Table of Contents

Advertisement

INSTALLATION, MAINTENANCE, AND TESTING MANUAL

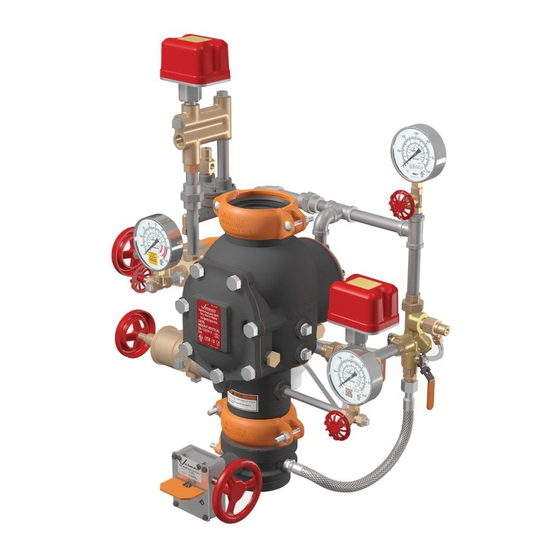

Series 768N FireLock NXT

• Read and understand all instructions before attempting to install, remove, adjust, or perform maintenance on any Victaulic piping products.

• Depressurize and drain piping systems before attempting to install, remove, adjust, or perform maintenance on any Victaulic piping

products.

• Wear safety glasses, hardhat, and foot protection.

• Save this installation, maintenance, and testing manual for future reference.

Failure to follow instructions and warnings could cause system failure, resulting in death or serious personal injury and property damage.

REV_C

™

Dry Valve

WARNING

KEEP THESE INSTRUCTIONS WITH THE

INSTALLED VALVE FOR FUTURE REFERENCE

I-768N

I-768N

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Victaulic 768N FireLock NXT Series

- Page 1 WARNING • Read and understand all instructions before attempting to install, remove, adjust, or perform maintenance on any Victaulic piping products. • Depressurize and drain piping systems before attempting to install, remove, adjust, or perform maintenance on any Victaulic piping products.

- Page 2 1/4-Turn Vent Ball Valve for Series 746-LPA Dry Accelerator (if applicable) Closed System Main Drain Valve Closed Slow-Fill Ball Valve of the Victaulic AMTA (if applicable) Open Charge Line Ball Valve of the Priming Manifold Assembly Open Fast-Fill Ball Valve of the Victaulic AMTA (if applicable)

- Page 3 Auto Drain Sleeve Ball Drip Plunger Auto Vent Sleeve of Series 776 Low-Pressure Actuator Charge Water Supply Main Control Line Ball Valve Valve System Main Drain Valve Water Supply Main Drain Valve Alarm Test Ball Valve WATER FLOW ALARM TEST Perform the water flow alarm test on a frequency required by the current NFPA-25 code.

-

Page 4: Table Of Contents

• Depressurize and drain the piping system before attempting to Compressor Requirements and Settings for a Series 768N FireLock install, remove, adjust, or maintain any Victaulic piping products. NXT Dry Valve Installed with a Series 746-LPA Dry Accelerator ..9... -

Page 5: Hydrostatic Testing

WARNING Remove all plastic caps and foam spacers from the valve. Install the valve assembly into the riser with two Victaulic rigid • If air testing is required, DO NOT exceed couplings. Refer to the instructions, supplied with the coupling, for 50 psi/345 kPa/3.4 Bar air pressure. -

Page 6: Trim Dimensions

I-768N / Series 768N FireLock NXT ™ Dry Valve / Installation, Maintenance, and Testing Manual TRIM DIMENSIONS A 4-INCH/114.3-MM FIRELOCK NXT™ DRY VALVE IS SHOWN BELOW 1 1/2 – 2-INCH/48.3 – 60.3-MM CONFIGURATIONS CONTAIN 3/4-INCH/19-MM DRAIN VALVES 2 1/2 – 3-INCH/73.0 – 88.9-MM CONFIGURATIONS CONTAIN 1 1/4-INCH/31-MM DRAIN VALVES 4 –... -

Page 7: Trim Components - Exploded View Drawing

I-768N / Series 768N FireLock NXT ™ Dry Valve / Installation, Maintenance, and Testing Manual TRIM COMPONENTS – EXPLODED VIEW DRAWING Orange shaded areas identify components that are optional equipment. These components are standard when the VQR assembly is ordered. Gray shaded areas identify components that are optional equipment. -

Page 8: Internal Valve Components - Section View And Exploded View Drawings

I-768N / Series 768N FireLock NXT ™ Dry Valve / Installation, Maintenance, and Testing Manual INTERNAL VALVE COMPONENTS – SECTION VIEW AND EXPLODED VIEW DRAWINGS Clapper Latch Diaphragm Assembly Clapper Seal Seat Exaggerated for Clarity Valve is shown in the “set” position The 1½-inch/48.3-mm and 2-inch/60.3-mm valve sizes contain washers under the heads of the cover plate bolts. -

Page 9: Air Supply Requirements

The “off” or “high” pressure setting should be 18 psi/124 kPa/1.2 Bar. When a base- or riser-mounted air compressor supplies air to a Series 768N FireLock NXT Dry Valve, it is not necessary to install the Victaulic Series 757 Regulated Air Maintenance Trim Assembly (AMTA). In this case, the air line of the compressor connects to the trim at the fitting where the Series 757 Regulated AMTA is installed normally (refer to the applicable trim drawing). -

Page 10: Initial System Setup

I-768N / Series 768N FireLock NXT ™ Dry Valve / Installation, Maintenance, and Testing Manual SECTION I • Initial System Setup I-768N_10 REV_C... - Page 11 I-768N / Series 768N FireLock NXT ™ Dry Valve / Installation, Maintenance, and Testing Manual INITIAL SYSTEM SETUP Step 1: Step 5: Confirm that all system drains are shut and that the system is free of When the system reaches approximately 10 psi/69 kPa/0.7 Bar, and no leaks.

- Page 12 I-768N / Series 768N FireLock NXT ™ Dry Valve / Installation, Maintenance, and Testing Manual INITIAL SYSTEM SETUP (CONTINUED) Step 8: Open the charge line ball valve. Allow water to flow through the auto drain tube. Step 9: Verify that the charge line pressure is equal to the supply pressure, and verify that the auto drain is set by pulling up on the auto drain sleeve.

- Page 13 Confirm that all valves are in their normal operating positions (refer to Closed (if applicable) the table to the right). Slow-Fill Ball Valve of the Victaulic AMTA (if applicable) Open Fast-Fill Ball Valve of the Victaulic AMTA (if applicable) Closed CAUTION •...

-

Page 14: Resetting The System

I-768N / Series 768N FireLock NXT ™ Dry Valve / Installation, Maintenance, and Testing Manual SECTION II • Resetting the System I-768N_14 REV_C... - Page 15 I-768N / Series 768N FireLock NXT ™ Dry Valve / Installation, Maintenance, and Testing Manual RESETTING THE SYSTEM Step 1: Step 6: Isolate the charge line ball valve by placing it in the closed position. Confirm that the system has been depressurized. The gauges should indicate zero pressure.

-

Page 16: Weekly External Inspection

I-768N / Series 768N FireLock NXT ™ Dry Valve / Installation, Maintenance, and Testing Manual SECTION III • Weekly External Inspection • Monthly External Inspection WARNING • The building owner or their representative is responsible for maintaining the fire protection system in proper operating condition. •... - Page 17 Record the system air pressure and water supply pressure. (if applicable) Confirm that the water supply pressure is within the range of Slow-Fill Ball Valve of the Victaulic AMTA (if applicable) Open normal pressures observed in the area. Significant loss of water...

-

Page 18: Required Main Drain Test

I-768N / Series 768N FireLock NXT ™ Dry Valve / Installation, Maintenance, and Testing Manual SECTION IV • Required Main Drain Test • Required Water Flow Alarm Test • Required Water Level and Low- Air Alarm Tests • Required Partial Operational Trip Test •... - Page 19 1/4-Turn Vent Ball Valve for Series 746-LPA Dry Accelerator accidentally. Closed (if applicable) • Opening the system main drain valve will cause the valve to Slow-Fill Ball Valve of the Victaulic AMTA (if applicable) Open operate. Fast-Fill Ball Valve of the Victaulic AMTA (if applicable) Closed Failure to pipe the system main drain valve to a proper wastewater drain will result in property damage.

- Page 20 I-768N / Series 768N FireLock NXT ™ Dry Valve / Installation, Maintenance, and Testing Manual REQUIRED WATER FLOW ALARM TEST Perform the water flow alarm test on a frequency required by the Open the alarm test ball valve. Confirm that mechanical and current NFPA-25 code.

-

Page 21: Required Water Level And Low-Air Alarm Tests

Record the system air pressure at which the low air alarm 1/4-Turn Vent Ball Valve for Series 746-LPA Dry Accelerator Closed (if applicable) activates. Slow-Fill Ball Valve of the Victaulic AMTA (if applicable) Open Close the system main drain valve. Fast-Fill Ball Valve of the Victaulic AMTA (if applicable) Closed Close the slow-fill ball valve on the AMTA (if equipped). -

Page 22: Required Partial Operational Trip Test

Open the remote system test valve (inspector’s test connection) or Victaulic recommends performing the partial operational (trip) test the system main drain valve to simulate an open sprinkler. annually (at minimum). NOTE: The frequency of the partial operational... -

Page 23: Required Full Operational Trip Test

™ Dry Valve / Installation, Maintenance, and Testing Manual REQUIRED FULL OPERATIONAL TRIP TEST Victaulic recommends the full operational (trip) test every 3 years (at Record the following: minimum). NOTE: The frequency of the full operational (trip) test must 6a. Time between opening the remote system test valve be increased in the presence of contaminated water supplies, corrosive/ (inspector’s test connection) and operation of the dry valve... -

Page 24: Required Internal Inspection

I-768N / Series 768N FireLock NXT ™ Dry Valve / Installation, Maintenance, and Testing Manual SECTION V • Required Internal Inspection WARNING • Depressurize and drain the piping system before attempting to remove the cover plate from the valve. • The building owner or their representative is responsible for maintaining the fire protection system in proper operating condition. - Page 25 15. While the clapper is rotated out of the valve body, pull the latch forward to inspect the diaphragm. If the diaphragm shows any signs of wear or damage, replace it with a new, Victaulic-supplied diaphragm. Refer to the “Removing and Replacing the Diaphragm”...

- Page 26 I-768N / Series 768N FireLock NXT ™ Dry Valve / Installation, Maintenance, and Testing Manual SECTION VI • Removing and Replacing the Clapper Seal • Removing and Replacing the Clapper Assembly • Installing the Cover Plate Gasket and Cover Plate •...

-

Page 27: Removing And Replacing The Clapper Seal

Pry the clapper seal, along with the seal ring, out of the clapper. Inspect the clapper seal. If the clapper seal is torn or worn, replace it with a new, Victaulic-supplied clapper seal. If replacing the clapper seal assembly with a new assembly, skip to step 7. -

Page 28: Removing And Replacing The Clapper Assembly

I-768N / Series 768N FireLock NXT ™ Dry Valve / Installation, Maintenance, and Testing Manual REQUIRED SEAL ASSEMBLY BOLT/BOLT SEAL TORQUES Nominal Size Required Torque inches or mm inch-lbs/N•m 1 ½ 2 ½ 76.1 mm 165.1 mm Install the clapper seal into the clapper carefully. Ensure that the seal ring snaps into the clapper completely. -

Page 29: Installing The Cover Plate Gasket And Cover Plate

Verify that the cover plate gasket is in good condition. If the gasket is torn or worn, replace it with a new, Victaulic-supplied gasket. Align the holes of the cover plate gasket with the holes in the cover plate. -

Page 30: Removing And Replacing The Diaphragm Assembly

I-768N / Series 768N FireLock NXT ™ Dry Valve / Installation, Maintenance, and Testing Manual REMOVING AND REPLACING THE DIAPHRAGM CAUTION Remove the system from service by following steps 1 – 10 of the • DO NOT over-tighten the cover plate bolts. “Required Internal Inspection”... -

Page 31: Cleaning The Cartridge In The Air And Priming Manifold Assemblies

Failure to follow this instruction could cause improper valve operation, resulting in property damage. Use only a new, Victaulic-supplied filter. Install the new filter onto the filter adapter, as shown above. Make sure the o-ring is positioned on the filter adapter, as shown above. -

Page 32: Troubleshooting

I-768N / Series 768N FireLock NXT ™ Dry Valve / Installation, Maintenance, and Testing Manual SECTION VII • Troubleshooting I-768N_32 REV_C... - Page 33 Actuator is pulled up, the screw does not stay set in the “UP” The Series 776 Low-Pressure Actuator has a broken seal. If the above procedure does not work, contact Victaulic. position. Water is leaking through the Series 776 Low-Pressure Actuator.

- Page 34 For complete contact information, visit victaulic.com I-768N 8918 REV C UPDATED 08/2016 Z000768N00 VICTAULIC AND FIRELOCK NXT ARE REGISTERED TRADEMARKS OR TRADEMARKS OF VICTAULIC COMPANY AND/OR ITS AFFILIATED ENTITIES IN THE UNITED STATES AND/OR OTHER COUNTRIES. © 2016 VICTAULIC COMPANY. ALL RIGHTS RESERVED.

Need help?

Do you have a question about the 768N FireLock NXT Series and is the answer not in the manual?

Questions and answers