Table of Contents

Advertisement

Advertisement

Table of Contents

Summary of Contents for AFi Lisa AFI-C200 Series

- Page 1 Maintenance Manual - Revision 1.4 - English version...

- Page 3 602398 This document has been prepared with the utmost care. However, AFI Centrifuge refuses to accept any responsibility in the event of errors or omissions. The same applies to any damage arising from the use of information contained in this manual.

- Page 4 Original Instructions - Rev.1.4 Service Manual– Lisa / Loreena Centrifuges 2/ 41...

- Page 5 This warranty shall not apply to any AFI Centrifuge product or part thereof which has been subject to misuse, abuse, accident, shipping damage, improper installation or service, or damage by fire, or flood. If the serial number of this product is altered, removed or defaced as to be illegible, the Warranty shall be null and void in its entirety.

- Page 6 Updates Date Revision Modification Paragraph Author 11 Oct. 2016 Error3 detection, Add counter 2.2, 3.7, 3.8, F. LE CAM modification menu & 3.11 overtemperature alarm. Reset. Ogival control unit change procedure July, 4th, 2017 Missing rotor detection, Auto- 2.2, 3.5, Erreur ! F.

-

Page 7: Table Of Contents

Table of contents DESCRIPTION OF THE CENTRIFUGE ......................7 ........................7 LECTRONIC ONTROL ENTER LOCK ................................. 9 ................................10 OTOR ..............................10 PEED SENSOR ............................10 ACHOMETER BOARD ............................10 EMPERATURE PROBE ............................10 MBALANCE SENSOR ..............................10 AS SPRING .......................... - Page 8 3.0 L ..........................37 ITER ENCHTOP ODEL 3.0 L ........................38 ITER LOOR TANDING ODEL ANNEXES ..............................39 ............................. 40 ETURN AUTHORIZATION ..............................41 ECHNOTES Original Instructions - Rev.1.4 Service Manual– Lisa / Loreena Centrifuges 6/ 41...

-

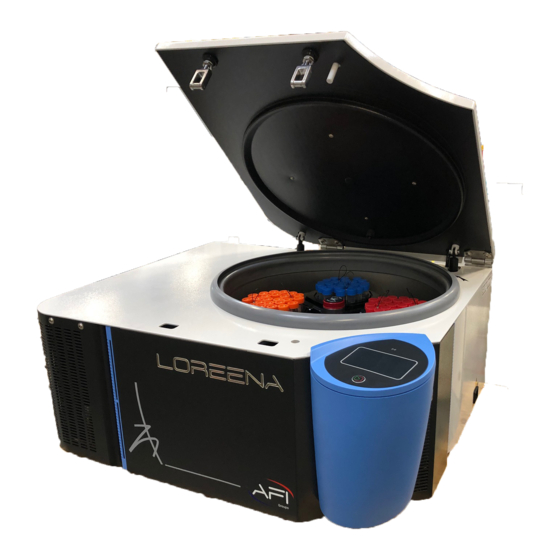

Page 9: Description Of The Centrifuge

Description of the Centrifuge The centrifuge range is composed of : 2 Liter centrifuges, LISA series : References Model Ventilated, 120V / 60Hz AFI-C200V AFI-C200VE Ventilated, 230V / 50Hz AFI-C200R Refrigerating, 120V / 60Hz AFI-C200RE Refrigerating, 230V / 50Hz 3 Liter centrifuges, LOREENA series. - Page 10 1.1.3 . Main Switch The main switch is located under the Control Center. It allows for completely shutting off power to the centrifuge. 1.1.4 . Cover Opening Button The lid opening is controlled by the button on the right side of the Control Center. 1.1.5 .

-

Page 11: Lock

Lock 1.2.1 . LISA Model The lock consists of a media on which the following are assembled: Description 1) Micro contact / Micro switch No. 1: It detects the open position of the lock. The deadbolt presses on the micro switch blade when the lid strike plate is completely released. -

Page 12: Motor

Motor It is a three phase induction motor powered in variable frequency. It has an integrated over temperature sensor. It measures the heating of the internal motor winding, and sends a signal from 130 degrees Celsius. It then sends the message “ERROR 04”. Speed sensor The speed sensor is a Hall Effect magnetic sensor, placed under the motor. -

Page 13: Absorption Of Vibrations

Absorption of vibrations Any system has its own resonance frequency, which will cause oscillations. The dissipative elements of these oscillations, which translate into vibrations, are anti-vibration mounts, numbering 4, coupled by an absorbent foam. This set will allow for absorbing parasitic movements whatever the rotor, its load, and its speed, providing that the load is balanced. -

Page 14: Troubleshooting

Troubleshooting Troubleshooting Problem Cause Solution No display: the screen No voltage Operate the switch under the Control Center. remains black. Connect the mains power cable. Check the electrical supply of the laboratory and restore it. The lid does not close: The lid has been opened with Press the control button to open the lid: the mechanism does not... - Page 15 The difference between the air Check the value of the temperature alarm threshold. temperature over Change program settings: speed and/or temperature. temperature alarm set point is greater than the set value. MOTOR The motor temperature is too A stop in “freewheel” mode occurs. OVERTEMPER high.

- Page 16 accelerometer working improperly. The connection to these parts is not good. Magnets from the tachometer might have been lost. OVERSPEED Major error, the centrifuge will The speed measured is higher than the maximum stop. speed allowed for this rotor. Contact a Certified Technician. I²C The board with tachometer / Problem of communication with the accelerometer.

-

Page 17: Settings

Settings Access to the Technician Menu Access the “Settings” menu using the following keys: This menu is reserved for authorized technicians. Dial access code : It is 4 last figures of serial number. Ex : Serial number : 18C200RE1234 Access code : 1234 1st page of settings : Next page Setting the temperature probe... -

Page 18: Setting The Temperature Probe

Setting the temperature probe Access the temperature probe calibration menu. The upper value “Probe Temp.” corresponds to the physical value measured by the temperature sensor, located in the lid. The lower value “Displayed Temp.” is the value displayed on the screen. This is the temperature value of the samples in the buckets, during a centrifugation cycle. - Page 19 Average 11. Press on the Next button to average the setting. (e.g. [480+520]/2 = 500 ) The average value is displayed. By default, the factory setting value is 500. Check The following steps are compulsory. High threshold: 12. Place the 15 gr + 10 gr weights in a bucket.

-

Page 20: Setting The Lock

Setting the lock 3.4.1 . Lock Operation : LISA Model The lock is in the locked position when the axis of the crankshaft and the oblong hole of the bolt are perpendicular. A marking is carried out on the visible face, corresponding to this position. 90°... - Page 21 The locked position sensor of the lock (5) goes to state 1. The motor reducer stops: The markings (9) of the crankshaft and the deadbolt are aligned: the lock is in the locked position. The lock is in closed position when the marks on the deadbolt and the crankshaft are aligned.

-

Page 22: Auto-Diagnostic

Auto-Diagnostic Access auto-diagnostic menu. Action buttons : : Contactor Compressor Lid mot. dir1 Lid mot. dir2 Flashing signal under electronic unit (Leds) Indicators : Speed : xx RPM Temperature : yy °C Contactor State ... -

Page 23: Information Update

Information update Caution: This information concerns the serial numbers of the electronic boards fitted on the centrifuge. In case of changing an electronic board, these values should be changed: Access the menu using the following key: SERIAL NUMBER: Unique serial number of the centrifuge SOFTWARE: The 2 following information items are updated... -

Page 24: Overtemperature Alarm Menu

600879 – NUWIND –NU-C300RF series – Floor model. 600865 – LOREENA –AFI -C300R series – Benchtop Refrigerating model 600869 – LOREENA –AFI -C300V series - Benchtop Ventilated model . 600878 – LOREENA –AFI-C300RF series - Floor model Original Instructions - Rev.1.4 Service Manual–... -

Page 25: Factory Reset

3.11 Factory Reset After loading a new version of software microcontroller, it may be necessary to perform a factory reset, which returns the device to factory configuration. This deletes the following data: - Lock setting (a default is recorded) - The imbalance calibration - User programs - The error counters (reset to 0) - The serial numbers of the unit and electronic cards... -

Page 26: Standard Exchange Of Components

Standard Exchange of Components Safety Rules Before any repair intervention, observe the safety rules by turning off and unplugging the centrifuge. In the event of non-compliance with these instructions, there is a risk of electrical shock. Terminology The kits and spare parts are specific to specific appliance models. The crosses in the right part of the table allow you to define the part corresponding to the device concerned. -

Page 27: Spare Parts & Tools

Shock absorber kit - Ventilated (Complete set) 71122504 Ogival control unit kit 230V/50hz - NU- AP2.003 C300VE 71122505 Ogival control unit kit 230V/50hz - AFI- AP2.003 C300VE 71122506 Ogival control unit kit 120V / 60 hz - NU- AP2.003 C300V... - Page 28 Refrigerating (Complete set) 71123004 Ogival control unit kit 230V/50hz - NU- AP2.003 C300RE & RFE 71123005 Ogival control unit kit 230V/50hz - AFI- AP2.003 C300RE & RFE 71123006 Ogival control unit kit 120V/60Hz - NU- AP2.003 C300R & RF 71123007 Ogival control unit kit 120V/60Hz - AFI- AP2.003...

-

Page 29: Setting Form

Setting form If the state of the control center allows record the values in the tables below. Details in AP2.003 "Ogive replacement". Programs : Acceleratio Name Speed Duration Temperature Braking Parameters : Accessing menus Access the following menus Access the parameters Function Description Value... - Page 30 Timing mode Error Counter 01 : / 02: / 03: / 04: / 05: / 06: / 07: / 08: / 09: / 10 : 11 : / 12: / 13: / 14: / 15: / 16: / 17: / 18: / 19: / 20 :...

-

Page 31: Functional Checks

Functional checks Safety Hinge: Check the tightness of the screws, and the integrity of the hinge by moving side-to-side. There should be no movement other than that of the hinge rotation. Control Center: The Control Center must be secured by a nut located near the switch and fixed to the body of the centrifuge. -

Page 32: Checking The Timer

Close lid. Start a cycle at the desired speed When the setpoint speed is reached, place the speedometer on the central porthole. The speed displayed in the measurement device must be equal to that displayed on the screen, within a tolerance of ±... -

Page 33: Electrical Diagrams

Electrical diagrams 2.0 Liter Ventilated Model : Lisa / C200V & C200VE series Original Instructions - Rev.1.4 Service Manual– Lisa / Loreena Centrifuges 31/ 41... -

Page 34: Liter Refrigerating Model : Lisa / C200R & C200Re

2.0 Liter Refrigerating Model : Lisa / C200R & C200RE series Original Instructions - Rev.1.4 Service Manual– Lisa / Loreena Centrifuges 32/ 41... -

Page 35: Liter Refrigerating Model : Loreena / C300V

3.0 Liter Refrigerating Model : Loreena / C300V Original Instructions - Rev.1.4 Service Manual– Lisa / Loreena Centrifuges 33/ 41... -

Page 36: Liter Refrigerating Model : Loreena / C300R-C300Re-C300Rf-C300Rfe

3.0 Liter Refrigerating Model : Loreena / C300R-C300RE- C300RF-C300RFE series Original Instructions - Rev.1.4 Service Manual– Lisa / Loreena Centrifuges 34/ 41... -

Page 37: Refrigerating System

Refrigerating System 2.0 Liter 115V Model Original Instructions - Rev.1.4 Service Manual– Lisa / Loreena Centrifuges 35/ 41... -

Page 38: Liter 230V Model

2.0 Liter 230V Model Original Instructions - Rev.1.4 Service Manual– Lisa / Loreena Centrifuges 36/ 41... -

Page 39: Liter Benchtop Model

3.0 Liter Benchtop Model Original Instructions - Rev.1.4 Service Manual– Lisa / Loreena Centrifuges 37/ 41... -

Page 40: Liter Floor Standing Model

3.0 Liter Floor Standing Model Original Instructions - Rev.1.4 Service Manual– Lisa / Loreena Centrifuges 38/ 41... -

Page 41: Annexes

Annexes Original Instructions - Rev.1.4 Service Manual– Lisa / Loreena Centrifuges 39/ 41... -

Page 42: Return Authorization

Return authorization Return authorization N° A return number will be provided after contacting us. In order to process your file, we ask you to return this document duly completed by you. This document must be affixed outside the package. Within 72 hours upon receipt of material, we will send you an acknowledgment of receipt.After diagnosis by our technicians, we will send you a quote. -

Page 43: Technotes

Technotes The following procedures are the technician's guide for performing the maintenance operations on the centrifuges. The technical note on the same number as the procedure represents the intervention steps, but in more detail. These technotes are supplied with the spare parts kits. Original Instructions - Rev.1.4 Service Manual–... - Page 44 PROCEDURE AP2.001 IMBALANCE SETTING The imbalance setting allows the safety during the operation of the centrifuge. The machine automatically detects the imbalance and stops immediately. Before starting the procedure switch on the machine and open the lid. CAUTION: THE FOLLOWING OPERATIONS MUST BE PERFORMED BY A QUALIFIED TECHNICIAN Preparing the operations...

- Page 45 PROCEDURE AP2.001 IMBALANCE SETTING Screen capture (25 g test) Step 3: repeat the operation with a weight of 25 grams then press on the validation" button Screen capture (validation of test) Step 4: check the imbalance calibration with 15 & 25 grams weights. Original Instructions - Rev.1.4 Service Manual–...

- Page 46 PROCEDURE AP2.002 SOFTWARE PROGRAMMING Microcontroler software update Step 1 : Switch Off the centrifuge & connect the (*)VCP electronic control unit "Ogive" to PC. cable (*) Use VCP cable if no compatible port on PC Connexions to PC Flash loader demons trator Connection parameters...

- Page 47 PROCEDURE AP2.002 SOFTWARE PROGRAMMING Step 3 : Once connection is recognized, select "STM32 connectivity line 256K", "38400 bauds even parity, no echo, 10s timeout" parameters Step 4 : Select & transfer the software to centrifuge microcontroller. Step 5 : Switch Off, disconnect cable & switch on the centrifuge to initialize.

- Page 48 PROCEDURE AP2.002 SOFTWARE PROGRAMMING Step 1 : Switch Off the centrifuge & connect the electronic control unit "Ogive" to PC via USB cable only. Step 2 Switch on the centrifuge then start"PPF file" application PPF file ressource : http://www.noritake- itron.com/NewWeb/TFT/Tools/Tools.asp Step 3 : Select &...

- Page 49 PROCEDURE AP2.003 OGIVE REPLACEMENT The ogive is located in the front right side of the machine (fig 1). Please remove it carefully. Before starting, open the lid, switch off the centrifuge and unplug power cable CAUTION: THE FOLLOWING OPERATIONS MUST BE PERFORMED BY A QUALIFIED TECHNICIAN Step 1: Remove the nut under the ogive then lift up and maintain the ogive...

- Page 50 PROCEDURE AP2.003 OGIVE REPLACEMENT Step 3: Put the new ogive in position. Connect the wires and plugs and screw the nut Connections and wires of the ogive Step 4: Switch on the centrifuge and proceed to the parameters settings and security checks.

- Page 51 PROCEDURE AP2.004 GAS SPRING REPLACEMENT (REFRIGERATING MODEL) The gas spring is located in the back right side of the machine (fig 1). Please pay attention to keep out little parts from hole. Before starting, open the lid, switch off the centrifuge and unplug power cable CAUTION: THE FOLLOWING OPERATIONS MUST BE PERFORMED...

- Page 52 PROCEDURE AP2.004 GAS SPRING REPLACEMENT (REFRIGERATING MODEL) Step 3: Put in position the new gas spring. Insert the axis OR tighten the screw under the centrifuge Extraction of the gas spring Step 4: Join the gas spring to the lid by inserting the axis and the snap ring View of the gas spring (bottom side).

- Page 53 PROCEDURE AP2.005 GAS SPRING REPLACEMENT (VENTILATED MODEL) The gas spring is located in the back right side of the machine (fig 1). Please pay attention to keep out little parts from hole. Before starting, open the lid, switch off the centrifuge and unplug power cable CAUTION: THE FOLLOWING OPERATIONS MUST BE PERFORMED...

- Page 54 PROCEDURE AP2.005 GAS SPRING REPLACEMENT (VENTILATED MODEL) Step 3: Untighten the bottom screw and extract the gas spring. Extraction of the gas spring Step4: Insert the new gas spring and tighten the screw and counter nut Step 5: Place the bowl and fix it Gas spring (lid view) Step 6: Align gas spring and lid holes, insert axis and the circlip.

- Page 55 PROCEDURE AP2.006 TEMPERATURE SENSOR REPLACEMENT Step 1: remove totally the temperature sensor. Please note the position of all the components. Step 2: spreads the slats before inserting the new sensor. Be sure the CE marking is the on the same side than the stripe Fig 1 Placing the sensor Original Instructions - Rev.1.4...

- Page 56 PROCEDURE AP2.006 TEMPERATURE SENSOR REPLACEMENT Step 3: tighten the new cap and check the temperature calibration. Sensor in position Calibrating the temperature sensor Original Instructions - Rev.1.4 Service Manual– Lisa / Loreena Centrifuges 2/ 2...

- Page 57 PROCEDURE AP2.007 LOCK REPLACEMENT The lock is located in front of the machine, behind the engraved panel. (fig 1 and 2) Before starting, open the lid, switch off the centrifuge and unplug power cable CAUTION: THE FOLLOWING OPERATIONS MUST BE PERFORMED BY A QUALIFIED TECHNICIAN Step 1: Remove the front panel and (fig 1)

- Page 58 PROCEDURE AP2.007 LOCK REPLACEMENT Step 4: Insert the new lock without Tightening the screws (use thread lock) Lock assembly Step 5: Connect all the wires and the power contactor. Switch on the machine and close the lid Power contactor and wires Original Instructions - Rev.1.4 Service Manual–...

- Page 59 PROCEDURE AP2.007 LOCK REPLACEMENT Step 6: Set the Unlocking Tempo Value (UT) Setting screen for the LT and UT tempos Step 7: Set the Locking Tempo value (LT) using the control panel: align the lines on the lock Step 8: Check the alignment by Opening and closing the lid at least 5 times Alignment marks for the lock Step 9: Put the front panel in place...

- Page 60 PROCEDURE AP2.008 LID AXIS REPLACEMENT The lid axis is located in the back of the machine (fig 1). Be sure to have enough space around the machine so as to work in good safety conditions Before starting, open the lid, switch off the centrifuge and unplug power cable CAUTION: THE FOLLOWING OPERATIONS MUST BE PERFORMED...

- Page 61 PROCEDURE AP2.008 LID AXIS REPLACEMENT Tightening of the screws (both side) Step 3: Lift and close the lid at least 3 times to ensure the success of operation View of the finished procedure Original Instructions - Rev.1.4 Service Manual– Lisa / Loreena Centrifuges 2/ 2...

- Page 62 PROCEDURE AP2.009 TACHOMETER SENSOR REPLACEMENT The tachometer sensor is located under the motor. Please note that the operation will be different according the model of the machine (Refrigerating or ventilated) Before starting, open the lid, switch off the centrifuge and unplug power cable CAUTION: THE FOLLOWING OPERATIONS MUST BE PERFORMED BY A QUALIFIED TECHNICIAN...

- Page 63 PROCEDURE AP2.009 TACHOMETER SENSOR REPLACEMENT Step 3: Remove the tachometer sensor. Please note the position of all the components and the wire’s implantation Tachometer sensor with magnet disc Step 4: Place the new parts in position. Apply thread lock on the screws Tachometer fully assembled Original Instructions - Rev.1.4 Service Manual–...

- Page 64 PROCEDURE AP2.009 TACHOMETER SENSOR REPLACEMENT Step 5: Place the motor. Tighten the fixation screws and connect it Step 6: Put the motor seal in position (apply a bead of silicone onto motor throat and peripheral seal throat for Refrigerating model) Motor installation Step 7: Complete the cabling then process to the safety and connections tests...

- Page 65 PROCEDURE AP2.010 MOTOR REPLACEMENT The motor is located under the bowl of the machine (fig 1). Before starting, open the lid, switch off the centrifuge and unplug power cable CAUTION: THE FOLLOWING OPERATIONS MUST BE PERFORMED BY A QUALIFIED TECHNICIAN Step 1: Remove the front panel then disconnect motor wires and tachometer plug.

- Page 66 PROCEDURE AP2.010 MOTOR REPLACEMENT Step 3: Place the new motor. Tighten the fixation screws and connect it Step 4: Put the motor seal in position (apply a bead of silicone onto motor throat and peripheral seal throat for Refrigerating Motor installation model) Step 5: Complete the cabling then process to the safety and connections tests...

- Page 67 PROCEDURE AP2.011 MOTOR SEAL REPLACEMENT (VENTILATED° The motor seal is located in the bottom of the bowl of the machine (fig 1). Before starting, open the lid, switch off the centrifuge and unplug power cable CAUTION: THE FOLLOWING OPERATIONS MUST BE PERFORMED BY A QUALIFIED TECHNICIAN Fig 1 Step 1: Remove the motor seal and clean...

- Page 68 PROCEDURE AP2.012 MOTOR SEAL REPLACEMENT (REFRIGERATING) The motor seal is located in the bottom of the bowl of the machine (fig 1). Before starting, open the lid, switch off the centrifuge and unplug power cable CAUTION: THE FOLLOWING OPERATIONS MUST BE PERFORMED BY A QUALIFIED TECHNICIAN Fig 1 Step 1: Remove the motor seal and clean...

- Page 69 PROCEDURE AP2.016 SHOCKS ABSORBERS REPLACEMENT The shocks absorbers are located on the bottom of the machine. Before starting, open the lid, switch off the centrifuge and unplug power cable CAUTION: THE FOLLOWING OPERATIONS MUST BE PERFORMED BY A QUALIFIED TECHNICIAN Fig 1 Step1: Extract the front panel and remove the motor.

- Page 70 PROCEDURE AP2.016 SHOCKS ABSORBERS REPLACEMENT Step 6: Reassemble the motor. Pay attention to the wires and the motor seal View of the completed part before the mounting Step 7: Process to the tests Motor installation Original Instructions - Rev.1.4 Service Manual– Lisa / Loreena Centrifuges 2/ 2...

- Page 71 PROCEDURE AP2.017 SHOCK ABSORBER REPLACEMENT (VENTILATED) The shocks absorbers are located on the bottom of the machine. Before starting, open the lid, switch off the centrifuge and unplug power cable CAUTION: THE FOLLOWING OPERATIONS MUST BE PERFORMED BY A QUALIFIED TECHNICIAN Fig 1 Step1: Extract the front panel and remove the motor.

- Page 72 PROCEDURE AP2.017 SHOCK ABSORBER REPLACEMENT (VENTILATED) Step 3: Extract the old absorbers and the old foam ring Centrifuge on the side Step 4: Reassemble the new absorbers and place the new foam ring Absorbers in position with new foam ring Step 5: Insert the weight, tighten the nuts then put the horizontal shock absorber in position...

- Page 73 PROCEDURE AP2.017 SHOCK ABSORBER REPLACEMENT (VENTILATED) Step 6: Place the centrifuge on its feet and fix the weight by tightening the nuts. Be careful to don’t twist the absorbers Correct mounting position Step 7: Reassemble the motor. Please pay attention to the wires and connections Motor mounting Step 8: process to the tests Manuel Maintenance –...

- Page 76 3, rue Nicolas Copernic ZA Nord Bazouges 53200 CHATEAU-GONTIER FRANCE Tél : +33(0)2 43 06 66 76 contact@ afigroups.com www.aficentrifuge.com Non-contractual photo. All rights reserved, including photos and illustrations. Copyright ® Société AFI Centrifuge – SIRET 513 982 645 00022.

Need help?

Do you have a question about the Lisa AFI-C200 Series and is the answer not in the manual?

Questions and answers