Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for ESD CAN-CBX-Pt100

- Page 1 CAN-CBX_Pt100 Page 1 of 120 Manual • Doc.-No.: C.3032.21 / Rev. 1.1 esd electronic system design gmbh Vahrenwalder Str. 207 • 30165 Hannover • Germany http://www.esd.eu Phone: +49 (0) 511 3 72 98-0 • Fax: +49 (0) 511 3 72 98-68...

- Page 2 The information in this document has been carefully checked and is believed to be entirely reliable. esd makes no warranty of any kind with regard to the material in this document, and assumes no responsibility for any errors that may appear in this document. In particular descriptions and technical data specified in this document may not be constituted to be guaranteed product features in any legal sense.

- Page 3 Document- I:\Texte\Doku\MANUALS\CAN\CBX\PT100\Englisch\CAN-CBX-PT100_Manual_en_11.wpd File: 2014-12-19 Date of print: CAN-CBX_Pt100 Rev. 1.0 PCB version: from V 2.03 Firmware version: Changes in the chapters The changes in the document listed below affect changes in the hardware and firmware as well as changes in the description of facts only. Revision Chapter Changes versus previous version...

- Page 4 The intended use of the CAN-CBX module is the operation as a CANopen slave with temperature sensor. The esd guarantee does not cover damages which result from improper use, usage not in accordance with regulations or disregard of safety instructions and warnings.

-

Page 5: Table Of Contents

Contents 1. Overview ..............8 1.1 Description of the Module . - Page 6 7.6 Support by esd ........

-

Page 7: Overview

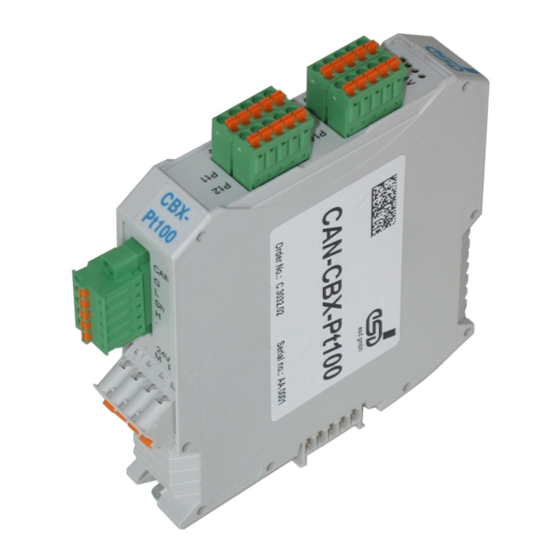

8.9.23 Self Starting Nodes Timing Parameters (1F91 ) ......80 8.9.24 Object Transmit PDO Communication Parameter 1800 - 1803 . - Page 8 Overview 1. Overview 1.1 Description of the Module Fig. 1: Block circuit diagram of the CAN-CBX_Pt100 module The CAN-CBX_Pt100 module is a CAN-CBX module designed for the connection of four temperature sensors. Simple electric resistance measurement can also be performed. Pt- and Ni- resistance sensors are supported.

-

Page 9: Quick Start

Quick Start 2. Quick Start Connect module (see connection diagram page 14) Write “-1” (FFFF FFFF ) in object 9133 (sub-index 1...4) (With every new A/D-conversion a TPDO with the measured value is sent.) Send NMT-Start command to module The PDOs are sent on 0180 + Module number 0280... -

Page 10: Technical Data

Technical Data 3. Technical Data 3.1 General technical Data nominal voltage: 24 V/DC Power supply voltage input voltage range: 24 V ±20% current consumption (24 V, 20 C): typical: ca. 120 mA (4-pin line connector with spring-cage connection, X100 ) - 24V-power supply voltage InRailBus (5-pin TBUS-connector, X101) - CAN interface and power supply voltage via InRailBus (5-pin line connector with spring-cage connection, X500A) -

Page 11: Microcontroller

Technical Data 3.2 Microcontroller Microcontroller 16 bit C MB90F497 2 Kbyte integrated Flash 64 Kbyte integrated EEPROM minimum 256 byte Table 2: Microcontroller 3.3 CAN Interface Number 5-pin line connector with spring-cage connection Connection or via InRailBus-connector (CAN-CBX-TBUS ) CAN Controller integrated in MB90F497, ISO11898-1 Electrical isolation of CAN Isolation voltage U: 500 V... -

Page 12: Sensor Resistor Inputs

The firmware of the module comes with CANopen® firmware according to CiA 301 [1] and supports the CiA DS 404 [4] profile for measuring devices. The CAN-CBX-Pt100 EDS-file can be downloaded from the esd website www.esd.eu. Page 12 of 120 CAN-CBX_Pt100 Manual •... -

Page 13: Connecting Diagram

Hardware Installation 4. Hardware Installation 4.1 Connecting Diagram 4.1.1 Power Supply and CAN Fig. 2: Connections of the CAN-CBX_Pt100 module Note: Please refer to page 33 for information on conductor connection and conductor cross section. The connector pin assignments can be found on page 27 and following. CAN-CBX_Pt100 Page 13 of 120 Manual •... -

Page 14: Connect Temperature Sensor In 2-Wire Configuration (Example Pt2)

Hardware-Installation 4.1.2 Connect Temperature Sensor in 2-Wire Configuration (Example Pt2) Fig. 3: Example temperature sensor connection in 2-wire configuration at Pt2 Note: Please refer to page 33 for information on conductor connection and conductor cross section. The connector pin assignments can be found on page 27 and following. Page 14 of 120 CAN-CBX_Pt100 Manual •... -

Page 15: Connect Temperature Sensor In 4-Wire Configuration (Example Pt2)

Hardware Installation 4.1.3 Connect Temperature Sensor in 4-Wire Configuration (Example Pt2) Fig. 4: Example temperature sensor connection in 4-wire configuration at Pt2 Note: Please refer to page 33 for information on conductor connection and conductor cross section. The connector pin assignments can be found on page 27 and following. CAN-CBX_Pt100 Page 15 of 120 Manual •... -

Page 16: Led Display

4.2 LED Display Fig. 5: Position of the LEDs in the front panel The CAN-CBX-Pt100 module is equipped with 4 status LEDs. The terms of the indicator states of the LEDs are chosen in accordance with the terms recommended by the CiA [3]. The indicator states are described in the following chapters. -

Page 17: Operation Of The Can-Error Led

Hardware Installation Note: Red and green LEDs are strictly switched in phase opposition according to the CANopen Specification [3]. For certain indicator states viewing all LEDs together might lead to a misinterpretation of the indicator states of adjacent LEDs. It is therefore recommended to look at the indicator state of an LED individually, by covering the adjacent LEDs. -

Page 18: Operation Of The Error-Led

Hardware-Installation 4.2.4 Operation of the Error-LED LED indication Display function Indicator Label Name Colour Description state no error CAN Overrun Error The sample rate is set too high, therefore the firmware is not able to transmit all data on the CAN bus. Internal software error e.g.: - stored data have an invalid checksum therefore... -

Page 19: Special Indicator States

Hardware Installation 4.2.6 Special Indicator States The special indicator state described in the following table is indicated by the CANopen-Status-LED and the CAN-Error-LED together: LED indication Description - CANopen-Status LED: 3 flashes Invalid nodeID: - CAN-Error LED: on The coding switches for the Node-ID are set to an invalid ID-value, when switching on. -

Page 20: Coding Switches

Hardware-Installation 4.3 Coding Switches Fig. 6: Position of the coding switches Attention: At the moment the module is switched ‘on’, the state of the coding switches is determined. Changes of the settings therefore have to be made before switching on the module, because changes of the settings are not determined during operation. -

Page 21: Setting The Baud Rate

Hardware Installation 4.3.2 Setting the Baud Rate The baud rate can be set with the coding switch Baud. Values from 0 to F can be set via the coding switch. The values of the baud rate can be taken from the following table: Bit rate Setting... - Page 22 Hardware-Installation 4.4 Installation of the Module Using InRailBus Connector If the CAN bus signals and the power supply voltage shall be fed via the InRailBus, please proceed as follows: Figure 7: Mounting rail with bus connector Position the InRailBus connector on the mounting rail and snap it onto the mounting rail using slight pressure.

-

Page 23: Connecting Power Supply And Can-Signals To Cbx-Inrailbus

Hardware Installation When mounting the CAN-CBX module the metal foot catch snaps on the bottom edge of the mounting rail. Now the module is mounted on the mounting rail and connected to the InRailBus via the bus connector. Connect the bus connectors and the InRailBus if not already done. Figure 9: Mounted CAN-CBX module 4.4.1 Connecting Power Supply and CAN-Signals to CBX-InRailBus To connect the power supply and the CAN-signals via the InRailBus, a terminal plug is needed. -

Page 24: Connection Of The Power Supply Voltage

Hardware-Installation 4.4.2 Connection of the Power Supply Voltage The power supply voltage can be supplied via the 24V connector or via the InRailBus. Attention! Please note the safety instructions containing the requirements on power supply current circuits (see page 4)! Attention! The connections for the 24 V power supply are internally connected and must not be supplied by two independent power sources at the same time! -

Page 25: Connection Of Can

Hardware Installation 4.4.3 Connection of CAN Fig. 12: Connecting the CAN signals to the CAN-CBX station Generally the CAN signals can be fed via the CAN connector of the first CAN-CBX module of the CBX station. The signals are then connected through the CAN-CBX station via the InRailBus. To loop the CAN signals through the CBX station the CAN bus connector of the last CAN-CBX module of the CAN-CBX station has to be used. -

Page 26: Connector Assignment

Connector Pin Assignment 5. Connector Assignment 5.1 Power Supply Voltage 24 V (X100) Device connector: Phoenix-Contact MSTBO 2,5/4-G1L-KMGY Line connector: Phoenix-Contact FKCT 2,5/4-ST, 5.0 mm pitch, spring-cage connection, Phoenix-Contact order no.: 19 21 90 0 (included in the scope of delivery) For conductor connection and conductor cross section see page 33. -

Page 27: Can

Connector Pin Assignment 5.2 CAN 5.2.1 CAN Interface The physical layer is designed according to ISO 11898-2. The CAN bus signals are electrically isolated from the other signals via a digital isolator and a DC/DC converter. Fig. 13: CAN Interface The CAN interface can be connected via the CAN connector or optionally via the InRailBus. -

Page 28: Can Connector

Connector Pin Assignment 5.2.2 CAN Connector Device Connector: Phoenix-Contact MC 1,5/5-GF-3,81 Line Connector: Phoenix-Contact FK-MCP 1,5/5-STF-3,81, spring-cage connection, Phoenix-Contact order no.:1851261 (included in the scope of delivery) For conductor connection and conductor cross section see page 33. Pin Position: Pin-Assignment: (line connector with labelling) Labelling Signal... -

Page 29: Can And Power Supply Voltage Via Inrailbus Connector

Connector Pin Assignment 5.2.3 CAN and Power Supply Voltage via InRailBus Connector Connector type: Mounting rail bus connector CAN-CBX-TBUS (Phoenix-Contact ME 22,5 TBUS 1,5/5-ST-3,81 KMGY) Pin Position: Pin Assignment: Signal (GND) (+24 V) CAN_GND CAN_L CAN_H (PE_GND) Signal Description: CAN_L, CAN_H ... -

Page 30: Temperature Sensor Interface Pt1

Connector Pin Assignment 5.3 Temperature Sensor Interface Pt1...Pt4 Device connector: 2x Phoenix Contact MCDN 1,5/5-G1-3,5P26THR Line connector: 4x Phoenix Contact FMC 1,5/5-ST-3,5 (spring-cage connection) Phoenix Contact order no: 1952296 (included in the scope of delivery) For conductor connection and conductor cross section see page 33. Pin Position: Signal description: Pin Signal... -

Page 31: Assignment Of Module Labelling To Name In Schematic Diagram

Connector Pin Assignment 5.3.1 Assignment of Module Labelling to Name in Schematic Diagram Labelling on the Name Schematic Diagram* CAN-CBX_Pt100 X500:A X500:B X800:A X800:B The schematic diagram is not part of this manual. CAN-CBX_Pt100 Page 31 of 120 Manual • Doc.-No.: C.3032.21 / Rev. 1.1... -

Page 32: Conductor Connection/Conductor Cross Sections

Connector Pin Assignment 5.4 Conductor Connection/Conductor Cross Sections The following table contains an extract of the technical data of the line connectors. Power Supply Temperature CAN- Interface Voltage Sensor Connector 24 V Interface Connector type plug component FKCT 2,5/..- FK-MCP (Range of articles) ST KMGY 1,5/..-STF-... -

Page 33: Correct Wiring Of Electrically Isolated Can Networks

Therefore the practical maximum number of nodes, bus length and stub length are typically much lower. esd has concentrated her recommendations concerning CAN wiring on the specifications of the ISO 11898-2. Thus this wiring hints forgoes to describe the special features of the derived standards CANopen, ARINC825, DeviceNet and NMEA2000. -

Page 34: Light Industrial Environment (Single Twisted Pair Cable)

6.2.1 General Rules Note: esd grants the EU Conformity of the product, if the CAN wiring is carried out with at least single shielded single twisted pair cables that match the requirements of ISO 118982-2. Single shielded double twisted pair cable wiring as described in chapter 6.3 ensures the EU Conformity as well. -

Page 35: Cabling

9-pin DSUB-termination connectors with integrated termination resistor and male and female contacts (gender changer) are available from esd (order no. C.1303.01). DSUB termination connectors with male contacts (order no. C.1302.01) or female contacts (order no. C.1301.01) and additional functional earth contact are available, if CAN termination and grounding of CAN_GND is required. -

Page 36: Heavy Industrial Environment (Double Twisted Pair Cable)

Wiring Notes 6.3 Heavy Industrial Environment (Double Twisted Pair Cable) 6.3.1 General Rules The following general rules for CAN wiring with single shielded double twisted pair cable should be followed: A cable type with a wave impedance of about 120 ±10% with an adequate wire cross-section ( 0.22 mm²) has to be used. -

Page 37: Device Cabling

DSUB9-connector from ERNI (ERBIC CAN BUS MAX, order no.:154039). The usage of esd’s T-connector type C.1311.03 is not recommended for single shielded double twisted pair cables because the shield potential of the conductive DSUB housing is not looped through this T-connector type. -

Page 38: Electrical Grounding

Table 12: Recommended cable lengths at typical bit rates (with esd-CAN interfaces) Optical couplers are delaying the CAN signals. esd modules typically reach a wire length of 37 m at 1 Mbit/s within a proper terminated CAN network without impedance disturbances like e.g. -

Page 39: Examples For Can Cables

Wiring Notes 6.6 Examples for CAN Cables esd recommends the following two-wire and four-wire cable types for CAN network design. These cable types are used by esd for ready configured CAN cables, too. 6.6.1 Cable for Light Industrial Environment Applications (Two-Wire) -

Page 40: Can Troubleshooting Guide

CAN Troubleshooting Guide 7. CAN Troubleshooting Guide The CAN Troubleshooting Guide is a guide to find and eliminate the most frequent hardware-error causes in the wiring of CAN networks. Figure. 18: Simplified diagram of a CAN network 7.1 Termination The termination is used to match the impedance of a node to the impedance of the transmission line being used. -

Page 41: Electrical Grounding

CAN Troubleshooting Guide 7.2 Electrical Grounding CAN_GND of the CAN network should be connected to Functional earth potential (FE) at only one point. This test will indicate if the CAN_GND is grounded in several places. To test it, please 1. Disconnect the CAN_GND from the earth potential (FE). -

Page 42: Can Transceiver Resistance Test

(>> 200%). Figure 20: Simplified diagram of a CAN node 7.6 Support by esd If you have executed the fault diagnostic steps of this troubleshooting guide and you even can not find a solution for your problem our support department will be able to assist. -

Page 43: Canopen Firmware

CANopen Firmware 8. CANopen Firmware Apart from basic descriptions of CANopen, this chapter contains the most significant information about the implemented functions. A complete CANopen description is too extensive for the purpose of this manual. Further information can therefore be taken from the CANopen documentation [1] and [4]. 8.1 Definition of Terms COB ... -

Page 44: Nmt-Boot-Up

CANopen-Firmware 8.2 NMT-Boot-up The CAN-CBX module can be initialized with the ‘Minimum Capability Device’ boot-up as described in [1]. Usually a telegram to switch from Pre-Operational status to Operational status after boot-up is sufficient. For this the 2-byte telegram ‘01 ’, ‘00 ’, for example, has to be transmitted with CAN- identifier ‘0000... -

Page 45: Communication Parameters Of The Pdos

CANopen Firmware 8.4 Communication Parameters of the PDOs The communication parameters of the PDOs (according to [1]) are transmitted as SDO (Service Data Objects) on ID ‘600 + Node-ID’ (Request). The receiver acknowledges the parameters on ID ‘580 + Node-ID’ (Response). The Node-ID (module No.) is configured via coding switches Low and High. - Page 46 CANopen-Firmware The CAN-CBX-module responds to every received telegram with a response telegram. This can contain the following command codes: = 67 : Read Response with 32 bit data, this telegram contains the parameter requested = 96 : Write Response, i.e. a parameter has been set successfully = 128 : Error Response, i.e.

- Page 47 CANopen Firmware Error Codes of the SDO Domain Transfer The following error codes might occur (according to [1]): Abort code Description 05040001 wrong command specifier 06010002 wrong write access 06020000 wrong index 06040041 object can not be mapped to PDO 06060000 access failed due to an hardware error 06070010...

-

Page 48: Overview Of Used Canopen-Identifiers

CANopen-Firmware 8.5 Overview of used CANopen-Identifiers Identifier Function Description [Hex] Network management SYNC Sync to all, (configurable via object 1005 Emergency Message + NodeID configurable via object 1014 TPDO1 + NodeID PDO1 from CAN-CBX_Pt100 (object 1800 TPDO2 + NodeID PDO2 from CAN-CBX_Pt100 (object 1801 TPDO3 + NodeID PDO3 from CAN-CBX_Pt100 (object 1802... -

Page 49: Default Pdo-Assignment

CANopen Firmware 8.6 Default PDO-Assignment PDOs (Process Data Objects) are used to transmit process data. The PDO mapping can be changed. The following tables show the default mapping at delivery of the module: CAN Identifier Length Transmission direction Assignment TPDO1 + Node-ID 4 byte Process value 1 (9130... -

Page 50: Reading The Analog Values

CANopen-Firmware 8.7 Reading the Analog Values 8.7.1 Messages of the Analog Inputs The transmission types for the analog inputs are described in the following: acyclic, synchronous: The transmission is initiated if a SYNC-message has been received (PDO- transmission type 0) and data has changed. cyclic, synchronous: The transmission is initiated if a defined number of SYNC-messages have been received (PDO-transmission type 1...240). -

Page 51: Communication Profile Area

CANopen Firmware 8.8 Communication Profile Area 8.8.1 Used Names and Abbreviations The following names are used in the tables for the description of the communication parameters: PDO-Mappable PDO-Mapping is possible for this Sub-index of the PDO Save to EEPROM the value of this parameter is stored in the local EEPROM, if the command ‘save’... -

Page 52: Implemented Canopen-Objects

Implemented CANopen Objects 8.9 Implemented CANopen-Objects A detailed description of the objects can be taken from the standard CiA 301 [1]. 8.9.1 Overview of used 1000-Objects and Default Values Sub- Access Product-specific Index index Description Data type mode values (max.) 1000 Device Type unsigned 32... - Page 53 Implemented CANopen Objects Sub- Access Index Description Data type index mode (max.) 1800 1. Transmit PDO-Parameter PDO CommPar (20 1801 2. Transmit PDO-Parameter PDO CommPar (20 1802 3. Transmit PDO-Parameter PDO CommPar (20 1803 4. Transmit PDO-Parameter PDO CommPar (20 1A00 1.

-

Page 54: Device Type (1000 )

Implemented CANopen Objects 8.9.2 Device Type (1000 INDEX 1000 Name device type Data type unsigned 32 Access mode Default value see chapter 8.9.1 (page 53) Example: Reading the Device Type The CANopen master transmits the read request with identifier ‘603 ’... -

Page 55: Error Register (1001 )

Implemented CANopen Objects 8.9.3 Error Register (1001 The CAN-CBX module uses the error register to indicate error messages. INDEX 1001 Name error register Data type unsigned 8 Access type Default value The following bits of the error register are being supported at present: Meaning generic current... -

Page 56: Pre-Defined Error Field (1003 )

Implemented CANopen Objects 8.9.4 Pre-defined Error Field (1003 INDEX 1003 Name pre-defined error field Data type unsigned 32 Access mode Default value The pre-defined error field provides an error history of the errors that have occurred on the device and have been signalled via the Emergency Object. - Page 57 Implemented CANopen Objects error-code x The 32-bit long error code consists of the CANopen-emergency error code described in [1] and the error code defined by esd (manufacturer-specific error field). Bit: 31 ..16 15 ..0 manufacturer-specific emergency-error-code...

-

Page 58: Cob-Id Of Sync-Message (1005 )

Implemented CANopen Objects 8.9.5 COB-ID of SYNC-Message (1005 INDEX 1005 Name COB-ID SYNC message Data type unsigned 32 Access mode Default value see chapter 8.9.1 (page 53) Structure of the parameter: Bit-No. Value Meaning 31 (MSB) do not care 0: Device does not generate SYNC message 1: Device generates SYNC message always 0 (11-bit ID) 28...11... -

Page 59: Communication Cycle Period (1006 )

Implemented CANopen Objects 8.9.6 Communication Cycle Period (1006 INDEX 1006 Name Communication Cylcle Period Data type unsigned 32 Access mode Default value Value range of the parameter: Value Meaning No transmission of SYNC messages 1...FFFFFFFF Cycle time in microseconds CAN-CBX_Pt100 Page 59 of 120 Manual •... -

Page 60: Manufacturer Device Name (1008 )

Implemented CANopen Objects 8.9.7 Manufacturer Device Name (1008 INDEX 1008 Name manufacturer device name Data type visible string Default value see chapter 8.9.1 (page 53) For detailed description of the SDO Uploads, please refer to [1]. Page 60 of 120 CAN-CBX_Pt100 Manual •... -

Page 61: Manufacturer Hardware Version (1009 )

Implemented CANopen Objects 8.9.8 Manufacturer Hardware Version (1009 INDEX 1009 Name manufacturer hardware version Data type visible string Default value string: e.g. ‘1.00’ (depending on version) The hardware version is read similarly to reading the manufacturer’s device name via the domain upload protocol. -

Page 62: Guard Time (100C ) Und Life Time Factor

Implemented CANopen Objects 8.9.10 Guard Time (100C ) und Life Time Factor (100D The CAN-CBX module supports the node guarding or alternatively the heartbeat function (see page 73). Note: By the recommendation of the CiA, the heartbeat-function shall be used preferentially. -

Page 63: Node Guarding Identifier

Implemented CANopen Objects 8.9.11 Node Guarding Identifier (100E The module only supports 11-bit identifiers. INDEX 100E Name node guarding identifier Data type unsigned 32 Access mode Default value + Node-ID Structure of the parameter node guarding identifier : Bit-No. Meaning 31 (MSB) reserved 29...11... -

Page 64: Store Parameters (1010 )

Implemented CANopen Objects 8.9.12 Store Parameters (1010 INDEX 1010 Name store parameters Data type unsigned 32 This object supports saving of parameters to a non-volatile memory, the EEPROM here. Therefore the parameter groups shown below are distinguished. After they are transferred, the parameters are immediately active. - Page 65 Implemented CANopen Objects The storage mode is shown in the content of this object: Bit 1 of object 1010 , sub-index 1 is not set, i.e the CAN-CBX-module does not save the configuration automatically. The storage must be initiated by writing the character string ‘save’ (73 order from CAN telegram) to object 1010 , sub-index 1-4.

-

Page 66: Restore Default Parameters (1011 )

Implemented CANopen Objects 8.9.13 Restore Default Parameters (1011 INDEX 1011 Name restore default parameters Data Type unsigned 32 Via this command the default parameters, valid when leaving the manufacturer, are restored. Therefor the parameter groups described below are distinguished. Every individual setting stored in the EEPROM will be lost. After a reset the default parameters will be active. - Page 67 Implemented CANopen Objects Bit 0 of object 1011 , sub-index 1 is set, i.e. the CAN-CBX module restores the default values initiated by writing the signature ‘load’ (64 , sequence in CAN telegram) in object 1011 , sub-index 1-4. On read access to the appropriate sub-index, the CANopen device provides information about its default parameter restoring capability with the following format: Bit: Content:...

-

Page 68: Cob_Id Emergency Message (1014 )

Implemented CANopen Objects 8.9.14 COB_ID Emergency Message (1014 INDEX 1014 Name COB-ID emergency object Data type unsigned 32 Default value + Node-ID This object defines the COB-ID of the emergency object (EMCY). The structure of this object is shown in the following table: Bit-No. -

Page 69: Inhibit Time Emcy (1015 )

Implemented CANopen Objects 8.9.15 Inhibit Time EMCY (1015 INDEX 1015 Name inhibit_time_emergency Data type unsigned 16 Access mode Value range 0...FFFF Default value The Inhibit Time for the EMCY message can be defined with this entry. The time is determined as a multiple of 100 s. -

Page 70: Consumer Heartbeat Time (1016 )

Implemented CANopen Objects 8.9.16 Consumer Heartbeat Time (1016 INDEX 1016 Name consumer heartbeat time Data type unsigned 32 Default value The heartbeat function can be used for mutual monitoring of the CANopen modules (especially to detect connection failures). Unlike node guarding/life guarding the heartbeat function does not require RTR-Frames. - Page 71 Implemented CANopen Objects Meaning of the variable consumer-heartbeat_time_x: consumer-heartbeat_time_x 31 ..24 23 ..16 15 ..0 reserved Node-ID heartbeat_time Assignment (always ‘0’) (unsigned 8) (unsigned 16) Node-ID Node-Id of the heartbeat producer to be monitored. heartbeat_time Within this time [ms] the heartbeat producer has to transmit the heartbeat on the node-guarding ID, to avoid the transmission of a heartbeat event.

-

Page 72: Producer Heartbeat Time (1017 )

Implemented CANopen Objects 8.9.17 Producer Heartbeat Time (1017 INDEX 1017 Name producer heartbeat time Data type unsigned 16 Default value 0 ms The producer heartbeat time defines the cycle time with which the CAN-CBX- module transmits a heartbeat-frame to the node-guarding ID. If the value of the producer heartbeat time is higher than ‘0’, it is active and stops the node-/ life- guarding (see page 63). -

Page 73: Identity Object (1018 )

0...FFFFFFFF unsigned 32 Description of the variables: vendor_id This variable contains the esd-vendor-ID. This is always 0000 0017 product_code Here the esd-article number of the product is stored. The nibbles of the long words have the following meaning: product_code = 1... - Page 74 Implemented CANopen Objects revision_number Here the software version is stored. In accordance with [1] the two MSB represent the revision numbers of the major changes and the two LSB show the revision number of minor corrections or changes. revision_no major_revision_no minor_revision_no serial_number Here the serial number of the hardware is read.

-

Page 75: Synchronous Counter Overflow Value (1019 )

Implemented CANopen Objects 8.9.19 Synchronous Counter Overflow Value (1019 INDEX 1019 Name Synchronous_Counter_Overflow Data type unsigned 8 Default value This object defines whether a counter is mapped into the SYNC message or not and further the highest value the counter can reach. The value range of the object is described in the following table: Value Description... -

Page 76: Verify Configuration (1020 )

Implemented CANopen Objects 8.9.20 Verify Configuration (1020 INDEX 1020 Name verify configuration Data type unsigned 32 Default value In this object the date and the time of the last configuration can be stored to check later whether the configuration complies with the expected configuration or not. The content of the parameters is not evaluated by the firmware. -

Page 77: Error Behaviour Object (1029 )

Implemented CANopen Objects 8.9.21 Error Behaviour Object (1029 INDEX 1029 Name error behaviour object Data type unsigned 8 Default value If an error event occurs (such as heartbeat error), the module changes into the status which has been defined in variable communication_error or output_error. Sub- Access Index... -

Page 78: Nmt Startup

Implemented CANopen Objects 8.9.22 NMT Startup (1F80 INDEX 1F80 Name NMT startup Data type unsigned 32 Default value The NMT startup is implemented to be able to start CANopen nodes in environments without NMT- master. Via NMT startup the auto startup of a CANopen node can be switched on or off. Further features of the parameters NMT startup are currently not supported. -

Page 79: Self Starting Nodes Timing Parameters (1F91 )

Implemented CANopen Objects 8.9.23 Self Starting Nodes Timing Parameters (1F91 INDEX 1F91 Name Self starting nodes timing parameters Data type unsigned 16 Sub- Access Index Description Value range Default Data type index mode number_of_entries unsigned 8 1F91 NMT master detection timeout 0...FFFF unsigned 16 Sub-index 1 of this object contains the timeout in [ms] between the change from “preoperational”... -

Page 80: Object Transmit Pdo Communication Parameter 1800

Implemented CANopen Objects 8.9.24 Object Transmit PDO Communication Parameter 1800 - 1803 This objects define the parameters of the transmit-PDOs. INDEX 1800 - 1803 Name transmit PDO parameter Data Type PDOCommPar Sub- Access Index Description Value range Default Data type index mode number_of_entries... -

Page 81: Transmit Pdo Mapping Parameter 1A00

Implemented CANopen Objects 8.9.25 Transmit PDO Mapping Parameter 1A00 - 1A03 This objects define the assignment of the transmit data to the Tx-PDOs. INDEX 1A00 - 1A03 Name transmit PDO mapping Data Type PDO Mapping The following table shows the assignment of the transmit PDO mapping parameters: Sub- Access Index... -

Page 82: Device Profile Area

Device Profile Area 8.10 Device Profile Area 8.10.1 Overview of the Implemented Objects 6110 ...9135 Index Name Data Type 6110 AI_sensor_type unsigned 16 6111 AI_autocalibration unsigned 32 6112 AI_operating_mode unsigned 8 6114 AI_ADC_sampling_rate unsigned 32 6131 AI_physical_unit_PV unsigned 32 6132 AI_decimal_digits_PV unsigned 8 6150... -

Page 83: Relationship Between The Implemented Analog Input Objects

Device Profile Area 8.10.2 Relationship Between the Implemented Analog Input Objects Example here: The module is in the “operational” status Fig. 21: Relationship between the implemented objects CAN-CBX_Pt100 Page 83 of 120 Manual • Doc.-No.: C.3032.21 / Rev. 1.1... -

Page 84: Ai Sensor Type (6110 )

Device Profile Area 8.10.3 AI Sensor Type (6110 Sub- Access Index Description Value range Default Data type index mode number_of_entries unsigned 8 AI_sensor_type_1 ... 2732 2710 unsigned 16 6110 AI_sensor_type_2 ... 2732 2710 unsigned 16 AI_sensor_type_3 ... 2732 2710 unsigned 16 AI_sensor_type_4 ... - Page 85 Device Profile Area 8.10.4 AI Autocalibration (6111 Sub- Access Index Description Value range Default Data type index mode number_of_entries unsigned 8 AI_autocalibration_1 unsigned 32 no default, write: 6111 AI_autocalibration_2 unsigned 32 69 6C 61 63 AI_autocalibration_3 unsigned 32 (= ASCII: ‘i’ ‘l’ ‘a’ ‘c’) AI_autocalibration_4 unsigned 32 Function:...

-

Page 86: Ai Operating Mode (6112 )

Device Profile Area 8.10.5 AI Operating Mode (6112 Sub- Access Index Description Value range Default Data type index mode Number_of_entries unsigned 8 AI_operating_mode_1 0, 1 unsigned 8 6112 AI_operating_mode_2 0, 1 unsigned 8 AI_operating_mode_3 0, 1 unsigned 8 AI_operating_mode_4 0, 1 unsigned 8 Description of parameter AI_operating_mode_x (x = 1...4): The parameter choses the desired operation mode. -

Page 87: Ai Adc Sampling Rate (6114 )

Device Profile Area 8.10.6 AI ADC Sampling Rate (6114 Sub- Access Index Description Value range Default Data type index mode Number_of_entries unsigned 8 AI_ADC_sampling_rate_1 03E8 ...61A80 61A80 unsigned 32 6114 AI_ADC_sampling_rate_2 03E8 ...61A80 61A80 unsigned 32 AI_ADC_sampling_rate_3 03E8 ...61A80 61A80 unsigned 32 AI_ADC_sampling_rate_4 03E8... -

Page 88: Ai Physical Unit (6131 )

Device Profile Area 8.10.7 AI Physical Unit (6131 Sub- Access Index Description Value range Default Data type index mode Number_of_entries unsigned 8 28 0000 AI_physical_unit_1 unit _1 unsigned 32 SensorType 2D 0000 28 0000 AI_physical_unit_2 unit _2 unsigned 32 SensorType 2D 0000 6131 28 0000... - Page 89 Device Profile Area Structure of the variable: 24 23 16 15 Prefix SI Numerator SI Denominator reserved Coding of the prefix for physical units: Prefix Factor Notation index SI Numerator and SI Denominator contain the physical units. Coding of the physical units : International symbol Name of unit Notation index...

-

Page 90: Ai Decimal Digits Pv (6132 )

Device Profile Area 8.10.8 AI Decimal Digits PV (6132 Sub- Access Index Description Value range Default Data type index mode Number_of_entries unsigned 8 AI_decimal_digits_PV_1 0...3 unsigned 8 6132 AI_decimal_digits_PV_2 0...3 unsigned 8 AI_decimal_digits_PV_3 0...3 unsigned 8 AI_decimal_digits_PV_4 0...3 unsigned 8 Description of the parameter AI_decimal_digits_PV_x (x = 1...4): This parameter contains the number of fractional digits of the process value (PV) in object “AI_PV”... -

Page 91: Ai Status (6150 )

Device Profile Area 8.10.9 AI Status (6150 Sub- Access Index Description Value range Default Data type index mode Number_of_entries unsigned 8 AI_status_1 0...5 unsigned 8 6150 AI_status_2 0...5 unsigned 8 AI_status_3 0...5 unsigned 8 AI_status_4 0...5 unsigned 8 Description of the variable AI_status_x (x = 1...4): These variables return the state of the corresponding analog input channel. -

Page 92: Analog Input Field Value (9100 )

Device Profile Area 8.10.10 Analog Input Field Value (9100 Sub- Access Index Description Value range Default Data type index mode Number_of_entries unsigned 8 80000000 AI_FV_1 integer 32 7FFFFFFF 80000000 AI_FV_2 integer 32 7FFFFFFF 9100 80000000 AI_FV_3 integer 32 7FFFFFFF 80000000 AI_FV_4 integer 32 7FFFFFFF... -

Page 93: Ai Interrupt Delta Input Fv (9103 )

Device Profile Area 8.10.11 AI Interrupt Delta Input FV (9103 Sub- Access Index Description Value range Default Data type index mode Number_of_entries unsigned 8 80000000 AI_interrupt_delta_input_FV_1 integer 32 7FFFFFFF 80000000 AI_interrupt_delta_input_FV_2 integer 32 7FFFFFFF 9103 80000000 AI_interrupt_delta_input_FV_3 integer 32 7FFFFFFF 80000000 AI_interrupt_delta_input_FV_4 integer 32... -

Page 94: Analog Input Process Value (9130 )

Device Profile Area 8.10.12 Analog Input Process Value (9130 Note: This object contains the important data (resistance or temperature values)! Sub- Access Index Description Value range Default Data type index mode Number_of_entries unsigned 8 80000000 AI_PV_1 integer 32 7FFFFFFF 80000000 AI_PV_2 integer 32 9130... -

Page 95: Ai Interrupt Delta Input Pv (9133 )

Device Profile Area 8.10.13 AI Interrupt Delta Input PV (9133 Sub- Access Index Description Value range Default Data type index mode Number_of_entries unsigned 8 80000000 AI_interrupt_delta_input_PV_1 integer 32 7FFFFFFF 80000000 AI_interrupt_delta_input_PV_2 integer 32 7FFFFFFF 9133 80000000 AI_interrupt_delta_input_PV_3 integer 32 7FFFFFFF 80000000 AI_interrupt_delta_input_PV_4 integer 32... -

Page 96: Ai Interrupt Lower Limit Pv (9134 )

Device Profile Area 8.10.14 AI Interrupt Lower Limit PV (9134 Sub- Access Index Description Value range Default Data type index mode Number_of_entries unsigned 8 80000000 AI_interrupt_lower_limit_PV_1 80000000 integer 32 7FFFFFFF 80000000 AI_interrupt_lower_limit_PV_2 80000000 integer 32 7FFFFFFF 9134 80000000 AI_interrupt_lower_limit_PV_3 80000000 integer 32 7FFFFFFF 80000000... -

Page 97: Ai Interrupt Upper Limit Pv (9135 )

Device Profile Area 8.10.15 AI Interrupt Upper Limit PV (9135 Sub- Access Index Description Value range Default Data type index mode Number_of_entries unsigned 8 80000000 AI_interrupt_upper_limit_PV_1 7FFFFFFF integer 32 7FFFFFFF 80000000 AI_interrupt_upper_limit_PV_2 7FFFFFFF integer 32 7FFFFFFF 9135 80000000 AI_interrupt_upper_limit_PV_3 7FFFFFFF integer 32 7FFFFFFF 80000000... -

Page 98: Manufacturer Specific Profile Area

Manufacturer Specific Profile Area 8.11 Manufacturer Specific Profile Area 8.11.1 Overview of Manufacturer Specifc Objects 2400 ... 2510 Index Name Data Type 2400 ADC_PGA unsigned 8 2401 Channel_enabled unsigned 8 2402 Accu_N unsigned 8 2403 Average_N unsigned 8 2410 Measuring_current unsigned 8 2420 Local_temperature (PCB) -

Page 99: Adc_Pga (2400 )

Manufacturer Specific Profile Area 8.11.2 ADC_PGA (2400 Sub- Access Index Description Value range Default Data type index mode Number_of_entries unsigned 8 ADC_PGA_1 1...4 unsigned 8 2400 ADC_PGA_2 1...4 unsigned 8 ADC_PGA_3 1...4 unsigned 8 ADC_PGA_4 1...4 unsigned 8 Description of the parameter ADC_PGA_x (x = 1...4): This parameter sets the gain (PGA) of the A/D-converters (ADS1255). -

Page 100: Channel Enabled (2401 )

Manufacturer Specific Profile Area 8.11.3 Channel Enabled (2401 Sub- Access Index Description Value range Default Data type index mode Number_of_entries unsigned 8 channel_enabled_1 false, true boolean 2401 channel_enabled_2 false, true boolean channel_enabled_3 false, true boolean channel_enabled_4 false, true boolean Description of the variable channel_enabled_x (x = 1...4): If a sensor has been detected for the measuring channel, this variable returns the “actual value”of the object “AI_Operating_mode_x”... -

Page 101: Accu N (2402 )

Manufacturer Specific Profile Area 8.11.4 Accu N (2402 Sub- Access Index Description Value range Default Data type index mode Number_of_entries unsigned 8 accu_count_1 0...8 unsigned 8 2402 accu_count_2 0...8 unsigned 8 accu_count_3 0...8 unsigned 8 accu_count_4 0...8 unsigned 8 Description of the parameter accu_count_x (x = 1...4): This parameter defines the number of analog values to be added. -

Page 102: Average N (2403 )

Manufacturer Specific Profile Area 8.11.5 Average N (2403 Sub- Access Index Description Value range Default Data type index mode Number_of_entries unsigned 8 average_count_1 0...4 unsigned 8 2403 average_count_2 0...4 unsigned 8 average_count_3 0...4 unsigned 8 average_count_4 0...4 unsigned 8 Description of the parameter average_count_x (x = 1...4): This parameter defines how many analog values are used to calculate the floating average. -

Page 103: Current Source Value (2410 )

Manufacturer Specific Profile Area 8.11.6 Current Source Value (2410 Sub- Access Index Description Value range Default Data type index mode Number_of_entries unsigned 8 current_source_value_1 0, 1 unsigned 8 2410 current_source_value_2 0, 1 unsigned 8 current_source_value_3 0, 1 unsigned 8 current_source_value_4 0, 1 unsigned 8 Description of the parameter current_source_value_x (x = 1...4):... -

Page 104: Local Temperature At Pcb (2420 )

Manufacturer Specific Profile Area 8.11.7 Local Temperature at PCB (2420 Sub- Access Index Description Value range Default Data type index mode Number_of_entries unsigned 8 2420 local_temperature 8000 ...7FFF integer 16 Description of the variable local_temperature: This variable contains the value of the temperature on the circuit board in steps of 1/256 C. The value is coded as described in the following: Value °... -

Page 105: Local Temperature At The Last Calibration (2421 )

Manufacturer Specific Profile Area 8.11.8 Local Temperature at the Last Calibration (2421 Sub- Access Index Description Value range Default Data type index mode Number_of_entries unsigned 8 last_calibration_temp_1 8000 ...7FFF temp integer 16 _last_cal 2421 last_calibration_temp_2 8000 ...7FFF temp integer 16 _last_cal last_calibration_temp_3 8000... -

Page 106: Calibration Delta Temperature (2422 )

Manufacturer Specific Profile Area 8.11.9 Calibration Delta Temperature (2422 Sub- Access Index Description Value range Default Data type index mode Number_of_entries unsigned 8 delta_calibration_temp_1 0...FFFF unsigned 16 2422 delta_calibration_temp_2 0...FFFF unsigned 16 delta_calibration_temp_3 0...FFFF unsigned 16 delta_calibration_temp_4 0...FFFF unsigned 16 Description of the variable delta_calibration_temp_x: The ADS1255 performs a self-calibration, if the temperature of the PCB (2420 ) deviates more than... -

Page 107: Calibration Data

With command Restore Default Parameters (1011 ) the initial setting of the calibration data adjusted by esd are reactivated. 8.11.10.1 Calibration and Process/Field-Value Calculation In the following formulas the parameter names are shown without the channel identifier at the end of the parameter names to improve the clarity. - Page 108 Manufacturer Specific Profile Area Process-Value Calculation 1) Correction FV corr AI FV corr with internal corrected field value in ADC-units corr AI_FV [Object 9100 analog input field value internal correction factor corr: tk Ih − corr gc Ih gc PGAy local temp ref temp Ih with gc_lh [objects 2502...

- Page 109 Manufacturer Specific Profile Area 2) Calculation PV (resistance value) × k Ih FV offset corr with Internal resistance value (only accessible for the user in the mode resistance (see Object 6110 Internal conversion factor for the high and the low measuring k_Ih: current (not accessible for the user);...

-

Page 110: Reference Temperature At Calibration (2500 )

Manufacturer Specific Profile Area 8.11.10.2 Reference Temperature at Calibration (2500 , 2501 Sub- Access Index Description Value range Default Data type index mode Number_of_entries unsigned 8 ref_temp_Ilow_1 8000 ...7FFF integer 16 2500 ref_temp_Ilow_2 8000 ...7FFF integer 16 ref_temp_Ilow_3 8000 ...7FFF integer 16 ref_temp_Ilow_4 8000... - Page 111 Manufacturer Specific Profile Area 8.11.10.3 Gain Correction at I and I (2502 , 2503 HIGH Sub- Access Index Description Value range Default Data type index mode Number_of_entries unsigned 8 gain_correction_Ilow_1 8000 ...7FFF integer 16 2502 gain_correction_Ilow_2 8000 ...7FFF integer 16 gain_correction_Ilow_3 8000 ...7FFF...

-

Page 112: Gain Correction At I 8.11.10.4 Gain Correction Pga=2/3/4 (2503 )

Manufacturer Specific Profile Area 8.11.10.4 Gain Correction PGA=2/3/4 (2503 - 2506 Sub- Access Index Description Value range Default Data type index mode Number_of_entries unsigned 8 gain_correction_PGA=2_1 8000 ...7FFF integer 16 2504 gain_correction_PGA=2_2 8000 ...7FFF integer 16 gain_correction_PGA=2_3 8000 ...7FFF integer 16 gain_correction_PGA=2_4 8000 ...7FFF... -

Page 113: Offset (2510 )

Manufacturer Specific Profile Area 8.11.10.5 Offset (2510 Sub- Access Index Description Value range Default Data type index mode Number_of_entries unsigned 8 offset_1 8000 ...7FFF integer 16 2510 offset_2 8000 ...7FFF integer 16 offset_3 8000 ...7FFF integer 16 offset_4 8000 ...7FFF integer 16 Description of the parameter offset_x (x = 1...4): By means of this objects the line resisance can be compensated. - Page 114 Manufacturer Specific Profile Area 8.11.10.6 Temperature Coefficient at I and I (2511 , 2512 HIGH Sub- Access Index Description Value range Default Data type index mode Number_of_entries unsigned 8 tk_Ilow_1 8000 ...7FFF integer 16 2511 tk_Ilow_2 8000 ...7FFF integer 16 tk_Ilow_3 8000 ...7FFF...

-

Page 115: Firmware Management Via Ds 302-Objects

Faulty program update can result in deleting of the memory and loss of the firmware. The module then can not be operated further! Note: esd offers the program CANfirmdown for a firmware update. Please, contact our support for this. In normal CiA 301 mode the objects 1F50 and 1F52 can not be accessed. -

Page 116: Download Control Via Object 1F51

Manufacturer Specific Profile Area 8.12.1 Download Control via Object 1F51 INDEX 1F51 Name Program Control Data type unsigned 8 Access type Value range 0...FE Default value Note: The value range of this objects in the implementing of the CAN-CBX_Pt100 differs from the value range specified in DS 302 [2]. -

Page 117: References

References/Glossary 9. References [1] CiA 301 Standard CANopen Application Layer and Communication Profile V4.2.0 (12.2011) CAN in Automation (CiA) e.V., Nürnberg, Germany [2] CiA 302 Draft Standard Proposal V4.1 (02.2009) Additional Application Layer Functions, Part 3: Configuration and program download [3] CiA 303 Draft Recommendation V1.3 (12.2009) CANopen Additional Specification, Part 3: Indicator specification... -

Page 118: Eu-Declaration Of Conformity

11. EU-Declaration of Conformity Page 118 of 120 CAN-CBX_Pt100 Manual • Doc.-No.: C.3032.21 / Rev. 1.1... -

Page 119: Order Information

Order Information 12. Order Information Type Features Order No. CAN-CBX_Pt100, CAN-CBX_PT100 4 temperature sensor inputs, C.3032.02 including 1x CAN-CBX-TBUS (C.3000.01) Accessories CAN-CBX-TBUS Mounting-rail bus connector of the CBX- InRailBus for CAN-CBX-modules, C.3000.01 (one bus connector is included in delivery of the CAN-CBX-module) CAN-CBX-TBUS- Connector... - Page 120 Order Information PDF Manuals Manuals are available in English and usually in German as well. For availability of English manuals see the following table. Please download the manuals as PDF documents from our esd website www.esd.eu for free. Manuals Order No.

Need help?

Do you have a question about the CAN-CBX-Pt100 and is the answer not in the manual?

Questions and answers