Simu DMI6Hz Manual

Hide thumbs

Also See for DMI6Hz:

- Original instructions manual (40 pages) ,

- Manual (16 pages) ,

- Instructions manual (8 pages)

Advertisement

Quick Links

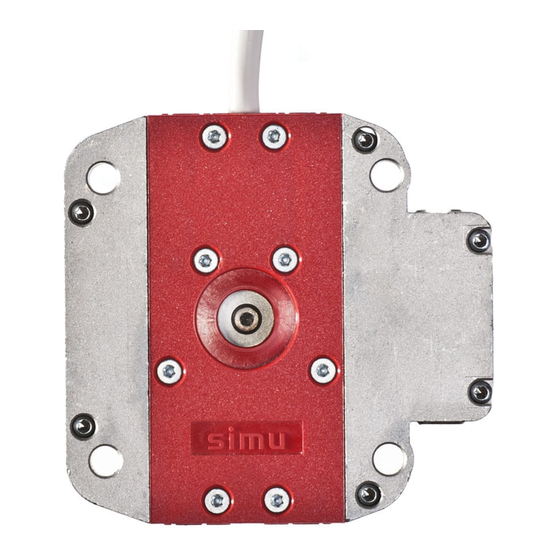

DMI5Hz - DMI6Hz MOTORS

USA

Tubular operators with integrated radio and manual override for blinds, awnings & roller shutters

®

S.A.S. au capital de 5 000 000

- This device complies with part 15 of the FCC Rules. Operating is subject to the following two conditions:

(1) This device may not cause harmful interference.

(2) This device must accept any interference received, including interference that may cause undesired operation.

- Caution: Changes or modifications not expressly approved by the party responsible for compliance could void the user's authority to operate the equipment.

1

ASSEMBLY

1.1 - TUBE PREPARATION

Warning: do not cut or drill the tube with the motor

installed.

- Cut the tube to the required length.

- Remove all burrs from the tube.

- If using a round tube, cut a notch (D wide by C long)

into one end of the tube.

- On round tubes measure length (A) and drill 4 holes

around the tube. For octagonal tubes 1 hole is

sufficient.

1.2 - INSTALLING THE TUBULAR MOTOR

1- Fit the adaptor over the crown. Align the slot in the

adaptor with the raised key and firmly fit the adaptor

over the crown. A crown adaptor is not necessary with

47mm (2") tubes.

2- Snap the drive wheel onto the drive shaft. Screw on

the drive stop if needed (60 Nm+ operators).

3- Slide the tubular motor into the tube. Do not force or

hammer on the head of the motor. If the motor does

not insert smoothly, remove the motor and file smooth

the edge of the tube. On round tubes confirm the

raised key on the crown fits snugly into the cut slot on

the end of the tube.

4- Secure the drive wheel to the tube. For the composite

drive, use four 3/16" dia. steel pop rivets or four 1/4"

dia. screws with steel grade SAE 5 or higher. For the

aluminum drive, use the three 5mm X 6mm cheese

head screws provided.

1.3 - MOUNTING THE TUBULAR MOTOR

The Hz DMI motor uses standard DMI accessories.

- Mount the motor as shown using only SIMU

accessories.

- Mount the motor heads at least 8" apart from each

other to prevent RF interference.

- Always install the power cable with a drip loop to

prevent water penetration.

- SIMU motors conform to IP44 requirements and as such

must be protected against direct weather elements such

as rain, sleet, ...etc. Failure to do so could result in

voiding the warranty.

- Z.I. Les Giranaux - BP71 - 70103 Arc-Les-Gray CEDEX - RCS GRAY B 425 650 090 - SIRET 425 650 090 00011 - n° T.V.A CEE FR 87 425 650 090

12 TRANSMITTERS MAXIMUM

1ft < d1 < 65ft

1.1

A

C

D

A

DMI5Hz

120V / 60Hz

DMI6Hz

120V / 60Hz

For the aluminum drive A is 20mm less than shown

1.2

1

1.3

5047058A

IMPORTANT - Review instruction throughly before installing Hz motors

For Composite Drive

ØB

Ø min.

ØB

T min.

mm

Ø / T min.

A

B C

D

754

26 4.2

47

5

754

-

-

840

36

8

60

5

840

-

-

3

4

2

d2 > 8 inches

4 X

Ø 3/16

STEEL SAE5 or higher

or

4 X

Ø 1/4

For the Aluminum

Drive use the 5mm X

6mm screws supplied

with the drive

1 / 3

Advertisement

Summary of Contents for Simu DMI6Hz

- Page 1 - Always install the power cable with a drip loop to prevent water penetration. - SIMU motors conform to IP44 requirements and as such must be protected against direct weather elements such as rain, sleet, ...etc. Failure to do so could result in voiding the warranty.

- Page 2 WIRING 2.1 - DMI Hz PERMANENT WIRING (shutter, shade or awning) Warning: All wiring must conform to the National Electric Code and local codes. OPERATOR - (1) The motor must be installed with a drip loop to prevent water intrusion. WIRING CHART MOTOR POWER...

- Page 3 4.7 - RETURNING TO ORIGINAL FACTORY MODE (deleting all transmitters). NOTE: When the motor is in factory mode is the only time the direction of rotation can be changed. To return the motor to Factory Mode, perform a double power cut as described in section 4.6. Press and hold for 8 seconds the Program Button of an already recorded transmitter.

Need help?

Do you have a question about the DMI6Hz and is the answer not in the manual?

Questions and answers