HWH 325 Series Operator's Manual

Touch panel-controlled leveling system

Hide thumbs

Also See for 325 Series:

- Operator's manual (15 pages) ,

- Operator's manual (20 pages) ,

- Operator's manual (13 pages)

Table of Contents

Advertisement

OPERATOR'S MANUAL

HWH TOUCH PANEL-CONTROLLED

325 SERIES LEVELING SYSTEM

UNDERSTAND OPERATOR'S MANUAL BEFORE USING. BLOCK FRAME AND TIRES

Ph: 800/321-3494 (or) 563/724-3396 | Fax: 563/724-3408

AP31338

H H

W

CORPORATION

R

FEATURING:

Touch Panel Leveling Control

BI-AXIS Hydraulic Leveling

R

Straight-Acting Jacks

Pilot Operated Suspension Air Dump

Two Room Extensions

HWH HYDRAULIC LEVELING

ON

NOT IN

PARK/

BRAKE

STORE

DUMP

OFF

CAUTION!

SECURELY BEFORE REMOVING TIRES OR CRAWLING UNDER VEHICLE.

HWH CORPORATION

(On I-80, Exit 267 South)

2096 Moscow Road | Moscow, Iowa 52760

www.hwh.com

R

ML31339/MP05.7101

07AUG03

Advertisement

Table of Contents

Summary of Contents for HWH 325 Series

- Page 1 CORPORATION OPERATOR’S MANUAL HWH TOUCH PANEL-CONTROLLED 325 SERIES LEVELING SYSTEM FEATURING: Touch Panel Leveling Control BI-AXIS Hydraulic Leveling Straight-Acting Jacks Pilot Operated Suspension Air Dump Two Room Extensions HWH HYDRAULIC LEVELING NOT IN PARK/ BRAKE STORE DUMP CAUTION! UNDERSTAND OPERATOR’S MANUAL BEFORE USING. BLOCK FRAME AND TIRES SECURELY BEFORE REMOVING TIRES OR CRAWLING UNDER VEHICLE.

-

Page 2: How To Obtain Warranty Service

HWH CORPORATION personnel will contact you to the problem quickly. If the dealer has difficulty solving determine whether or not your claim is valid. If it is, HWH the problem, he should immediately contact the Customer CORPORATION will authorize repair or replacement of the Service Department, at HWH CORPORATION. -

Page 3: Control Functions

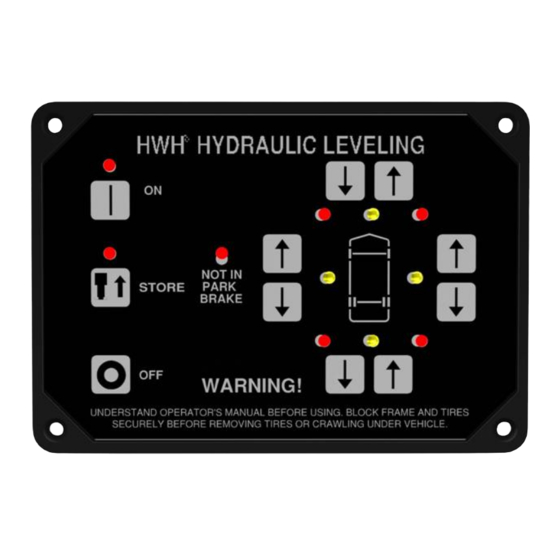

325 - CONTROL IDENTIFICATION LEFT SIDE EXTEND BUTTON FRONT RETRACT BUTTON HWH HYDRAULIC LEVELING POWER ON LIGHT FRONT EXTEND BUTTON "ON" BUTTON WARNING LIGHTS (4-Red) RIGHT SIDE EXTEND BUTTON STORE LIGHT NOT IN PARK/ "STORE" BUTTON BRAKE RIGHT SIDE RETRACT BUTTON... -

Page 4: Pump Run Time

For cold weather information see "COLD WEATHER OPERATIONS" below. The HWH systems with a computer processor monitor the pump run time and will turn the pump off if the run time exceeds a specified time. This time can vary with different systems. Due to available electronics or system design, the pump run time programs will also vary. -

Page 5: Operating Procedures

OPERATING PROCEDURES GENERAL INSTRUCTIONS GENERAL INSTRUCTIONS Site selection - Maintain adequate clearance in all Read all room extension operating procedures before directions for vehicle, room extensions, awnings, doors, before extending or retracting any room. steps, etc. Vehicle may move in any direction due to jacks extending or retracting, settling of jacks or vehicle, It is the operator’s responsibility to check that the jacks are completely retracted and any room extension or... - Page 6 OPERATING PROCEDURES 325 SERIES LEVELING SYSTEM JACK RETRACTION CAUTION: THE OPERATOR MUST BE SURE THAT EXTEND POSITION STORE/TRAVEL POSITION THERE ARE NO OBJECTS UNDER THE VEHICLE AND THAT ALL PEOPLE ARE CLEAR OF THE VEHICLE. 1. Turn the ignition to "ON" or "ACC" or start the engine.

- Page 7 Use the manual valve release for retracting the jacks only removed to gain access. Open valve 1-1/2 to 2 full turns. if the STORE feature on the HWH control panel will not DO NOT turn the 1/4" valve release nut more than retract the jacks.

- Page 8 NOTE: If the MANUAL RETRACT WINCH is attached to room. DO NOT reverse direction of the room, contact the room remove it before extending the room. HWH Customer Service for assistance 1-800-321-3494. CAUTION: KEEP PEOPLE AND OBSTRUCTIONS NOTE: Releasing the ROOM CONTROL SWITCH will CLEAR OF ROOM WHEN OPERATING.

- Page 9 Follow steps 2 and 3 and try pushing the room in. it to the room according to the vehicle manufacturer’s Contact the vehicle manufacturer or HWH Customer instructions. To extend the WINCH STRAP firmly grasp Service at 1-800-321-3494 or 563-724-3396 for assistance.

- Page 10 IMPORTANT: If at any stage something is not THE ROOM. understood or if the room begins to bind DO NOT force the room, contact HWH Customer Service for assistance 1. Determine which extend and retract solenoid valves are 1-800-321-3494. assigned to the room. Manually open the valve release nuts IMPORTANT: DO NOT EXTEND THE ROOM for the extend and retract solenoid valves by turning the 1/4"...

- Page 11 IMPORTANT: If at any stage something is not CAP-DIP understood or if the room begins to bind DO NOT force STICK the room, contact HWH Customer Service for assistance 1-800-321-3494. HYDRAULIC PUMP/MANIFOLD LEVELING SYSTEM MANIFOLD NOT SHOWN Manual Retraction Bolt Thumb Screw MP35.953D...

-

Page 12: Maintenance

Dexron automatic transmission fluid contains red dye and can cause staining should a leak occur. DO NOT USE All jacks and any HWH room extension cylinders should be brake fluid or hydraulic jack fluid. Use of these can damage completely retracted before checking the oil level. The oil seals. - Page 13 Move the adjustment for that light very, very, slightly in qualified RV repair center, your vehicle or coach the OPPOSITE direction that is given in the above manufacturer, or HWH CORPORATION for service or repair. instructions for LED’s A, B, C, and D. This will allow MP45.3259 07MAY09 MP44.1501...

- Page 14 HYDRAULIC LINE CONNECTION DIAGRAM 305/325 SERIES LEVELING SYSTEM (WITH 4 STRAIGHT-ACTING JACKS) NOTE: BEFORE OPERATING ANY MANUAL VALVE RELEASE READ AND UNDERSTAND PROCEDURE FOR MANUAL JACK RETRACTION IN OPERATOR’S INSTRUCTIONS. THIS MANIFOLD IS SHOWN WITH (1) LARGE VALVE WITH A VALVE RELEASE "T"-HANDLE, (2) SMALL VALVES WITH VALVE RELEASE NUTS...

- Page 15 HYDRAULIC SCHEMATIC 305/310/325 SERIES LEVELING SYSTEM WITH STRAIGHT-ACTING JACKS RELIEF VALVE 12 VOLT D.C. HYDRAULIC SOLENOID MANIFOLD POWER UNIT ASSEMBLY RETURN PRESSURE PRESSURE/RETURN 50 PSI SHUTTLE VALVE SWITCH CHECK SOL.VALVE SOL.VALVE SOL.VALVE SOL.VALVE VALVE INNER CHECK VALVE OUTER LEFT RIGHT...

- Page 16 HYDRAULIC LINE CONNECTION DIAGRAM ONE OR TWO ROOM EXTENSIONS ROOM 1 (A) CAP END CONNECTION - A SEE HYDRAULIC LINE CONNECTION DIAGRAMS FOR ROOM EXTENSIONS FOR SPECIFIC CYLINDER ROOM 1 CYLINDER CONNECTION DIAGRAMS ROD END EXTEND SOLENOID CONNECTION - B VALVE VALVE RELEASE...

- Page 17 CYLINDER MUST BE THE SAME LENGTH AND DIAMETER. THE B1 LINES MUST BE HIGH PRESSURE HOSE. NOTE: DIFFERENT TYPES OF HOSE, ESPECIALLY HIGH PRESSURE HOSE, HAS BEEN USED. THE PRINTING ON A 1/8" OR 3/16" HOSE BEING REPLACED MUST MATCH THE ORIGINAL HOSE. ALL HWH 1/4" HOSE IS THE SAME. VIEW 1 ROD END...

- Page 18 HYDRAULIC LINE CONNECTION DIAGRAM SINGLE CYLINDER "GUIDED" ROOM EXTENSION NOTE: THE ROD END CONNECTION FROM THE MANIFOLD TO THE ROOM CYLINDER IS ALWAYS PRESSURIZED. CAP END ROD END CONNECTION - A CONNECTION - B CYLINDER EXTEND - ROOM EXTEND CYLINDER RETRACT - ROOM RETRACT CHECK OIL LEVEL WITH ROOM RETRACTED.

- Page 19 HYDRAULIC FLOW DIAGRAM VERTICAL ARM OR DUAL CYLINDER ROOM EXTENSION WITH SYNCHRONIZING CYLINDER STATIONARY POSITION FRONT CYLINDER FIXED TO VEHICLE SYNCHRONIZING VALVE SYNCHRONIZING VALVE SYNCHRONIZING CYLINDER FIXED TO VEHICLE REAR CYLINDER CYLINDER CYLINDER EXTEND RETRACT VALVE VALVE RETURN PRESSURE MP65.9455 10NOV03...

- Page 20 HYDRAULIC FLOW DIAGRAM SINGLE CYLINDER ROOM EXTENSION STATIONARY POSITION FIXED TO VEHICLE CYLINDER CYLINDER CYLINDER EXTEND RETRACT VALVE VALVE CHECK VALVE RETURN PRESSURE MP65.9459 06NOV02...

- Page 21 ELECTRICAL CONNECTION DIAGRAM 325 SERIES LEVELING SYSTEM AIR DUMP - PARK BRAKE - MASTER WARNING LIGHT AND BUZZER TOUCH PANEL - JACK WARNING LIGHTS AND PRESSURE SWITCHES TOUCH PANEL HWH HYDRAULIC LEVELING WARNING WARNING NOT IN PARK/ SWITCH SWITCH BRAKE...

- Page 22 6230 325 SERIES LEVELING 6241 SYSTEM - AIR DUMP 1400 6240 TO HWH 4400 GROUND STUD 6240 TO HWH GROUND STUD - 6240 12 PIN BROWN NOTE: ROOM EXTENSION MANIFOLD NOT SHOWN 12 PIN BLACK 4 PIN LEVELING GRAY MANIFOLD...

- Page 23 ELECTRICAL CONNECTION DIAGRAM 325 SERIES LEVELING SYSTEM TOUCH PANEL CONNECTIONS HWH HYDRAULIC LEVELING NOT IN PARK/ BRAKE STORE DUMP CAUTION! UNDERSTAND OPERATOR’S MANUAL BEFORE USING. BLOCK FRAME AND TIRES SECURELY BEFORE REMOVING TIRES OR CRAWLING UNDER VEHICLE. PIN 1 LINK LIGHT...

-

Page 24: Electrical Connection Diagram

ELECTRICAL CONNECTION DIAGRAM 325 SERIES LEVELING SYSTEM CONTROL BOX CONNECTION INFORMATION 12 PIN BROWN PIN 12 PIN 1 PIN 1 12 PIN PIN 1 PIN 12 BLACK 12 PIN PIN 1 8 PIN GRAY PIN 4 BLACK PIN 12 4 PIN... - Page 25 ELECTRICAL CONNECTION DIAGRAM 325 SERIES LEVELING SYSTEM CONTROL BOX - LED - FUSE LOCATION AND DESCRIPTION RELAY DESCRIPTION FUSE 1-YELLOW RIGHT REAR COIL 2-RED RIGHT REAR OUTPUT F1 - 15 AMP 3-YELLOW LEFT REAR COIL 4-RED LEFT REAR OUTPUT F2 - 15 AMP...

- Page 26 ELECTRICAL CONNECTION DIAGRAM TWO ROOM EXTENSIONS TOP VIEW TO HWH GROUND 6245 6246 STUD ON PUMP 5051 5151 5050 5150 6810 12 PIN BROWN 1E - ROOM 1 CYL EXTEND - ROOM EXTEND 12 PIN GREEN 1R - ROOM 1 CYL RETRACT - ROOM RETRACT...

- Page 27 ELECTRICAL CONNECTION DIAGRAM TWO ROOM EXTENSIONS ROOM CONTROL CONNECTIONS ROOM CONTROL SWITCHES AND CONNECTIONS ARE SUPPLIED BY 0.E.M. PIN 13 PIN 15 PIN 1 - BLACK 5000 - ROOM 1 EXTEND PIN 14 PIN 2 - BLACK 5100 - ROOM 1 RETRACT PIN 10 PIN 12 PIN 3 - BLACK 6810 - ROOM 1 SWITCHED BATTERY...

- Page 28 ELECTRICAL CONNECTION DIAGRAM TWO ROOM EXTENSIONS CONTROL BOX CONNECTION INFORMATION - (PAGE 1 OF 2) 12 PIN PIN 1 PIN 12 GREEN WIRE WIRE PIN # WIRE DESCRIPTION AND FUNCTION COLOR NUMBER GREEN CONNECTOR 12 PIN GREEN CONNECTOR BLACK 5050 SWITCHED +12 FOR ROOM 1 CYL EXT SOLENOID VALVE BLACK 5150...

- Page 29 ELECTRICAL CONNECTION DIAGRAM TW0 ROOM EXTENSIONS CONTROL BOX CONNECTION INFORMATION - (PAGE 2 OF 2) 12 PIN BLACK PIN 1 PIN 12 LEVEL SENSOR ADJUSTMENT WIRE WIRE PIN # WIRE DESCRIPTION AND FUNCTION COLOR NUMBER CN2 - 12 PIN BLACK CONNECTOR (SIDE MOUNTED) SWITCHED +12 BATT FROM PUMP RELAY - ROOM 1 BLACK 6810...

- Page 30 BREATHER CAP - DIPSTICK - 1/4" NUT DRIVER 1 1/2" DIAMETER VALVE RELEASE SOLENOID VALVE NOTE: DO NOT turn the valve release nut more than 4 and 1/2 (four and one half) turns counter clockwise. Damage to the valve may result. VALVE RELEASE PLASTIC PLUG 2 1/4"...

Need help?

Do you have a question about the 325 Series and is the answer not in the manual?

Questions and answers