Subscribe to Our Youtube Channel

Summary of Contents for Neutronics 7100E

- Page 1 Instruction manual Model 7100E Trace oxygen analyzer/controller Document Number: MN-A-0009 Revision Level: B Part Number: C5-06-4900-14-0 Revision Date: August 10, 2016...

-

Page 5: Table Of Contents

Model 7100E Instruction Manual Contents Welcome ............................... 5 Notice ................................5 Safety instructions ............................6 Designated use ............................. 6 Operational safety ............................6 Introduction and overview ........................7 General ............................7 Features ............................7 System hardware overview ......................9 Main board ..........................9 Relay board ........................... - Page 6 Instruction Manual Model 7100E System installation and start-up ......................16 Installing the analyzer ......................... 16 Step 1 – locate and mount the analyzer unit ............... 17 Step 2 –install the remote sensor ..................18 Step 3 –install the analyzer ....................20 Starting up and Commissioning the System ................

-

Page 7: Welcome

Neutronics, Inc. This work is protected under Title 17 of the US Code and is the sole property of Neutronics Inc. No part of this document may be copied or otherwise reproduced, or stored in any electronic information retrieval system, except as specifically permitted under US copyright law, without the prior written consent of Neutronics Inc. -

Page 8: Safety Instructions

Always assure the pressure of gas entering the Model 7100E is 1-3 psig. Always calibrate the Model 7100E at an equivalent pressure and flow rate to the measured gas. Always allow the Model 7100E to cool down before attempting to access the sensor. -

Page 9: Introduction And Overview

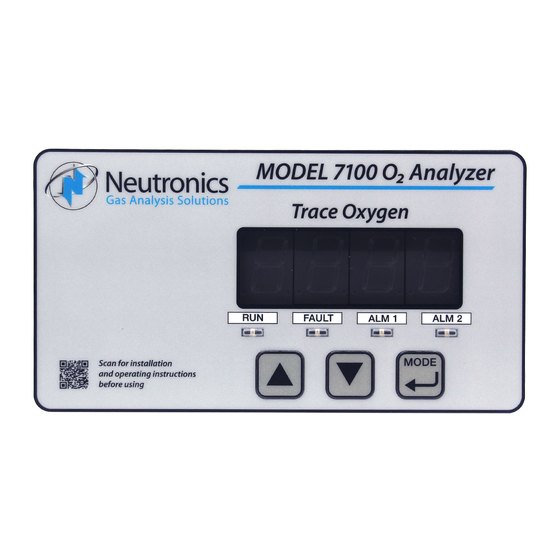

The Compact Series analyzer modules are designed to be flush mounted to a panel or console. Because of the small size of the Model 7100E analyzer, it can be integrated into a variety of equipment or control panels. The remote sensor assembly is designed for mounting close to the sampling point to assure the fastest response possible. - Page 10 Introduction and overview Model 7100E Fig.1, analyzer front and rear view Control Control panel Panel Power Supply Board Relay Board Chassis Main Board Display Display Board board Fig. 2, basic internal analyzer components Revision A, dated 24-Jun-2016 Manual P/N: C5-06-4900-14-0...

-

Page 11: System Hardware Overview

Relay board The relay board houses relay contacts for all of the Alarm and Control features of the 7100E. The relays are mapped discretely to each alarm to provide electrical outputs for reporting and process control use. -

Page 12: Sensor

Model 7100E Sensor The Neutronics ZR-400E mini-zirconia percent range oxygen sensor (Figure 3) is a cost effective solution for many applications. It is a solid-state device based on a zirconia solid electrolyte sensor with a low power, on-board heater, and two electrodes. Unlike many solid-state oxygen sensors, the ZR-400E does not require a reference gas for normal operation. -

Page 13: Enclosure (Chassis)

A sample gas exhaust port is provided for installation with a process oxygen sampling system. Gas must be directed from the sample exhaust port to a suitable vent source that does not apply significant backpressure on the sampling system. The unit can be installed in-line with any Neutronics Inc. process sampling system. - Page 14 Introduction and overview Model 7100E 4-20 mA Output RS-232 COM Line Analog Voltage Output Range ID Output Fault Relay Outputs Alarm 1 & 2 Relay Outputs Relay Board Line Remote Power Main Board Filter Sensor Supply Display Mains Power Board...

-

Page 15: Analyzer Inputs And Outputs

Fault relay output The fault relay output is used to indicate that there is at least one system fault active on the Model 7100E analyzer (section 4.3.1 – fault codes and definitions). The relay output action is non-fail-safe, and is not configurable. -

Page 16: Analog Current Output

ID voltage when the analyzer is configured for auto-ranging (section 1.4.8). Range ID output The Model 7100E can be configured by the user to automatically switch its measurement range, based on the concentration of oxygen measured while in-service, to provide the most accurate, and highest resolution outputs at all times. -

Page 17: 7-Segment Alphanumeric Display

RUN indicator LED The purpose of the RUN Indicator LED is to inform the user via the control panel that the Model 7100E is measuring the concentration of the sample gas and updating the display and outputs accordingly, and has not detected any alarm, or fault conditions. -

Page 18: System Installation And Start-Up

System installation and start-up Model 7100E System installation and start-up 3.1 Installing the analyzer Step 1 Step 2 Step 3 • Locate the • Install the • Install the analyzer... sensor... analyzer • panel • process cutout sampling system Fig. 7, installation outline... -

Page 19: Step 1 - Locate And Mount The Analyzer Unit

Step 1 – locate and mount the analyzer unit The Model 7100E is designed to be mounted flush to the surface of a stationary equipment control panel. Select a suitable location for the analyzer unit where the digital display and status LEDs will be easy to read, and the interface buttons on the display panel will be easy to access. -

Page 20: Step 2 -Install The Remote Sensor

Model 7100E Step 2 –install the remote sensor The Model 7100E is supplied with one (1) Model ZR-400E oxygen sensor assembly (Figure 9), one (1) sensor interface cable, and one (1) sensor flow-through head for connection to a sampled process gas stream (if required). - Page 21 Model 7100E System installation and start-up 3.1.2.2 Sample inlet port Pneumatic connection to the measured process for sample extraction is made at either of the two interchangeable 1/8” FNPT fittings around the side of the flow-through head. For connecting the flow- through head to the measured process, use 1/8"...

-

Page 22: Step 3 -Install The Analyzer

Model 7100E analyzer will be installed. CAUTION: The Model 7100E housing is not rated waterproof. Do not mount the analyzer or the sensor in an area where it may contact water or other liquid elements. - Page 23 Model 7100E System installation and start-up A label depicting the terminal block arrangement is affixed to the top of the chassis for easy reference during installation and maintenance (VAC configuration shown in Figure 12). The terminal blocks feature screwed terminals. The terminal blocks are also removable for ease of wiring or removal of the analyzer module.

- Page 24 System installation and start-up Model 7100E 3.1.3.1 Alarm-1 relay output Connections from the Alarm-1 relay contacts to the user’s process control equipment are made at terminal block TB2 on the rear of the analyzer chassis. The oxygen alarm relay contacts are voltage-free Form C relay contacts, SPDT, 5A @ 250 VAC, 5A @ 30 VDC.

- Page 25 TB3 on the rear of the analyzer chassis. The analog current output is a negative ground, non-isolated 0- 20 mA, or 4-20 mA current loop. 12 VDC Power is supplied by the Model 7100E analyzer. Maximum electrical loading is 250 Ohms. Be certain to match the terminal pins against the terminal ID label on the top of the analyzer chassis.

- Page 26 System installation and start-up Model 7100E 3.1.3.8 RS-232 Service port Connections from the range ID output to the user’s auxiliary equipment are made at terminal block TB3 on the rear of the analyzer chassis. Be certain to match the terminal pins against the terminal ID label on the top of the analyzer chassis.

-

Page 27: Starting Up And Commissioning The System

1 & 2 Fig. 16, start-up outline The Model 7100E is shipped ready to use. Factory default configuration settings are listed in Appendix C. Those settings will be suitable for most applications. Review the factory default configuration settings before commissioning your system. If you wish to change any of the factory default settings, refer to sections 4.1.1 and 4.1.2. -

Page 28: Step 2 - Calibrate The Unit

Factory Configuration Settings. Verify that the current settings are suitable for the application. Refer to Appendices E and F for all valid range and output settings available on the Model 7100E. If any changes are necessary, they can be performed via the control panel (section 4.1.1) or the service port (section 4.1.2). -

Page 29: Analyzer Operation

Analyzer operation 4.1 System organization The Model 7100E has two types of operational modes – User-type, and System-type. User modes are initiated and controlled by the user to setup and maintain the analyzer. The User modes are: Calibration, Set/View Alarm-1, Set/View Alarm-2, View Active Faults, and Setup (Figure 17). -

Page 30: User Modes

“MODE” key. When a user mode is accessed via the control panel, the Model 7100E aborts any system mode active, and holds the state of Alarm-1, Alarm-2, Fault, and Heater OK relay outputs until the user returns the unit to Run mode. - Page 31 Model 7100E Analyzer operation CALIBRATION – introduction 4.2.1.1 For best application-driven accuracy, the Model 7100 is capable of a flexible two-point calibration, customized by the user to fit the application. There is no need for a fixed “zero” calibration, and calibration gases may be selected almost anywhere within the analyzer’s configured range.

- Page 32 The oxygen sensor requires removal from on-line service to perform calibration. Calibration or other maintenance of the Model 7100E analyzer and sensor should be performed when the measured process is not operating. If the unit has been installed with a Neutronics process sampling system, please refer to the equipment manual for detailed instructions.

-

Page 33: Set/View Alarm-1 Mode

CALIBRATION Step-7; Return the oxygen sensor to online service When calibration procedures are complete, the Model 7100E is ready to return to service. Disconnect calibration gas from the oxygen sensor by completely removing the installed 1/8" FNPT fitting from the sensor flow-through head sample inlet port. -

Page 34: Set/View Alarm-2 Mode

4.3 System modes The Model 7100E has five System modes – Self-Test & warm-up, Run, Alarm-1 Active, Alarm-2 Active, or Fault Active. Self-Test & Warm-up are fixed routines that are initiated upon each start-up. The remaining... -

Page 35: Alarm-1 Active Mode

FAULT ACTIVE mode The Model 7100E initiates Fault Active mode when it has detected that one or more Fault conditions have been satisfied (section 4.3.1). The “FAULT” indicator LED will light and the Fault relay will change state. The Fault status will be cleared automatically when no Fault conditions have been satisfied. The “FAULT”... -

Page 36: Maintenance And Troubleshooting

All configuration parameters may be changed by the user via the Service Port. Important: Before changing any of the Model 7100E settings, refer to Appendix C – Factory Setup for reference. If the user has any questions before proceeding with changing analyzer settings, please contact the Neutronics Service Department for assistance. - Page 37 5.1.1.1 User Setup A: Display range select This parameter allows the user to map the display and electrical output range scale of the Model 7100E to suit the application (Appendix E – Range / Output Chart). Valid Settings: 1 (fixed range 0-10 PPM) • 2 (fixed range 0-100 PPM) • 3 (fixed range 0-1000 PPM) • 4 (fixed range0-2000 PPM) •...

- Page 38 5.1.1.9 User Setup 8: Factory setup restore This parameter allows the user to return the Model 7100E to its initial factory-commissioned settings. Always perform a gas calibration after restoring factory settings. Valid Settings: 88. A setting of 88 will activate the Factory Setup restore.

-

Page 39: System Setup Via Service Port

Fig. 21, user setup menu selections System setup via service port The Model 7100E analyzer features a Service Port, which is accessible for programming the system, monitoring the analyzer output, and determining active fault codes for troubleshooting. The Service Port has been designed for communication with a PC based computer or other device capable of receiving and transmitting ASCII data packets over a standard RS-232 serial interface. - Page 40 Turn off your PC computer, and remove power from the Model 7100E. Complete the instructions for wiring and connecting the Model 7100E to a PC computer (section 2.1.3.10). Apply power to the Model 7100E, and start up the PC computer.

- Page 41 If the typed letters DO show on the monitor screen and serial communications with the Model 7100E still has not been established, then PC COM port pins 2 & 3 (7100E pins 9 & 10) may be reversed. Verify the cable wiring (section 2.1.3.10).

- Page 42 Maintenance and troubleshooting Model 7100E The STANDARD ACCESS level commands: Typed command Description of queried function Short software version Analyzer Model number Sensor output in Percent Oxygen Sensor output in Volts Active Fault codes Active Fault code descriptions Long software version Unit Serial Number There are several data formats of the ASCII data dump available.

- Page 43 Alarm-1 status Alarm-2 status • Checksum End Transmit. For detailed information on data formats, please contact the Neutronics Service Department. 5.1.2.4.5 Tab delimited data format Tab delimited format can be selected via the analyzer control panel, or through the RS-232 interface in Standard Access level.

- Page 44 5.1.2.9 System information display The System Information Display U10 is a list of all the current settings for the Model 7100E analyzer. It is accessed from the Setup Main Menu by typing “1” or “I” on the RS-232 Terminal. 5.1.2.10...

- Page 45 “6” or “H” on the RS-232 terminal. 5.1.2.10.7 Fault relay active during warm-up This setting determines the active status of the Fault relay during the Model 7100E warm-up routine (section 4.3.1.2). The activate setting may be set to “YES” or “NO”. This setting is accessed from the Alarm Relay Setup Menu by typing “7”...

- Page 46 Maintenance and troubleshooting Model 7100E 5.1.2.10.8 Relays disabled after CAL/Setup This setting determines the time that relays will be held in their last state before returning to Run mode from the control panel or service port user menus. The relays disabled time may be set anywhere from 0 to 14,400 seconds.

- Page 47 The RS-232 Display/Auto-Range Setup menu U14 provides access for the user to map the display and Analog output range scale(s) of the Model 7100E to suit the application (Appendix E – Range / Analog output Chart). The Analog Output Range may be set to 1 (fixed range 0-10 PPM) • 2 (fixed range 0-100 PPM) •...

- Page 48 Maintenance and troubleshooting Model 7100E Fig. 25, serial output configuration menu 5.1.2.12.1 Baud rate This menu sets the RS-232 baud rate. The baud rate can be set to 1 (300BPS), 2 (1200BPS), 3 (2400BPS), 4 (4800BPS), 5 (9600BPS), 6 (19200BPS) or 7 (38400BPS). This menu is accessed from the RS-232 Serial Setup menu by typing “1”...

- Page 49 The Assume Low-End Calibration range code (Zero Calibration Range in the setup menu) allows the user to set the range of acceptable LOW calibration gas for the Model 7100E two-point calibration system. During calibration, the Model 7100E analyzer will automatically recognize an applied calibration gas as a LOW range calibration gas if its oxygen concentration is within the range set by the Assume Low-End Calibration range code.

-

Page 50: Change Factory Settings Via Hardware Jumpers

5.1.3.1.1 Remove the unit from service Make certain that all interfacing to the Model 7100E is disabled at the user device. Make sure that interrupting outputs, from the unit will not interfere with normal process monitoring or control. Disconnect power from the Model 7100E unit. Disconnect the removable terminal blocks from the rear of the Model 7100E chassis. -

Page 51: Routine Periodic Maintenance

Model 7100E does not require any major periodic servicing. Calibration of the sensor on a known gas source should be performed on a regular basis. -

Page 52: Troubleshooting

The purpose of the alarm is to provide a control output to indicate that the sensor has not yet reached its operating temperature, and the Model 7100E is not yet ready for in-service oxygen measurement. - Page 53 The “non-native display range” fault indicates oxygen reading that is above the range configuration entered in the Model 7100E setup (section 4.1.2.12). Fault code-11 is active when fault code 5 is active. Possible causes of fault code-11 may be: Incorrect or contaminated calibration gases, faulty process or calibration sampling lines/components.

-

Page 54: Chapter 6 - Appendices

Appendix A Model 7100E Chapter 6 – Appendices 6.1 Appendix A – Spare parts list PART NUMBER DESCRIPTION 5-06-4900-14-1 Operations Manual VAC fuses for power supply board (for VAC units only), C1-11-1220-03-0 1A, 250 VAC, Slo-Blo Replacement terminal block – TB1 C1-17-0052-00-0 Replacement terminal block –... -

Page 55: Appendix B - Specifications

Model 7100E Appendix B 6.2 Appendix B – Specifications Oxygen sensor External Compact Zirconium Oxide 0.75” 7-segment LED digital display, 4 characters Displays oxygen from 0 to 2000 parts-per-million. 0–9.9 PPM 10–99 PPM Resolution: 100–999 PPM XXX. 1,000-2,000 PPM XXXX. - Page 56 Appendix B Model 7100E 0-10 PPM 0-100 PPM Range 0-1000 PPM 0-2000 PPM Accuracy + 1.5 % of range @ calibrated temperature and pressure Response time < 5 seconds Warm up time 60-seconds Analyzer: 0-95 % non-condensing Humidity Sensor: 0-90 % non-condensing Analyzer: 32-122°...

-

Page 57: Appendix C - Analyzer Factory Configuration Settings

Model 7100E Appendix D 6.3 APPENDIX C – Analyzer factory configuration settings Alarm and Relay Setup Information Alarm-1/Alarm-2 relays fail-safe/non-fail-safe non-failsafe Alarm-1/Alarm-2 relay ascending/descending Ascending Alarm-1 trigger level 50 PPM Alarm-2 trigger level 100 PPM Display Range Analog Voltage Output 0–10 PPM Fixed... -

Page 58: Appendix D - Control Panel Hot-Key Functions

Appendix C Model 7100E 6.4 APPENDIX D – Control panel hot-key functions For convenience in operating and troubleshooting, the Model 7100 has four control panel Hot-Key functions that can be performed quickly via the control panel without entering the normal setup menus or the service port user menus. -

Page 59: Appendix E - Range / Output Chart

Model 7100E Appendix E & F 6.5 APPENDIX E – Range / Output chart Range id Range name Measured range Display Analog range voltage output 0.1–9.9 PPM 0–10 PPM 3.13 VDC 10–99 PPM 0–100 PPM 3.75 VDC Auto range 100–999 PPM XXX. -

Page 60: Limited Warranty

NEUTRONICS, INC., except NEUTRONICS, INC. sensors which shall be free of said defects for a period of time from date of shipment as specified in the NEUTRONICS INC. technical specifications for that specific sensor.

Need help?

Do you have a question about the 7100E and is the answer not in the manual?

Questions and answers