Summary of Contents for Dobot CR3

- Page 1 User Guide Dobot CR3 Hardware User Guide Issue: V1.3 (Translated Version) Date: 2021-07-07 Shenzhen Yuejiang Technology Co., Ltd...

- Page 2 Even if follow this document or any other related instructions, Damages or losses will be happening in the using process, Dobot shall not be considered as a guarantee regarding all security information contained in this document.

- Page 3 Dobot CR3 Hardware User Guide Preface Purpose This Document describes the functions, technical specifications, installation guide of DOBOT CR3 robot, making it easy for users to fully understand and use it. Intended Audience This document is intended for: Customer ...

-

Page 4: Table Of Contents

Dobot CR3 Hardware User Guide Contents Contents Security Precautions ....................1 Security Warning Sign ...................... 1 General Security........................ 1 Personal Security ......................5 Overview ........................7 Technical Specifications ....................7 Robot Body Technical Parameters ............... 7 Controller Technical Parameters ................9 Product Size ........................ - Page 5 Dobot CR3 Hardware User Guide Contents Controller Installation Location................. 39 Robot Installation Location ................40 Connecting cables ......................41 Precautions ......................41 Connecting Controller and Robot by Heavy Duty Cables ......... 42 Connecting Emergency Stop Switch ..............42 Connecting WiFi Module .................. 43 Connecting to Power Supply ................

-

Page 6: Security Precautions

Dobot CR3 Hardware User Guide 1 Security Precautions Security Precautions This topic describes the security precautions that should be noticed when using this product. Please read this document carefully before using the robot for the first time. This product needs to be carried out in an environment meeting design specification. - Page 7 Dobot CR3 Hardware User Guide 1 Security Precautions circuit, otherwise, it is vulnerable to injury the device or the person. You should comply with the local laws and regulations when operating the robot. The security precautions in this document are only supplemental to the local laws and regulations.

- Page 8 Dobot CR3 Hardware User Guide 1 Security Precautions Shenzhen Yuejiang Technology Co., Ltd. assumes no responsibility for robot damage or personal injury caused by failure to follow product instructions or other improper operations. Handling operations such as lifting rings and driving need to use appropriate and reliable lifting equipment.

- Page 9 Dobot CR3 Hardware User Guide 1 Security Precautions correct. If the controller needs to be restarted due to power failure, when restarting, the robot must be manually returned to the initial position of the automatic operation program before restarting the automatic operation.

-

Page 10: Personal Security

Dobot CR3 Hardware User Guide 1 Security Precautions Be careful during the robot carrying or installing. Please follow the instructions on the packing box to put down the robot gently and place it correctly in direction of the arrow. - Page 11 Dobot CR3 Hardware User Guide 1 Security Precautions Please ensure that the robot establishes safety measures near the operation area, such as guardrails, to protect the operator and surrounding people. When a person is trapped by the robot, rescuers can push hard on the joints of the robot until the person is freed.

-

Page 12: Overview

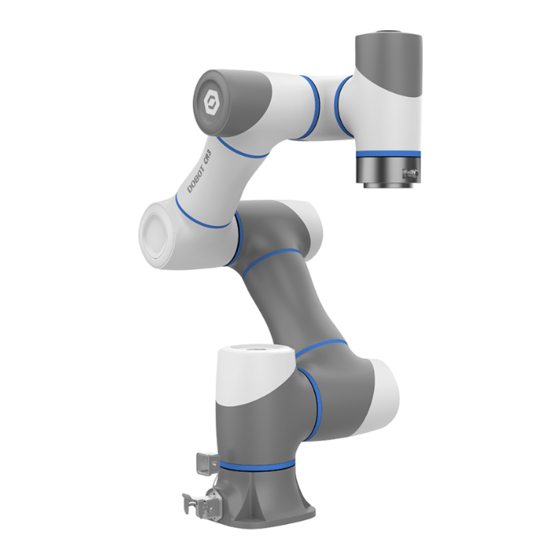

DOBOT CR3 has a repeat positioning accuracy of ± 0.02mm, a max load of 3kg. It is a product with the advantages of both industrial robots and collaborative robots. - Page 13 Dobot CR3 Hardware User Guide 2 Overview Rated Voltage DC 48V Maximum Speed of 2 m/s End-effector ±360° ±360° ±155° Motion Range (° ) ±360° ±360° ±360° 180° /s 180° /s 180° /s Joint Maximum Speed(° /s) 180° /s 180° /s 180°...

-

Page 14: Controller Technical Parameters

Dobot CR3 Hardware User Guide 2 Overview NFPA 79:2018 Electrical Standard for Industrial Machinery EN ISO 10218-1:2011 Steel wire and wire products. General. Test methods EN 60204-1:2018 Safety of machinery. Electrical equipment of machines. General requirements; IEC 60204-1:2016 Safety of machinery. Electrical equipment of machines. -

Page 15: Product Size

Dobot CR3 Hardware User Guide 2 Overview Temperature: 0℃ - 45℃ Environment Humidity: ≤95%, and no condensation Protection Grade IP20 Cooling Method Forced air cooling Safety Function Emergency stop function and reserved external safety interface (can be controlled by I/O interface) Protective stop interface, Automatic Operation Remote Confirmation Indicator Status The indicator light will be steady red when the power is on;... -

Page 16: Controller Size

Dobot CR3 Hardware User Guide 2 Overview Figure 2.2 Robot body size Controller Size Figure 2.3 Controller size Nameplate Description The nameplate includes the product name, model number, weight and certification mark, as shown in Figure 2.4. Issue V1.3 (2021-07-07) User Guide Copyright ©... -

Page 17: Security Warning Labels

Dobot CR3 Hardware User Guide 2 Overview Figure 2.4 Nameplate Security Warning Labels The operator must strictly abide by the warning mark content on the body and controller to avoid the occurrence of danger. The specific content of the warning labels is shown in Figure 2.5. -

Page 18: Robot Workspace

Dobot CR3 Hardware User Guide 2 Overview Robot Workspace Figure 2.6 shows the workspace of CR3 robot. Figure 2.6 CR3 robot workspace End-effector Size Issue V1.3 (2021-07-07) User Guide Copyright © Yuejiang Technology Co., Ltd... -

Page 19: End-Effector Load Description

Dobot CR3 Hardware User Guide 2 Overview Figure 2.7 End-effector Size End-effector Load Description The robot actuator can bear the load of the cylinder whose center of mass is located at an axial distance of LD80mm from the center of the End -effector and a radial distance of LR60mm and no more than 3kg. -

Page 20: Home Description

Dobot CR3 Hardware User Guide 2 Overview Table 2.3 Stop time and angle Stop angle(° ) Axis Stop time(ms) 10.18 14.09 15.24 4.76 4.48 4.74 Home Description After some parts (motors, reduction gear units) of the robot have been replaced or the robot has been hit, the origin of the robot will be changed. -

Page 21: Product Features

Dobot CR3 Hardware User Guide 2 Overview Figure 2.10 Factory posture Product Features Motion Function The motion trajectory consists of a series of interpolated motions since the interpolated motion is the basic motion type. According to the different trajectories, motion functions are classified as joint interpolated motion, linearly interpolated motion, circular interpolated motion and continuous path. - Page 22 Dobot CR3 Hardware User Guide 2 Overview Figure 2.12 Move mode Jump: The trajectory looks like a door. From point A to point B, the robot will move in the Move mode Move up to the lifting height (StartHeight is a relative height).

- Page 23 Dobot CR3 Hardware User Guide 2 Overview Figure 2.14 Jump mode (1) If the heights of point A and point B are the same with zLimit, the trajectory is shown in Figure 2.15. Figure 2.15 Jump mode (2) 2.11.1.3 ARC (Circular Interpolated Motion) The trajectory is an arc, which is determined by three points (the current point, any point and the end point on the arc), as shown in Figure 2.16.

-

Page 24: Coordinate System

2.11.2.1 Joint Coordinate System The Joint coordinate system is determined by the motion joints. Figure 2.18 shows the Joint coordinate system of a CR3robot. All the joints are rotating joints. Figure 2.18 Joint coordinate of a CR3 robot Issue V1.3 (2021-07-07) User Guide... - Page 25 Tool coordinate system which is located at the robot flange without end effector and cannot be changed. And the others can be customized by users. Figure 2.20 shows the default Tool coordinate system of a CR3 robot. R are the orientation data, which are designated by rotating the tool center point (TCP) around the X, Y, Z axes under the default Tool coordinate system.

- Page 26 Dobot CR3 Hardware User Guide 2 Overview Figure 2.20 The default Tool coordinate system of CR3 robot 2.11.2.4 User Coordinate System The User coordinate system is a movable coordinate system which is used for representing equipment like fixtures, workbenches. The origin and the orientations of axes can be defined based on site requirements, to measure point data within the workspace and arrange tasks conveniently.

-

Page 27: Singularity Point

Dobot CR3 Hardware User Guide 2 Overview Figure 2.21 The default User coordinate system of CR3 robot Singularity Point When the robot moves under the Cartesian coordinate system, the resultant velocity of the two axes cannot be in any direction if the directions of them are aligned, resulting in that the degrees of freedom of the robot are degraded. - Page 28 Dobot CR3 Hardware User Guide 2 Overview Figure 2.22 Wrist singularity point Shoulder singularity point: The TCP is located in the plane performed by Joint1 and Joint2. Figure 2.23 Shoulder singularity point Elbow singularity point: The Rear arm and Forearm in a straight line.

-

Page 29: Collision Detection

Dobot CR3 Hardware User Guide 2 Overview Figure 2.24 Elbow singularity point Collision Detection Collision detection is mainly used for reducing the impact on the robot, to avoid damage to the robot or external equipment. If the collision detection is activated, the robot arm will stop running automatically when the robot arm hit an obstacle. - Page 30 Dobot CR3 Hardware User Guide 2 Overview Table 2.4 Key description Description Open/close hand-hold Long press and then release: Open hand-hold teach, and the LED indicator turns teach blue and blinks Short press and then release: Close hand-hold teach, and the LED indicator turns green ...

-

Page 31: Electrical Specifications

Dobot CR3 Hardware User Guide 3 Electrical Specifications Electrical Specifications Controller I/O Interface Description A robot controller contains I/O interfaces, for connecting to external equipment, such as air pump, PLC, etc. These I/O interfaces provide 32 digital inputs, 16 digital outputs, 2 analog outputs, and 2 analog inputs, as shown in Figure 3.1. - Page 32 Dobot CR3 Hardware User Guide 3 Electrical Specifications Name Definition Digital input 5 Digital input 6 Digital input 7 Digital input 8 I/O 0V I / O interface reference level Internal reference level I/O17 Digital input 17 /output 1 I/O18...

- Page 33 Dobot CR3 Hardware User Guide 3 Electrical Specifications Name Definition I/O29 Digital input 29/output 13 I/O30 Digital input 30/output 14 I/O31 Digital input 31/output 15 I/O32 Digital input 32/output 16 I/O 24V I / O interface 24V power input Internal 24V power output...

-

Page 34: Emergency Stop I/O Description

Dobot CR3 Hardware User Guide 3 Electrical Specifications Figure 3.2 Controller I/O Connection NOTE The inner power supply and the outer power supply of every I/O can’t exceed 500mA. The inner power supply and the outer power supply can’t exist at the same time, the inner supply power outputs the max current which can’t exceed 2A;... -

Page 35: Protective Stop

Dobot CR3 Hardware User Guide 3 Electrical Specifications I/O28 and DI12, I/O29 and DI13 are I/O28(X18:4) DI12(X19:4) Short connection redundant circuits of the user emergency stop interface. Any one of the disconnections will I/O29(X18:5) DI13(X19:5) Short connection cause the user emergency stop function to be... -

Page 36: End I/O Interface Description

Dobot CR3 Hardware User Guide 3 Electrical Specifications Figure 3.3 Remote confirmation tips End I/O Interface Description The cable used for the end pins is the designated cable,the model is Lumberg RKMV 8-354. The end I/O pins are shown below. - Page 37 Dobot CR3 Hardware User Guide 3 Electrical Specifications DO_1 Digital output 1 Figure 3.5 End I/O connection Lumberg RKMV 8-354 I/O pins are shown below. Figure 3.6 Lumberg RKMV 8-354 I/O pins Table 3.6 Lumberg RKMV 8-354 I/O pins description...

-

Page 38: Interface Board

Dobot CR3 Hardware User Guide 3 Electrical Specifications Blue DO_1 Interface Board External Interface Board Description Figure 3.7 shows the interface board of the CC series controller. Table 3.7 lists the description. Figure 3.7 Interface board of the controller Table 3.7 Interface description... -

Page 39: Digital Input

Dobot CR3 Hardware User Guide 3 Electrical Specifications Description For controlling the controller power on and off Power interface For accessing single-phase 1100/220V power supply External DC 48V power supply reserved port For accessing the AGV, the AGV will supply 48V DC power to the robot... -

Page 40: Multiplex Digital Input/ Digital Output

Dobot CR3 Hardware User Guide 3 Electrical Specifications Table 3.8 Technical specifications Item Specification Input channel 16 channels Connection method Crimping terminal Input type Optical coupling type Input voltage (DC) 0V or 24V±10% Isolation method Optical coupling isolation Multiplex Digital Input/ Digital Output 3.4.3.1 Introduction... -

Page 41: Analog Input

Dobot CR3 Hardware User Guide 3 Electrical Specifications Item Specification Load current of single channel 500mA Output current Isolation method Digital isolation Analog Input 3.4.4.1 Introduction An analog input can be set to a current input or voltage input by the DIP switch for measuring current or voltage. -

Page 42: Incremental Encoder Abz Input

Dobot CR3 Hardware User Guide 3 Electrical Specifications Figure 3.11 Simple analog output circuit Table 3.11 lists the relation between the DIP switch and analog output. Table 3.11 The relation between the DIP switch status and analog output Analog output type... - Page 43 Dobot CR3 Hardware User Guide 3 Electrical Specifications NOTE If a ground wire is required, it can be fixed to the control cabinet with screws. Non- special circumstances (strong magnetic interference, etc.) Issue V1.3 (2021-07-07) User Guide Copyright © Yuejiang Technology Co., Ltd...

-

Page 44: Installation And Commissioning

Dobot CR3 Hardware User Guide 4 Installation and Commissioning Installation and Commissioning Installation Environment To maintain the controller and robot performance and to ensure the safety, please place them in an environment with the following conditions. Install indoors with good ventilation. -

Page 45: Robot Installation Location

Dobot CR3 Hardware User Guide 4 Installation and Commissioning Figure 4.1 Installation space requirement Robot Installation Location The stability of a robot depends on the installation. You can design the platform according to the size of the hole of the base and the real environment for mounting a robot. And the installation height of the robot should be above 0.6 meters.The platform must not only bear the robot but also... -

Page 46: Connecting Cables

Dobot CR3 Hardware User Guide 4 Installation and Commissioning Figure 4.2 Robot base size Connecting cables Precautions The specifications and installation of the external wiring should comply with local laws and regulations. Do not disassemble the controller by yourself. Otherwise, it may result in electric leakage. -

Page 47: Connecting Controller And Robot By Heavy Duty Cables

Dobot CR3 Hardware User Guide 4 Installation and Commissioning internal module or external device to malfunction. Before connecting, check whether the insulation and shield of the external cable are damaged. Connecting Controller and Robot by Heavy Duty Cables Connect controller and robot by heavy-duty cables. Figure 4.3 shows the connection of the controller with heavy-duty cables. -

Page 48: Connecting Wifi Module

Dobot CR3 Hardware User Guide 4 Installation and Commissioning Figure 4.4 Connecting emergency stop switch NOTICE Before running a robot, please make sure that the emergency stop switch has been turned on (the red button has been released). Otherwise, the robot cannot work normally. -

Page 49: Connecting To Power Supply

Dobot CR3 Hardware User Guide 4 Installation and Commissioning Figure 4.5 Connecting WiFi module Connecting to Power Supply Plug power cable into controller. As shown in Figure 4.6. Figure 4.6 Connecting to Power Supply Three-Position Enabling Accessory The three-position enabling accessory can enable the robot, and it has the function of teaching. -

Page 50: Maintenance And Repair

Remove all parts that do not belong to Dobot. Before returning to Dobot, please make a backup copy of the files. Dobot will not be responsible for the loss of programs, data or files stored in robot. ... - Page 51 Dobot technical engineer. In addition, overhauls are required every 20,000 hours of operation time or every 4 years. If you are not clear about the maintenance processes, please contact Dobot technical engineer. Issue V1.3 (2021-07-07) User Guide...

Need help?

Do you have a question about the CR3 and is the answer not in the manual?

Questions and answers