Braun Corporation RA300 Operator, Installation, Service Manual

Commercial transit ramp for low-floor transit vehicles

Hide thumbs

Also See for RA300:

- Operator, installation, service manual (47 pages) ,

- Operator, installation, service manual (43 pages)

Table of Contents

Advertisement

Quick Links

Operator's/Installation/Service Manual

Braun

Braun

Commercial

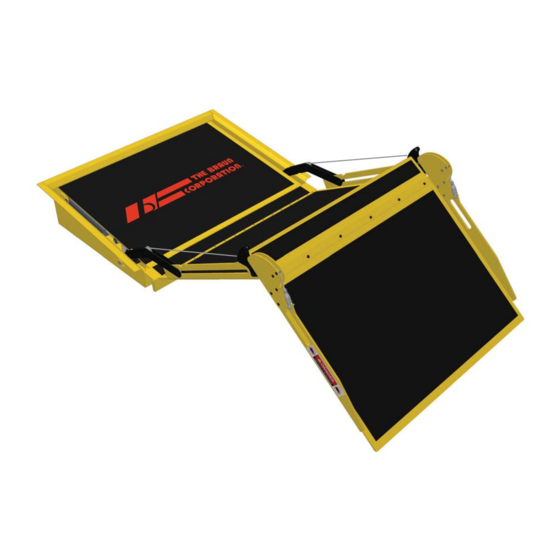

RA300 Transit Ramp

RA300 Transit Ramp

for

Low-Floor Transit Vehicles

Model BF3462Y

Model BF3462Y

"Providing Access to the World"

International Corporate Hdqrs: P .O. Box 310

1-800-THE LIFT

®

(574) 946-6153

35883

December 2009

®

®

Winamac, IN 46996 USA

FAX: (574) 946-4670

W ARNING

Read manual

before operating,

installing or

servicing ramp.

Failure to do so

may result in

serious bodily

injury and/or

property damage.

Advertisement

Table of Contents

Summary of Contents for Braun Corporation RA300

- Page 1 Operator's/Installation/Service Manual Braun Braun Commercial RA300 Transit Ramp RA300 Transit Ramp Low-Floor Transit Vehicles W ARNING Model BF3462Y Model BF3462Y Read manual ® before operating, ® "Providing Access to the World" installing or International Corporate Hdqrs: P .O. Box 310...

- Page 2 Congratulations We at The Braun Corporation wish to express our fullest appreciation on your new purchase. With you in mind, our skilled craftsmen have designed and assembled the finest ramp available. This manual includes operating instructions, installation instructions, servicing instructions and instructions for troubleshooting, if needed.

-

Page 3: Table Of Contents

Hydraulic Diagram and Parts List - BF3462Y ... 35 Installation/Service Safety Repair Parts Safety Symbols ............14 Ramp Operation Safety Precautions ....14, 15 RA300 Ramp Exploded View Installation Instructions Repair Parts List ............36 Installation Requirements......... 15 Exploded View (Fold Out) ......37A, 38A Chassis Requirements .......... -

Page 4: Ramp Terminology

RAMP TERMINOLOGY Ramp Terminology Illustration Refer to the illustration below and the illustrations on next page for identification of components and clarification of direction terminology. Details regard- ing lift model variations, terminology, direction and components are provided on pages 4 and 5. Manual Release Assembly... -

Page 5: Ramp Components Terminology Illustration

RAMP TERMINOLOGY Ramp Components Terminology Illustration Pump Counter Cylinder Cylinder Relays Manual Release Assembly Cam/Microswitch Assembly Pump Manual Ramp Manual Release Drive Arm Release lever Assembly Counter Pump Cylinder Relays Weldment Cam/Microswitch Cylinder Assembly Pump Manual Release RIGHT lever Note: The assist chains, electrical harness, sub floor and transition threshold LEFT... -

Page 6: Introduction

RAMP TERMINOLOGY Introduction Braun RA300 Series transit The RA300 provides fully Instructions are provided for ramps are designed for use in automatic operation of ramp manual operation of the ramp. low-floor transit vehicles. The functions. The electric/hy- See Manual Operation on the... -

Page 7: Ramp Components

(casing) mounted in the vehicle the ramp is deployed. The tion features vertical side plates floor system which contains the RA300 stows (folds) onto the sub and full antiskid surface. hydraulic pump and electrical floor providing an unobstructed components that power the ramp... -

Page 8: Ramp Operation

RAMP OPERATION Safety Symbols SAFETY FIRST! Know That..All information contained CAUTION W ARNING in this manual and supplements (if included), is pro- This symbol indicates This symbol indicates vided for your safety. Familiarity important safety important information with proper operation instructions information regarding regarding how to as well as proper maintenance... - Page 9 (certified) service personnel. W ARNING Never modify (alter) a Braun Corporation ramp. W ARNING Do not use accessory devices not authorized by The Braun Corporation. W ARNING Do not remove any guards or covers. W ARNING If the information contained in this manual is not fully understood, contact The Braun Corporation immediately.

-

Page 10: Ramp Access Doors And Interlocks

Ramp safety and ramp passenger any abnormal condition. Dis- ity aids. The commercial oriented safety information is included. continue use immediately and RA300 is operated by the transit contact The Braun Corporation vehicle driver/attendant. Unless Read and become familiar with at 1-800-THE LIFT ®... -

Page 11: Operation Procedure Review

RAMP OPERATION Operation Procedure Review The Braun Corporation recom- Transit agency supervisors W ARNING mends that transit agency su- should train and educate all pervisors and driver/attendants driver/attendants on the proper Read and become review the safety precautions and use and operation of the vehicle,... -

Page 12: Ramp Power Operation

RAMP OPERATION Ramp Power Operation The power ramp is attendant operated and activated Before operating the ramp, park the vehicle on a by the control switch provided by the vehicle con- level area, away from vehicular traffic. Place the verter (ramp installer). A momentary contact switch vehicle transmission in “Park”... -

Page 13: Ramp Manual Operation

RAMP OPERATION Ramp Manual Operation Cable-Activated Manual Release Manual Operation Safety A cable-activated manual release engages and Two oval-shaped HAND HOLD slots are provided disengages the hydraulic system. A T-handle is on the ramp (see Figure B). Carefully deploy provided for activation of the manual release (see (unfold) and stow (fold) the ramp using the HAND Figure A). -

Page 14: Ramp Passenger Safety

RAMP OPERATION Ramp Manual Operation (continued) Figure B Keep clear of area Keep clear of Keep clear of where ramp side plates drive arms. assist chains. stow in pan (floor). Side Plates HAND HOLD Keep clear of hinged areas. Use HAND HOLDS to carefully unfold and fold the ramp. - Page 15 RAMP OPERATION Ramp Passenger Safety W ARNING W ARNING Position and fasten Be aware of the wheelchair- ramp slope. equipped occupant seat belt before loading onto the wheelchair ramp. Failure to do so may result in serious Stabilizing Wheelchairs: Pow- Wheelchair passengers who bodily injury and/or ered and manual wheelchairs...

-

Page 16: Ramp Installation

RAMP INSTALLATION Safety Symbols SAFETY FIRST! Know That..All information contained CAUTION W ARNING in this manual and supplements (if included), is pro- This symbol indicates This symbol indicates vided for your safety. Familiarity important safety important information with proper operation instructions information regarding regarding how to as well as proper maintenance... -

Page 17: Installation Requirements

Disconnect the power cable at the battery prior to servicing. W ARNING Keep hands, arms and all other body parts clear of moving parts. W ARNING Never modify (alter) a Braun Corporation ramp. Replacement parts must be Braun authorized replacements. W ARNING W ARNING Never install screws or fasteners (other than factory equipped). -

Page 18: Door Opening

RAMP INSTALLATION Installation Requirements (continued) Door Opening: Open the door(s) Minimum Clear Door Opening remove molding that creates an fully and check the clear door Dimensions are defined as uneven mounting surface should opening width dimension. Speci- finished door opening, includ- be removed. - Page 19 RAMP INSTALLATION "Floor Pocket" Clear Opening Dimensions Note: See Figure C and D also. Figure F Right Clear Door Opening Width Dimension Left As viewed from outside the vehicle Figure G Vehicle chassis “floor pocket” configuration Door(s) must must be aligned cen- open outward.

- Page 20 RAMP INSTALLATION Installed Ramp - Stowed Figure H Stowed RA300 positioned in the “floor pocket.” Right Installed Ramp - Deployed Left As viewed from outside the vehicle Figure J There must be a minimum 1/8” clearance between the deployed ramp assembly and the vehicle floor or any obstruction on the...

- Page 21 BLANK for LAYOUT Page 19...

-

Page 22: Electrical Connections

RAMP INSTALLATION Electrical Connections The ramp installer provides an W ARNING appropriate control switch for the end user. A momentary contact Route cables clear ramp control switch (center off) of exhaust system, will typically be mounted near other hot areas and the driver. -

Page 23: Electrical Connections Illustration

RAMP INSTALLATION Electrical Connections An 8-pin Deutsch connector is mounted at the front of the ramp pan (see Figure L). A mating 8-pin Deutsch connector (male plug) is supplied with the ramp. Terminate the power supply, the ground, DEPLOY signal (+), DE- BF3462Y PLOY indicator, STOW signal (+) CONNECTOR - P1... -

Page 24: Maintenance And Lubrication

MAINTENANCE and LUBRICATION Lubrication Diagram Gear and Inboard Gear Rack Ramp Hinge (internal) Outboard Ramp Hinge (concealed) Assist Chain Assemblies Drive Arm and Cam Gear Shaft (after Smooths or 1500 Cycles) Drive Arm Slot Chains Note: See the Maintenance/Lubrication Schedule for recommended applications per number of cycles or elapsed time. -

Page 25: Maintenance And Lubrication Schedule

Use of improper lubricants can attract dirt or improper operation. Contact your sales represen- other contaminants which could result in wear or tative or call The Braun Corporation. One of our damage to the components. Ramp components national Product Support representatives will direct... - Page 26 MAINTENANCE and LUBRICATION Chains at gears and chain assist assemblies Clean and lubricate. Apply Light Oil - See continued Lubrication Diagram Drive arm slot Apply Door-Ease. See Lubrication Diagram Inspect drive arm pivot points (mounting Tighten, replace or correct as needed. screws, nuts and bearings) for positive secure- ment, wear or damage Cycles...

- Page 27 MAINTENANCE and LUBRICATION continued Hydraulic Fluid (Pump) - Check level. Note: Use Braun 32840-QT hydraulic fluid (Exxon ® Fluid should be changed if there is visible Univis HVI 26). Do not mix with Dextron III or contamination. Inspect the hydraulic system other hydraulic fluids.

-

Page 28: Microswitch Adjustment

MICROSWITCH ADJUSTMENT Microswitches: Three micro- W ARNING switches (limit switches) are incorporated in the RA300 electri- Improper microswitch cal system. Ramp microswitches adjustment may re- are: Drift-In, Drift-Out and Coun- sult in serious bodily ter. Adjust microswitch(es) as injury and/or property detailed (if necessary only). - Page 29 MICROSWITCH ADJUSTMENT Drift In Microswitch (Cam 1) Figure M Turn Cam 1 counter-clockwise to start Drift In function sooner (shut pump off). Turn Cam 1 clockwise to start Drift In function later (allow ramp to stow further before pump shuts off). Drift Out Microswitch (Cam 2) Figure N Turn Cam 2 clockwise to start Drift Out function sooner...

-

Page 30: Depoly And Stow Pressure Adjustment

DEPLOY and STOW PRESSURE ADJUSTMENT Hydraulics B-3202-0106 Hydraulic Pump: Hydraulic Fluid: Use Braun fully deployed. Fill to maximum Fixed displacement external gear 32840-QT hydraulic fluid (Exxon ® fluid level indicated on reservoir type hydraulic pump with 12 VDC Univis HVI 26). Do not mix with (fill line molded in reservoir). -

Page 31: Troubleshooting

If the property damage. function and related symptom in problem continues, contact The the Troubleshooting Diagnosis Braun Corporation. FUNCTION SYMPTOM POSSIBLE CAUSE REMEDY 1.11 Battery terminals dirty Clean and tighten 1.12 Chassis ground connection (frame... - Page 32 TROUBLESHOOTING FUNCTION SYMPTOM POSSIBLE CAUSE REMEDY continued continued 2.20 Locked in 2.21 Ramp was stopped within the Activate Stow function until ramp is out Intermediate Deploy “Drift Out” range during Stow of the Deploy “Drift Out” range. Then Position function activate Deploy function.

- Page 33 TROUBLESHOOTING FUNCTION SYMPTOM POSSIBLE CAUSE REMEDY 3.11 See 1.00 3.12 Drift In Microswitch out of adjust- Adjust or replace. See Microswitches in 3.10 ment or damaged Systems Descriptions for details 3.13 Drift In Microswitch harness discon- Connect, repair or replace Operation nected, damaged or otherwise damaged...

-

Page 34: Electrical Schematic - Bf3462Y

CIRCUIT PROTECTION BATTERY GROUND DEVICE MOTOR (30 AMP.) * RECOMMENDED WIRE GUAGE COUNTER RA300 TRANSIT RAMP ASSEMBLY DRAWING SHOWN WITH RAMP IN STOWED POSITION 12 GA. RD 12 GA. BK "DRIFT IN" MICROSWITCH STOW RELAY 14 GA. BL/BK 14 GA. BL/BK 12 GA. -

Page 35: Wiring Diagram - Bf3462Y

TROUBLESHOOTING Wiring Diagram - BF3462Y Page 33... -

Page 36: Hydraulics

HYDRAULICS Hydraulic Schematic - BF3462Y Cylinder, Double Description Symbol Acting Pump, Bidirectional Relief Valve Displacement Pump Motor, Check Valve Bidirectional Flow Control Hydraulic Port Valve Fixed Orifice Filter Screen Reservoir, 3 Way 2 Position Vented Shuttle Valve “B” “A” .033 .020 69 BAR 86 BAR... -

Page 37: Hydraulic Diagram And Parts List - Bf3462Y

Cylinder - 1514.3 - Compact C1514.3-9800 Cylinder - 1514.3 - Compact C1514.3-9900 Pump - Power Unit - Hydraulic - RA300 35572-12V Hose Assembly - 12" - 1/8" Dia - SW/SW 16004A-012 Hose Assembly - 13" - 1/8" Dia - SW/SW 16004A-013 Hose Assembly - 14"... -

Page 38: Repair Parts

REPAIR PARTS Item Qty. Description BF3462Y PAN WELDMENT BF34202WY BEARING-FLANGE-3/4" X 1/4"-12FDU04 24012 GEAR RACK WELDMENT RA40402WBKN BEARING-UHMW-1" X 0.16" 34966 DRIVE ARM WELDMENT-FRONT SIDE BF34261FWBKN DRIVE ARM WELDMENT-REAR SIDE BF34261RWBKN BEARING-FLANGED-5/8" SHAFT 29754 NUT-PIVOT-7/16-20, FOLD-N-RAMP 29756 DRIVE ARM-ROLLER-UHMW FF00015 BEARING-THRUST-3/4"... -

Page 39: Exploded View (Fold Out)

EXPLODED VIEW Page 37A Page 38A... - Page 40 SPECIFICATION AND DIMENSIONS Power Unit: Hydraulic Pump Module Deployed View Voltage: 12 VDC 38.70" Current: 30 Amps (Max) Inputs Required: +12 Volt Supply (-) Ground Ramp “Out” Signal (+) Ramp “In” Signal (+) Interlock Signal Notes: Mounting holes/brackets per application 94.92"...

- Page 41 "Providing Access to the World" ® Over 300 Braun Dealers Worldwide ® "Providing Access to the World" International Corporate Hdqrs: P .O. Box 310 Winamac, IN 46996 USA ® 1-800-THE LIFT (574) 946-6153 FAX: (574) 946-4670...

- Page 42 All illustrations, descriptions and specifications in this manual are based on the latest product information available at the time of publication. The Braun Corporation reserves the right to make changes at any time without notice. time of publication. The Braun Corporation reserves the right to make changes at any time without notice.

Need help?

Do you have a question about the RA300 and is the answer not in the manual?

Questions and answers