Summary of Contents for IFM SDG082

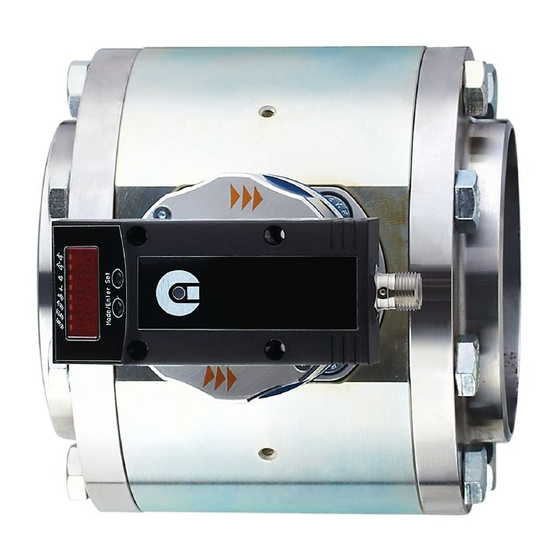

- Page 1 Operating instructions Compressed air meters SDG082 SDG087 SDG102 SDG107 SDG152 SDG157 SDG202 SDG207...

-

Page 2: Table Of Contents

Contents 1 Preliminary note ���������������������������������������������������������������������������������������������������3 1�1 Symbols used ������������������������������������������������������������������������������������������������3 2 Safety instructions �����������������������������������������������������������������������������������������������3 3 Items supplied������������������������������������������������������������������������������������������������������4 4 Functions and features ����������������������������������������������������������������������������������������5 5 Function ���������������������������������������������������������������������������������������������������������������5 5�1 Processing of the measured signals ��������������������������������������������������������������5 5�2 Volumetric flow monitoring �����������������������������������������������������������������������������6 5�3 Consumed quantity monitoring (totalizer function) ����������������������������������������6 5�4 Switching function ������������������������������������������������������������������������������������������7 5�5 Analogue function ������������������������������������������������������������������������������������������7 6 Installation������������������������������������������������������������������������������������������������������������9... -

Page 3: Preliminary Note

10�3�6 Counter reset using an external signal ���������������������������������������������20 10�4 Settings for temperature monitoring ����������������������������������������������������������20 10�4�1 Limit monitoring temperature (OUT2) �����������������������������������������������20 10�4�2 Analogue output temperature (OUT2) ����������������������������������������������20 10�5 User settings (optional) ������������������������������������������������������������������������������20 10�5�1 Standard unit of measurement for volumetric flow ���������������������������20 10�5�2 Standard display �������������������������������������������������������������������������������21 10�5�3 Measured value damping �����������������������������������������������������������������21 10�5�4 Error behaviour of the outputs ����������������������������������������������������������21... -

Page 4: Items Supplied

• If the operating instructions or the technical data are not adhered to, personal injury and/or damage to property can occur� • Ensure before mounting the components into or removing them from the compressed air system that the installation is at a standstill and no pressure is applied�... -

Page 5: Functions And Features

4 Functions and features The unit monitors the standard volume flow of compressed air in industrial use� It detects the process categories volumetric flow quantity and consumed quantity� Application area: compressed air systems in industrial use� All indications apply for standard volume flow to DIN ISO 2533, i�e� volume flow at 1013 hPa, 15 °C and 0 % relative air humidity�... -

Page 6: 5�2 Volumetric Flow Monitoring

5.2 Volumetric flow monitoring The flow is monitored by a calorimetric measuring system� • 2 switching signals for volumetric flow limit values can be provided (output 1 and output 2)� Switching functions → 5.4� • An analogue signal which is proportional to the volumetric flow (4���20 mA) can be provided on output 2�... -

Page 7: 5�4 Switching Function

5.4 Switching function OUTx changes its switching status if it is above or below the set switching limits� Hysteresis or window function can be selected� Hysteresis function Window function SP = set point SP = upper limit rP = reset point rP = lower limit HY = hysteresis FE = window... - Page 8 Factory setting Measuring range scaled MEW = final value of the measuring range Volumetric flow above the measuring range: output signal > 20 mA� Volumetric flow below the measuring range: output signal between 3�6 and 4 mA�...

-

Page 9: Installation

6 Installation ► The rules and regulations for the installation and operation of com- pressed air equipment must be observed� ► Ensure that no pressure is applied to the installation during mounting� 6.1 Installation location • Behind the cold dryer / near the load� •... -

Page 10: 6�3 Installation Position

6.3 Installation position • Permitted installation positions: pipe length vertical, any position (fig� 1, 2), pipe length horizontal, unit vertical (fig� 3, 4), unit on side, pipe length left (fig� 5)� • Avoid the installation position in fig� 6 (unit on side, pipe length right)� If the flow rate is low, the specified measurement accuracy cannot be adhered to�... -

Page 11: 6�4 Install The Pipe Section Into The Pipe

6.4 Install the pipe section into the pipe ► Loosen the screws (1) on the flanges, remove the flanges (2) from the measur- ing section (4)� ► Remove the seals (3) from the flange slots� ► Weld the flanges into the pipe� The welding operation must be carried out by authorised personnel�... -

Page 12: 6�5 Insert The Sensor Into The Quick-Change Fitting

6.5 Insert the sensor into the quick-change fitting ► Manually turn the quick-change fitting (4) in the direction CLOSE - ZU until it stops� ► Remove the protective cover from the measuring probe of the sensor (1)� ► Insert the sensor into the quick- change fitting�... -

Page 13: Electrical Connection

7 Electrical connection The unit must be connected by a qualified electrician� The national and international regulations for the installation of electrical equipment must be adhered to� Voltage supply according to EN 50178, SELV, PELV� ► Disconnect power� ► Connect the unit as follows: BK: black BN: brown OUT2... -

Page 14: Operating And Display Elements

8 Operating and display elements 2 3 4 5 6 7 8 Mode/Enter Set 1 to 8: Indicator LEDs - LED 1���6: process value in the indicated unit of measurement - LED 7, LED 8: switching state of the corresponding output� 9: Alphanumeric display, 4 digits - Current flow volume - Current medium temperature... -

Page 15: Menu

9 Menu Nm/s °C Nl/min x 10 FOU1 FOU2 ImPS ImPR Hno Hnc Fno Fnc ImP Hno Hnc Fno Fnc In.D SELd DIn2 SEL2 rEF.P rEF.T [Mode / Enter] [Set] (LED is lit) = current meter reading * (LED flashes) = stored meter reading... - Page 16 Explanation of the menu ImPS Pulse value (consumed quantity at which 1 pulse is delivered) ImPR Configuration of the output for consumed quantity monitoring: YES (pulse signal), no (switching signal) SP1 / rP1 Upper / lower limit value for the volumetric flow at which OUT1 switches Output function for OUT1 (volumetric flow): - Hno, Hnc, Fno, Fnc: switching signal for the limits - ImP: consumed quantity monitoring (totaliser function)

-

Page 17: Parameter Setting

10 Parameter setting During parameter setting the unit remains in the operating mode� It continues its monitoring function with the existing parameters until the parameter setting has been completed� 10.1 General parameter setting 3 steps must be taken for each parameter setting: Select parameter ►... -

Page 18: 10�2 Settings For Volumetric Flow Monitoring

• Change from menu level 1 to menu level 2: ► Press [Mode/Enter] until [EF] is displayed. Mode/EnterSet ► Press [Set] briefly� > The first parameter of the submenu is displayed (here: [HI])� Mode/EnterSet • Locking / unlocking The unit can be locked electronically to prevent unintentional settings� ►... -

Page 19: 10�2�3 Analogue Output Flow Rate (Out2)

10.2.3 Analogue output flow rate (OUT2) ► Select [SEL2] and set FLOW� ► Select [OU2 ] and set the analogue function: I (4���20 mA)� ► Select [ASP2] and set the volumetric flow value at which the minimum current value is provided�... - Page 20 10.3.6 Counter reset using an external signal ► Select [OU2] and set In�D� ► Select [DIn2] and set the counter reset signal: HIGH = reset for high signal LOW = reset for low signal +EDG = reset for rising edge -EDG = reset for falling edge 10.4 Settings for temperature monitoring 10.4.1 Limit monitoring temperature (OUT2)

- Page 21 10.5.2 Standard display ► Select [SELd] and define the standard unit of measurement FLOW = display shows the current volumetric flow value in the standard unit of meas- urement� TOTL = display shows the current meter reading in the unit providing the highest ac- curacy�...

- Page 22 10.5.7 Low flow cut-off ► Select [LFC] and set the limit� 10.6 Service functions 10.6.1 Read min/max values Read minimum or maximum measured values: ► Select HI or LO HI = maximum volumetric flow, LO = minimum volumetric flow Delete memory: ►...

- Page 23 • If necessary, clean them at regular intervals� To do so, use a suitable cleaning liquid (e�g� alcoholic solution)� • Avoid mechanical damage to the measuring probes� 12 Technical data and scale drawing Technical data and scale drawing at www�ifm�com�...

Need help?

Do you have a question about the SDG082 and is the answer not in the manual?

Questions and answers