Denison Hydraulics Premier Series Service Information

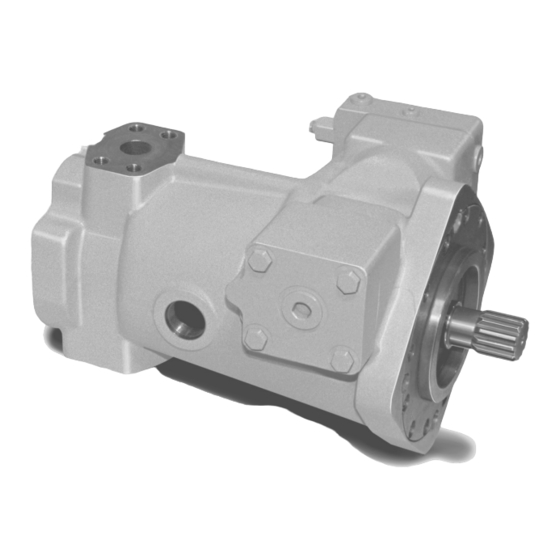

Piston pumps for open circuit

Hide thumbs

Also See for Premier Series:

- Service information (80 pages) ,

- Service information (48 pages) ,

- Service information (47 pages)

Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Denison Hydraulics Premier Series

- Page 1 DENISON HYDRAULICS Premier Series piston pumps for open circuits P12 & P200 service information replaces LT2-00054-2 Revised 5/03 Publ. LT2-00054-2-A Internet http://www.denisonhydraulics.com E-mail: denison@denisonhydraulics.com www.comoso.com...

-

Page 2: Table Of Contents

The shaft seal and all "O" rings necessary for total seal replacement may be obtained by ordering Seal Kit . These seals are suitable for petroleum base fluids. For fire resistant fluids contact DENISON HYDRAULICS, Inc. or their authorized distributors to obtain the appropriate seal kit number. -

Page 3: Port Identification

IDENTIFICATION OF PORTS AND ADJUSTMENTS CCW ROTATION SHOWN TIGHTENING TORQUE FOR HYDRAULIC PLUGS PORT SIZE ft-lbs SAE-2 SAE-4 SAE-6 SAE-8 SAE-10 SAE-14 SAE-20 1/8 BSPP 1/4 BSPP 3/8 BSPP 1/2 BSPP 1-1/2 BSPP FLUID CONNECTIONS ....DESCRIPTION..................P12 ....P200 PORT A ..INLET ..................3.5"... - Page 4 IDENTIFICATION OF PORTS AND ADJUSTMENTS www.comoso.com...

- Page 5 IDENTIFICATION OF PORTS AND ADJUSTMENTS P200 P200 P200 P200 www.comoso.com...

- Page 6 "X"-PQ CONTROL www.comoso.com...

- Page 7 IDENTIFICATION OF PORTS AND ADJUSTMENTS www.comoso.com...

-

Page 8: Start Up Procedure

START UP START UP PROCEDURE FOR NEW INSTALLATION Read and understand the instruction manual. Identify components and their function. Visually inspect components and lines for possible damage. Check reservoir for cleanliness. Drain and clean as required Check fluid level and fill as required with filtered fluid at least as clean as that recommended. Fill pump case with clean oil prior to starting. -

Page 9: Trouble Shooting Charts

TROUBLESHOOTING Component problems and circuit problems are often interrelated. An improper circuit may operate with apparent success but will cause failure of a particular component within it. The component failure is the effect, not the cause of the problem. This general guide is offered to help in locating and eliminating the cause of problems by studying their effects. - Page 10 TROUBLESHOOTING Effect of Trouble Possible Cause Fault Which Needs Remedy Compensator, Compensator Override Low system pressure Compensator malfunction Dirt in spool orifice Damaged cone or seat Broken differential spring Improperly adjusted differential spring Failure to compensate Differential adjustment Differential set too high Sluggish response Differential adjustment Differential set too low...

-

Page 11: Exploded View Of Pump

PUMP PARTS LISTS Figure 1 Exploded view of pump with pressure compensator control (For PQ Control) PARTS LIST FOR INDICATOR ASSEMBLY item description part no. qty. Pivot nut 032-92491 Indicator 033-70624 fork 032-92490 pivot shaft 032-92492 glyd ring 679-00030 Soc. setscrew, 10-32 x 3/16 312-09030 O-ring, 70 S-1 ARP 114 671-00114... - Page 12 PUMP PARTS LISTS item description part no. part no. P200-DIN P200-DIN qty. P12-SAE P200-ISO 50mm 60mm shaft assembly keyed, no rear drive S22-16523 S22-16527 S22-16531 S22-16548 a (shaft) 032-92961 032-92962 032-92967 032-92969 b (bearing) 230-82215 230-82215 230-82215 230-82217 c (seal) 620-82080 620-82099 620-82099...

- Page 13 PUMP PARTS LISTS item description part no. part no. qty. P12-SAE P200-ISO/DIN Belleville washer 032-91597 032-91597 stop 032-92728 032-92728 retaining ring 032-92707 032-92707 screw, button head (PQ control) 353-25079 353-25079 wear plate 032-92695 032-92695 lockwasher 348-10016 348-10016 bearing 032-91602 032-91602 washer 345-10012 345-10012...

-

Page 14: Rework Limits

DISASSEMBLY INSTRUCTIONS Disassembly Disassemble only as far as necessary to replace or repair worn parts. If the pump has a rear drive, the mounting adapter and coupling must be removed prior to pump disassembly Refer to figure 3 page 15. Clean outside surface of the pump before disassembly. -

Page 15: Rear Drive Adapters

REAR DRIVE PARTS LISTS ISO 224 Figure 3 Rear drive options SAE REAR DRIVES code flange SAE 82-2 SAE 82-2 SAE101-2/4 SAE101-2/4 SAE127-2/4 SAE127-2/4 SAE152-4 SAE165-2/4 coupling 16-4 22-4 22-4 25-4 32-4 38-4 44-4 44-4 item part (“A”) (modified “A”) (“B”) (“B-B”) (“C”) -

Page 16: Conversion

CONVERSION Figure 4 CAM BEARINGS/CRADLE ORIENTATION TO HOUSING ROTATION CONVERSION The following parts and assembly are required for changing shaft rotation: A different barrel and port plate assembly is required. The barrel and port plate are matched assemblies, and should not be ordered separately. -

Page 17: Reassembly

PUMP REASSEMBLY INSTRUCTIONS SHAFT SEAL REPLACEMENT See illustration. Remove worn or damaged seal from retainer. Clean gasket sealant from retainer. Install new seal by applying gasket sealant to retainer and pressing seal in retainer. SEAL KITS ........P12 S22-12830 . - Page 18 PUMP REASSEMBLY INSTRUCTIONS 4. Press bearing outer race (11) into housing (7). BARREL AND INNER RACE ASSEMBLY Thread seven M8-1,25 studs into bearing inner race. Lower barrel (14) over studs and seat. If the inner race is heated to 150 F, 65 C, barrel will slide into position without force.

- Page 19 PUMP REASSEMBLY INSTRUCTIONS - Continued - Rocker cradle assembly 20.Apply threadlocking compound to two screws (47) and assemble two cam bearings (42) to cradle (6). Torque to 33 lbs-in., (3.8 Nm). THREAD LOCK- ING COMPOUND 33 IN-LB, 3,8 Nm 21. Press bearing (1b) on shaft (1a). Press on inner race only. 22.

- Page 20 PUMP REASSEMBLY INSTRUCTIONS CONTROLS ASSEMBLY Remove cap tools T-2 from housing and replace with control cap assemblies (50) and (31). The control caps must be positioned on the housing for either CW or CCW pump rotation. See figure 5 for correct orientation. The control piston (44) was assembled previously for the correct pump rotation.

-

Page 21: Controls

CONTROLS GENERAL The instructions contained in this manual cover complete disassembly and reassembly of the controls. Before pro- ceeding with the disassembly or reassembly of any unit, this manual should be studied in order to become familiar with proper order and parts nomenclature DESCRIPTION OF OPERATION A pilot operated valve spool and sleeve combination is the core of the control function. - Page 22 CONTROLS HYDRAULIC STROKER In the hydraulic stroker, the pin which controls stroke position is connected to a spring loaded piston. A control pres- sure of 50 psi (3,5 bar) causes the piston to commence to move against the spring, to position the pin in proportion to the control pressure, and thus cause the pump to stroke in proportion to control pressure.

-

Page 23: Pressure Compensator

PRESSURE COMPENSATOR CONTROL CCW ROTATION CW ROTATION ITEMS NOT SHOWN C10, C50 C20, C80 PRESSURE COMPENSATOR parts list P200 QUANTITY ITEM DESCRIPTION PART NO. PART NO. C10, C50 C20, C80 Max. Vol. Stop (Fig. 7) S22-12983 S22-12983 Max Vol. Handwheel (Fig. 8) S22-12915 S22-12915 *Compensator Control (Fig. - Page 24 PRESSURE COMPENSATOR CONTROL COMPENSATOR DISASSEMBLY 1. See Figure 6. Back off max. volume screw or handwheel to full displacement. Remove max. volume screw or hand- wheel assembly. 2. Remove bolts holding cap to pump. 3. Remove plug (15) and attached parts. Remove spring (11) and spool (18). 4.

- Page 25 PRESSURE COMPENSATOR CONTROL SYSTEM PRESSURE PORT C1 COMPENSATOR ADJUSTMENT VENT CONN. V FIGURE 6 P200 PARTS LIST FOR FIGURE 6 ITEM DESCRIPTION PART NO. QTY. PART NO. QTY. P12 code C10, C50 S22-15311 Cap-Sleeve Assembly S22-12880 S22-12881 P200 code C10, C50, S22-15312 adjusting Plug 032-91814 032-91814...

-

Page 26: Maximum Volume Stop; Handwheel

MAXIMUM VOLUME STOP PARTS LIST FOR FIGURE 7 max. volume stop S22-12983 ITEM DESCRIPTION PART NO. QTY. Plug, SAE-10 488-35055 O-Ring, 90 S-1 ARP 910 691-00910 Nut, 3/4 -10UNC Hex 031-91049 Screw, Soc. Set 3/4 10 x 3 311-45049 O-Ring,70 S -1 ARP 118 671- 00118 Figure 7 max. -

Page 27: Buck-Up Cap Assembly

BUCK-UP CAP 140 lb. ft FIGURE 9 Buck-up cap assembly PARTS LIST FOR FIGURE 9 buck-up cap S22-15653 ITEM DESCRIPTION PART NO. QTY. Piston 324-26448 Spring 032-92244 Spring 032-92316 Sleeve 032-92247 Control Cap 032-92248 O-Ring 691-00126 Plug, SAE-20 449-00614-0 Plug 488-35046 O-Ring 691-00902... -

Page 28: Torque Limiter

TORQUE LIMITER CONTROL CCW ROTATION CW ROTATION ITEMS NOT SHOWN J10 * K10* J20 * * K20** TORQUE LIMITER PARTS LIST torque limiter P200 QUANTITY ITEM DESCRIPTION PART NO PART NO. J10* K10* J20** K20** Maximum Volume Stop (Fig. 7) S22-12983 S22-12983 Max Vol. - Page 29 TORQUE LIMITER CONTROL DISASSEMBLY 1. See Figure 11. Remove 2 screws holding torque limiter body (16) to cap assembly (1). 2. Remove all parts from torque limiter body (16) except pin (30) and arm assembly (28). It is not necessary to remove these parts unless broken or worn.

- Page 30 TORQUE LIMITER CONTROL FIGURE 10 Torque limiter cap PARTS LIST FOR FIGURE 10 P200 P12 torque limiter cap S22-16408 ITEM DESCRIPTION PART NO. QTY. PART NO. QTY P200 torque limiter cap S22-16409 Cap-Sleeve Assembly S22-12912 S22-12922 Adjusting Plug 032-91814 032-91814 O-ring, 90 S-1 ARP 902 691-00902 691-00902...

- Page 31 TORQUE LIMITER CONTROL 75 lb. ft. (102 Nm) 75 lb. ft. (102 Nm) 5 lb. ft. FIGURE 11 Torque Limiter PARTS LIST FOR FIGURE 11 P12 code J10 ,J50, S22-15732 P200 QTY. P12 code K10, K50, S22-15315 ITEM DESCRIPTION PART NO. PART NO. P200 code J10, J50, S22-15733 Cap (Figure 10) - J Version S22-16408 S22-16409...

-

Page 32: Load Sensing Control

LOAD SENSING PRESSURE COMPENSATOR CONTROL CCW ROTATION CW ROTATION ITEMS NOT SHOWN L10, L50 L20, L80 M10, M50 M20, M80 LOAD SENSING CONTROL parts list P200 QUANTITY ITEM DESCRIPTION PART NO. PART NO. L10, L50 L20, L80 Maximum Volume Stop (Fig. 7) S22-12983 S22-12983 Max Volume Handwheel (Fig. - Page 33 LOAD SENSING PRESSURE COMPENSATOR CONTROL DISASSEMBLY 1. See Figure 12 Back off max. volume screw or handwheel to full displacement. Remove max. volume assembly . 2. Remove bolts holding cap to pump. 3. Remove isolation valve (29) from block (28). Remove plug (15) and attached parts. Remove spring (11) and spool (18). 4.

- Page 34 LOAD SENSING PRESSURE COMPENSATOR CONTROL FIGURE 12 load sensing compensator control PARTS LIST FOR FIG. 12 P200 LOAD SENSING ITEM DESCRIPTION PART NO. QTY PART NO. QTY COMPENSATOR Cap-Sleeve Assembly S22-15143 S22-15176 P12 S22-15536 L1 Adusting Plug 032-91814 032-91814 P200 S22-15537 L1 Socket Setscrew 312-13200 312-13200...

-

Page 35: Load Sensing Torque Limiter

LOAD SENSING TORQUE LIMITER CONTROL CCW ROTATION CW ROTATION ITEMS NOT SHOWN V10 * W10* V20 * * W 20** LOAD SENSING TORQUE LIMITER Y10 * Z10* Y20 * * Z 20** PARTS LIST load sensing torque limiter P200 QUANTITY ITEM DESCRIPTION PART NO PART NO. - Page 36 LOAD SENSING TORQUE LIMITER CONTROL DISASSEMBLY 1. See Figure 13. Remove 2 screws holding torque limiter body (16) to cap assembly (1). 2. Remove all parts from torque limiter body (16) except pin (30) and arm assembly (28). It is not necessary to remove these parts unless broken or worn.

- Page 37 LOAD SENSING TORQUE LIMITER CONTROL 38a 38b P200 QTY. PARTS LIST FOR FIGURE 13 ITEM DESCRIPTION PART NO. PART NO. P12 code V10, V50, S22-16193 Cap (Figure 14) S22-15791 S22-15411 P12 code W10, W50, S22-16191 Adapter 032-91507 Screw 032-91461 032-91461 P200 code W10, W50, S22-16192 O-ring, 70 S-1 ARP 008 671-00008 671-00008...

- Page 38 LOAD SENSING TORQUE LIMITER CONTROL Ref. Figure 14 Load sensing torque limiter cap PARTS LIST FOR FIGURE 14 P200 P12 load sensing torque limiter cap ITEM DESCRIPTION PART NO. QTY. PART NO. QTY S22-15791 Cap-Sleeve Assembly S22-15792 S22-15410 P200 load sensing torque limiter cap Adjusting Plug 032-91814 032-91814...

-

Page 39: Rotary Servo

ROTARY SERVO CONTROL CCW ROTATION CW ROTATION ITEMS NOT SHOWN R10* R1P*** R1J * * R 1K** PARTS LIST rotary servo P200 QUANTITY ITEM DESCRIPTION PART NO. PART NO. R10* R1J** R1K** R1P*** #Rotary Servo (Fig. 15) S22-16005 S22-16006 #Control Cap (Fig.26) S22-15528 S22-15529 #Low Torque Override (Fig. - Page 40 ROTARY SERVO CONTROL DISASSEMBLY 1. See Figure 15. Remove 2 screws holding body (16) to cap assembly (1). 2. Remove all parts from body (16) except pin (30) and arm assembly (28). It is not necessary to remove these parts unless broken or worn.

- Page 41 ROTARY SERVO CONTROL TORQUE (102 Nm) USE THREAD LOCKING COMPOUND TORQUE 5 FT- LB (6,8 Nm) HYDRAULIC SEALANT FIGURE 15 rotary servo PARTS LIST FOR FIGURE 15 P200 ROTARY SERVO ITEM DESCRIPTION PART NO. QTY. PART NO. QTY. P12 S22-16005 Cap (Figure 16) S22-16449 S22-16451...

- Page 42 PORT CONTROL PRESSURE TO OPPOSITE SIDE www.comoso.com...

-

Page 43: Hydraulic Stroker

HYDRAULIC STROKER CONTROL CCW ROTATION CW ROTATION ITEMS NOT SHOWN H10* H1P*** H1J * * H 1K** PARTS LIST hydraulic stroker P200 QUANTITY ITEM DESCRIPTION PART NO. PART NO. H10* H1J** H1K** H1P*** #Hydraulic Stroker (Fig. 17) S22-16003 S22-16004 #Control Cap (Fig. 26) S22-15528 S22-15529 #Low Torque Override (Fig. - Page 44 HYDRAULIC STROKER CONTROL DISASSEMBLY 1. See figure 17. Remove 2 screws holding body (16) to cap assembly (1). 2. Remove all parts from body (16) except pin (30) and arm assembly (28). It is not necessary to remove these parts unless broken or worn.

- Page 45 HYDRAULIC STROKER CONTROL FIGURE 17 Loctite 569 hydraulic stroker PARTS LIST FOR FIG. 17 P200 P12 hydraulic stroker S22-16003 ITEM DESCRIPTION PART NO. QTY. PART NO. QTY P200 hydraulic stroker S22-16004 Cap (Figure 16) S22-16449 S22-16451 Screw 032-91461 032-91461 O-Ring, 70 S -1 ARP 010 671-00010 671-00010 Clevis pin...

-

Page 46: Electrohydraulic Stroker

ELECTROHYDRAULIC STROKER CONTROL CCW ROTATION CW ROTATION ITEMS NOT SHOWN E10* E1P*** E1J * * E 1K** PARTS LIST electrohydraulic stroker P200 QUANTITY ITEM DESCRIPTION PART NO. PART NO. E10* E1J** E1K** E1P*** #Electrohydraulic Stroker (Fig. 18) S22-16001 S22-16002 #Control Cap (Fig. 26) S22-15528 S22-15529 #Low Torque Override (Fig. - Page 47 ELECTROHYDRAULIC STROKER CONTROL DISASSEMBLY 1. See Figure 18. Remove 3 screws (37) holding block (36) to body (16). 2. Remove 2 screws holding body (16) to cap assembly (1). 3. Remove all parts from body (16) except pin (30) and arm assembly (28). It is not necessary to remove these parts unless broken or worn.

- Page 48 www.comoso.com...

- Page 49 ELECTROHYDRAULIC STROKER CONTROL Ref. Figure 18 ELECTROHYDRAULIC STROKER www.comoso.com...

-

Page 50: Pq Control

PQ HIGH RESPONSE CONTROL NOT SHOWN PQ CONTROL parts list P200 QUANTITY ITEM DESCRIPTION PART NO. PART NO. PQ Control (Fig.21) S22-15963 S22-15964 Max Volume Stop (Fig. 23) S22-16126 S22-16126 CW Tube Assembly (Fig. 19) S22-16681 S22-16682 CCW Tube Assembly (Fig. 20) S22-16683 S22-16684 Control Piston 032-93031 032-93031 O-Ring, 90 S-1 ARP 013... - Page 51 PQ HIGH RESPONSE CONTROL DISASSEMBLY 1. See Figure 21. With pump on full stroke, remove plug (12) and spring (3) from cap (2). 2. Remove LVDT feedback assembly (8) from cap. Remove sensor base (5), spring (14) and feedback follower assembly (6 and 11) 3.

- Page 52 PQ HIGH RESPONSE CONTROL Torque 75 lb. ft. (103 Nm) (APPLY THREAD LOCKING COMPOUND FIGURE 21 PQ control PARTS LIST FOR FIGURE 21 P12 PQ control S22-15963 P200 PQ control S22-15964 P200 ITEM DESCRIPTION PART NO. QTY. PART NO. QTY. Piston servo cone 032-92509 032-92509...

- Page 53 PQ HIGH RESPONSE CONTROL Torque 75 lb. ft. (103 Nm) (APPLY THREAD LOCKING COMPOUND Ref. Figure 21 PQ CONTROL CONTROL CAP DISASSEMBLY 1. See Figure 23. Remove nut (9) and maximum volume screw (11). 2. Remove guide (1). 3. Remove 4 screws (12) holding cap to pump. 4.

-

Page 54: Control Tubing; Control Cap

SECONDARY CONTROLS Figure 24 Figure 25 P12 control tubing P200 control tubing PARTS LIST FOR FIGURE 25 P200 control tubing P22-16575 ITEM DESCRIPTION PART NO. QTY. PARTS LIST FOR FIGURE 24 Servo tube w/nut & sleeve S22-17274 P12 control tubing P22-16574 Male conection fitting 492-15427 ITEM DESCRIPTION... -

Page 55: Compensator Override Control

COMPENSATOR OVERRIDE CONTROL Figure 27 system Compensator override control pressure PARTS LIST FOR FIGURE 27 P200 compensator override control ITEM DESCRIPTION PART NO. QTY. PART NO. QTY P12 compensator override S22-16007 Cap-Sleeve Assembly S22-15989 S22-15990 P200 comp. override S22-16008 Adustment Plug 032-91814 032-91814 O-ring, 90 S-1 ARP 902... - Page 56 COMPENSATOR OVERRIDE CONTROL DISASSEMBLY 1. See Figure 27. Remove tube line to cap. 2. Remove maximum volume stop assembly (items 12, 13, 19, 20, 24). 3. Remove cap assembly. 4. Remove plug (15) and attached parts. Remove spring (11) and spool (18). 5.

-

Page 57: Torque Limiter Override Control

TORQUE LIMITER OVERRIDE system pressure FIGURE 28 torque limiter override cap P200 PARTS LIST FOR FIGURE 28 ITEM DESCRIPTION PART NO. QTY. PART NO. QTY torque limiter override cap Cap-Sleeve Assembly S22-15991 S22-15992 P12 cap S22-15993 Adjustment Plug 032-91814 032-91814 P200 cap S22-15994 O-ring, 90 S-1 ARP 902 691-00902... - Page 58 TORQUE LIMITER OVERRIDE use hydraulic sealant use hydraulic sealant FIGURE 29 TORQUE LIMITER OVERRIDE P200 QTY. PARTS LIST FOR FIGURE 29 torque limiter override ITEM DESCRIPTION PART NO. PART NO. P12 code J S22-16183 Cap (Figure 28) S22-15993 S22-15994 P12 code K S22-16009 Screw 032-91461 032-91461...

- Page 59 TORQUE LIMITER OVERRIDE DISASSEMBLY 1. See figure 29. Remove 2 screws holding torque limiter body (16) to cap assembly (1). 2. Remove all parts from torque limiter body (16) except pin (30) and arm assembly (28). It is not necessary to remove these parts unless broken or worn.

-

Page 60: Testing

TEST PROCEDURE Test Conditions: (If using service facility test stand) Fluid: Mobil 4259 DE (ISO VG-32 or equivalent) RPM: 1770 ± 30 RPM Inlet Temp: 120 F ± 10 F. (49 C ± 4 Inlet Condition: Atmospheric to + 5 psi (0,345 bar) Case Pressure: 25 psi ±5 psi (1,72 bar ±... - Page 61 TEST PROCEDURE minimum stroke adjustment, under plug cylinder gage port C2 servo input shaft set maximum volume servo conn. X gage port V1 gage port XG ROTARY SERVO CONTROL CAP TEST CIRCUIT ROTARY SERVO WITH COMPENSATOR OVERRIDE ROTARY SERVO TEST (continued) Plumb servo supply [5 gpm (19 lpm) minimum at 700 psi +/- 30 psi (48 bar +/- 2 bar) ] to control port X.

-

Page 62: Compensator Test

TEST PROCEDURE compensator adjustment port C1 vent V TEST CIRCUIT COMPENSATOR OVERRIDE CAP COMPENSATOR OVERRIDE ROTARY SERVO INPUT COMPENSATOR TEST Outlet relief valve should be set to minimum pressure. If the pump contains a servo, hydraulic or electrohydraulic stroker control, test that control first, (pg. 60, 64 or 65) then set the control to give full stroke on the pump. -

Page 63: Load Sensing Test

TEST PROCEDURE Raise compensator from minimum to maximum outlet pressure. At each condition, increase the outlet pressure until the pump fully de-strokes. At no time should the outlet pressure vary over 150 psi (10.3 bar) from the compensator set- ting. The control should be steady and stable at all conditions. Calculate compensator leakage by subtracting leakage flow at full flow from leakage flow fully compensated. -

Page 64: Hydraulic Stroker Test

TEST PROCEDURE servo pressure cylinder gage port C2 gage conn. minimum stroke adjustment, under plug zero flow adjustment control port H servo pressure control port H port X P200 HYDRAULIC STROKER CAP TEST CIRCUIT HYDRAULIC STROKER COMPENSATOR OVERRIDE HYDRAULIC STROKER, HYDRAULIC STROKER TORQUE LIMITER OVERRIDE HYDRAULIC STROKER TEST... -

Page 65: Electrohydraulic Stroker Test

TEST PROCEDURE minimum stroke adjustment, under plug port C2 port E, P12 port E, P200 port X zero adjustment port XG port H port V1 TEST CIRCUIT ELECTROHYDRAULIC STROKER CAP ELECTROHYDRAULIC STROKER COMPENSATOR OVERRIDE ELECTROHYDRAULIC STROKER TEST Before testing electrohydraulic stroker, disable the compensator or torque limiter override, if applicable, by turning the compensator differential adjustment fully in. -

Page 66: Torque Limiter And Torque Limiter Override Test

TEST PROCEDURE TORQUE LIMITER AND TORQUE LIMITER OVERRIDE TEST The torque limiter design is a compensator with a means of vary- ing pump stroke with pressure in this manner: The compensator vent port applies pressure to a pin. The pin moves against two independently adjustable springs. - Page 67 TEST PROCEDURE Set the compensator to 3000 psi (207 bar), 6000 psi (414 bar), and 7250 psi (500 bar) [One turn approximately equals 2000 psi (138 bar)]. At each condition, increase the outlet pressure until the pump fully de-strokes. At no time should the outlet pressure vary more than 150 psi (10.3 bar) from the compensator setting.

-

Page 68: Load Sensing Torque Limiter Test

TEST PROCEDURE LOAD SENSING TORQUE LIMITER Caution: Load sensing control is limited to 5000 psi (345 bar) maximum pressure. Pump should be connected to speed control valve, load sensing line and load valve as shown. Install gages on outlet pressure and "V" capable of measuring pressure difference to 10 psi (0.69 bar). - Page 69 TEST PROCEDURE Fully open the speed control valve. Set the torque limiter by using the formula: HP=P Q /(Eff. * 1714), or P=HP(Eff.*1714)/Q, or Q=HP(Eff*1714)/P where P = Pressure in psi Q = flow in GPM Eff. = overall efficiency or kW = P Q /(Eff.

-

Page 70: Pq Control Test

TEST PROCEDURE PRESSURE/FLOW (PQ) CONTROL Connect PQ control driver card 020-14133 to pump as indicated. 1. Adjust maximum volume stop to full displacement by backing off screw CCW until there is no contact with control piston. 2. Set test stand relief valve at 500 psi. Jog electric motor to verify correct rotation. Start electric motor. With power off to the control, pump should be at full displacement at 500 psi, about 66 gpm. -

Page 71: Final Pump Test

TEST PROCEDURE FINAL PUMP TEST Operate the pump with the following outlet pressures for the times indicated. 1000 psi ± 100 psi (69 bar ± 6.9 bar) 3 minutes minimum 3000 psi ± 100 psi (207 bar ± 6.9 bar) 2 minutes minimum 5000 psi ±... - Page 72 TEST PROCEDURE CCW ROTATION SHOWN FLUID CONNECTIONS ......DESCRIPTION..................P12 ... . .P200 PORT A ..INLET ..................3.5" SAE CODE 61 3.5" SAE CODE 61 5/8-11 SCREWS M16-2 SCREWS PORT B ..SYSTEM ..................1-1/2 SAE CODE 62 1-1/2 SAE CODE 62 5/8-11 SCREWS M16-2 SCREWS PORT C1 ..OFF-STROKE CYLINDER GAGE ............SAE-4 .

-

Page 73: Tools

ASSEMBLY TOOLS 7.25 2.05 SLOT (184,1) (52,0) EACH SIDE .12 (9,6) 3.25 (3,05) (82,6) FOR M6 (19,0) SOC. HD. 3.00 1.00 (76,2) (25,4) SCREW PRESS FIT FOR 1/2 1.50 (12,7mm) DOWEL PIN x 4 (101,6mm) (38,1) LONG (Lifting tool) Barrel & inner race assembly 3.75 (95,2) 2.25... - Page 74 ASSEMBLY TOOLS (Installation tool) Retainer & shaft bearing In cradle 2.55 (Installation tool) Shaft seal over shaft Length Length Dia. Dia. Shaft P12 keyed 1.878/1.880 47.70/47.75 1.755/1.760 44.58/44.70 3.00 76.2 4.50 114.3 P12 splined 1.878/1.880 47.70/47.75 1.725/1.730 43.82/43.94 3.00 76.2 4.50 114.3 P200 ISO...

-

Page 75: Characteristics

TYPICAL CHARACTERISTICS Specification Term P200 displacement at max. angle ..................../rev. 12.2 12.2 /rev pressure continuous ......................6000 6000 pressure intermittent (not to exceed 6 sec./minute) ............7250 7250 speed, @ atmospheric inlet ....................2100 2100 max. with boost 2700 2700 rotating inertia ...................... - Page 76 INSTALLATION PROCEDURES, AND TECHNICAL SPECIFICATIONS AND LIMITS GENERAL The DENISON HYDRAULICS P12/P200 Series is a variable displacement open circuit axial piston pump with advanced pumping and control concepts. MOUNTING This pump is designed to operate in any position. The pump shaft must be in alignment with the shaft of the prime mover and should be checked with a dial indicator.

- Page 77 CONVERSIONS & FORMULAS DEFINITION & UNIT /rev x 16.387 = cm /rev /rev x 0.06102 = in /rev displacement gpm x 3.78 = L/min L/min x 0.2642 = gpm flow hp x 0.7457 = kW kW x 1.341 = hp power lb-ft x 1.3567 = Nm Nm x 0.7376 = lb-ft...

-

Page 78: Ordering Code

PUMP ORDERING CODE Premier pumps Model number sheet Example model code: Revised 6/24/02 Pump Displacement 4.9 cu.in./rev. 80.3 cc/rev. 6.7 cu.in./rev. 109.8 cc/rev. 8.6 cu.in./rev. 140.9 cc/rev. 12.2 cu.in./rev. 200.0 cc/rev. 16.0 cu.in./rev. 262.2 cc/rev. Style High speed (>1800 RPM)(for P16/260 only) Quiet (for P16/260 only) All other sizes leave blank... - Page 79 NOTES www.comoso.com...

- Page 80 : / / w w w . d e n i s o n h y d r a u l i c s . c o m © Copyright 2002 Denison Hydraulics Inc. All rights reserved. 4-30-02 www.comoso.com...

Need help?

Do you have a question about the Premier Series and is the answer not in the manual?

Questions and answers