Summary of Contents for TOPP K200

- Page 1 INSTRUCTIONS FOR INSTALLATION AND USE AUTOMATION AND ELECTROMECHANICAL DRIVERS K200 FOR LINEAR SLIDING DOORS WITH ONE OR TWO PANELS installer's manual/original instructions COD. 0P5506 VER 0.0 REV 08.19...

-

Page 3: Table Of Contents

6.1- Maintenance.............................pag. 51 6.2- Spare parts and optional accessories ....................pag. 51 6.3- Disposal ............................pag. 52 6.4- Troubleshooting..........................pag. 52 7- EC DECLARATION OF INCORPORATION OF PARTLY COMPLETED MACHINERY ......pag. 53 EU DECLARATION OF CONFORMITY....................pag. 53 K200 INSTRUCTIONS FOR INSTALLATION AND USE... -

Page 4: 1- General Information

& TOPP srl reserves the right to amend or improve the manual and the products described therein at any time without notice. & The data contained in this manual were written and checked with the maximum care; TOPP srl is not liable for possible errors due to omissions or printing errors, or errors in transcription. -

Page 5: User

It should be applied by the installation technician in a clearly visible position on the outside of the automation unit. PROPER USE The K200 automation mechanism was designed and produced exclusively to operate (open and close) linear sliding doors in residential, public and industrial buildings. -

Page 6: Technical Data

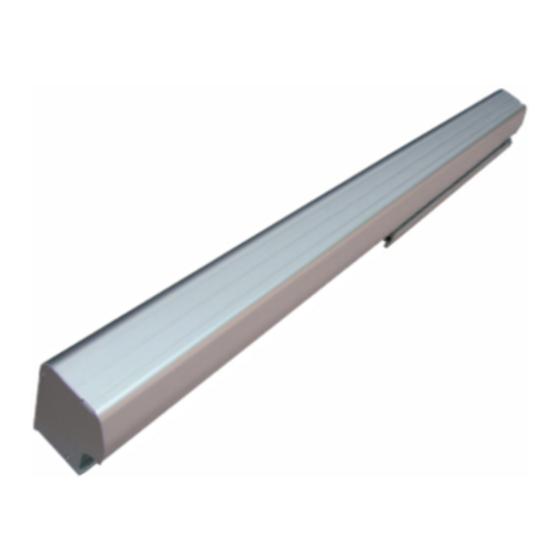

PACKING Every standard product package (cardboard carton) contains: N.1 K200 automatic door (complete with motor unit and belt transmission preassembled on the crossbar, side caps, casing, door stop limit switch, cable raceway, emergency battery,raceway,rubber cable sleeves); N.1 package of hardware consisting of 2 self-tapping screws TC d6x70 and 2 nylon anchor bolts 10x60;... -

Page 7: Models

1 LEFT DOOR PANEL VPA = net doorway width VPA* VL = gross opening LT/LC = automation length / LT/LC casing length BP = rail + runner on the floor PC = electric wire raceway K200 INSTRUCTIONS FOR INSTALLATION AND USE... -

Page 8: Sliding Doors With One Panel

In some countries the laws forbid this type of assembly as there is a possible risk of getting the fingers caught. Fig. 5a Fixed door panel Sliding door panel Automation Fig. 5b Fixed door panel Sliding door panel Tubular jamb Automation Fig. Fixed door panel Sliding door panel Wall end Overlap Automation INSTRUCTIONS FOR INSTALLATION AND USE K200... -

Page 9: Description Of Parts And Dimensions

Plastic runner on floor Toothed transmission belt Wire raceway 17 - Belt transmission with pulley 18 - Door stop Low voltage transformer 19 - Metal motor module 10 - Electronic control circuit 20 - Logline K200 INSTRUCTIONS FOR INSTALLATION AND USE... - Page 10 Fig. Crossbar supporting bracket Fig. INSTRUCTIONS FOR INSTALLATION AND USE K200...

-

Page 11: General Recommendations

& Before installing the automation, verify that the structure to be automated is stable, sturdy and able to withstand the weight of the automation and, if necessary, take steps to ensure that it is. Topp Srl is not liable for failure to comply with the rules of good workmanship in the construction of the door panels to motorize, or for any distortions that may develop with use of the device. -

Page 12: Installing The Adapter And Track

Drill the door panel at the top and fasten the adapter using cylindrical M6 screws or cylindrical self-tapping d5.5 screws depending on the type of material; Drill the door at the bottom and fasten the rail using flared self-tapping cylindrical screws diam. 4.8. Fig. 10 Adapter Door panel Rail INSTRUCTIONS FOR INSTALLATION AND USE K200... -

Page 13: Installing The Carriageson The Door

Fastening nut Standard adapter Fig. 12 Single door panel, opening toward the left Single door panel, opening toward the right Fig. 13 Double door panel, simultaneous opening toward the right and left 15÷70 15÷70 K200 INSTRUCTIONS FOR INSTALLATION AND USE... -

Page 14: Fastening And Adjustment Of The Sliding Panels

Fig. 15 Fig. 14 Load-bearing wheels Anti-derailing wheels Anti-derailing wheels Height adjustment Load-bearing Fastening screw wheels Carriage Carriage fastening screw fastening screw Carrello LEFT RIGHT Adjustment screw Fig. 16 Rear part of door panel INSTRUCTIONS FOR INSTALLATION AND USE K200... - Page 15 Fig. 17 Lower carriage bracket Standard adapter Runner on floor Fig. 18 K200 INSTRUCTIONS FOR INSTALLATION AND USE...

-

Page 16: Installing The Motor Module, Belt Transmission, Belt,Logline

INSTALLING THE MOTOR MODULE, BELT TRANSMISSION, BELT,LOGLINE K200 - model with 2 door Fig. 20 Fig. 19 panels (Fig.19) L Belt L Logline 1000 876 876 2 x 1736 928 928 2 x 1840 1046 1100 1200 980 980 2 x 1944... - Page 17 No. 6 hexagonal wrench -Tighten screws “VTF” after checking that the transmission is aligned with the crossbar. Fig. 23a Belt tension adjustment Fig. 23b Motor module belt trasmission K200 INSTRUCTIONS FOR INSTALLATION AND USE...

-

Page 18: Fastening The Drive Brackets On The Door Panel

FASTENING DOOR DRIVE BRACKETSE Fig. 24 2 DOORS – simultaneous opening toward the right and left INSTRUCTIONS FOR INSTALLATION AND USE K200... - Page 19 Horizontal adjustment slots Door drive bracket Lower belt bracket Fig. 26 1 LEFT DOOR – opening toward the left M6x8 screws Front door carriage M6x10 screws Horizontal adjustment slots Door drive bracket Upper belt bracket K200 INSTRUCTIONS FOR INSTALLATION AND USE...

-

Page 20: Installing The Door Block

Attention!: The door block system is not to be considered Manual release as a device for protection against break-ins. INSTRUCTIONS FOR INSTALLATION AND USE K200... -

Page 21: Installing The Casing

Fig.32 Ref.4 Fasten the casing to the beam using the two screws type TCEI M5x10. Fig. 32 antivibration felt Rating place and “CE” marking M3,5x9,5 screws for fastening casing M5x10 screws for fastening casing K200 INSTRUCTIONS FOR INSTALLATION AND USE... -

Page 22: 4- Electrical Connection

Make sure that all the cables are inside the duct and that they cannot come into contact with moving parts once positioned. During installation, make sure that the conductor cables are secured by an additional attachment near the terminals or electrical connections, i.e. using bands. Make sure that the cables are stripped near the terminals. INSTRUCTIONS FOR INSTALLATION AND USE K200... -

Page 23: Electronic Circuit Board

7. Transformer input 8. Emergency battery system 9. Door block 2 input 13 11 14 (pharmacy) 10. Door block 1 input K200 11. Lighted display 12. Gearmotor input 13. DOWN key Dip-Switch 1=off 14. ENTER key Dip-Switch 2=on 15. Dip-switch... -

Page 24: Pre-Wired Electrical Connections

LAMP 14. LATERAL SECURITY 32. 24V SAFETY 1 22. EXTERNAL CURTAINS 15. GND RADAR 16. 24V 23. GND 24V* 24. 24V Ÿ Ÿ SIGNAL A Ÿ GND (shield) Ÿ SIGNAL B Ÿ * Unregolated INSTRUCTIONS FOR INSTALLATION AND USE K200... -

Page 25: Electrical Wiring Diagram (Flow Chart)

ELECTRICAL WIRING DIAGRAM (FLOW CHART) Fig. 35 INSTRUCTIONS FOR INSTALLATION AND USE K200 K200... -

Page 26: Connection Of Detection Sensors

NO ATT. white white COM. ATT. grey grey grey grey +24V green/black green/black N.C. SIC white/black white/black COM. SIC yellow yellow NO ATT. COM. ATT. white white grey grey grey grey +24V INSTRUCTIONS FOR INSTALLATION AND USE K200... - Page 27 RX1 - TX1 = First beam RX2 - TX2 = Second beam ACTIVATION yellow yellow N.O. white white grey grey grey grey +24V ACTIVATION yellow yellow N.O. white white grey grey +24V grey grey INSTRUCTIONS FOR INSTALLATION AND USE K200 K200...

- Page 28 RX2 - TX2 = Second beam yellow yellow N.O. ACT. white white grey grey grey grey +24V green/black green/black N.C. SIC. white/black white/black yellow yellow N.O. ACT. white white grey grey grey grey +24V INSTRUCTIONS FOR INSTALLATION AND USE K200...

- Page 29 +24V yellow yellow N.O. ACT. white white grey grey grey grey +24V green/black green/black N.C. SIC. white/black white/black yellow yellow N.O. ACT. white white grey grey grey grey +24V INSTRUCTIONS FOR INSTALLATION AND USE K200 K200...

- Page 30 Fig. ¬Digital program switch menu: PARAMETERS>OTHER PARAMETERS> SAFETY SENSOR LOGIC: N.C. WITHOUT TEST program parameter 9 with the dot IS2 INTERNAL ACTIVATION/SAFETY IS2 EXTERNAL ACTIVATION/SAFETY SENSOR SENSOR IS5 LATERAL SENSOR N.C. N.C. INSTRUCTIONS FOR INSTALLATION AND USE K200...

- Page 31 RX1 - TX1 = First beam Rx2 - TX2 = Second Beam ACTIVATION yellow yellow N.O. white white grey grey grey grey +24V N.C. ACTIVATION yellow yellow N.O. white white grey grey grey grey +24V INSTRUCTIONS FOR INSTALLATION AND USE K200 K200...

- Page 32 NO ACT. white white COM. ACT. grey grey grey grey +24V green/black green/black N.C. SIC white/black white/black COM. SIC yellow yellow NO ACT. COM. ACT. white white grey grey grey grey +24V N.C. N.C. INSTRUCTIONS FOR INSTALLATION AND USE K200...

- Page 33 N.C. N.C. N.O. yellow yellow ACT. white white grey grey grey grey +24V green/black green/black N.C. SIC. wite/black wite/black yellow yellow N.O. ATT. white white grey grey grey grey +24V INSTRUCTIONS FOR INSTALLATION AND USE K200 K200...

- Page 34 RX1 - TX1 = First beam Rx2 - TX2 = Second beam ACTIVATION yellow yellow N.O. white white N.C. grey grey grey grey +24V ACTIVATION N.C. yellow yellow N.O. white white grey grey grey grey +24V INSTRUCTIONS FOR INSTALLATION AND USE K200...

- Page 35 ACTIVATION green green N.O. white white brown brown +24V black black TST- TEST TST+ N.C. rose rose SECURITY blue blue yellow yellow ACTIVATION green green N.O. white white brown brown +24V INSTRUCTIONS FOR INSTALLATION AND USE K200 K200...

- Page 36 SECURITY blue blue green green ACTIVATION white white N.O. black black +24V braun braun TST- TEST grey grey TST+ N.C. yellow yellow SECURITY blue blue green green ACTIVATION white white N.O. black black +24V INSTRUCTIONS FOR INSTALLATION AND USE K200...

- Page 37 +24V TST- black black TEST TST+ N.C. rose rose SECURITY blue blue yellow yellow ACTIVATION green green N.O. white white brown brown +24V 16 15 13 11 10 IS5 LATERAL S. INSTRUCTIONS FOR INSTALLATION AND USE K200 K200...

- Page 38 N.O. black black +24V TST- braun braun TEST grey grey TST+ N.C. yellow yellow SECURITY blue blue green green ACTIVATION white white N.O. black black +24V 16 15 13 11 10 IS5 LATERAL S. INSTRUCTIONS FOR INSTALLATION AND USE K200...

- Page 39 PARAMETERS> OTHER PARAMETERS> SAFETY SENSOR LOGIC: N.C. WITH TEST Or program parameter 9 without the dot ELECTRICAL WIRING DIAGRAM FOR OPTEX USING ACTIVATION/SAFETY SENSOR MONITORED IS5 LATERAL S. 1 IS5 LATERAL S. 2 INSTRUCTIONS FOR INSTALLATION AND USE K200 K200...

- Page 40 ¬ PARAMETERS> OTHER PARAMETERS> SAFETY SENSOR LOGIC: N.C. WITH TEST Or program parameter 9 without the dot ELECTRICAL WIRING DIAGRAM FOR HOTRON USING ACTIVATION/SAFETY SENSOR MONITORED IS5 LATERAL S. 1 Is5 LATERAL S. 2 INSTRUCTIONS FOR INSTALLATION AND USE K200...

-

Page 41: Program Selection With Ms1 Knob

Cable ‘shielding’ should only be used for cable lengths in excess of 20 meters. For shorter cables cut the wire at the level of the sheath 1 2 3 4 5 DS2 DIGITAL SELECTOR CIRCUIT INSTRUCTIONS FOR INSTALLATION AND USE K200 K200... -

Page 42: Connection Of Key Device

Digital program switch menu: ¬ PARAMETERS> OTHER PARAMETERS> SAFETY SENSOR LOGIC:N.C. WITH TEST Or program parameter 9 without the dot 11 12 RX1 - TX1 = First Beam INSTRUCTIONS FOR INSTALLATION AND USE K200... -

Page 43: Connetion Of Door Block And Pharmacy Function

Or program parameter 9 with the dot 11 12 RX1 - TX1 = First Beam 4.11 CONNETION OF DOOR BLOCK AND PHARMACY FUNCTION Door block with Door block with manual release manual release incorporated 1 incorporated 2 pharmacy function INSTRUCTIONS FOR INSTALLATION AND USE K200 K200... -

Page 44: 5- Use And Operation

“default battery operation mode”: the “continuous operation mode” and will continue to operate as set as in the selector program. The "battery operation mode" can be changed in other modes, using the Topp DS2 digital program switch. Emergency opening or closing can be set. In the case has been selected a different mode operation than the standard one, the automation will resume to function as the program set by the selector after restoring the 230V mains. -

Page 45: Reset Phase: Learning

MS1, automation will not perform any reset (near) as long as this mode will not be changed or if the request will be 'opening to boost key or emergency opening / fire. Once changed how automation will perform the reset (near) as shown above. INSTRUCTIONS FOR INSTALLATION AND USE K200... -

Page 46: Programming Parameters

1. Press the “DOWN” key and hold for 5 seconds. The sequence of characters “Radio” appears on the 7-segment display. 2. If you have the Topp remote control TS2 press the smooth side of the first key (open function). If the Topp TS1 4-channel remote control is available, press the second key (Close Function). -

Page 47: List Of Errors And Warning

Lateral sensor 2 malfunction. Antipanic sensor malfunction. Obstacle not removed. Check for obstacles or friction. Motor poles inverted. Reverse the cables. Doors free. Bus voltage low. Bus voltage high. Motor bridge voltage high. Causes the door block. INSTRUCTIONS FOR INSTALLATION AND USE K200... -

Page 48: Self Restore Management Of Errors C-D-E-K-N-P-Q

During the slow opening in the preceding paragraph, the occupation of the side sensors causes a slow reclosing Ÿ During the movement, the contemporary employment of at least one safety sensor side and a sensor safety Ÿ compartment passage controls the stop of the door. INSTRUCTIONS FOR INSTALLATION AND USE K200... -

Page 49: Self Restore Management Of Errors F-G-H-I-J

If the doors are smashed until the automation mode is closed and subsequently repositioned does not run no movement reset. For proper operation of the automated system with panic mounted photocells TOPP F3. 5.11 SELF RESTORE MANAGEMENT AFTER OPENING FIRE OR AN OPENING OF EMERGENCY The opening of emergency or fire causes the immediate opening of the automation, but in case where the sensors... -

Page 50: Digital Switch

(near). This allows you to decrease the value of the function selected and return to the previous menu This allows you to scroll the menu downward. Hold for 4 sec to enter the menu INSTRUCTIONS FOR INSTALLATION AND USE K200... -

Page 51: Maintenance

In order for the automation unit to operate correctly, the user shall be carried out periodical maintenance on the same. This maintenance activity may be carried out either by TOPP, in accordance with a specific agreement made with the user, or by the installation technician or by other competent and qualified technical personnel in possession of all legal requirements. -

Page 52: Disposal

Check the radar contacts, electromechanical block, switch not open contacts The door does not function and the display of Check the malfunction signal consulting the list of messages and the control circuit shows symbols or letters alarms INSTRUCTIONS FOR INSTALLATION AND USE K200... -

Page 53: 7- Ec Declaration Of Incorporation Of Partly Completed Machinery

36066 Sandrigo (VI) Italia herewith declares that the person authorised to compile the technical file is Name: Plaza Trinidad - Topp S.r.l. Address: via Galvani,59 36066 Sandrigo (VI) and that to the partly completed machinery ELECTROMECHANICAL AUTOMATION FOR LINEAR SLIDING... - Page 54 INSTRUCTIONS FOR INSTALLATION AND USE K200...

- Page 55 INSTRUCTIONS FOR INSTALLATION AND USE K200...

- Page 56 TOPP S.r.l. Società a Socio Unico soggetta a direzione e coordinamento di 2 Plus 3 Holding S.p.a. Via Galvani, 59 - 36066 Sandrigo (VI) - Italia Tel. +39 0444 656700 - Fax +39 0444 656701 Info@topp.it - www.topp.it...

Need help?

Do you have a question about the K200 and is the answer not in the manual?

Questions and answers