Summary of Contents for Phoenix Mecano DewertOkin MEGAMAT XS

- Page 1 MEGAMAT XS Installation Instructions (Translation of the original installation instructions)

-

Page 3: Foreword

MEGAMAT XS Foreword Foreword Document revision history Version Date Modification, change 03/12 First release 07/12 Edition II 12/12 RoHS 09/2019 Installation, ratings plate, declaration of conformity and installation Disclaimer and exclusion of liability DewertOkin is not responsible for damage resulting from: •... -

Page 4: Notice For Customers In Eu Nations

Foreword MEGAMAT XS Notice for customers in EU nations German Inspection Authority (TÜV SÜD Product Service) testing label The construction of the MEGAMAT XS drive has been inspected by the German TÜV SÜD Product Service Inspection Authority. TÜV SÜD Product Service also monitors the production of the MEGAMAT XS. -

Page 5: Table Of Contents

MEGAMAT XS Table of Contents Table of Contents Foreword Document revision history Disclaimer and exclusion of liability Manufacturer's address Creation of a complete operating instruction manual for the entire end product Notice for customers in EU nations Table of Contents General Information About these installation instructions Availability of this document... - Page 6 Table of Contents MEGAMAT XS Disposal 10.1 Packaging material 10.2 Drive components Declaration of incorporation/installation EU Declaration of Conformity Additional information 73115 4.0...

-

Page 7: General Information

MEGAMAT XS General Information General Information About these installation instructions These installation instructions must be followed closely in order to install this drive successfully and safely in the end product. These instructions are not an operating manual for the end product. These instructions will help you to minimize danger, repair costs and down times. -

Page 8: Conventions Used

General Information MEGAMAT XS Conventions used Notices which do not relate to safety are indicated in these instructions with a triangle: Triangular notice symbol Safety notice explanations WARNING WARNING indicates a hazardous situation which, if not avoided, could result in death or serious injury. -

Page 9: Safety Notices

MEGAMAT XS Safety notices Safety notices Proper and intended usage The MEGAMAT XS drive is meant to be installed in an end product. • It provides motor adjustment capabilities for movable reclining bed parts. It should be used in conjunction with suitable fittings and mechanics: •... -

Page 10: Safety Notices Within The Installation Instruction And The Operating Instructions For The Entire Machine

Safety notices MEGAMAT XS Safety notices within the installation instruction and the operating instruc- tions for the entire machine The manufacturer of the end product is only permitted to operate the MEGAMAT XS drive (by itself an incomplete machine) • when the end product (for which the MEGAMAT XS drive is intended) is in compliance with all protective measures specified in the Machinery Directive 2006/42/EC, and •... -

Page 11: Product Identification

MEGAMAT XS Safety notices Product identification 2.5.1 Ratings plate A ratings plate on each drive specifies the exact name and serial number of the drive. It also states the technical specifications valid for that particular drive. The following illustration shows where the specifications are located on the drive's ratings plate. -

Page 12: Possible Combinations

Possible combinations MEGAMAT XS Possible combinations The MEGAMAT XS single drive can be combined for use with other single drives, double drives or control units. The following basic combinations are possible: • a MEGAMAT XS with handset and control unit, •... -

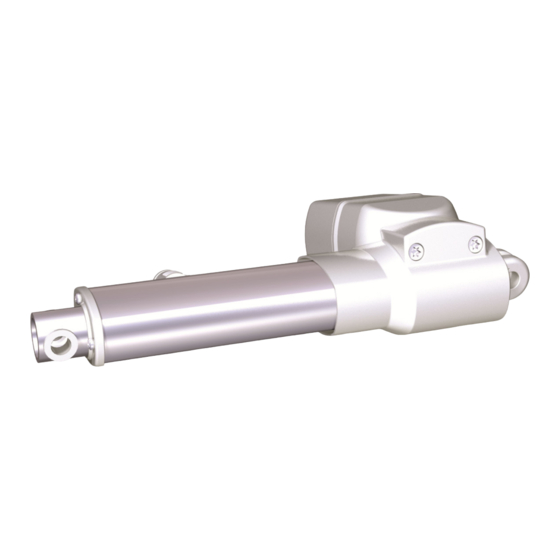

Page 13: Description

MEGAMAT XS Description Description The MEGAMAT XS drive is an electrically driven motor that is responsible for moving the end product in a linear direction. This adjustment is created by the in and out movement of a stroke pipe. The movements of the MEGAMAT XS drive are controlled using a control unit or a double drive which is connected to a DewertOkin handset. - Page 14 Description MEGAMAT XS 4.1.1 Stroke pipe options There are two types of stroke pipes available for different types of applications. The stroke pipe can be screwed onto the spindle screw or it can be mounted unattached. The drive only exerts pushing force when the stroke pipe is mounted loosely (unattached).

-

Page 15: Technical Specifications

MEGAMAT XS Technical specifications Technical specifications Input voltage 24 V DC – 29 V DC Current consumption at rated load Max. 4.0 A, depending on version (refer to the ratings plate on the drive) Permitted push force Max. 3000 N, depending on version (refer to the ratings plate on the drive) Permitted pull force Max. - Page 16 Technical specifications MEGAMAT XS Min. 168 Figure 6 Dimensions of MEGAMAT XS drive (in mm), minimum installation dimension: 145 mm 73115 4.0...

-

Page 17: Installation

MEGAMAT XS Installation Installation Safety notices to observe during installation Basic safety rules must be followed in order to ensure that the end product can be continually op- erated in a safe manner. These rules must be observed while using the end product and while in- stalling the drive. -

Page 18: Installation Procedure

Installation MEGAMAT XS Avoiding an over-extension of the stroke pipe (when mounted unattached) CAUTION There must be a fixed mechanical end stop built into the end product for MEGAMAT XS drive models where the stroke pipe is not attached to the spindle screw. If no fixed me- chanical end stop exists, the stroke pipe can over-extend. - Page 19 MEGAMAT XS Installation 6.2.1 An installation example Before installing the drive, make sure that you are observing all of the safety notices found in the "Safety notices to observe during installation" section. CAUTION The mains power cable should be unplugged during the installation. Figure 7 Installing the drive (example) A Safety clip...

- Page 20 Installation MEGAMAT XS CAUTION You should never screw the stroke pipe into the drive. A stroke pipe that has been screwed into the drive can result in fatigue fractures. 5 If the stroke pipe clevis (C) does not align exactly with the gear clevis (E), the stroke pipe may be unscrewed out of the drive by no more than a half turn.

- Page 21 MEGAMAT XS Installation Routing the electrical cables When routing the cables, be sure that: • the cables cannot get jammed, • no mechanical load (such as pulling, pushing or bending) will be put on the cables, and • the cables cannot be damaged in any way. Fasten all cables (especially the mains cable) to the end product using sufficient strain relief and kink prevention methods.

-

Page 22: Operating Notes

Operating notes MEGAMAT XS Operating notes The factual information contained within may be used when you are creating the end-product man- ual. The installation instructions do not contain all information required for the safe operation of the end product. They only describe the installation and operation of the drive as a partially assembled piece of machinery. -

Page 23: Notice For Operating With Optional Configuration

MEGAMAT XS Operating notes Notice for operating with optional configuration 7.2.1 Configuration: Attached nut CAUTION You should never screw the stroke pipe into the drive. A stroke pipe that has been screwed into the drive can result in fatigue fractures. CAUTION The stroke pipe may only be turned one half rotation out of the drive. -

Page 24: Troubleshooting

Troubleshooting MEGAMAT XS Troubleshooting This chapter describes troubleshooting methods for fixing problems. If you experience an error that is not listed in this table, please contact your supplier. CAUTION Only qualified specialists who have received electrician training should carry out trou- bleshooting and repairs. -

Page 25: Maintenance

MEGAMAT XS Maintenance Maintenance You should only use spare parts which have been manufactured or approved by DewertOkin. Only these parts will guarantee a sufficient level of safety. Maintenance Type of check Explanation Time interval Check the function and A qualified electrician should carry Periodic inspections can safety of the electrical sys-... -

Page 26: 10. Disposal

Disposal MEGAMAT XS 10. Disposal 10.1 Packaging material The packaging material should be sorted into recyclable components and then disposed of in ac- cordance with the appropriate national environmental regulations (in Germany according to the re- cycling law KrWG from 01.06.2012; internationally according to the EU Directive 2008/98/EC (Waste Framework Directive WFD as of 12.12.2008)). -

Page 27: Declaration Of Incorporation/Installation

Einbauerklärung Declaration of Incorporation nach Anhang II der EU-Maschinenrichtlinie According to Appendix II of the EU Machinery 2006/42/EG Directive 2006/42/EC Der Hersteller The manufacturer: DewertOkin GmbH Weststraße 1 32278 Kirchlengern Deutschland - Germany erklärt hiermit, dass nachstehend beschriebene declares that the incomplete machines described below unvollständigen Maschinen MEGAMAT XSZ... -

Page 28: Eu Declaration Of Conformity

EU Declaration of Conformity EG-Konformitätserklärung In compliance with Appendix IV of the EMC-Directive Nach Anhang IV der EMV-Richtlinie 2014/30/EU 2014/30/EU In compliance with Appendix IV of the LVD-Directive Nach Anhang IV der EU-Niederspannungsrichtlinie 2014/35/EU 2014/35/EU Nach Anhang VI der RoHS-Richtlinie 2011/65/EU In compliance with Appendix VI of the EU RoHS (inkl. -

Page 29: Additional Information

Additional information MEGAMAT XS drive system The following standards and norms were used in the versions with at least IPX4 and higher in according to EN 60601-1:2006 + A1:2013, IEC 60601-1:2005 + A1:2012 (short description: Edition 3.1), Medical electrical equipment. EN 60601-1-2:2015, IEC 60601-2-2:2014 (short description: Edition 4.0), EMC IEC/EN60601-1, Section 4 General requirements... - Page 30 DewertOkin GmbH Weststrasse 1 Kirchlengern 32278, Germany Tel: +49 (0)5223/979-0 Fax.: +49 (0)5223/75182 http://www.dewertokin.de Info@dewertokin.de ID No.: 73115...

Need help?

Do you have a question about the DewertOkin MEGAMAT XS and is the answer not in the manual?

Questions and answers