Summary of Contents for RADWAG X2 Series

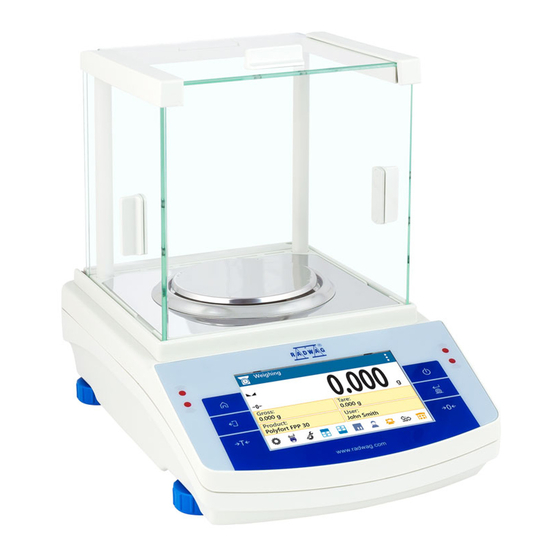

- Page 1 X2 Synergy SERIES AS X2.PLUS Analytical Balances PS X2 Precision Balances WLC X2 Precision Balances BRIEF USER MANUAL IMMU-16-S-03-03-21-EN www.radwag.com...

- Page 2 If you are reading this, it means that you are bound to achieve success. You have purchased a device that has been designed and manufactured to give you years of service. Congratulations and thank you for selecting RADWAG product. MARCH 2021...

-

Page 3: Table Of Contents

CONTENTS General Information ..................5 1.1. Dimensions ..................5 1.2. Connectors ................... 6 1.3. Intended Use ..................7 1.4. Precautions ..................7 1.5. Warranty Conditions ................9 1.6. Supervision over metrological parameters ..........9 1.7. User manual significance ................ 9 1.8. - Page 4 - 4 -...

-

Page 5: General Information

1. GENERAL INFORMATION 1.1. DIMENSIONS AS X2 PLUS series PS X2 series - 5 -... -

Page 6: Connectors

WLC X2 series 1.2. CONNECTORS X2 balances 1. Ethernet RJ45 connector 2. USB 1, Type A connector 3. USB 2, Type B connector 4. COM 1 connector 5. COM 2 connector 6. Power supply socket - 6 -... -

Page 7: Intended Use

Balances to be decommissioned, should be decommissioned in accordance with valid legal regulations. • Do not use the balance is areas endangered with explosion. The X2 series is not designed to operate in EX zones. NOTE: This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to part 15 of the FCC Rules. - Page 8 (1)this device may not cause harmful interference, and (2) this device must accept any interference received, including interference that may cause undesired operation. NOTE: The grantee is not responsible for any changes or modifications not expressly approved by the party responsible for compliance.

-

Page 9: Warranty Conditions

1.5. WARRANTY CONDITIONS A. RADWAG feels obliged to repair or exchange all elements that appear to be faulty by production or by construction, B. Defining defects of unclear origin defects and means of their elimination can only be realized with assistance of manufacturer and user representatives, C. -

Page 10: Transport And Storage

2. TRANSPORT AND STORAGE 2.1. DELIVERY CHECKLIST Upon delivery it is necessary to check the package, make sure that your package bears no signs of damage. 2.2. PACKAGE Keep all package elements should your device be transported in the future. Remember that only original packaging can be used for shipping purposes. - Page 11 AS X2.PLUS • remove a transport lock (1) – gently press the transport lock and turn it accordingly to <OPEN> instruction, keep the transport lock should your balance be transported in the future. • Install components following the above diagram: •...

-

Page 12: Settings

WLC X2, 128x128 mm WLC X2, 195x195 mm • remove tape protecting the grounding spring, located on one of the rubber mandrels (1) • install components following the above diagram: • weighing pan (2), • glass draft shield (3). 3.3. SETTINGS It is necessary to level the balance prior connecting it to the mains. -

Page 13: Maintenance Activities

• Level the balance by turning its feet left/right, follow the pictograms, level marker moves towards the centre of the circle. • When the marker takes central position, its colour turns from red to green – the balance is correctly levelled. Go to the home screen. - Page 14 Cleaning draft shield panes: Select dissolvent depending on a dirt. Never soak the glass panes in alkaline solutions since they interact with glass and may cause damage. Do not use abrasive substances. For organic dirt use acetone first, next use water or detergent. For other than organic dirt use diluted acid solutions (soluble salts of hydrochloric or nitric acid) or base solutions (ammonium or sodium base).

- Page 15 AS X2.PLUS series balances; disassembly steps: Detach the front part of Detach the back part the frame and take out of the frame and take the front pane. out the top pane. Remove the back pane Remove the left and of the chamber.

-

Page 16: Powering The Device

3.5. POWERING THE DEVICE Balance can be connected to the mains only with a power adapter that comes standard with the particular model. Nominal power supply of the power adapter (specified on the power adapter data plate) should be compatible to the power from the mains. Plug the balance to the mains –... -

Page 17: Keyboard - Buttons Functions

5. KEYBOARD – BUTTONS FUNCTIONS Button Overview Press to switch the balance ON/OFF Press to Zero the balance Press to Tare the balance Press to send measurement to a printer or a computer Function key <Esc>, press to abandon parameter changes or exit to previous menu level Function key <Home>, press to exit to home screen Programmable proximity sensors, press to enable operation of freely selected functions - 17 -... -

Page 18: Weighing Mode Home Screen

6. WEIGHING MODE HOME SCREEN The home screen of balance software can be divided into 4 sections: • Top section displaying data on active working mode (pictogram and name), metrologically important data and button enabling selection of functions available for a particular working mode. -

Page 19: Operating Balance Menu

7. OPERATING BALANCE MENU Operation of balance software menu is intuitive and uncomplicated. The touch panel makes the software operation easy. Pressing a function key, a soft key or an area on the display initiates an assigned function or process Touch screen operation is also possible while wearing gloves. -

Page 20: Weighing Operation

8. WEIGHING OPERATION Load a weighed object on a balance weighing pan. On stabilization of weighing result, indicated by stability marker visible on the left side of balance display, read the measurement result. Record / printout of the measurement result is available on pressing <PRINT> key: •... -

Page 21: Logging

8.2. LOGGING Full access to user parameters and to editing databases requires logging as an operator with <Administrator> permissions level. The logging procedure should be carried out on each switching on of the balance. First Log In operation – procedure: •... -

Page 22: Weighing Unit Selection

8.4. WEIGHING UNIT SELECTION Change of weighing unit is carried out by pressing the weighing unit icon visible next to the value of measurement result, or by clicking key (if displayed in an information section). Clicking the unit triggers its replacement, the clicked unit is replaced with the unit that is next on the list of available units. -

Page 23: Adjustment

8. ADJUSTMENT In order to ensure the highest weighing accuracy, it is recommended to periodically introduce a corrective factor of indications to balance memory, the said factor must be referred to a mass standard. In other words, balance adjustment shall be performed from time to time. Adjustment should be carried out: •... -

Page 24: User Adjustment

In order to start user adjustment, enter <Adjustment> submenu and select ‘User adjustment’ option. Then follow the commands displayed on a screen. WORKING MODES – GENERAL INFORMATION Standard version of X2 series balances features the following working modes: Weighing Means of operation: weight of a load is determined through an indirect measurement. A balance measures gravitational force which attracts the load. -

Page 25: Running Working Mode

Peak Hold Means of operation: max temporary indication occurring in course of the weighing process is hold on a display. Formulations Means of operation: by mixing specified ingredients you can obtain particular mixture, in order to program given formulation you have to specify weight of particular ingredients. Particular working modes settings feature specific functions. -

Page 26: Databases

10. DATABASES Balance software features the following databases < >: Products (5 000 products) Users (100 users) Packaging (100 packaging types) Customers (1 000 customers) Formulations (100 formulations consisting of 25 ingredients maximally) Formulations reports (500 reports) Ambient Conditions (10 000 records) Weighings (50 000 records) Alibi (512 000 records) CAUTION! It is not possible to edit some of the databases for a balance cooperating with E2R software. -

Page 27: Communication Protocol

General information A. A character based communication protocol balance-terminal is designed for establishing communication between a RADWAG balance and a peripheral device via RS-232C serial interface. B. It consists of commands sent from a peripheral device to the balance and responses from the balance. -

Page 28: Error Messages

14. ERROR MESSAGES - 28 -... - Page 29 - 29 -...

- Page 30 - 30 -...

Need help?

Do you have a question about the X2 Series and is the answer not in the manual?

Questions and answers