Summary of Contents for Clarke BOXER II 14/100P

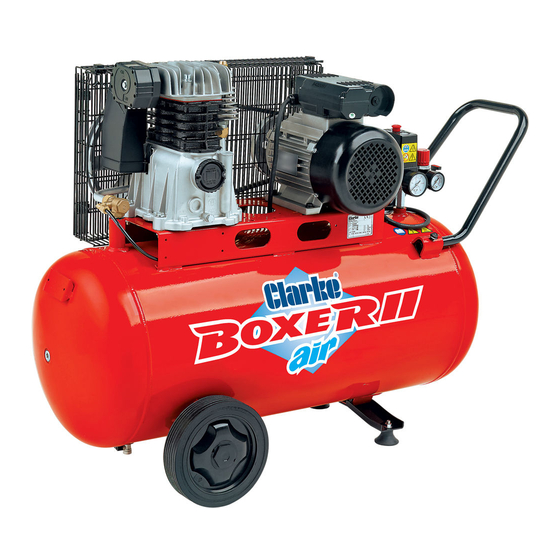

- Page 1 100L BELT DRIVEN AIR COMPRESSOR MODEL NO: BOXER II 14/100P PART NO: 2245313 OPERATION & MAINTENANCE INSTRUCTIONS ORIGINAL INSTRUCTIONS GC0721...

-

Page 2: Environmental Recycling Policy

GUARANTEE This CLARKE product is guaranteed against faulty manufacture for a period of 12 months from the date of purchase. Please keep your receipt as proof of purchase. -

Page 3: Safety Precautions

2. DO NOT operate your compressor with the guard removed. 3. Repairs must only be carried out by a qualified engineer. If problems occur, contact your CLARKE dealer. 4. Before carrying out any maintenance make sure that the pressure is released from the air reservoir and that the compressor is disconnected from the electrical supply. -

Page 4: Safety Symbols

SAFETY SYMBOLS Read this instruction booklet carefully before positioning, operating or adjusting the compressor. Risk of electric shock. The compressor must be disconnected from the mains supply before removing any covers. DO NOT use in a damp environment. Risk of accidental start-up. The compressor could start automatically in the event of a power cut and subsequent reset. -

Page 5: Electrical Connections

ELECTRICAL CONNECTIONS WARNING: READ THESE ELECTRICAL SAFETY INSTRUCTIONS THOROUGHLY BEFORE CONNECTING THE PRODUCT TO THE MAINS SUPPLY. Connect the mains lead to a standard, 230 Volt (50Hz) electrical supply through an approved 13 amp BS 1363 plug, or a suitably fused isolator switch. If the plug has to be changed because it is not suitable for your socket, or because of damage, it must be removed and a replacement fitted, following the wiring instructions shown below. -

Page 6: Attach The Wheels

ASSEMBLY CAUTION: TO PREVENT INJURY, GET ASSISTANCE WHEN LIFTING THIS COMPRESSOR. ATTACH THE WHEELS 1. Slide the axle through the wheel and hole in the wheel frame. • Use the same hole on each side and make sure that the machine is horizontal to the floor. -

Page 7: Before Use

2. Ensure the oil level is between the min and max marks on the dipstick. • Only use CLARKE -ISO100 (SAE30) compressor oil, available from your CLARKE dealer Part No. 3050796. • Take care not to to fill above the maximum mark. -

Page 8: Operation

OPERATION If the compressor has not been used for more then 24 hours, open the drain valve (on the bottom of the reservoir) and drain any condensate which has collected. See page 11. MOVING THE AIR COMPRESSOR • Stop the compressor and disconnect it from the power supply before you move it. -

Page 9: Turning The Compressor On

TURNING THE COMPRESSOR ON 1. Plug the compressor into the power supply. 2. Lift the On/Off button. • The compressor will operate until the reservoir is fully pressurised. It will then shut down. • The compressor will start up again when the pressure in the reservoir decreases. -

Page 10: Removing Tools From The Air Hose

REMOVING TOOLS FROM THE AIR HOSE WARNING: ALWAYS SET THE PRESSURE REGULATOR TO ZERO BEFORE YOU REMOVE OR REPLACE A TOOL. 1. Push down on the On/Off button to stop the compressor. 2. Turn the outlet valve handle to the off position. -

Page 11: Draining The Reservoir

DRAINING THE RESERVOIR CAUTION: YOU MUST DRAIN THE RESERVOIR AFTER EACH DAYS USE AND BEFORE YOU PUT YOUR COMPRESSOR INTO STORAGE. 1. Turn the compressor off and disconnect from the power supply. 2. Put a container below the drain valve to collect the condensate. 3. -

Page 12: Maintenance

Ensure the oil level is between the min and max marks on the dipstick. See “Check the Oil level” on page 7 and top-up if necessary - (use SAE30 compressor oil available from your CLARKE dealer). CLEAN THE AIR FILTER The air filter must be examined monthly or more often in dusty conditions. - Page 13 REPLACING THE OIL After the first 100 hours use, replace the oil using CLARKE ISO100 (SAE30) compressor oil. Then replace the oil after every 500 hours of operation or every 6 months. To empty the oil from the engine, remove the oil drain plug from the crankcase.

-

Page 14: Replacing The Drive Belt

REPLACING THE DRIVE BELT WARNING: MAKE SURE THAT THE COMPRESSOR IS DISCONNECTED FROM THE ELECTRICAL SUPPLY BEFORE REPLACING THE DRIVE BELT. 1. Rotate the clips on the front of the safety cage. 2. Remove the front of the cage and remove the damaged drive belt. -

Page 15: Specifications

SPECIFICATIONS MODEL II 14/100P OXER Part Number 2245313 Motor Size 3 HP Voltage 230 VAC (50Hz) Air Displacement 394 L/min (14 cfm) Max Pressure 10 Bar (145 psi) Receiver Capacity 100 L Ingress Protection IP20 Fuse Rating 13 A Duty cycle S3/50% Oil requirements ISO100 (SAE30) compressor oil... -

Page 16: Troubleshooting

TROUBLESHOOTING CAUTION: DO NOT TRY TO REPAIR OR ADJUST IF YOU ARE UNCERTAIN. IF YOU HAVE ANY QUERIES, CONTACT YOUR CLARKE DEALER. PROBLEM PROBABLE CAUSE REMEDY The compressor Bad electrical 1. Check electrical has stopped connections. connections. and does not 2. -

Page 17: Component Parts

COMPONENT PARTS Parts & Service: 020 8988 7400 / E-mail: Parts@clarkeinternational.com or Service@clarkeinternational.com... -

Page 18: Parts List

PARTS LIST NO DESCRIPTION NO DESCRIPTION CRANKCASE GASKETS SET 213167002 CYLINDER PISTON RING SET CYLINDER HEAD PISTON ASSEMBLY CRANKSHAFT LOWER COVER NON RETURN VALVE VALVE HOLDER ASSEMBLY TAP BALL VALVE CONROD DRAIN.VALVE 3/8 GASKET PRESSURE REGULATOR INTAKE FILTER ASSEMBLY GAUGE 50mm 10BAR AIR COOLER GAUGE 40mm CYLINDER HEAD BOLT... -

Page 19: Declaration Of Conformity

DECLARATION OF CONFORMITY Parts & Service: 020 8988 7400 / E-mail: Parts@clarkeinternational.com or Service@clarkeinternational.com...

Need help?

Do you have a question about the BOXER II 14/100P and is the answer not in the manual?

Questions and answers