Summary of Contents for Kverneland CLC PRO

- Page 1 CLC PRO - CLC PRO CLASSIC - CLC PRO CUT Operator’s manual Translation of original document Issue 03/2017 Printing 4.2017 Language English From serial No. RFCSTxx010628 Execution Rigid/Folding Reference. A135313540...

- Page 2 Copyright and usage rights are held by the Kverneland Group Les Landes Génusson SAS, France. Copying, transfer to other media, translation or even partial use of this text without Kverneland’s written consent is prohibited. All rights reserved. The content of these operating instructions...

-

Page 3: Table Of Contents

Table of contents Table of contents Introduction ..........Adjustments ..........Who should read this user’s manual? Adjusting the working depth Meaning of symbols Adjustment of the rear accessories Actipack and Actiring rollers Safety ............Lighting kit for folding machine For your safety Front cutting discs (FCD) The HAZARD, WARNING Front mixer discs (FMD) -

Page 4: Introduction

Introduction Who should read this Introduction This user’s manual is addressed to farmers and individuals trained and certified in agricultural activities and who have received training in user’s manual? the use of this machine. Safety note for the user Familiarize yourself with the contents of this user manual before starting to use it or climbing on the machine. -

Page 5: For Your Safety

Safety For your safety Safety This section contains general safety information. The various chapters in this user manual include specific safety instructions, among other things. Be sure to comply with all safety guidelines • in the interest of your own safety, •... - Page 6 Safety Note for the manager: As required by law, you should regularly inform those working on the machine of the existence of safety instructions. SAFETY PRIORITY The “Safety priority” symbol is used in this manual and on the pictograms placed on the machine in order to warn the user of the presence of a risk of bodily injury.

-

Page 7: The Hazard, Warning And Caution Safety Stickers

Safety The HAZARD, To ensure user safety, stickers are applied to the machine. Do not remove these stickers. WARNING and When the stickers become illegible or when they lose their adhesion, CAUTION safety order new ones and place them in the corresponding places. stickers Safety pictograms on the machine... - Page 8 Safety...

- Page 9 Safety Folding machines...

- Page 10 Safety...

- Page 11 Safety Meaning of safety symbols HAZARD: Pivoting or folding moving parts may cause serious injuries or death. Stand away from the range of movement of all pivoting parts. HAZARD: Rotating parts can cause serious injuries or death. Stand away from the range of movement of all rotating parts. HAZARD: Hazardous zone Risk of cuts/feet getting tangled in the rotating parts.

- Page 12 Safety HAZARD Risk of cuts / crushing Freely-rotating rollers Before beginning adjustments, ensure that the rollers have been immobilized. In order to avoid all serious or fatal injuries: keep your legs and hands outside the roller rotation zone. HAZARD Risk of falling Risk of falling to the ground or onto cutting or blunt-edged parts of the machine while it is operating.

- Page 13 Safety WARNING Risk of projected debris Metal fragments may be projected if you hit the coulters directly with a hammer. To avoid any serious injury: systematically use the Knock-On tool (A133147030) and always be sure to wear protective safety glasses. CAUTION Maximum hydraulic pressure The tractor’s hydraulic pressure must not exceed 210 bar (3,045 psi).

- Page 14 Safety Meaning of symbols specific to the Knock-on accessory WARNING Never directly hit the coulters with a hammer. The coulters are made from treated steel. During assembly or disassembly operations, never directly hit the coulters with a hammer. Such a hit could produce fragments, break parts and cause serious injuries.

- Page 15 The user must ensure that the tractor/machine unit is compliant with current prescriptions regarding machine transport on the road network. Signaling systems CLC Pro rigid - Front view - as an option on the 2.50-m machines (6’6”) Marking Dimensions 3.00m (9’10”) - 3.50m (11’6”) - 4.00m (13’1”) Max.

- Page 16 Safety CLC Pro & Pro Classic foldable - Front view - as an option Marking Dimensions 2.75m (9’) Max. 80 mm (approx. 3”)

- Page 17 Safety CLC Pro foldable - Rear view Marking Dimensions 2.75m (9’) Max. 270 mm (approx. 11”) The working depth of rollers must be set at its minimum level. Panels In some states of the United States and some Canadian provinces,...

-

Page 18: Safety Rules

Safety Safety rules General recommen- Before starting up, check that the machine is not endangering any dations persons and that the protection and safety devices (e.g. guards, hoods, warning labels, etc.) are in place and functional. Before you start work, familiarize yourself with all the equipment, controls and functions on your machine. - Page 19 Safety Hitching HAZARD Never stand between the machine and the tractor during maneuvers. No one should stand between the tractor and the machine when maneuvering the tractor or during lifting operations. This could cause serious injury or even death. Follow instructions for hitching exactly : •...

- Page 20 Safety Transport IMPORTANT Machine movement On a curved road section, beware of machine movements as well as a shifting of the load. Adjust your forward speed accordingly. Regulations • Respect the driving code at all times when on the road on the road network.

- Page 21 Safety HAZARD Avoid all contact of the machine with electrical voltage lines. Any contact with electrical voltage lines can cause serious or even fatal injuries. Take all necessary precautions in order to avoid any contact while handling the machine adjacent to electrical voltage lines. WARNING Be mindful of the return to the initial position of locked tine.

- Page 22 Safety Safety for children WARNING Do not assume that children will remain calmly in place where you last saw them. Remain vigilant and turn off the motor if children are present in your work space. Never let children play on the machine or use it. IMPORTANT Adapt your speed when the ground is sloped.

- Page 23 Safety Maintenance HAZARD Apply the brakes or immobilization system prior to any actions taken on the tractor-tool assembly. Be sure to always apply the brakes or the vehicle immobilization system prior to any action taken on the tractor-tool assembly. Failing to do so may cause serious or even fatal injuries. WARNING Beware of sharp edges and corners.

- Page 24 Safety Unhitching WARNING Never stand between the tractor and the machine during unhitching. Before unhitching the machine, be sure that no one is positioned between the machine and the tractor. Individuals may get pinned between the tractor and machine, thereby leading to serious or even fatal injuries. In order to avoid any hazard during unhitching: ...

-

Page 25: Other Instructions

Safety Hydraulic installation HAZARD Any action taken on the hydraulic system must always be performed by a trained and certified technician. For further information, refer to Chapter "Replacement of the hydraulic system parts" page 93. Other instructions Follow instructions In addition to the instructions listed above, always follow: •... -

Page 26: Presentation Of The Machine

Presentation of the machine Field of Presentation of the machine This machine is considered to be interchangeable equipment within the meaning of European directive 2006/42/EC and is considered to application be agricultural equipment within the meaning of directive ASABE S390. This chapter contains general information about your machine as well as information concerning the following points: •... -

Page 27: General Description

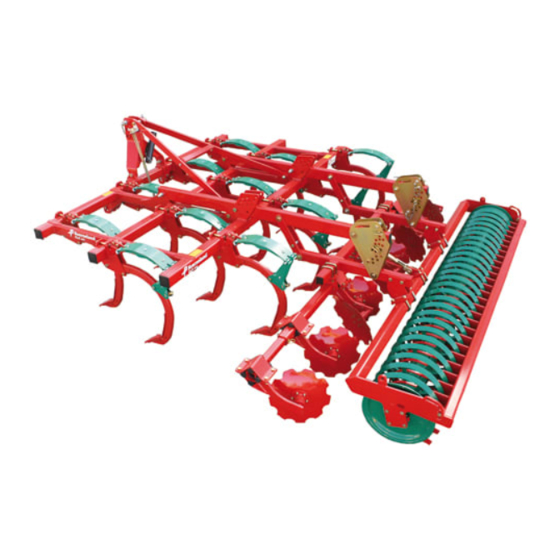

Presentation of the machine General Description Designation Sub-assemblies 100 x 100 chassis (4” x 4”) Coupling of the upper link bar Accessory support arm Couplings of the lower bars Stubble/cultivator module Rear accessories... -

Page 28: Technical Specifications

Presentation of the machine Technical specifi- cations CLC Pro and CLC Pro Classic Characteristics Fixed models Folding models Working width (m/ft) 3.00 ( 3.50 ( 4.00 ( 4.00 ( 4.50 ( 5.00 ( 9’10” 11’6” 13’1” 13’1” 14’9” 16’5” Transportation width (m/ft) 3.00 (... - Page 29 Presentation of the machine CLC Pro Cut Folding models Characteristics Fixed models Without depth control With depth control wheels wheels Working width (m/ft) 3.00 ( 3.50 ( 4.00 ( 4.50 ( 4.00 ( 4.50 ( 9’10” 11’6” 13’1” 14’9” 13’1”...

- Page 30 Presentation of the machine Types of coulters / blades by tine type Bolted coulters Plow point 60 mm 3/8” Blade 300 mm (12”) Tiger 80 mm carbide coulter (3”) Tiger 150 mm carbide coulter (6”) Tiger 80 mm carbide coulter (3”) + Blades 345 mm ( ”)

- Page 31 Presentation of the machine Tine / deflector protection For CLC tines Tine protector 65 mm (2 ”) 80-mm deflector (3”) 80-mm spiral deflector (3”) (right and left) 100-mm deflector (4”) 100-mm spiral deflector (4”) (right and left)

-

Page 32: Rear Accessory Variants

Presentation of the machine Rear accessory variants There are three configurations mounted on parallelogram Hollow disc + roller [+] • Working depth check by roller. • The leveling is performed by notched discs mounted on rubber spring safety. • Compaction is performed by the rear roller. Combi-disc (gang of discs + roller) [+] •... -

Page 33: Roller Variants

Presentation of the machine Roller variants Cage roller diameter 550 mm [+] ( ” • Compaction of light to medium soils. Actipack roller diameter 560 mm [+] ( ” • Compaction and crumbing of all types of soil. • This roller is also suitable for clay and sticky soils. Actiring roller diameter 540 mm [+] ( ”... -

Page 34: Depth Control Wheels

Presentation of the machine Depth control wheels Rigid cultivator Wheel 6.00x9: • Diameter 540 mm x 160 mm ( 21 1/4” 6 1/4” Folding cultivator Wheel 10/80x12: • Diameter 710 mm x 274 mm ( 28” x 11”... -

Page 35: Other Optional Equipment [+]

Presentation of the machine Other optional equipment [+] Signaling and lighting All lights, reflectors, license plates and signaling or warning panels on the tractor must be perfectly visible. If this is not possible, you must install lights and a license plate on the machine. -

Page 36: Distribution Of Right And Left Deflectors

Presentation of the machine Front mixer discs • Front Mixing Discs (FMD) • Curved discs are located on the first beam at the front of the machine. • They are placed in front of the first row of tines to mix and incorporate the straw debris into the earth upstream of the tines. -

Page 37: Configurations

Presentation of the machine Configurations CLC PRO 3.00 m ( ) - average step 280 mm ( 9’10” 11” Right Left deflector deflector CLC PRO 3.50 m ( ) - average step 280 mm ( 11’ 11”... - Page 38 Presentation of the machine CLC PRO 4.00 m ( ) - average step 280 mm ( 13’ 11” CLC PRO 4.00 m ( ) folding - average step 290 mm ( 13’ ”...

- Page 39 Presentation of the machine CLC PRO 4.50 m ( ) folding - average step 280 mm ( 15’ 11” CLC PRO 5.00 m ( ) folding - average step 290 mm ( 16’ ”...

-

Page 40: Configuration With Front Cutting Discs

Presentation of the machine Configuration with front cutting discs CLC PRO Cut 3.00 m ( ) - average step 420 mm ( 9’10” 17” CLC PRO Cut 3.50 m ( ) - average step 385 mm ( 11’6” 15 1/2”... - Page 41 Presentation of the machine CLC PRO Cut 4.00 m ( ) Folding - average step 350 mm ( 13’1” 13 3/4” CLC PRO Cut 4.50 m ( ) Folding - average step 335 mm ( 14’9” 13”...

-

Page 42: Safety

Safety Unhitching Safety DANGER Heightened risk of injury when uncoupling the machine. To avoid injury: Immobilize the tractor, lower the machine, engage the parking brake, make sure that the machine is on flat and sufficiently stable ground. -

Page 43: Acceptance And Assembly

Acceptance and assembly Inspection at Acceptance and assembly the time of acceptance WARNING Where a machine is partly disassembled, follow the assembly instructions. If the machine is delivered partially assembled, carefully follow the instructions given in the assembly booklet in order to avoid serious injury. -

Page 44: Fastening Of The Rear Accessory [+]

Acceptance and assembly Fastening of the rear accessory [+] Present the rear accessory (or accessories) (leveling system with or without roller) at the rear of the machine. Check the alignment of the roller(s) with the chassis. Tighten the attachments. ... -

Page 45: Rear Accessory Configurations

Acceptance and assembly Rear accessory configurations Leveling discs CU3300 - 3.00 m ( 9’10” CU3350 - 3.50 m ( 11’6” CU3400 - 4.00 m ( 13’1”... - Page 46 Acceptance and assembly CU3400F - 4.00 m folding 13’1” CU3450F - 4.50 m folding 14’9” CU3500F - 5.00 m folding 16’5”...

- Page 47 Acceptance and assembly Leveling tines CU3300 - 3.00 m 9’10” CU3350 - 3.50 m 11’6” CU3400 - 4.00 m 13’1”...

- Page 48 Acceptance and assembly CU3400F - 4.00 m folding 13’1” CU3450F - 4.50 m folding 14’9” CU3500F - 5.00 m folding 16’5”...

-

Page 49: Installing The Rear Struts

Acceptance and assembly Installing the rear struts CAUTION Risk of collision. The struts must be positioned with care in order to avoid any collisions when folding and unfolding. All folding and unfolding operations must be made with the struts retracted. On folding machines In order to save space, you may prefer to store the machine with the chassis folded using the set of storage struts. - Page 50 Acceptance and assembly Installation on the roller arms Present the struts on the arms (A). Tighten the attachments. Working position • The struts are retracted Storage position...

-

Page 51: Hitching

Hitching Hitching DANGER Never stand between the tractor and the machine when coupling. It is extremely dangerous to stand between the machine and the tractor when coupling, you could be crushed. This could cause serious injury or even death. Comply fully with safety instructions. By complying with the instructions you will be able to use your machine under optimum safety conditions. -

Page 52: Folding Machines

Hitching Folding machines CAUTION Risk of shocks The struts must be carefully stored in order to avoid any shock when folding or unfolding the machine. The struts must be in the retracted position during folding and unfolding steps. Hitching Move the tractor adjacent to the machine. ... -

Page 53: Electrical Connections

Lighting Electrical Lighting connections IMPORTANT Check the electrical cables Check the electrical cables regularly. They must not rub on any part of the machine or hang in space. Replace any torn or damaged electrical cables, they could damage the machine. Lighting for North The machine is fitted with lighting equipment for travel on roads. - Page 54 Lighting Lighting operation for North America IMPORTANT Comply with local requirements for road travel lighting equipment. Contact your specialist dealer, if the lighting does not function as recommended. Check the lighting using the following table: Machine lights Tractor lights Left yellow Left red Right red...

-

Page 55: Transport

Transport Safety Transport DANGER Passenger transportation. It is strictly prohibited to transport individuals positioned on the machine. WARNING Read the safety instructions carefully prior to the transpor- tation step. Before traveling on roads with the machine, please read the following safety instructions carefully. Compliance with these instructions is essential and helps avoid accidents. -

Page 56: Before Traveling On Public Roads

Transport Before traveling on public roads WARNING Respect of applicable regulations concerning transport on public roads Respect applicable regulations when driving on public roads: • The unit must be equipped with suitable warning signs, alarm and safety devices. • The machine must comply with the transportation widths and authorized weights, as well as the axle loads, tire load limits and total weights allowed. - Page 57 Transport Respect the legal transportation width Tipping elements Make sure that you fold back and lock all the tipping elements on the machine. Fixed machines equipped with a leveling mechanism [+] If you have a rigid machine fitted with leveling discs or leveling tines, make sure that the two exterior leveling discs or exterior leveling tines have been retracted.

- Page 58 Transport Fixed machines fitted with hollow discs or leveling tines [+] The two exterior hollow discs or exterior leveling tines must be retracted when driving on the road. Remove the shaft and push the edging tube home. Insert the shaft and lock with the pin. Edging disc Shaft Folding machines...

-

Page 59: Switching On

Switching on Switching on DANGER Respect of safety instructions Failure to respect the safety instructions may cause serious injury or even death. Refer to Chapter Safety, page 5. Ban on transporting individuals. Under no circumstances is the machine to be used to transport people or objects. -

Page 60: Adjustments - Versatility

Adjustments - Versatility Adjustments - Versatility Several types of coulter equipment (coulters + deflectors) can be equipped on CLC type tines to better adapt to the type of work to be carried out. Coulter range From superficial tilling to deep work, the use of the correct coulter at the right depth will allow considerable fuel and money savings. -

Page 61: Adjustments

Adjustments Adjustments DANGER Respect of safety instructions Failure to respect the safety instructions may cause serious injury or even death. Refer to Chapter Safety, page 5. Never stand on the rollers even if they are placed on the ground. WARNING Keep at a safe distance when changing the settings. -

Page 62: Adjusting The Working Depth

Adjustments Adjusting the The working depth of the stubble tines and leveling systems is controlled by the rear roller and/or by the optional depth control wheels working depth at the front of the machine. Nevertheless, certain leveling mechanisms have additional adjustments. - Page 63 Adjustments WARNING Keep at a safe distance when changing the settings. Always keep a safe distance from the machine when adjusting settings. Failure to follow this instruction could result in serious injury, even death. In particular, there is a risk that your legs could be crushed.

- Page 64 Adjustments Transport In order to reduce the transport overhang, it is recommended to remove the upper shafts to enable the accessory to return to its lowest and most compact position. Raise the machine so that its weight is no longer being supported by the roller while ensuring that the roller is still touching the ground.

- Page 65 Adjustments Roller arm The working depth is adjusted using the perforated plates at the rear and is determined by the shaft positioned above the arm. Adjusting shaft Perforated plate Raise the machine so that its weight is no longer being supported by the roller while ensuring that the roller is still touching the ground.

- Page 66 Adjustments Adjustment of depth control wheels [+] During the operation, make sure that the chassis remains horizontal in working position. Fixed machines Raise the machine. Hold the wheel. Remove the pin on the adjustment shaft (A). ...

-

Page 67: Adjustment Of The Rear Accessories

Adjustments WARNING Keep at a safe distance when changing the settings. Always keep a safe distance from the machine when adjusting settings. Failure to follow this instruction could result in serious injury, even death. In particular, there is a risk that your legs could be crushed. - Page 68 Adjustments Combi-disc The combi-disc is a gang of discs used for mixing and leveling. Adjusting the working depth of the gang of discs • The hydraulic jacks are used to move the roller(s). The working depth of the gang of discs is adjusted by adding or removing the chocks located at the jack rod.

- Page 69 Adjustments Adjusting the edging discs (fixed machine) Remove the spindle C and its pin. Slide the assembly on its tube to adjust the distance between the edging disc and the path of the flow of soil. Place the spindle C and pin in one of the four positions. It is possible to adjust the height of the disc depending on the working depth of the gang of discs by using the spindle D.

- Page 70 Adjustments Adjusting the edging disc distance relative to the machine on fixed machines. Remove the pin locking the lateral adjustment shaft (C). Remove the side adjustment shaft. Slide the assembly on its tube to adjust the distance between the edging disc and the path of the flow of soil.

-

Page 71: Actipack And Actiring Rollers

Adjustments Actipack and Actiring rollers Rear manifold Disc roller Active knife skids Introduction Use this configuration if you want: • A leveled, fine tilth finish. • To sow immediately after harrowing. Notes and recommenda- Adjust the knife skid height (D) according to the following: tions •... - Page 72 Adjustments Passive knife skids DANGER No one should stand close to the tractor’s controls while the rollers are being adjusted. Introduction Use this configuration if: • You want a coarser level and surface finish in order to avoid any risk of surface breakdown. •...

- Page 73 Adjustments Actiflex roller IMPORTANT No reverse gear with the roller in contact with the soil. Do not reverse while the roller is in contact with the ground. This could damage the blades, as there is no safety mechanism. Configuration with the leveling blades Use this configuration if you want: •...

-

Page 74: Lighting Kit For Folding Machine

Adjustments Lighting kit for folding machine IMPORTANT Do not fold the machine if the lights are in the working position. This could cause serious damage to the machine. • Working position: The signaling arm is adjusted in the upper position. •... -

Page 75: Unhitching

Unhitching Unhitching DANGER Respect of safety instructions Failure to respect the safety instructions may cause serious injury or even death. Refer to Chapter Safety, page 5. WARNING There is a serious risk of injury when unhitching the machine. To prevent any danger: ... - Page 76 Unhitching Folded position DANGER No one should stand close to the tractor’s controls while you are adjusting the struts. WARNING • Never let go of the struts while they are in the locked position. They could cause injury by falling onto a part of the body. •...

- Page 77 Unhitching Adjust the front struts Lower the machine onto a stable surface so that its weight is being supported by the rear struts and that the tension applied on the upper link is released. Unhitch the upper link. ...

-

Page 78: Maintenance

Maintenance Cleaning Maintenance IMPORTANT Do not clean using a rotating nozzle Never use a high pressure cleaner with a rotating nozzle to clean your machine. This could damage the machine. The equipment may be cleaned using a high pressure cleaner. ... -

Page 79: Maintenance

Maintenance For your safety Maintenance Special safety instructions DANGER Conditions necessary for maintenance work. Carry out maintenance work only if you have the necessary knowledge and tools at your disposal. A lack of knowledge or inappropriate tools may lead to accidents. Prevent any unintentional movement of the machine Carry out repairs or maintenance or eliminate malfunctions with the machine hitched only when:... - Page 80 Maintenance Protection measures Additives mixed with oils and lubricants can be harmful to your health. when handling oils Since regulations do not require manufacturers to identify these hazards, it is essential that you follow the advice below: and lubricants DANGER Avoid contact with the skin Avoid all skin contact with these products.

-

Page 81: General

Maintenance General These notes refer to routine maintenance work. For any maintenance work, the machine must be configured and locked in its working position. If the transport position is required for any maintenance work, refer to the maintenance instructions and read the relevant information. - Page 82 Maintenance Frequency Image Part Each Every 40 Each hours year Folding cylinder Discs Double tube roller/bar Tandem disc bearing Wheels...

-

Page 83: Wear Rings

Maintenance Wear rings IMPORTANT The wear rings must be changed when they stop protecting the different parts of the machine. If used wear rings are not replaced, damaged machine parts will not be covered by the warranty. If damaged rings are not replaced, their housing may also suffer from wear. -

Page 84: Inspection

Maintenance Double tube roller bar Inspection Screwed assemblies Regularly check wheel nuts for tightness and the hub clearance adjustment. All the bolts must be tightened: • After the initial period of use. • According to the frequency of use. • In any event, at least once a season. - Page 85 Maintenance Fasteners CAUTION Use only the screws supplied The securing screws supplied are special screws for specific requirements. Commercially available screws will not stand up to the stresses on the machine. If you use inappropriate screws or if you do not tighten them to the recommended torque, the machine could be damaged.

- Page 86 Maintenance Checking the tightening torques of the Knock-on accessory To ensure correct attachment of bolted assemblies, respect the following tightening torques: Number Torques N.m Torques ft.lbf Tires Check the pressure of tires regularly and inflate as needed. Recommended Model Tire pressure Depth control...

-

Page 87: Replacing The Tines

Maintenance Replacing the tines WARNING Never loosen more than one spring at the same time. If you loosen several springs at the same time, the machine may tip over. This could cause serious injury or even death. Carry out the adjustment on one spring. ... - Page 88 Maintenance Tines with blade springs Unlock the retaining screw without removing it (E). Completely release the blade spring using the tightening screw (C). Unscrew and remove the pivot screw (D) and retaining screw (E). Replace the tine. ...

-

Page 89: Coulter Wear

Maintenance Coulter wear WARNING Keep out of the danger zone. When being dismantled, the shares may fall and cause injury. Therefore, when dismantling the shares, always make sure that no part of your body is beneath them. IMPORTANT If the coulters are not replaced in time, the excessively worn parts could fall off while working and the tines could wear. - Page 90 Maintenance Replacing the coulters DANGER When being dismantled, the coulters may fall and cause injury. Consequently, before you dismantle these coulters: Make sure that no part of your body is positioned under these coulters. The specific beveled Knock-on tool must be used to replace the coulters.

- Page 91 Maintenance Distribution of plow Standardization of the symmetrical installation of points irrespective of points 60 mm ( ”) the type of machine and arrangement of tines. • Right side (central tine included): right points on the right and on the left •...

-

Page 92: Wearing Of The Knife Skids On Actipack And Actiring

Maintenance Wearing of the knife skids on Actipack and Actiring Regularly check the wear of the knife skids (A). Replace them before wear can cause the part to be lost during operation. Wearing of the leveling blades on Actiflex Leveling blade Primary coulter wear zone... -

Page 93: Replacement Of The Hydraulic System Parts

Maintenance Replacement of the hydraulic system parts DANGER Work on the hydraulic system must only be carried out by a trained and authorized technician. DANGER The hydraulic system is pressurized. Before any intervention on the hydraulic system: Lock the folding extension and all the hydraulically controlled accessories in rest position. - Page 94 Maintenance Combi-disc rigid machine Check the depth of the gang of discs Combi-disc folding machine Check the depth of the gang of discs Folding...

- Page 95 Maintenance Jack: A13500916...

-

Page 96: Warranty

Warranty Warranty On delivery of the tool, check that all accessories are present and that no damage has occurred during transport. Any claims must be made to us in writing within 6 days. The warranty will apply only if the conditions appearing on the delivery contract have been met by the buyer. -

Page 97: Scrapping The Machine

Scrapping the machine Scrapping the machine Do not spread on the ground or pour into sewers used grease or other substances such as motor oil, hydraulic oil, coolant fluid, brake fluid, fuel, etc. At the end of the machine’s life, it must be scrapped in accordance with environmental rules. -

Page 98: Index

Index Index General recommendations Hitching Adjusting Hydraulic system Maintenance Safety rules Blades Screwed assemblies Signaling Standard equipment Storage Combi Symbols Coulter range Coulters Technical specifications Tightening torques Deflector range Tire pressure Tires Transport Fasteners User safety Greasing Wheels with rubber tires Lighting kit Lubricants Maintenance...

Need help?

Do you have a question about the CLC PRO and is the answer not in the manual?

Questions and answers