Summary of Contents for Plockmatic Pro XL

- Page 1 Pro XL Unpacking & Installation Instruction Packing Instruction - Reverse the unpacking procedure T09350B 16 April 2021...

- Page 2 The product (System) which is connected to this machine will be class A NOTE The domestic environment is an environment where the use of broadcast radio and television recievers may be expected within a distance of 10 m of the apparatus concerned. 16 April 2021 T09350B Pro XL...

- Page 3 Precautions required or actions to take after miss-operation Limitations like numerical limits, functions that cannot be used together or conditions, under which a particular function cannot be used or obtained. Information. Keys that appear on the machine’s display panel. 16 April 2021 T09350B Pro XL...

- Page 4 This is a Class A product. In a domestic environment this product may cause radio interference in which case the user may be re- quired to take adequate measures. • The product (System) which is connected to this machine will be class A. 16 April 2021 T09350B Pro XL...

- Page 5 Do not expose fingers or other parts of the body to moving, rotating or cutting devices such as for instance between upper and lower trimmer knives. • Allways locate the equipment on a solid support surface with adequate strength tor the weight of the machine. 16 April 2021 T09350B Pro XL...

-

Page 6: Table Of Contents

Top shoot installation (DigiFold Pro XL only) .....1-14 2.10 Feeder table extension installation (optional) ....1-15 2.11 Fuse replacement (if required) ..........1-16 Power On and Calibration Check - Pro XL .......1-17 Plug in and power on ............1-17 Module alignment check ............1-18 Creaser calibration check ..........1-20 Page intentionally blank. -

Page 7: Unpacking Instruction - Pro Xl

Unpacking Instruction - Pro XL WARNING! Two people are required to pack/unpack the Pro XL, only qualified/ trained personnel should perform the procedures described in this 2. Remove components [C] placed on top of unit and then ramp [D]. document. - Page 8 [3] Remove outer cardboard box [E], plastic wrap [F] and protection foam [4] Fold down cardboard box base [H] & place ramp supports [K] under [G]. pallet. 16 April 2021 Pro XL Unpacking & Installation Instruction...

- Page 9 [6] Lower the feet [L] (x8) to raise machine. Remove Foam supports [M] (x4) from under machine. Raise Feet [L] (x8) so the machine is resting on the wheels. WARNING! Two people are required to carefully roll down the Pro XL. NOTE: Cardboard base removed for clarity. 16 April 2021 Pro XL...

- Page 10 [7] Carefully roll unit down the Ramp. Position the unit in the desired loca- tion. WARNING! Two people are required to carefully roll down the Pro XL. Page intentionally blank. 16 April 2021 Pro XL Unpacking & Installation Instruction...

-

Page 11: Installation Instruction - Pro Xl

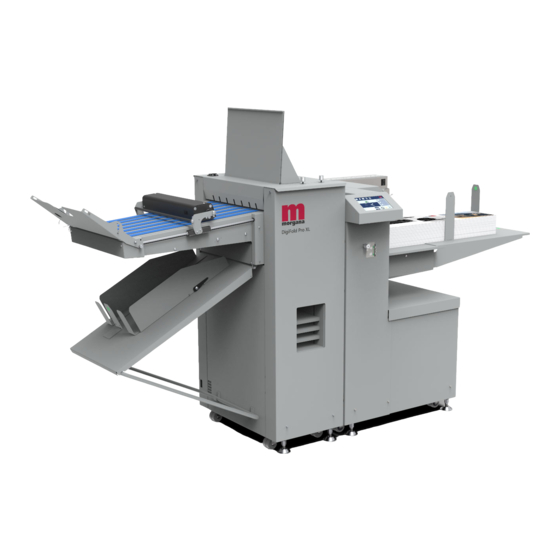

Height AutoCreaser Pro XL AutoCreaser Pro XL 1690mm / 66.5” 730mm / 28.7” 1160mm / 45.7” AutoCreaser Pro XL with feeder table fully extended 2540mm / 100” 730mm / 28.7” 1160mm / 45.7” DigiFold Pro XL DigiFold Pro XL 2130mm / 83.9”... -

Page 12: Power Requirements

3. Be sure to ground the machine. 4. Never place anything on the power cord. Power supply Voltage [V ac] Current Switched-mode 100 - 240V, 50/60Hz 8 – 4A Tolerance -10/+6% Page intentionally blank. 16 April 2021 Pro XL Unpacking & Installation Instruction... -

Page 13: Accessory Check

Accessory check Item Qty Description Installation kit contents: Safety instruction AutoCreaser Pro XL Operator manual DigiFold Pro XL Operator manual Power cord kit Fuse kit T12A CAN termination plug Digital thickness gauge 28T rotary perforation blade (7 TPI) Rotary perforation / slitting anvil... -

Page 14: Levelling The Machine

4. Use both multi-tools or two 19 mm wrenches to lock off the machine chine off the floor. Check that the casters move freely and the machine feet [B]. does not rock. 16 April 2021 Pro XL Unpacking & Installation Instruction... -

Page 15: Tilt Knob Installation

Tilt knob installation Stacker installation (AutoCreaser Pro XL only) 1. If creaser tilt adjustment knob [A] is not installed, screw it in its socket 1. Hook the stacker [A] on the stacker brace [B] as shown. as shown. 16 April 2021... -

Page 16: Stacker Installation (Digifold Pro Xl Only)

Stacker installation (DigiFold Pro XL only) 4. Insert two screws [E] into shaft [F] to secure the conveyor in place WARNING! 5. Plug in two electrical connectors [G] from the conveyor into the ma- After installation check the exit guide [J] does not touch the fold roller [K]. -

Page 17: Optional Bst4000 Installation (Digifold Pro Xl Only)

Optional BST4000 installation (DigiFold Pro XL only) Installing the BST4000 in conjunction with the DigiFold Pro XL requires the BST4000 sensor moves to the DigiFold Pro XL delivery. This is because the BST4000 sensor cannot always identify black or very dark printed sheets against the BST4000 black transport belt. - Page 18 19. Ensure sensor [M] is aligned with cut-out [F]. 20. Secure cable [P] and sensor [M] with cable ties. CAUTION! After installation check the cables are secured away from moving parts. Continued on next page... 16 April 2021 Pro XL 1-13 Unpacking & Installation Instruction...

-

Page 19: Top Shoot Installation (Digifold Pro Xl Only)

Top shoot installation (DigiFold Pro XL only) 21. Adjust sensor [M] sensitivity by releasing sensor retaining nut [N]. 1. Open DigiFold Pro XL top cover [A]. 22. Adjust potentiometer screw [Q]. 2. Locate top shoot screws [B] (x8) into DigiFold top cover. -

Page 20: Feeder Table Extension Installation (Optional)

1. Attach paper support from the install kit to the pull-out part of the table extension using the included multi tool or another 7 mm wrench. 2. Ensure the built-in pull-out table [A] is fully stowed. 16 April 2021 Pro XL 1-15 Unpacking & Installation Instruction... -

Page 21: Fuse Replacement (If Required)

2. Replace the fuse with the T12A fuse and its matching grey fuse holder. Lock the fuse holder in place. 100-140V AC 140-240V AC T12A 6.3x32 mm T6.3A 5x20 mm 16 April 2021 Pro XL 1-16 Unpacking & Installation Instruction... -

Page 22: Power On And Calibration Check - Pro Xl

Power On and Calibration Check - Pro XL Plug in and power on WARNING Do not plug in the machine with the wrong power cord. 1. Plug in the main power cord [A] between the machine and the wall 2. Plug in the CAN termination plug [B]. -

Page 23: Module Alignment Check

Make sure that during this check the sheet remains parallel to the registration wall. 4. If sheet [A] does not enter the rollers at the same time refer to “4.1 Feeder alignment to AutoCreaser/DigiFold Pro XL”. Center in cut-out Continued on next page... - Page 24 10. Rotate the knob clockwise to secure it. 11. Run another proof sheet to check if the crease is now perpendicular to sheet edge. Repeat steps 6 to 10 if necessary. 16 April 2021 Pro XL 1-19 Unpacking & Installation Instruction...

-

Page 25: Creaser Calibration Check

Creaser calibration check Fold calibration check (DigiFold Pro XL only) To check that the machine has not lost its factory set fold calibration during To check that the machine has not lost its factory set crease calibration shipping and/or handling carry out the following procedure: during shipping and/or handling carry out the following procedure: 1. -

Page 26: Page Intentionally Blank

Software version 2. To check if there are software updates available for this machine go to Plockmatic Group website and log in to the Partner Centre (https:// plockmaticgroup.com/customer-login/). Find the latest software down- load for this machine and compare version numbers. -

Page 27: Calibration Procedures - Pro Xl

9. Repeat steps 7 & 8 until the modules are aligned. 10. Reinstall covers that were removed as part of this procedure, unless calibration of AutoCreaser/DigiFold Pro XL is required. Removing Feeder – Front cover 5. To remove [C] unscrew skew adjustment locking knob [D] and use a 7 mm wrench or a T20 screwdriver to remove 3x bolts [E]. -

Page 28: Creaser Calibration

4. Measure the distance between the lead edge of the paper and the crease at the registered side and at the operator side. Crease Measure Feed direction Measure Continued on next page... 16 April 2021 Pro XL 1-23 Unpacking & Installation Instruction... - Page 29 If the error is positive, increase the NVM. If the error is negative, decrease the NVM • The NVM is stored in units mm×10, so if the error is 0.5 mm change the NVM by 5 units. AutoCreaser Pro XL “Crease” • Calibrating the first position creaser – NVM001 “Crease Tool 1 distance from Q20”...

-

Page 30: Fold Calibration

NVM by 5 units. • Calibrating the fold knife 1 – NVM003 “Fold knife 1 distance from Q40” • Calibrating the fold knife 2 – NVM004 “Fold knife 2 distance from Q40” 16 April 2021 Pro XL 1-25 Unpacking & Installation Instruction... -

Page 31: Updating Software - Single Point Download

6. Press “Yes” in the dialog box that comes up. 7. Follow instructions on screen. For further information refer to software technical bulletin. 6. When finished use the Exit Service button [E] to return to the Home screen. 16 April 2021 Pro XL 1-26 Unpacking & Installation Instruction...

Need help?

Do you have a question about the Pro XL and is the answer not in the manual?

Questions and answers