Subscribe to Our Youtube Channel

Summary of Contents for Daikin VAM 150FJVE

- Page 1 SiE00-01 Service Manual Heat Recovery Ventilation [Applied Models] VAM 150FJVE VAM 250FJVE VAM 350FJVE VAM 500FJVE VAM 650FJVE VAM 800FJVE VAM1000FJVE VAM1500FJVE VAM2000FJVE...

- Page 2 SiE00-01 Heat Recovery Ventilation VAM 150FJVE VAM 250FJVE VAM 350FJVE VAM 500FJVE VAM 650FJVE VAM 800FJVE VAM1000FJVE VAM1500FJVE VAM2000FJVE Table of Contents...

-

Page 3: Table Of Contents

SiE00-01 1. Introduction .....................v 1.1 Safety Cautions ..................v Part 1 General Constructions ............1 1. General Constructions ................2 1.1 Explanation....................2 Part 2 Product Specification ............5 1. Product Specification ................6 1.1 Specification .................... 6 Part 3 Operation ................9 1. Operation ....................10 1.1 Explanation for Systems................ - Page 4 SiE00-01 1.11 Data Transmission Error (Between LCD Master Remote Controller and Slave Remote Controller) ............... 44 1.12 Field Setting Error.................. 45 1.13 Overlapping Central Control Address............ 46 1.14 Main Unit PCB Assembly ..............47 1.15 Dedicated LCD Remote Controller ............48 1.16 How to Check ..................

- Page 5 SiE00-01 Table of Contents...

-

Page 6: Introduction

SiE00-01 Introduction 1. Introduction Safety Cautions Cautions and Be sure to read the following safety cautions before conducting repair work. Warnings The caution items are classified into “ Warning ” and “ Caution ”. The “ Warning ” items are especially important since they can lead to death or serious injury if they are not followed closely. The “... - Page 7 Introduction SiE00-01 1.1.1 Cautions in Operation and Maintenance...

- Page 8 SiE00-01 Introduction...

- Page 9 Introduction SiE00-01 1.1.2 Using Icons Icons are used to attract the attention of the reader to specific information. The meaning of each icon is described in the table below: 1.1.3 Using Icons List Icon Type of Description Information Note A “note” provides information that is not indispensable, but may nevertheless be valuable to the reader, such as tips and tricks.

-

Page 10: Part 1 General Constructions

SiE00-01 Part 1 General Constructions 1. General Constructions ................2 1.1 Explanation....................2 General Constructions... -

Page 11: General Constructions

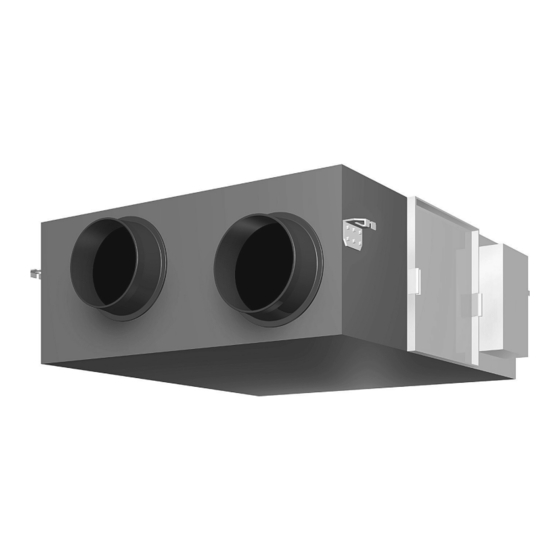

General Constructions SiE00-01 1. General Constructions Explanation VAM150FJVE VAM250FJVE VAM350FJVE VAM500FJVE VAM650FJVE VAM800FJVE VAM1000FJVE Ceiling Hock Duct Connection Flange Exhaust Fan Air Filter (Long Life Filter) Damper Switch Box Maintenance Cover Heat Exchange Elements Name Plate Air Supply Fan Remote Controller (Option Parts) Damper Motor EA (Exhaust Air) [Exhaust Air to Outdoor] OA (Outdoor Air) [Fresh Air from Outdoor]... - Page 12 SiE00-01 General Constructions VAM1500FJVE VAM2000FJVE Ceiling Hock Duct Connection Flange Exhaust Fan Air Filter (Long Life Filter) Damper Switch Box Maintenance Cover Heat Exchange Elements Name Plate Air Supply Fan Remote Controller (Option Parts) Damper Motor EA (Exhaust Air) [Exhaust Air to Outdoor] OA (Outdoor Air) [Fresh Air from Outdoor] Maintenance Space for The Air Filters, Heat RA (Return Air) [Exhaust Air from Room]...

- Page 13 General Constructions SiE00-01 General Constructions...

-

Page 14: Part 2 Product Specification

SiE00-01 Part 2 Product Specification 1. Product Specification ................6 1.1 Specification .................... 6 Product Specification... -

Page 15: Product Specification

Product Specification SiE00-01 1. Product Specification Specification (50 / 60Hz) Model Name VAM150FJVE VAM250FJVE VAM350FJVE Power Supply Single Phase 220 – 240 V / 220 V, 50 / 60 Hz Temperature Exchanging Ultra-High 74 / 74 72 / 72 75 / 75 Efficiency High 74 / 74... - Page 16 SiE00-01 Product Specification (50 / 60Hz) Model Name VAM500FJVE VAM650FJVE VAM800FJVE Power Supply Single Phase 220 – 240 V / 220 V, 50 / 60 Hz Temperature Exchanging Ultra-High 74 / 74 74 / 74 74 / 74 Efficiency High 74 / 74 74 / 74 74 / 74...

- Page 17 Product Specification SiE00-01 (50 / 60Hz) Model Name VAM1000FJVE VAM1500FJVE VAM2000FJVE Power Supply Single Phase 220 – 240 V / 220 V, 50 / 60 Hz Temperature Exchanging Ultra-High 75 / 75 75 / 75 75 / 75 Efficiency High 75 / 75 75 / 75 75 / 75...

-

Page 18: Part 3 Operation

SiE00-01 Part 3 Operation 1. Operation ....................10 1.1 Explanation for Systems................ 10 1.2 Operation with The Remote Control for Air Conditioning Operation HRV Units. (BRC301B61) ......11 Operation... -

Page 19: Operation

Operation SiE00-01 1. Operation Explanation for Systems This product is operated differently depending on the system configuration. For the operation of the remote controller for indoor unit and centralized controller, refer to the instruction manual provided with each unit. Operation for Each System System Example Operation Method Independent... -

Page 20: Operation With The Remote Control

SiE00-01 Operation Operation with The Remote Control for Air Conditioning Operation HRV Units. (BRC301B61) For non-independent systems, starting/stopping operation and timer operation may not be possible. Use the air conditioner remote control or the Centralized controller in such cases. Operation for 1. - Page 21 Operation SiE00-01 4. Ventilation mode changeover: button “ “ (Automatic) mode ..The temperature sensor of the unit automatically changes the ventilation of the unit in [Bypass] mode and [Heat Exchange] mode. “ “ (Heat Exchange) mode ..In this mode, the air passes through the heat exchange element to effect [Total Heat Exchanging] ventilation.

- Page 22 SiE00-01 Operation Operating The HRV When the VRV-system air conditioner is connected with the HRV unit with a direct duct, the remote Unit Using The controller of the air conditioner cannot be used to select the VENTILATION mode. To use the HRV unit Remote Controller without operating the air conditioner, set the air conditioner in the FAN VENTILATION mode and select the of The VRV.

- Page 23 Operation SiE00-01 Operation...

-

Page 24: Part 4 Maintenance

SiE00-01 Part 4 Maintenance 1. Maintenance..................16 1.1 Maintenance for The Air Filter ............... 16 1.2 Maintenance for The Heat Exchange Element........19 Maintenance... -

Page 25: Maintenance

Maintenance SiE00-01 1. Maintenance Maintenance for The Air Filter Caution During operation, never check or clean the HRV. It may cause electrical shock and it is very dangerous to touch the rotating part. Be sure to turn off the OPERATION switch and disconnect the power. CLEANING FREQUENCY AT LEAST ONCE EVERY TWO YEARS (FOR GENERAL OFFICE USE) (CLEAN THE ELEMENT MORE FREQUENTLY IF NECESSARY.) - Page 26 SiE00-01 Maintenance 2. Take out the heat exchange elements from the unit body. VAM150 1000FJVE Heat Exchange Element (X2) Handle Rail Filter x 2 VAM1500 2000FJVE Heat Exchange Element (X4) Handle Rail Filter x 4 3. To clean the air filter, lightly pat it with hand or remove dust with a vacuum cleaner. If excessively dirty, wash it in water.

- Page 27 Maintenance SiE00-01 5. Install the maintenance cover securely in place. Caution 1. Do not wash the air filter in hot water. 2. Do not dry the air filter over a fire. 3. Do not expose the air filter to direct sunlight. 4.

-

Page 28: Maintenance For The Heat Exchange Element

SiE00-01 Maintenance Maintenance for The Heat Exchange Element CLEANING FREQUENCY AT LEAST ONCE EVERY TWO YEARS (FOR GENERAL OFFICE USE) (CLEAN THE ELEMENT MORE FREQUENTLY IF NECESSARY.) 1. Use a vacuum cleaner to remove dust and foreign objects on the surface of the heat exchange element. Use the vacuum cleaner equipped with a brush on the tip of the suction nozzle. - Page 29 Maintenance SiE00-01 Maintenance...

-

Page 30: Part 5 Control Functions

SiE00-01 Part 5 Control Functions 1. Control Functions ..................22 1.1 List of Control Functions................ 22 1.2 Explanation of Individual Functions ............23 1.3 Layout of switches on Printed Circuit Board.......... 28 Control Functions... -

Page 31: Control Functions

Control Functions SiE00-01 1. Control Functions List of Control Functions Classification Function name Outline of function 1. Basic functions 1.1 Ventilation Controls supply air fan motor, exhaust air fan motor and damper (functions related to operation control motor. basic performance) function 1.2 Abnormality Detects abnormalities in thermistor, damper motor and data... -

Page 32: Explanation Of Individual Functions

SiE00-01 Control Functions Explanation of Individual Functions 1.2.1 Ventilation Operation Control Controls ventilation fan motors (supply and exhaust air fans) and damper motor. 1) Normal operation Operation chart Cleaning Filter sign Normal ventilation Operation time reset mode selection Stop Ventilation fan motor Damper motor Total heat (ventilation mode) - Page 33 Control Functions SiE00-01 1.2.2 Pre-cool/Pre-heat Pre-cool/pre-heat operations require the following conditions. 1. System Pre-heat operation is possible only in air conditioner linked system (1 group, 2-group link). Check the system first. 2. Heat recovery ventilation setting Set Preheat ON/OFF to ON. Pre-cool/pre-heat On/OFF setting can be made in air conditioner or using field setting mode of LCD remote controller of heat recovery ventilation unit.

- Page 34 SiE00-01 Control Functions 1.2.3 Cold Area Mode Stops or lowers ventilation airflow during defrosting operation and compressor non-operating condition when equipment in heating mode, thus reducing heating load and cold air draft. Operation chart (in heating operation only) Normal ventilation Operation Defrosting operation mode selection...

- Page 35 Control Functions SiE00-01 2) Link control of 2 or more groups (zone link) Heat recovery ventilation unit can be operated when one or more air conditioners are operating. Allows independent operation of heat recovery ventilation unit from VRV-system remote controller during interim periods (direct duct connection is not allowed in this system).

- Page 36 SiE00-01 Control Functions Details of setting Mode Setting Setting Setting position Operation method mode switch Indication of Field 18(28) Indication — — — — ventilation mode / setting Indication Not indication Refer to P54 Fresh up air Indication Indication — —...

-

Page 37: Layout Of Switches On Printed Circuit Board

Control Functions SiE00-01 Layout of switches on Printed Circuit Board 1.3.1 Printed Circuit Board Damper Damper Primary Secondary Supply Exhaust air fan air fan Outdoor Thermistor Indoor Thermistor Damper 2 Damper 1 KRP50-2 Power supply Factory setting REMOTE CENTRAIZD THE INPUT Be sure to give CONTROLLER CONTROL... -

Page 38: Part 6 Circuit Operations

SiE00-01 Part 6 Circuit Operations 1. Circuit Operations .................30 1.1 Circuit Configuration ................30 1.2 Circuit Functions..................31 Circuit Operations... -

Page 39: Circuit Operations

Circuit Operations SiE00-01 1. Circuit Operations Circuit Configuration Fan motor Damper motor PCB assembly Fan motor, Transformer damper motor relay Detection and cut-off of+16V current +16V Power supply Thermistor + 5V circuit Thermistor interface circuit To circuits and Relay drive microcomputer circuit Centralized control... -

Page 40: Circuit Functions

SiE00-01 Circuit Operations Circuit Functions Classification Circuit Function Input/output Central data transmission interface Used by centralized control equipment for operation control. Allows control of up to 64 groups of air conditioners and heat recovery ventilation units. Use of KRP2A61 allows zone link operation. - Page 41 Circuit Operations SiE00-01 Circuit Operations...

-

Page 42: Part 7 Troubleshooting

SiE00-01 Part 7 Troubleshooting 1. Troubleshooting ..................34 1.1 Error Code Indication................34 1.2 Overall Alarm..................35 1.3 Overall Malfunction................36 1.4 Indoor Air Thermistor Error..............37 1.5 Outdoor Air Thermistor Error ..............38 1.6 Damper System Error (Alarm) ............... 39 1.7 Damper System Error (Alarm) ............... -

Page 43: Troubleshooting

Troubleshooting SiE00-01 1. Troubleshooting Error Code Indication When an abnormality is generated, take necessary measures by referring to displayed error code. After the cause of abnormality is removed, operate equipment and check proper functioning. Indication of unit No. of abnormal Inspection indication Error code heat reclaim ventilation unit... -

Page 44: Overall Alarm

SiE00-01 Troubleshooting Overall Alarm 6 6 6 6 0 0 0 0 — Remote Controller Error Code Inspection Unit No. LCD Display LED Indication Remote Controller Main Unit Error Detection Abnormalities are detected based on open circuit in external input terminals (J1-JC). Method Error Generating When external input terminal (J1-JC) is shorted during operation... -

Page 45: Overall Malfunction

Troubleshooting SiE00-01 Overall Malfunction 6 6 6 6 0 0 0 0 Remote Controller Error Code Inspection Unit No. LCD Display LED Indication Remote Controller Main Unit Error Detection Errors are detected based on open circuit in external input terminals (J1-JC). Method Error Generating When external input terminal (J1-JC) is shorted during operation (“Overall Alarm”... -

Page 46: Indoor Air Thermistor Error

SiE00-01 Troubleshooting Indoor Air Thermistor Error 6 6 6 6 4 4 4 4 — Remote Controller Error Code Inspection Unit No. LCD Display LED Indication Remote Controller Main Unit Error Detection Temperature detected by inside air temperature sensor is used to detect errors. Method Error Generating When value detected by inside air temperature sensor is -40ºC or below (open circuit) or 70ºC or higher... -

Page 47: Outdoor Air Thermistor Error

Troubleshooting SiE00-01 Outdoor Air Thermistor Error 6 6 6 6 5 5 5 5 — Remote Controller Error Code Inspection Unit No. LCD Display LED Indication Remote Controller Main Unit Error Detection Temperature detected by outside air temperature sensor is used to detect errors. Method Error Generating When value detected by outside air temperature sensor is -40ºC or below (open circuit) or 70ºC or higher... -

Page 48: Damper System Error (Alarm)

SiE00-01 Troubleshooting Damper System Error (Alarm) 6 6 6 6 A A A A — Remote Controller Error Code Inspection Unit No. LCD Display LED Indication Remote Controller Main Unit Error Detection Measurement of damper motor limit ON/OFF time. Method Error Generating When damper motor limit switch 1 (or 2) remains ON (or OFF) for more than a certain time duration after Conditions... -

Page 49: Damper System Error (Alarm)

Troubleshooting SiE00-01 Damper System Error (Alarm) 6 6 6 6 A A A A Remote Controller Error Code Inspection Unit No. LCD Display LED Indication Remote Controller Main Unit Error Detection Measurement of damper motor limit switch ON/OFF time and temperatures detected by outdoor and indoor Method air thermistor. -

Page 50: Dedicated Lcd Remote Controller

SiE00-01 Troubleshooting Dedicated LCD Remote Controller 8 8 8 8 8 8 8 8 Error Detection When “ ” remains on remote controller display. Method Error Generating Remote control setting error Conditions Eg. one remote controller set to “SUB” and a second remote controller set to “MAIN, MAIN” or “SUB, SUB” Possible Causes Master-slave setting of remote controller Remote controller PCB assembly error... -

Page 51: Data Transmission Error (Between Lcd Remote Controller And Main Unit)

Troubleshooting SiE00-01 Data Transmission Error (Between LCD Remote Controller and Main Unit) U U U U 5 5 5 5 Remote Controller Error Code Inspection Unit No. LCD Display LED Indication Remote Controller Main Unit Error Detection Microcomputer checks if data is transmitted properly between main unit and remote controller. Method Error Generating When data transmission is not performed correctly for a certain time period. -

Page 52: Data Transmission Error (Lcd Remote Controller)

SiE00-01 Troubleshooting 1.10 Data Transmission Error (LCD Remote Controller) U U U U 5 5 5 5 Remote Controller Error Code Inspection Unit No. LCD Display LED Indication Remote Controller Main Unit Error Detection Microcomputer checks if data is transmitted properly between main unit and remote controller. Method Error Generating When data transmission is not performed correctly for a certain time period. -

Page 53: Data Transmission Error (Between Lcd Master Remote Controller And Slave Remote Controller)

Troubleshooting SiE00-01 1.11 Data Transmission Error (Between LCD Master Remote Controller and Slave Remote Controller) U U U U 8 8 8 8 Remote Controller Error Code Inspection Unit No. LCD Display LED Indication Remote Controller Main Unit Error Detection Microcomputer checks if data is transmitted properly between master-slave remote controller. -

Page 54: Field Setting Error

SiE00-01 Troubleshooting 1.12 Field Setting Error U U U U A A A A Remote Controller Error Code Inspection Unit No. LCD Display LED Indication Remote Controller Main Unit Error Detection Microcomputers checks if data are transmitted correctly on the communication wire Method Error Generating Please consult flow chart below... -

Page 55: Overlapping Central Control Address

Troubleshooting SiE00-01 1.13 Overlapping Central Control Address U U U U C C C C Remote Controller Error Code Inspection Unit No. LCD Display LED Indication Remote Controller Main Unit Error Detection Remote controller microcomputer checks for double-setting of addresses. Method Error Generating When same address is set to two or more units. -

Page 56: Main Unit Pcb Assembly

SiE00-01 Troubleshooting 1.14 Main Unit PCB Assembly Error Detection Check microcomputer operation monitor. Method Error Generating When main unit PCB assembly does not operate. Conditions When communication circuit errors. Possible Causes Fuse (excess current) Power transformer Noise Main unit PCB Troubleshooting Turn off power, then restart. -

Page 57: Dedicated Lcd Remote Controller

Troubleshooting SiE00-01 1.15 Dedicated LCD Remote Controller When no indication is displayed on remote controller Error Detection Check to see if remote controller displays indication. Method Error Generating When main unit PCB assembly does not operate. Conditions When communication circuit errors. Possible Causes Error on communication wire. -

Page 58: How To Check

SiE00-01 Troubleshooting 1.16 How to Check Check 1 Dedicated LCD remote controller (Option) Main unit PCB (HL034) Check 2 Dedicated LCD remote controller (Option) Main unit PCB (HL035) Check 3 Dedicated LCD remote controller (Option) LCD remote controller Remote controller for heat recovery ventilation Main unit PCB (HL036) -

Page 59: Thermistor

Troubleshooting SiE00-01 1.17 Thermistor Error Detection Remove thermistor and check resistance with tester. Method Error Generating Deterioration of thermistor. Conditions Possible Causes Faulty thermistor Broken wire Faulty control PCB Faulty contact in connector Troubleshooting Remove thermistor from main unit PCB (X12A, X13A), and check resistance using tester. -

Page 60: Power Transformer

SiE00-01 Troubleshooting 1.18 Power Transformer Error Detection Check resistance and voltage with tester, and insulation resistance with megger. Method Error Generating Overcurrent (by surging etc.). Deterioration of transformer. Conditions Possible Causes Deterioration of transformer. Troubleshooting Check resistance of primary side of transformer. -

Page 61: Damper Motor

Troubleshooting SiE00-01 1.19 Damper Motor Error Detection Check damper motor and limit switch when damper motor does not operate. Method Error Generating Deterioration of damper motor. Deterioration of limit switch. Conditions Possible Causes Deterioration of damper motor. Deterioration of limit switch. Troubleshooting Place tester probes at connectors of limit... -

Page 62: Part 8 Supplementary Explanation

SiE00-01 Part 8 Supplementary Explanation 1. Supplementary Explanation ..............54 1.1 Field Setting, Service Mode Operation..........54 Supplementary Explanation... -

Page 63: Supplementary Explanation

Supplementary Explanation SiE00-01 1. Supplementary Explanation Field Setting, Service Mode Operation 1.1.1 Field Setting Initial setting (mode Nos. 17, 27, 18, 28) Field setting mode Unit No. Setting position No. Setting switch No. Mode No. 1, 7 (HL039) Step 1 With equipment in normal mode, press the button for more than 4 seconds to enter field setting mode. - Page 64 SiE00-01 Supplementary Explanation Centralized control group No. setting Field setting mode (Mode No. 00) Setting of Individual No. (Mode No. 30) Group No. Mode No. 1, 5 (HL040) Step 1 With equipment in normal mode, press the button for more than 4 seconds to enter field setting mode.

- Page 65 Supplementary Explanation SiE00-01 1.1.2 Service Mode Operation Turn on the forced fan (Mode No.43) Mode No. Unit No. 1, 4 (HL041) Step 1 With equipment in field setting mode, press the button for more than 4 seconds to enter service mode. ↔...

- Page 66 SiE00-01 Supplementary Explanation Unit No. reallocation (Mode Field setting mode No.45) Unit No. before reallocation Unit No. after reallocation Mode No. 1, 6 (HL042) Step 1 With equipment in field setting mode, press the button for more than 4 seconds to enter service mode.

- Page 67 Supplementary Explanation SiE00-01 1.1.3 Operation Changeover Control For group control of systems containing heat recovery ventilation units and air conditioners (VRV system), remote controllers of air conditioners are connected with remote controllers of new heat recovery ventilation units. In such system, both remote controllers display “Operation changeover control” according to the ON/OFF of cooling/heating selection privilege.

- Page 68 SiE00-01 Supplementary Explanation 1.1.4 Field Setting The following shows the procedure for field setting using remote controller of new heat recovery ventilation unit. (HL044) List of field setting mode Nos. Centralized control group No. setting General setting 10-29 Centralized control group No. setting (group) Error record display Sensor data Forced fan ON...

- Page 69 Supplementary Explanation SiE00-01 1.1.5 LCD and Operation Panel (Reference Information) The following shows the operation panel and LCD of remote controller of new heat recovery ventilation unit. (HL045) LCD is equipped with a new function that graphically displays currently selected ventilation mode, as shown below.

- Page 70 SiE00-01 Supplementary Explanation 1.1.6 Ventilation Volume (Freshup) Ventilation volume (Freshup) setting (With Freshup) (Without Freshup) changes as follows. High High Freshup Function modes change in sequence every time button is pressed. High Freshup (HL051) Inspection Inspection operation is shown below. Unit Cyclic (Normal screen)

- Page 71 Supplementary Explanation SiE00-01 1.1.7 Field Setting (Example of setting operation) Centralized control 1. Press for more than 4 seconds. group No. setting 2. Set mode No. to “00” using (mode No.: 00) 3. Set centralized control group No. using ] or 4.

- Page 72 SiE00-01 Supplementary Explanation Individual Settings Heat recovery Ventilation Unit Air Conditioner Ventilation Volume Ventilation Mode Airflow Volume Airflow Direction As indicated by LCD As indicated by LCD High Swing Supplementary Explanation...

- Page 73 Supplementary Explanation SiE00-01 Supplementary Explanation...

-

Page 74: Part 9 Appendix

SiE00-01 Part 9 Appendix 1. Appendix ....................66 1.1 Wiring Diagram..................66 Appendix... -

Page 75: Appendix

Appendix SiE00-01 1. Appendix Wiring Diagram VAM150FJVE / VAM250FJVE / VAM350FJVE / VAM500FJVE / VAM650FJVE / VAM800FJVE / VAM1000FJVE Appendix... - Page 76 SiE00-01 Appendix VAM1500FJVE / VAM2000FJVE Appendix...

- Page 77 Appendix SiE00-01 Appendix...

-

Page 78: Index

SiE00-01 Index Direct duct connection with air conditioner .... 23 Display OFF in automatic ventilation mode ... 60 Abnormality control function ........22 Duct Connection Flange ........2, 3 Air conditioner link function ........22 Air Conditioner Link Operation .......25 Air conditioner link operation ........31 EEPROM ............... - Page 79 SiE00-01 Operation chart ............. 23 Operation for INDIVIDUAL SYSTEM ....11 General Constructions ..........2 Operation mode selector ........13 General setting ............59 Operation with The Remote Control Group function ............22 for Air Conditioning Operation Group No. setting for centralized controller HRV Units.

- Page 80 SiE00-01 Unit No. reallocation ..........59 Unit No. reallocation (Mode No.45) ......57 Ventilation capacity changeover function ....22 Ventilation mode changeover function ....22 Ventilation mode setting .........27 Ventilation mode:Total heat exchange ....60 Ventilation Operation Control .........23 Ventilation operation control function .....22 Ventilation volume (Freshup) setting changes ..61 When no indication is displayed on remote controller ........48 Yes / No setting for direct duct Connection...

- Page 81 SiE00-01 Index...

-

Page 82: Drawings & Flow Charts

SiE00-01 Drawings & Flow Charts Air Conditioner Link Operation HOW TO OPERATE WITH TIMER ....... 12 1 group link control ..........25 Link control of 2 or more groups ......26 Air flow rate can be changed over ......11 Initial setting (mode Nos. 17, 27, 18, 28) ....54 Inspection operation .......... - Page 83 SiE00-01 VAM500EJVE / VAM800EJVE / VAM1000EJVE ...66 Ventilation mode changeover ........12 Ventilation mode:Total heat exchange ....60 Ventilation volume (Freshup) setting changes ..61 When “88” remains on remote controller display ...41 When no indication is displayed on remote controller ........48 Wiring Diagram ............66 Drawings &...

- Page 84 Daikin Europe NV is approved by LRQA for its Quality Management System in accordance with the ISO9001 standard. ISO9001 pertains to quality assurance regarding design, development, manufacturing as well as to services related tot the product.

Need help?

Do you have a question about the VAM 150FJVE and is the answer not in the manual?

Questions and answers