Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Proceq ZG8150

- Page 1 ZG8150 Inline Glossmeter Technical Manual...

- Page 2 Manual for inline user Revision History Date Author, Comments Feb 6, 2020 CSAR Initial document SGIA Add drawings April 30, 2020 PEGG New formatting and text revision August 10, 2020 PEGG Corrections and final formatting 10/08/2020 © Copyright 2020, PROCEQ SA...

-

Page 3: Table Of Contents

28 – GetIsOnStandard ..................... 15 53 – LaserEnable ..................... 16 6.10 56 – Error ......................... 16 6.11 64 – ResetDevice ....................17 6.12 70 – AdvancedUserCalibration ................18 6.13 78 – AcceptUserCalibration ..................18 10/08/2020 © Copyright 2020, PROCEQ SA... - Page 4 Illustrations, descriptions as well as the technical specifications conform to the instruction manual at hand at the time of publishing or printing. However, Proceq SA policy is one of continuous product development. All changes resulting from technical progress, modified construction or similar are reserved without obligation for Proceq to update.

-

Page 5: Introduction

1 Introduction The ZG8150 is a glossmeter for use in a production test system. With a dedicated cable it can be connected to a USB or RS232 interface on the host (e.g. PC). For that a dedicated cable is used and the device has to be configured accordingly. -

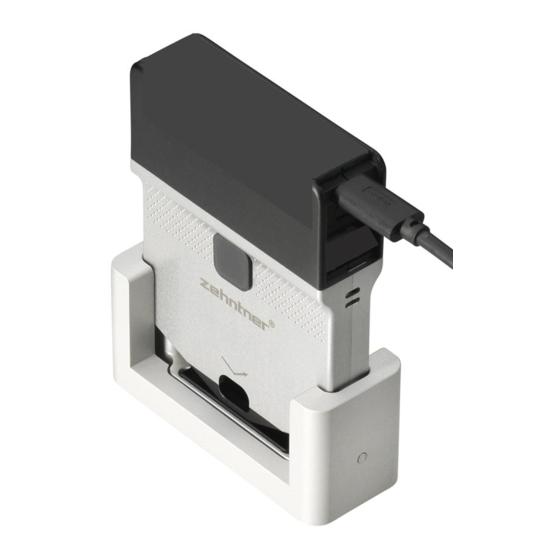

Page 6: Mounting Of The Device

2 Mounting of the device To integrate the ZG8150 into a production line, the device can be mounted to fixtures or robotic arms. To facilitate the mounting, the device has a threaded hole on the top and two mounting guide holes. -

Page 7: Dimensional Drawings

3 Dimensional Drawings 10. August 2020 © Copyright 2020, PROCEQ SA... -

Page 8: Mounting Example - With Custom Mounting Plate

3.1 Mounting Example – with custom mounting plate The following example shows how the ZG8150 can be mounted on a custom made mounting plate, which allows versatile mounting options to robot arms or fixtures. NOTE: This mounting plate is for reference purposes to make your integration easier and not available as a product. -

Page 9: Mounting Tolerances

3.2 Mounting Tolerances In order to guarantee the specified performance, the device shall be mounted to fulfill the following mounting tolerances. 10. August 2020 © Copyright 2020, PROCEQ SA... -

Page 10: Connection Setup

USB connection. Connector Type Description Setting Value A (male) Plugged on PC side Baudrate 115200 C (male) Plugged on device side Data Bits Stop Bits Parity None Flow Control None 10. August 2020 © Copyright 2020, PROCEQ SA... -

Page 11: Rs232 Connection Setup

In order to communicate to a RS232 port the device needs to be setup for RS232 communication (see section 6). The serial port of the computer has to be set to the following communication settings: Setting Value Baudrate 115200 Data Bits Stop Bits Parity None Flow Control None 10. August 2020 © Copyright 2020, PROCEQ SA... -

Page 12: Firmware Update

“PqUpgrade” will find the device. “PqUpgrade” will start the device in USB virtual com port setup. In order to return to the same communication setup as before the update a reset is required. 10. August 2020 © Copyright 2020, PROCEQ SA... -

Page 13: Communication Protocol

5 Communication protocol The communication with the ZG8150 is completely string based. All commands are composed of ASCII-character strings. This allows an easy control of the device, for example with a commercially available terminal program such as “HyperTerminal”. 5.1 Command and return string... -

Page 14: Parameter "Anglebinary

For example a device with the geometries 20°/60°/85°, A0 would be 20°, A1 = 60°, A2 = 85°. 5.4 Invalid measurement values It can happen that a measurement return values smaller than zero. Value Meaning No measurement value Overflow 10. August 2020 © Copyright 2020, PROCEQ SA... -

Page 15: Commands

Return string: 3|TID|AngleBinary|Unit|ValueAn: Parameter: AngleBinary Angle combination ValueAn Measured value per angle n (n = 0…2), format %4.1f Unit GU or % Example 3|xy|2: Send Command: 2 TID: xy AngleBinary: 2 (angle A1) 10. August 2020 © Copyright 2020, PROCEQ SA... -

Page 16: Stopscanmeasurement

A1 = 70.5, 70.9, 71.0, 70.7, … 6.3 5 – StopScanMeasurement This command stops the scan measurements. Command: Command string: 5|TID: Return string: 5|TID: Example 5|xy: Send Command: 5 TID: xy Receive 5|xy: Command: 5 TID: xy 10. August 2020 © Copyright 2020, PROCEQ SA... -

Page 17: Setflash

1000, 1500, 2000, 2500, 3000, 3500, 4000, 4500, 5000 1100 UsbSettings Communication setting. USB setup: 0 (integer) RS232 setup: 1 (integer) 1560 Units Measurement units Gloss units: 0 (integer) Percent: 1 (integer) 10. August 2020 © Copyright 2020, PROCEQ SA... -

Page 18: Startcontinuousmeasurement

A1 = 87.6, 89.4, 92.3, 94.5, … 6.7 18 – StopContinuousMeasurement This command stops the continuous measurements. Command: Command string: 18|TID: Return string: 18|TID: Example 18|xy: Send Command: 18 TID: xy Receive 18|xy: Command: 18 TID: xy 10. August 2020 © Copyright 2020, PROCEQ SA... -

Page 19: Getisonstandard

28|TID|Data: Parameter: Data 0 = is not on standard, 1 = is on standard Example Send 28|xy: Command: 18 TID: xy Receive 28|xy|1: Command: 18 TID: xy Data: 1 (is on standard) 10. August 2020 © Copyright 2020, PROCEQ SA... -

Page 20: Laserenable

PARAMETER_ERROR The index of a setting is wrong. NO_ACCESS_RIGHTS The user has no accees rights. ACCESS_DENIED No access because it is not possible to access the resource. 10. August 2020 © Copyright 2020, PROCEQ SA... -

Page 21: Resetdevice

Receive Command: 56 56|xy|0|30: TID: xy Command: 0 Error: 30 6.11 64 – ResetDevice This command performs a reset. Command: Command string: 64|TID: Return string: Example Send 64|xy: Command: 64 TID: xy 10. August 2020 © Copyright 2020, PROCEQ SA... -

Page 22: Advancedusercalibration

Command string: 78|TID|AngleBinary: Return string: 78|TID: Parameter: AngleBinary A single angle which was user calibrated before. Example Send Command: 78 78|xy|2: TID: xy AngleBinary: 2 (angle A1) Receive Command: 78 78|xy: TID: xy 10. August 2020 © Copyright 2020, PROCEQ SA... - Page 23 For safety and liability information, please download at www.proceq.com/downloads Subject to change. Copyright © 2020 by Proceq SA, Schwerzenbach. All rights reserved. 10. August 2020 © Copyright 2020, PROCEQ SA...

- Page 24 10. August 2020 © Copyright 2020, PROCEQ SA...

- Page 25 1 Fusionopolis Way Unit B, 19th Floor #20-02 Connexis South Tower Five Continent International Mansion, No. 138632 Singapore Zhao Jia Bang Road +65 6382 3966 Shanghai 200032 info-asia@proceq.com +86 21 631 774 79 info-china@proceq.com 10. August 2020 © Copyright 2020, PROCEQ SA...

Need help?

Do you have a question about the ZG8150 and is the answer not in the manual?

Questions and answers