Summary of Contents for nord BIM 1001

- Page 1 BIM 1004 MOTORS AC Induction, Single and Polyphase Installation and Maintenance Instructions BIM 1004/2007/09 Page 1 of 20 www.nord.com...

- Page 2 NOTES BIM 1004/2007/09 Page 2 of 20 www.nord.com...

-

Page 3: Table Of Contents

Conduit Hole Thread Size & NPT Adapters..............15 Table 6 Motor Option Codes & Nomenclature................17 Table 7 Space Heater Data......................19 Table 8 Encoder Wiring Designations ................... 19 Table 9 Blower Cooling Fan Data ....................20 BIM 1004/2007/09 Page 3 of 20 www.nord.com... -

Page 4: Introduction

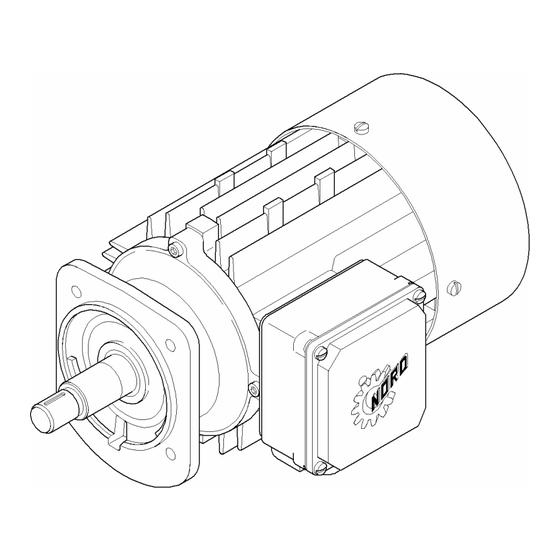

Table 1. Related Publications DESCRIPTION AND OPERATION General This manual provides general installation and maintenance information for the NORD family of motors described in this section. Description The NORD motors covered in this manual are single phase and poly-phase motors (refer to Table 2), can be single speed or two-speed, and may include the options listed in the Motor Options Section. -

Page 5: Figure 1 Motor Nameplates

E 191510 LR 112560 NEMA DUTY % PF ° C ENCL CODE Brake www.nord.com E 191510 LR 112560 NEMA DUTY % PF ° C ENCL CODE Brake Figure 1. Motor Nameplates Field Definition Field Definition Model Number ENCL Enclosure Description... -

Page 6: Inspection

NORD Gear Corporation Manual BIM- or replace the brake pad according to the 1090, Motor Brakes Installation and instructions in NORD Gear Corporation Maintenance Instructions. -

Page 7: Testing And Fault Isolation

General NOTE: NORD electric motors do not require periodic testing. However, if a motor is removed from its installation, NORD recommends that the motor be checked according to the static and dynamic testing provided below before it is reinstalled. Finding a condition that will require future repair before the motor is reinstalled decreases the overall maintenance time. -

Page 8: Table 4 Motor Fault Isolation

If the motor bearing drag increases as the motor operates, replace the bearings according to REPAIR. Table 4. Motor Fault Isolation BIM 1004/2007/09 Page 8 of 20 www.nord.com... -

Page 9: Lubrication

Observe all WARNINGs and CAUTIONs. If you have any questions about the procedure to use to handle, install, or remove a specific motor, call NORD Gear Corporation. Please read the following WARNINGS & CAUTIONS prior to any work on the motor. - Page 10 Installation with NEMA and IEC Flanges Refer to NORD Gearbox Inputs Installation and Maintenance Instructions in BIM1009. Make sure the flanges are clean and free of gasket material. Install a new gasket between the mating flanges, if applicable. Carefully move the motor to insert the motor shaft and its hub/sheave into the adapter spline, making sure the shaft key enters the mating keyway.

- Page 11 C. Before placing the motor in service, visually inspect the motor exterior for evidence of deterioration during storage. Turn the motor shaft by hand to make sure the shaft turns smoothly and freely. BIM 1004/2007/09 Page 11 of 20 www.nord.com...

-

Page 12: Connection Diagrams

V1 T2 U1 T1 W1 T3 V5 T8 V2 T5 U2 T4 U5 T7 W2 T6 W5 T9 Low Voltage low voltage Figure 2. Motor Connection and Wiring Diagrams BIM 1004/2007/09 Page 12 of 20 www.nord.com... -

Page 13: Repair

REPAIR General These instructions can be generally applied to NORD motor applications. The exploded view provided in the PARTS INFORMATION section shows the parts orientation for NORD motors. To procure replacement parts from NORD, contact NORD’s customer service department (refer to INTRODUCTION). -

Page 14: Parts List

Retaining Ring Fan Clip NPT Thread Adapter ** See Table 5 for part numbers ** Plug (includes O-ring) TBLK Terminal Block TBLK-1 Screw, Terminal Block Mounting ø ø ø Jumper Bar (not illustrated) BIM 1004/2007/09 Page 14 of 20 www.nord.com... -

Page 15: Figure 3 General Motor Exploded View And Generic Parts List (2

M25x1.5–3/4” NPT 18524250 M25x1.5–3/4” NPT 18524250 2xM32x1.5 M32x1.5–1” NPT 18524320 2xM40x1.5 M40x1.5–1.5” NPT 18524400 M40x1.5–1.5” NPT 18524400 2xM50x1.5 M50x1.5–1.5” NPT 118524170 M50x1.5–1.5” NPT 118524170 2xM63x1.5 Table 5. Conduit Hole Thread Size & NPT Adapters BIM 1004/2007/09 Page 15 of 20 www.nord.com... - Page 16 Figure 3. General Motor Exploded View and Generic Parts List (Sheet 2 of 2) BIM 1004/2007/09 Page 16 of 20 www.nord.com...

-

Page 17: Motor Options & Nomenclature

MOTOR OPTIONS & NOMENCLATURE General NORD offers many options for its motors. The option code will be shown in the motor nomenclature. Below are the available options Code Description Code Description With Brake TENV Motor – Without Fan Brake – Corrosion Protected OL/H TENV Motor - Without Fan &... -

Page 18: Table 7 Space Heater Data

18900810 110V 18900820 90 – 112 230V 18900800 460V 18900810 110V 18900830 132-180 100W 230V 18900840 460V 18900850 110V 18900860 230V 18900870 200 & 225 120W 460V 18900880 Table 7. Space Heater Data BIM 1004/2007/09 Page 18 of 20 www.nord.com... -

Page 19: Table 8 Encoder Wiring Designations

Signal line (0-) Brown Signal line (A+) (A+) Green Signal line (A-) Gray Signal line (B+) (B+) White/ Common Green White 0 V sens 0 V sens Sense Common Brown/ Supply Voltage Green BIM 1004/2007/09 Page 19 of 20 www.nord.com... -

Page 20: Table 9 Blower Cooling Fan Data

380-500 0.16 F132 380-575 0.14 380-500 0.18 F160 380-575 0.28 380-500 0.30 F180 380-575 0.28 380-500 0.30 F200 380-575 0.28 380-500 0.30 F225 380-575 0.28 380-500 0.30 Table 9. Blower Cooling Fan Data BIM 1004/2007/09 Page 20 of 20 www.nord.com...

Need help?

Do you have a question about the BIM 1001 and is the answer not in the manual?

Questions and answers