5 Oil level The installation position must comply with the version on the name plate. -

Page 78: Oil Level Screw

Industrial gear units – Manual with installation instructions 5.2.5.1 Oil level screw 1. The corresponding oil level screw must be removed. 2. Check the oil level in the gear unit with the dipstick supplied (Part No.: 28300500), as shown in Figure 33. -

Page 79: Oil Level Tanks (Option: Ot)

Damage to the gear unit due to high oil level If the gear unit is delivered with oil and installation position M5 the oil reservoir tank vessel is completely filled by NORD. High oil levels may result in damage to the gear unit. •... -

Page 80: Seal Adapter For Agitators (Option: Safomi)

Industrial gear units – Manual with installation instructions 5.2.5.6 No-seal adapter for agitators (Option: SAFOMI) NOTICE Damage to the gear unit due to insufficient lubricant Oil foam formation may indicate contamination of the oil, e.g. due to the entry of foreign liquids. Contamination impairs the lubricant properties of the gear oil and may result in damage to the gear unit. - Page 81 5 Service and maintenance Information Incorrect oil level indication due to formation of vacuum with the version without a vent pipe for the air space When draining the oil, or in case of leaks, a vacuum may form above the oil bath in the gear unit. This may cause incorrect indication of the oil fill level in the 3D oil inspection glass.

-

Page 82: Visual Inspection Of The Rubber Elements Of The Elastic Torque Arm (Option: Ed)

The piping of lubrication circulation systems or vent lines for full oil level in combination with oil level tanks must be checked for leaks. The affected pipes must be replaced in case of leaks. In this case, please contact NORD Service. 5.2.7.2 Hose lines (Option: LC, LCX, CS1-X, CS2-X, OT) Hose lines are used as intake and pressure lines for lubricant circulation and for cooling units. -

Page 83: Oil Change

Wear protective gloves and goggles when changing the oil. Information Getriebebau NORD recommends regular analysis of the gear oil to optimise the oil change interval. The position of the oil drain screw or the optional drain tap, the vents and devices for checking the oil level should be obtained from the order-related dimension sheet. -

Page 84: Checking The Cooling Coil For Deposits (Option: Cc)

(copper pipe and brass fittings). Check the cooling coil and the cover for leaks if strong corrosion is found on the connections. Please contact the NORD Service department. 5.2.12 Cleaning or replacing the vent 5.2.12.1 Vent filter (Option: FV) The ventilation filter uses a wire mesh as the filter material and enables an equalisation of pressure between the interior of the gear unit and the environment. -

Page 85: Drying Agent Filter / Wet Air Filter (Option: Db)

5 Service and maintenance 5.2.12.3 Drying agent filter / Wet air filter (Option: DB) Legend Second filter element Polycarbonate housing Foam pad Connecting thread Air inlet Filter element Silica gel Active carbon pad (optional) Foam pad Figure 38: Drying agent filter, example version Drying agent filters are intended to prevent damp oil, condensation and rust in the system, as well as to increase the service life of the oil and the machine filters. -

Page 86: Replacing The Shaft Sealing Ring

MSS7 seals are two-part seals which consist of a liner with an axial dust lip and a radial shaft sealing ring with a radial dust lip (Figure 40: MSS7 seal). Please contact the NORD Service department in case of any queries. -

Page 87: Re-Lubricating The Bearing In The Output Flange (Option: Vl2/3/4/6, Kl2/3/4/6)

Exceptions to this are gear units SK 5..07 to SK 6..07 in installation position M5/M6. In this installation position, the upper bearings are lubricated with grease. Please contact the NORD Service department for replacement of the grease in the roller bearings. Recommended grease: Petamo GHY 133N - Klüber Lubrication. (see chapter 7.3.1 "Roller bearing greases") -

Page 88: Re-Greasing The Taconite Seal

Industrial gear units – Manual with installation instructions Quantity Grease quantity VL [g] Grease quantity KL [g] SK5.07 SK6.07 SK7.07 SK8.07 SK9.07 SK10.07 SK11.07 SK12.07 SK13.07 SK14.07 SK15.07 Table 14: Grease quantities for re-greasing the lower output shaft bearing 5.2.16 Re-greasing the Taconite seal Input and/or output shafts may be equipped with Taconite seals, depending on the version. -

Page 89: Checking V-Belts (Belt Drives)

5 Service and maintenance 5.2.17 Checking v-belts (belt drives) WARNING Entanglement hazard • The protective cover must be correctly installed before re-commissioning. V-belt pulleys should be visually inspected at regular intervals. In case of severe signs of wear, a V-groove and profile gauge should be used as an aid to determine the degree of wear. Dirt on the belt pulley or the belts causes friction losses. -

Page 90: Figure 42: Examples Of Inspection Covers

Industrial gear units – Manual with installation instructions Figure 42: Examples of inspection covers Checking inspection covers 1. Check fastening screws for firm fit. 2. Check sealing of the cover. If sealings or screws are damaged or not usable, replace them. Proceed as described below. Disassembly of the inspection cover 1. -

Page 91: General Overhaul

We recommend that the general overhaul is carried out by the NORD Service Department. During general overhaul, the gear unit is completely dismantled. The following work steps are carried out: •... -

Page 92: Disposal

Industrial gear units – Manual with installation instructions 6 Disposal Observe the current local regulations. In particular, lubricants must be collected and disposed of correctly. Gear unit components Material Gearwheels, shafts, roller bearings, keys, circlips, … Steel Gear unit housing, housing components, … Grey cast iron Light alloy gear unit housing, light alloy housing components, …... -

Page 93: Appendix

7 Appendix 7 Appendix 7.1 Versions and mounting position 7.1.1 Parallel gear units Figure 43: Helical gear unit installation positions with standard mounting surface B 1050 en-3921... -

Page 94: Helical Bevel Gear Unit

Industrial gear units – Manual with installation instructions 7.1.2 Helical bevel gear unit Figure 44: Bevel gear unit installation positions with standard mounting surface 7.2 Standard positions of the oil drain, vent and oil level The configuration and the position of the oil drain, vent and oil level should be primarily obtained from the dimension sheet for the order. - Page 95 7 Appendix 5x17 – 5x07, 6x07 7x07-10x07 11x07-15x07 11x17 207 307 407 507 207 307 407 507 207 307 407 507 sight glass 7/13 7/13 7/13 7/13 7/13 7/13 4/12 4/12 4/12 gauge Dipstic 15/17 /OT 15/17 /OT 15/17 /OT 15/17 /OT 15/18 /OT 15/18 /OT 9/10...

-

Page 96: Table 16: Position Of Housing Options On Oil Screw Holes (Standard Installation Positions)

Industrial gear units – Manual with installation instructions 5x17 – 5x07, 6x07 7x07-10x07 11x07-15x07 11x17 207 307 407 507 207 307 407 507 207 307 407 507 16/17 /OT 16/17 /OT 9/10 9/10 9/10 /OT 9/10 9/10 9/10 13/14 /OT 13/14 /OT Key: Housing Standard position in housing... - Page 97 7 Appendix Gear units SK 5207 – SK 10507 M1 oil screw holes B 1050 en-3921...

- Page 98 Industrial gear units – Manual with installation instructions Gear units SK 5207 – SK 10507 M2 oil screw holes B 1050 en-3921...

- Page 99 7 Appendix Gear units SK 5207 – SK 10507 M3 oil screw holes B 1050 en-3921...

- Page 100 Industrial gear units – Manual with installation instructions Gear units SK 5207 – SK 10507 M4 / oil screw holes B 1050 en-3921...

- Page 101 7 Appendix Gear units SK 5207 – SK 10507 M5 oil screw holes B 1050 en-3921...

-

Page 102: Figure 45: Numbering Of Oil Screw Holes On Sk 5207 - Sk 10507

Industrial gear units – Manual with installation instructions Gear units SK 5207 – SK 10507 M6 oil screw holes Figure 45: Numbering of oil screw holes on SK 5207 – SK 10507 B 1050 en-3921... - Page 103 7 Appendix Gear units SK 11207 – SK 15507 M1 oil screw holes B 1050 en-3921...

- Page 104 Industrial gear units – Manual with installation instructions Gear units SK 11207 – SK 15507 M2 oil screw holes B 1050 en-3921...

- Page 105 7 Appendix Gear units SK 11207 – SK 15507 M3 oil screw holes B 1050 en-3921...

- Page 106 Industrial gear units – Manual with installation instructions Gear units SK 11207 – SK 15507 M4 oil screw holes B 1050 en-3921...

- Page 107 7 Appendix Gear units SK 11207 – SK 15507 M5 oil screw holes B 1050 en-3921...

-

Page 108: Figure 46: Numbering Of Oil Screw Holes On Sk 11207 - Sk 15507

Industrial gear units – Manual with installation instructions Gear units SK 11207 – SK 15507 M6 oil screw holes Figure 46: Numbering of oil screw holes on SK 11207 – SK 15507 B 1050 en-3921... - Page 109 7 Appendix Gear units SK 5217 – SK 11217 M1 oil screw holes B 1050 en-3921...

- Page 110 Industrial gear units – Manual with installation instructions Gear units SK 5217 – SK 11217 M4 oil screw holes B 1050 en-3921...

- Page 111 7 Appendix Gear units SK 5217 – SK 11217 M5 oil screw holes B 1050 en-3921...

-

Page 112: Figure 47: Numbering Of Oil Screw Holes On Sk 5217 - Sk 11217

Industrial gear units – Manual with installation instructions Gear units SK 5217 – SK 11217 M6 oil screw holes Figure 47: Numbering of oil screw holes on SK 5217 – SK 11217 B 1050 en-3921... -

Page 113: Lubricants

This table shows comparable roller bearing greases from various manufacturers. The manufacturer can be changed within a grease type. Only change lubricant type or ambient temperature range after consultation with Getriebebau NORD. Otherwise no guarantee can be accepted for the function of the gear unit. -

Page 114: Gear Oils

This table shows comparable lubricants from various manufacturers. The oil manufacturer can be changed within a viscosity and lubricant type. Only change the lubricant type or the viscosity after consultation with Getriebebau NORD. Mixing different oil types is not permissible. When changing gear oil, different oils of one oil type with the same viscosity may be mixed in a maximum ratio of 1/20 (5 %). -

Page 115: Table 18: Lubricant Oil Table

7 Appendix Viscosity class Renolin PG 150 Klübersynth CLP PG 150 GH 6-150 Renolin PG 220 Klübersynth CLP PG 220 GH 6-220 Renolin PG 320 Klübersynth CLP PG 320 GH 6-320 Renolin PG 460 Klübersynth CLP PG 460 GH 6-460 Klübersynth CLP PG H1 150 UH 1 6-150... -

Page 116: Minimum Starting Temperatures

Industrial gear units – Manual with installation instructions 7.3.3 Minimum starting temperatures Depending on the type of lubrication, the lubricant class, as well as the ambient temperature and additional heating and cooling methods, minimum requirements for the specific oil must be taken into consideration for selection and commissioning. -

Page 117: Lubricant Quantities

7 Appendix 7.3.4 Lubricant quantities The lubricating oil quantity stated on the type plate is a guideline value. The precise quantity varies depending on the exact gear ratio and any options (e.g. OSG, OST, OT). Ensure that the oil level is correct. Adjust the oil level as necessary (see Section 5.2.5 "Oil level"). Information After changing the lubricant, and in particular after the initial filling, the oil level may change during the first few hours of operation, as the oil galleries and hollow spaces only fill gradually during operation. -

Page 118: Screw Tightening Torques

Industrial gear units – Manual with installation instructions 7.4 Screw tightening torques Screw tightening torques [Nm] Screw fastenings in strength classes Screw Threaded pin fastenings on Dimensions Cap screws 10.9 12.9 V2A-70 on coupling covers V4A-70 1150 1300 1600 2250 2650 1400 2780... -

Page 119: Troubleshooting

Shut down the gear unit immediately in case of malfunction. Gear unit malfunctions Fault Possible cause Remedy Oil level too low Correct oil level, Consult NORD Service Bearing damage Consult NORD Service Unusual running noises, Gear wheel damage Consult NORD Service vibrations... -

Page 120: Table 22: Overview Of Malfunctions

Shrink disc slip Check shrink disc rotate although motor is running Breakage in gear unit Consult NORD Service Cooling system defective Observe the separate operating manual Cooling system failure Pump does not deliver oil Check pump and replace as necessary... -

Page 121: Leakage And Leak-Tightness

7 Appendix 7.7 Leakage and leak-tightness Gear units are filled with oil or grease to lubricate the moving parts. Seals prevent the escape of lubricants. A complete seal is technically not possible, as a certain film of moisture, for example on the radial shaft sealing rings is normal and advantageous for a long-term seal. -

Page 122: Noise Emissions

7.10 Warranty NORD GmbH & Co. KG accepts no liability for damage to persons, materials or assets as a result of failure to observe this operating manual, operating errors or incorrect use. General wearing parts, e.g. radial seals are excluded from the warranty. -

Page 123: Abbreviations

Counter-clockwise, left rotation Personal Protective Equipment °dH Water hardness in German hardness degrees Directive 1 dH = 0.1783 mmol/l Deutsches Institut für Normung [German Volatile Corrosion Inhibitor Standards Institute] Ester oil Viscosity group European Community Document from Getriebebau NORD B 1050 en-3921... - Page 124 Industrial gear units – Manual with installation instructions Key word index Flange ............41 Address ............122 Agitator version ........26, 87 Gear unit types ..........16 Ambient temperature ........116 General overhaul .......... 91 Auxiliary drive unit ......... 24 GRIPMAXX™...

- Page 125 Key word index Repairs ............122 Roller bearing greases ........ 113 Name plate ............ 20 Running noises ..........76 Noise emission ..........122 Noise level ........... 122 Safety information ......... 13 SAFOMI ............80 Oil change ............. 83 Sensors ............57 Oil dip-stick ............

- Page 126 Industrial gear units – Manual with installation instructions B 1050 en-3921...

- Page 127 Key word index B 1050 en-3921...

Need help?

Do you have a question about the MAXXDRIVE B 1050 and is the answer not in the manual?

Questions and answers