Table of Contents

Advertisement

Quick Links

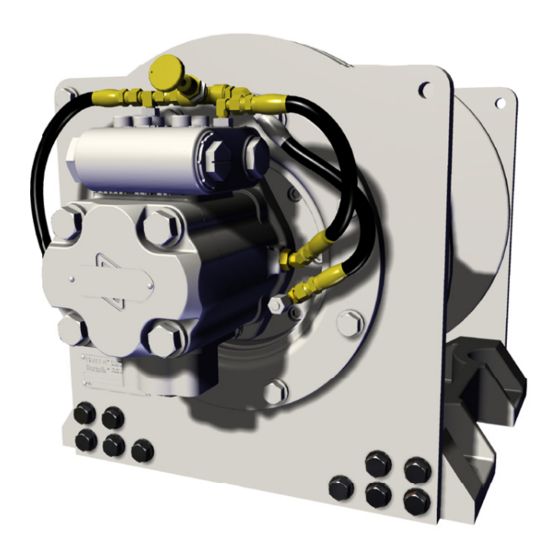

Hydraulic Hoist Series

PD10-75B, PD10-77B, PD15-75B, PD15-77B

INSTALLATION, MAINTENANCE,

Visit our Web site at www.paccarwinch.com for the most comprehensive collection of winch, hoist, and drive

information on the Internet. Most publications and specification sheets are available for downloading.

LIT2689

August 2016

Printe d in USA

AND SERVICE MANUAL

WRITE HOIST SERIAL NUMBER BELOW

First 2 numbers indicate

year manufactured

For serial number location, see page 3

PD10-75B/77B

PD15-75B/77B

1

©2016 PACCAR Inc.

All rights reserved

Advertisement

Table of Contents

Summary of Contents for Paccar BRADEN PD10B Series

- Page 1 Visit our Web site at www.paccarwinch.com for the most comprehensive collection of winch, hoist, and drive information on the Internet. Most publications and specification sheets are available for downloading. LIT2689 ©2016 PACCAR Inc. August 2016 All rights reserved Printe d in USA...

-

Page 2: Table Of Contents

Table of Contents Explanation of Model Number .......................3 General Safety Recommendations ......................4 Theory of Operation ..........................5 Hoist Installation ............................7 Recommended Fastener Torque ......................9 Wire and Braided Rope Installation ......................9 Preventive Maintenance ........................10 Recommended Oil Change Information.....................10 Troubleshooting ............................12 Hoist Disassembly ..........................16 List of Components ..........................18 Exploded-view Drawing ........................19 Planet Carrier Service ..........................20... -

Page 3: Explanation Of Model Number

Drawings in this manual represent a typical unit sold through our distribu- tion channels. Some hoists, particularly those sold directly to original equipment manufacturers (OEM), may differ in appearance and options. Refer to the following PACCAR Winch publications for related information: • LIT2688 – Parts List PD10-75B/77B, PD15-75B/77B... -

Page 4: General Safety Recommendations

GENERAL SAFETY RECOMMENDATIONS Safety and informational callouts used in this manual include: CAUTION WARNING CAUTION – This emblem is used to warn against poten- WARNING – This emblem is used to warn against hazards tial or unsafe practices which COULD result in personal and unsafe practice which COULD result in severe per- injury and product or property damage if proper proce- sonal injury or death if proper procedures are not followed. -

Page 5: Theory Of Operation

THEORY OF OPERATION DESCRIPTION OF HOIST Refer to figures 1, 2, and 3. The hoist has four basic component parts: The static brake system has three operating compo- 1. Hoist base nents: 2. Hydraulic motor and brake valve 3. Brake cylinder and motor support 1. - Page 6 Figure 3. Lowering (2) oil that can flow through it and the speed at which the load will be lowered. Increasing the flow of oil to the motor will cause the pressure to rise and the opening in the brake valve Static Brake to enlarge, speeding up the descent of the load.

-

Page 7: Hoist Installation

HOIST INSTALLATION VENT PLUG ABOVE CENTERLINE 1. The hoist should be mounted with the centerline of the drum in a horizontal position. The mounting plane of the Centerline base may be rotated in any position around this center- line. 4. The vent plug must always be located above the horizontal centerline. - Page 8 HOIST ASSEMBLY WINCH ASSEMBLY W/BRAKE VALVE W/BRAKE VALVE & STATIC BRAKE & STATIC BRAKE BRAKE VALVE HOIST BRAKE BRAKE VALVE WINCH BRAKE CONTROL VALVE 2-SPEED SELECTOR VALVE CONTROL VALVE PUMP PUMP DO NOT use a control valve with any detents or latch- ing mechanism that would hold the control valve in an Oil having 150 to 330 SUS (30-60 cSt) viscosity at 104°F actuated or running position when the operator releases...

-

Page 9: Recommended Fastener Torque

RECOMMENDED FASTENER TORQUE Higher or lower torques for special applications will be specified such as the use of spanner nuts, nuts on shaft ends, jam nuts, and where distortion of parts or gaskets is critical. Lubricated torque values are based on use of SAE 30-weight engine oil applied to threads and face of bolt or nut. Avoid using thread lubricants (such as antiseize compound) because the applied torque may vary by 10 to 40%, depending upon the product used. -

Page 10: Preventive Maintenance

PREVENTIVE MAINTENANCE 1. OIL LEVEL A regular program of preventive maintenance for your plan- etary hoist is strongly recommended to minimize the need The gear oil level should be checked every 500 operating for emergency servicing and promote safe, reliable hoist hours or three months, whichever occurs first. - Page 11 3. VENT PLUG 7. WARM-UP PROCEDURES The vent plug is located in the drum support as shown. It is A warm-up procedure is recommended at each start-up and important to keep this vent clean and unobstructed. When- is essential at ambient temperatures below +40°F (4°C). ever gear oil is changed, remove vent plug, clean in solvent The prime mover should be run at its lowest recommended and reinstall.

-

Page 12: Troubleshooting

RECOMMENDED GEAR OIL PREVAILING AMBIENT TEMPERATURE PREVAILING AMBIENT TEMPERATURE F -40 F -40 Use gear oil detailed in Range A Use gear oil detailed in Range B Use gear oil detailed in Range C C -40 C -40 SHADED TEMPERATURE RANGE IN THE CHART ABOVE NOT RECOMMENDED FOR SEVERE APPLICATIONS SUCH AS SUSTAINED SHADED TEMPERATURE RANGE IN THE CHART ABOVE NOT RECOMMENDED FOR SEVERE APPLICATIONS SUCH AS FAST DUTY CYCLES OR FREQUENT WINCHING. - Page 13 TROUBLE PROBABLE CAUSE REMEDY 3. Friction brake will not release as a 3. Disassemble brake to inspect brake The hoist will not lower the load or result of damaged brake discs. discs. Check stack-up height as de- does not lower the load smoothly. scribed in “Motor Support —...

- Page 14 TROUBLE PROBABLE CAUSE REMEDY The hoist will not hoist the rated load. 1. The hoist may be mounted on an un- 1. Mounting surface: even or flexible surface which causes a. If necessary, use shim stock to level distortion of the hoist base and binding hoist.

- Page 15 TROUBLE PROBABLE CAUSE REMEDY 2d. Hydraulic pump not operating ef- 2d. HYDRAULIC Pump: ficiently. d1. Same as REMEDY D2. The hoist runs hot. d2. Prime mover low on horsepower or RPM. Tune/adjust prime mover. d3. Check suction line for damage. d4.

-

Page 16: Hoist Disassembly

HOIST DISASSEMBLY SERVICE PRECAUTIONS • Before any part is removed from the hoist, all service instructions should be read and understood. • Work in a clean, dust free area because cleanliness is of utmost importance when servicing hydraulic equipment. • Inspect all replacement parts, prior to installation, to detect any damage which might have occurred in shipment. - Page 17 10. Remove the bearing from inside of closure. 11. Remove the primary sun gear and thrust washer from the primary planet carrier. 8. Remove the motor support capscrews and install two cap- screws and a short piece of chain into the motor mount- ing bolt holes.

-

Page 18: List Of Components

HOIST DISASSEMBLY continued 15. Remove drum and set hoist on base. Remove eight bear- ing-support capscrews and bearing support; be careful to avoid damaging seals or bearing surfaces. 16. Remove seal and bearing from support end of the drum. 17. Thoroughly clean and inspect drum and base. Check ring gear (machined into inside surface of drum) teeth for nicks, spalling or excessive wear. -

Page 19: Exploded-View Drawing

LIT2688: Parts List for BRADEN Hydraulic Hoist Series PD10-75B/77B and PD15-75B/77B winches. NOTE: Standard PD15-75B configurations are defined in this publication. Nonstandard or OEM-specific units may require further information. Please contact PACCAR Winch for help with nonstandard or OEM-specific assemblies. -

Page 20: Planet Carrier Service

PLANET CARRIER SERVICE OUTPUT PLANET CARRIER DISASSEMBLY 3. Now you can remove the planet shafts, bearings, spacer, thrust washers and gears. Thoroughly clean all parts and inspect for damage and wear. The bearing rollers should not exhibit any irregularities. If the rollers show any sign 1. - Page 21 PRIMARY PLANET CARRIER 1. To service the primary planet carrier, the steps are the same as for the output carrier, except that there is only one bearing for each gear and no bearing spacer. 2. Insert two bearings and a bearing spacer into a gear with the spacer between the bearings.

-

Page 22: Motor Support - Brake Cylinder Service

MOTOR SUPPORT — BRAKE CYLINDER SERVICE NOTE: For BRADEN Hydraulic Hoist Series PD10-75B/77B CLEAN AND INSPECT and PD15-75B/77B winches, the discs are lobed, even though some drawings show differently. 1. Thoroughly clean and inspect all parts at this time. Check brake piston sealing surfaces on brake cylinder DISASSEMBLY and motor support. - Page 23 2. Insert first a steel brake disc followed by a friction brake 4. Place steel brake disc on flat surface and check for distor- disc. Then alternate steel and friction discs until seven tion with a straight edge. Check surface for signs of mate- friction discs and eight steel discs have been installed.

- Page 24 5. To check brake stack height, place pressure plate on top 7. Install the spring spacer, then the brake springs. of brake spacer. Hold pressure plate down firmly by hand and measure clearance in three places between motor support and pressure plate. Average gap must measure between .153 inch (4 mm) maximum and .080 inch (2 mm) minimum.

- Page 25 BRAKE CYLINDER PRESSURE TEST 1. Install the –4 JIC fitting into the brake-release port. Con- nect a hand pump with an accurate 0-2,000 PSI (0-13,800 kPa) gauge and shut-off valve to this fitting. Apply 1,000 PSI (6,900 kPa) to the brake. Close shut-off valve and let stand for five minutes.

-

Page 26: Brake Clutch Service

BRAKE CLUTCH SERVICE DISASSEMBLY 4. Next, slide the sprag clutch out, inspect the sprag clutch 1. Remove the snap ring and sprag bushing retainer from closely for abnormal wear, cracks, pitting or corrosion. one end only. Check small clips for breakage or bright spots; the signs of excessive wear. - Page 27 6. Turn the assembly over with the snap ring down. Install 2. Turn the assembly over and install the sprag clutch in the the second retainer and snap ring. Make certain the snap bore of the outer race. ring is seated in the groove properly. 3.

-

Page 28: Hoist Assembly

HOIST ASSEMBLY CAUTION CAUTION Hoists with a three-piece fabricated base use special shoul- Make certain the snap ring is installed on the bearing sup- der capscrews to fasten side plates to the base plate. DO port. This snap ring will keep the output planet carrier cor- NOT use standard capscrews in their place. - Page 29 7. Install the output sun gear and thrust washer into output planet carrier. 11. Install a new bearing in the drum closure as required. 8. Install the output planet carrier into the drum while meshing the planet gears with the ring gear and the planet housing with the bearing support.

- Page 30 15. Install the motor side plate onto the base. Tighten 18. If the brake discs are misaligned, preventing the instal- side-plate capscrews to the recommended torque using lation of the clutch, then with a hand pump, apply 750- hardened steel washers. 1,000 PSI to the brake-release port.

- Page 31 22. Engage the motor shaft with the brake clutch inner race and lower motor into place. Tighten capscrews to recommended torque. 23. Install the hoses that connect the manifold and brake valve to the brake cylinder. Measure the distance from the motor mounting surface to the inner brake race.

-

Page 32: Brake Valve Service

BRAKE VALVE SERVICE ITEM DESCRIPTION PART QTY. Break valve housing Valve spring retainer 24424 Spring retainer 24183 Plug 22450 Spool Damper piston O-ring * 24186 Check-valve poppet 24423 Pilot orifice 24200 Check-valve spring 24190 Spool spring 24192 O-ring * 23601 O-ring * 24193 O-ring *... - Page 33 ASSEMBLY 5. Remove the damper piston from the spool. The piston will come out slowly, because of a partial vacuum formed 1. Install new O-rings on the plug and spring retainers. as it is removed. Use extreme care to avoid damaging the polished surfaces of the piston or spool.

-

Page 34: Reversing Direction Of Drum Rotation

REVERSING DIRECTION OF DRUM ROTATION Motor Case Drain Motor Case Drain Brake Brake Lowering Lowering Motor Motor Valve Valve Port Port Hoisting Hoisting Port Port Brake Release Brake Release Circuit Circuit M = Manifold Block Figure 6 Figure 7 To change the direction of rotation and brake operation, two components must be changed on the hoist. First, the motor must be made to rotate in the opposite direction. - Page 35 7. Before installing the brake clutch, be sure the inner race turns freely in the opposite direction the drum will turn to haul-in wire rope. An easy way to check the rotation is to hold the outer race in one hand and rotate the inner race.

- Page 36 METRIC CONVERSION TABLE English to Metric Metric to English LINEAR inches (in.) X 25.4 = millimeters (mm) millimeters (mm) X 0.03937 = inches (in.) feet (ft.) X 0.3048 = meters (m) meters (m) X 3.281 = feet (ft.) miles (mi.) X 1.6093 = kilometers (km) kilometers (km)

Need help?

Do you have a question about the BRADEN PD10B Series and is the answer not in the manual?

Questions and answers