Advertisement

Quick Links

WARNING:

The Model 8681 Adaptive Offset Controller must be wired to 24 VAC only. Wiring the unit to

110 VAC will cause serious unit damage and void the warranty.

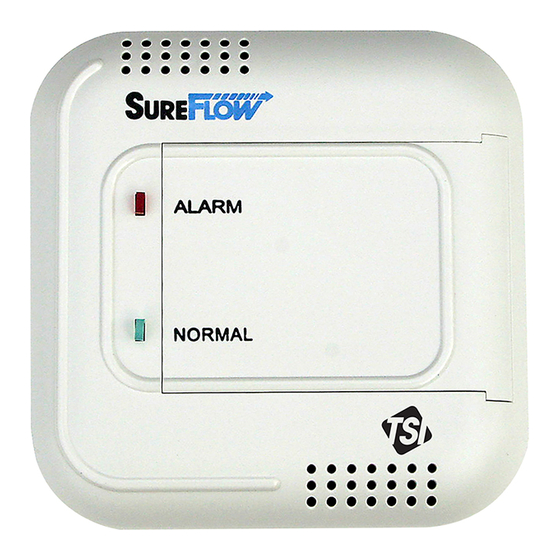

These installation instructions guide the installer through the installation of the TSI Model 8681 SureFlow

Adaptive Offset Controller and all TSI options. Some options may not have been provided by TSI, so please

review those product installation instructions. Please read these instructions thoroughly before beginning

installation.

Overview

Figure 1 provides an overview of the various components installed. The order the components are installed is

not important. The building prints will define the location of the dampers, flow stations, and pressure sensor. If

no location is defined, these instructions show "typical" installation locations.

_____________________

TSI and TSI logo are registered trademarks of TSI Incorporated.

SureFlow is a trademark of TSI Incorporated.

ADAPTIVE OFFSET CONTROLLER

Figure 1: Typical Laboratory Installation

MODEL 8681 SUREFLOW

INSTALLATION INSTRUCTIONS

™

™

Advertisement

Summary of Contents for TSI Instruments SUREFLOW 8681

- Page 1 MODEL 8681 SUREFLOW ™ ADAPTIVE OFFSET CONTROLLER INSTALLATION INSTRUCTIONS WARNING: The Model 8681 Adaptive Offset Controller must be wired to 24 VAC only. Wiring the unit to 110 VAC will cause serious unit damage and void the warranty. These installation instructions guide the installer through the installation of the TSI Model 8681 SureFlow ™...

-

Page 2: Component List

Component List NOTE: There are a large variety of options that can be installed with the Adaptive Offset Controller. The system you are installing may or may not have all components or quantity of components listed below. Only TSI supplied devices, listed below, are covered in these installation instructions. Please refer to the manufacturer’s installation instructions for proper installation of non TSI devices. - Page 3 Digital Interface Module Installation 1) Select the mounting location of the Digital Interface Module (DIM). The construction plans normally show the mounting location. If no location is specified, then the unit is typically installed as shown in Figure 1, either in the laboratory or in the hallway.

- Page 4 Wiring 2) Refer to Figures 12 and 13 wiring diagram for WARNING: Do not connect more than 24 VAC pressure sensor, DIM, TSI Damper/actuator, and to any terminal. TSI flow station wiring. Refer to Figure 14 wiring diagram for transformer wiring. Do not apply voltage to the RS-485 output, analog output, or control output.

-

Page 5: Pressure Sensor Installation

Pressure Sensor Installation This product is classified by Underwriters Laboratories, Inc. for use in through- ® penetration firestop systems. See UL fire resistance directory. The pressure sensor (P/N 800326) is typically installed above the main entrance to the laboratory (Figure 3). WARNING: 800326 pressure sensor must be mounted through the wall between the controlled space (laboratory) and referenced space (hallway),... - Page 6 NOTE: If 12” sensor tube is not long enough, add a 1” to 2” adapter and extend with 2" OD tube. The base of the dummy housing will need to be drilled out to accommodate 2” tube. Do not extend sensor tube with 1”...

- Page 7 Flow Station Installation 1) Select the mounting location of the flow station. The construction plans normally show the mounting location. If no location is specified, then typically the flow station is installed upstream of the damper actuator. WARNING: Figure 7 gives the minimum straight length duct diameters required for the flow station to operate correctly.

- Page 8 6) Verify that the jumpers on the pressure transducer are installed correctly, per Figure 9. The default pressure transducer output range is 0 to 0.5 in. H 7) Mount the pressure transducer within 10 feet of the flow station. The transducer must be mounted on a wall in the correct position per Figure 10 (screws not provided).

- Page 9 Damper/Actuator Installation WARNING: Building prints normally determine damper location and mounting configuration. They supersede the guidelines below. 1) The actuators are shipped mounted to the damper. No adjustments are needed prior to mounting the assembly. 2) The damper must be installed with the damper shaft parallel to the ground (Figure 11). 3) Slip-fit dampers mount INSIDE the duct work.

- Page 10 WARNING: Controller must be wired exactly as wire diagram shows. Making modifications to the wiring may severely damage the unit. Figure 12: Adaptive Offset Wiring Diagram – Electric Actuator Version Page 10 of 12...

- Page 11 WARNING: Controller must be wired exactly as wire diagram shows. Making modifications to the wiring may severely damage the unit. Figure 13: Offset (Flow Tracking) Wiring Diagram – Electric Actuator Version Page 11 of 12...

-

Page 12: Transformer Installation

Transformer Installation Transformers are provided for the DIM/AOC, each damper/actuator, and each flow station (TSI). WARNING: Each damper/actuator and flow station has a separate transformer that must be installed. Do not wire more than one device per transformer. WARNING: Make sure no power is applied until all wiring is complete.

Need help?

Do you have a question about the SUREFLOW 8681 and is the answer not in the manual?

Questions and answers