Xylem AC Fire Pump 8100 Series Installation, Operation And Maintenance Manual

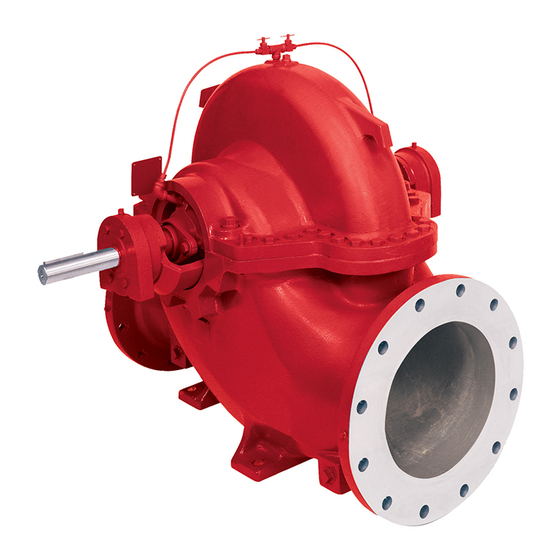

Centrifugal split case fire pumps

Hide thumbs

Also See for AC Fire Pump 8100 Series:

Summary of Contents for Xylem AC Fire Pump 8100 Series

- Page 1 Installation, Operation, and Maintenance manual AC6102 Rev 5 Centrifugal Split Case Fire Pumps Series 8100, 8150, 8200, 9100...

- Page 2 Series 8100/8150/8200/9100 Fire Pump AC6102 Rev 05...

- Page 3 EC Declaration of Conformity Pump supplied complete with driver We, the manufacturer: A-C Fire Pump Systems 8200 N. Austin Ave. Morton Grove, IL 60053, USA, declare under our sole responsibility that the product Horizontal Split Case Centrifugal Fire Pump, Series 8100, 8150, 8200, and 9100;...

- Page 4 Series 8100/8150/8200/9100 Fire Pump AC6102 Rev 05...

-

Page 5: Table Of Contents

5.2.3 Engine driven pump units (Model 150E) ……… 12 Table of contents 1 Introduction ………………………………………………. Storage ………………………….…………………. 13 5.3.1 Temporary storage ……………………………… General …………………………………………… 5.3.2 Long Term Storage ……….…………………… 13 Target Group ……………………………... Safety symbols used in this manual ……... 8 6 Description ……………………………………………..…. - Page 6 Series 8100/8150/8200/9100 Fire Pump Maintenance interval ……………….……………. 29 7.5.3.2 Gap and Angular alignment (X-Y) ……………… 19 Lubrication ……………………………….…….….. 29 7.5.3.3 Parallel Offset Alignment (P) …………...………. 19 9.3.1 Lubricating grease requirements ………….…… 29 7.5.3.4 Insert Grid …………………………………………. 19 9.3.2 Grease lubrication ……………………….…….…. 30 7.5.3.5 Pack with grease and assemble covers ……….

- Page 7 10.5.1.1 Tightening sequence …………………………….. 37 10.5.2 Other Bolt Locations ……………………………… 38 10.6 Spare Parts ………………………………………... 38 10.6.1 Ordering Spare Parts …………………………….. 38 10.6.2 Storage of spare parts …………………………… 38 11 Troubleshooting …………………………………………… 39 12 Replacement Parts ………………………………………… 41 12.1 Series 8100 Horizontal Split Case Fire Pump … 41 12.2 Series 8150 Horizontal Split Case Fire Pump …...

- Page 8 Series 8100/8150/8200/9100 Fire Pump AC6102 Rev 05...

-

Page 9: Introduction

NOTICE Introduction Instructions that are not safety related but pertain to the operation of the pump. General The A-C Fire Pump product line of horizontal split case WARNING centrifugal fire pumps are the product of careful The sound pressure is so high that hearing engineering and skilled workmanship and, if properly protection must be used. -

Page 10: Warning And Instruction Labels

Series 8100/8150/8200/9100 Fire Pump Warning and Instruction Labels Safety Awareness The safety instructions labels placed directly on the pump The safety directions contained in this manual, health and must be observed and legible at all times. If the labels are safety regulations as well as any internal work, operating missing or illegible, contact your local A-C Fire Pump and safety rules issued by the user must be observed. -

Page 11: Product Warranty

2.11 Product Warranty Operational Limits 2.11.1 Coverage WARNING Do not operate the pump at pressures, flow A-C Fire Pump undertakes to remedy defects in their rate or liquid temperature other than those for products under these conditions: which the pump has been rated. Failure to follow these instructions could result in •... -

Page 12: Delivery, Handling, And Storage

Series 8100/8150/8200/9100 Fire Pump Delivery, handling, and storage Delivery The pump is delivered from the factory in a container specially designed for transport by fork-lift truck or a similar vehicle. Upon receipt, check the pump visually to determine whether any damage has happened during transport or handling. -

Page 13: Vertical - Half Pedestal - Model

5.2.2.3 Vertical – Full Pedestal – Model 300 Install eyebolts in the three holes provided at the top of the support, being sure to tighten securely. Attach nylon sling, chain or wire rope using latch hook or standard shackle and end loop. -

Page 14: Storage

Series 8100/8150/8200/9100 Fire Pump Storage CAUTION Damage due to dirt and humidity resulting in corrosion and contamination of the pump unit. NOTICE For special protection of electric motors, diesel engines, and couplers, refer to the manufacturer’s instruction for their long term storage procedures. -

Page 15: Description

Item Description Description Manufacturer Approval Agencies General Size The horizontal split case centrifugal fire pump is a single stage [series 8100, 8150 and 9100] and two stage [series Model Type 8200] non self-priming pump. Serial number Designation Head [feet] Rated flow rate [GPM] The fire pump can be identified by size designation stated on the nameplate;... -

Page 16: Design Detail

Series 8100/8150/8200/9100 Fire Pump 6.4.4 Shaft sleeves Item Description The shaft sleeves are made of bronze and protect the Manufacturer shaft from wear and from contact with the pumped liquid. CE Mark Shaft sleeves are locked in place by threaded bronze shaft sleeve nuts. -

Page 17: Noise Characteristics

Noise characteristics Installation The maximum measured A-weighted sound pressure level This section describes the installation of a complete ] for the pump and motor, measured at a distance of pump unit. 3.3 ft. [1m] from the pump, under full load, in accordance with EN ISO 3746 is 90dB. -

Page 18: Leveling The Baseplate

Series 8100/8150/8200/9100 Fire Pump grooved before the concrete sets; this provides a bonding remove coupling guard, see section 8.2 Coupling Guard, for surface for the grout. checking alignment.) Foundation bolts should be set in concrete as shown in Fig. If alignment needs improvement, add shims or wedges at 6. -

Page 19: Initial Alignment

Initial Alignment 7.5.1 Straightedge method of alignment The most simple alignment check is with a straight edge and WARNING calipers. This method is the least accurate, but will serve if a Disconnect and lock out power before dial indicator or laser is not available. performing alignment. -

Page 20: Angular Alignment

Series 8100/8150/8200/9100 Fire Pump The clearance must not exceed the Parallel Offset installation 7.5.2.1 Angular Alignment limits specified in Table 5. To check angular alignment, mount dial indicator (A) to the If adjustment is needed, loosen the motor bolts and add or coupling half (X), and position the dial indicators button on the remove an equal amount of shims under each motor foot to face of the opposite coupling half (Y). -

Page 21: Pipe Connections

Cover Maximum Fastener Allowable SIZE Lube Wt. Tightening Speed Torque (rpm) in.lb 1040T 11.3 3600 1.90 1050T 22.6 3600 2.40 1060T 22.6 3600 3.00 1070T 22.6 1800 4.00 1080T 22.6 1800 6.10 Table 5 Continued Pipe connections CAUTION Do not draw piping into place by using force at the flanged connections of the pump. -

Page 22: Maximum Forces And Moments Allowed On Pump Flange

Series 8100/8150/8200/9100 Fire Pump 7.6.2 Maximum forces and moments allowed on pump flange 7.6.2.1 8100 series Horizontal Split Case maximum forces and moments allowed Maximum forces (F) in lbf (N) and moments (M) in lbf.ft (Nm) Size Suction Discharge 3X2X11 (165) (205) (178) -

Page 23: 9100 Series Horizontal Split Case Maximum Forces And Moments Allowed

7.6.2.4 9100 series Horizontal Split Case maximum forces and moments allowed Maximum forces (F) in lbf (N) and moments (M) in lbf.ft (Nm) Size Suction Discharge 12X8X21 (858) (1076) (743) (306) (382) (766) (351) (436) (480) (125) (156) (312) 12X8X22 (858) (1076) (743) -

Page 24: Suction Piping

Series 8100/8150/8200/9100 Fire Pump 7.6.3 Suction piping The sizing and installation of the suction piping is extremely important. It must be selected and installed so that pressure losses are minimized and sufficient liquid will flow into the pump when started and operated. Many NPSH (Net Positive Suction Head) problems can be directly attributed to improper suction piping systems. -

Page 25: Discharge Piping

Globe valves should not be used, particularly where NPSH is 7.6.4 Discharge piping critical. If the discharge piping is short, the pipe diameter can be the The pump must never be throttled by the use of a valve on same as the discharge opening. If the piping is long, the pipe the suction side of the pump. -

Page 26: Pressure Gages

Series 8100/8150/8200/9100 Fire Pump The exhaust pipe shall be covered with high-temperature Final alignment insulation or otherwise guarded to protect from personal injury. WARNING The exhaust pipe and muffler, if used, shall be suitable for the Do not operate pump with coupling out of use intended, and the exhaust back-pressure shall not alignment. -

Page 27: Start-Up, Operation And Shutdown

Assure that pump bearings are properly lubricated. Assure that coupling is properly lubricated, if required. Start-up, operation and Assure that pump is full of liquid and all valves are shutdown properly set and operational, with the discharge valve closed and the suction valve open. Purge all air from top of casing. -

Page 28: Removing The Coupling Guard

Series 8100/8150/8200/9100 Fire Pump 8.2.1 Removing the coupling guard Identify the parts of the coupling guard, see Fig. 19. Unfasten the (4) cap screws, [item 6], that secure the outer guard, [item 8], to the inner guard, [item 5]. Spread the outer guard, [item 8], and pull it off the inner guard, [item 5]. -

Page 29: Operation

Operation Shutdown WARNING WARNING Pump units have a sound pressure level Escaping pressurized liquids. Liquid draining higher than 85 dB(A). Hearing protection from the pump could result in personal injury must be worn when the pump is running. and equipment damage. WARNING NOTICE Do not operate the pump at or near zero flow,... -

Page 30: Maintenance

Series 8100/8150/8200/9100 Fire Pump Maintenance Interval Maintenance Inspection intervals should be carried out in accordance with WARNING the maintenance table, Table 6. Rotating parts. Disconnect and lock out power before performing maintenance. Failure to follow these instructions could result in serious personal injury. -

Page 31: Grease Lubrication

9.3.2 Grease Lubrication 9.4.2 Packing maintenance In accordance with the maintenance schedule, the packing WARNING should be visually inspected once a month and the leakage Never check the temperature of the bearing rate checked. If the leakage rate is excessive then the gland frame by hand, use a temperature measuring nuts may be tightened, until the required leak rate is obtained, device. -

Page 32: Packing Adjustment

Series 8100/8150/8200/9100 Fire Pump Check the shaft to ensure that it can be rotated after fitting each packing ring. Fit as many rings as possible into the stuffing box without having any packing protruding, and without over-compressing the packing NOTE: The last ring in each box may not be required until after the pump has operated for a period of time. -

Page 33: Service

for 8150, 8200 and 9100 can be identified by the description in the parts lists. Service 10.2.1 Rotating Element The procedures outlined in this section cover the dismantling Isolate driver and lock out power supply in accordance and reassembly of four different model types of Horizontal with local regulations. -

Page 34: Shaft Sleeve

Series 8100/8150/8200/9100 Fire Pump 10.2.4 Shaft sleeve 10.4 Assembly Refer to section 12, Replacement Parts, for exploded Loosen set screws [3-902-3] in shaft nuts [3-015-9] and drawings and parts lists. Part numbers listed in this procedure then remove shaft nuts using pin spanner wrench. refer to the 8100 series pumps;... -

Page 35: Impeller

10.4.2 Impeller Pump Size Packing Size 10.4.2.1 Series 8100, 8150 and 9100 3X2X11F-S 8.755 Assemble the impeller key [3-911-1] in the shaft [3-007- 0.375 6X4X9F 9.312 Check the impeller [4-002-0] and casing to determine the correct impeller rotation, and locate the impeller on 6X4X10F-M 10.625 0.500... -

Page 36: Series 8200

Series 8100/8150/8200/9100 Fire Pump Pump Size Packing Size 12X8X21F 13.50 12X8X22F-M 0.625 14X10X20F 15.81 16X12X23F 14X10X20F-L 16.60 Table 10 Series 9100 Impeller Location 10.4.2.2 Series 8200 Fig. 22 Series 8200 Impeller location Assemble the impeller key [3-911-1] in the shaft [3-007- Identify the first and second stage impellers [4-002-0] by the casted label, and locate the second stage impeller on the shaft in accordance with Fig. -

Page 37: Series 8150

Allow the bearing to cool to room temperature. Coat the 10.4.3.4 Series 9100 exposed sides with 2 to 3 oz. [55 to 85 g] of the Press bearing isolators [1-333-1] in each bearing cover recommended grease. [3-018-3, 3-018-4]. Install gaskets [3-409-9] on each Coat the inside of the bearing housing [3-025-4] with bearing cover. -

Page 38: Series 9100

Series 8100/8150/8200/9100 Fire Pump the inboard bearing housing towards the coupling 10.5 Tightening Torques slightly will ease assembly). Bolt the outboard bearing housing in place. Ensure that 10.5.1 Casing Bolts both housings are seated properly in the lower half The standard bolt class is SAE J429 or higher with a non- casing. -

Page 39: Other Bolt Locations

10.5.2 Other bolt locations Torque Grade Head Bolt Size Max Value Identification ft-lb [N.m] 5/16-18 11 [15] 3/8-16 20 [27] 7/16-14 32 [43] 1/2-13 49 [66] 5/8-11 97 [132] Fig. 23 Bolt tightening pattern 3/4-10 172 [230] 250 [340] Torque 3/8-16 31 [42] Grade... -

Page 40: Troubleshooting

Series 8100/8150/8200/9100 Fire Pump Troubleshooting Between regular maintenance inspections, be alert for signs of driver or pump trouble. Common symptoms are listed below. Correct any trouble immediately and avoid costly repair and shutdown. WARNING Disconnect and lock out power to the pump before trying to determine a failure. - Page 41 Table 14 Troubleshooting List AC6102 Rev 05...

-

Page 42: Replacement Parts

Series 8100/8150/8200/9100 Fire Pump Replacement Parts 12.1 Series 8100 Horizontal Split Case Fire pump Fig. 23 Exploded view of 8100 Horizontal Split Case Fire Pump AC6102 Rev 05... - Page 43 Table 15 List of components 8100 Horizontal Split Case Fire pump Cat. No. Description Cat. No. Description 0-910-0 Pipe Plug (Casing) 3-025-3 Housing, Inboard Bearing 0-912-0 Pipe Fitting 3-025-4 Housing, Outboard Bearing 0-944-0 Spirol Pin (Shaft Sleeve) 3-026-3 Bearing, Inboard 0-950-0 Pipe Nipple 3-026-4...

-

Page 44: Series 8150 Horizontal Split Case Fire Pump

Series 8100/8150/8200/9100 Fire Pump 12.2 Series 8150 Horizontal Split Case Fire pump Fig. 24 Exploded view of 8150 Horizontal Split Case Fire Pump AC6102 Rev 05... - Page 45 Table 16 List of components 8150 Horizontal Split Case Fire pump Cat. No. Description Cat. No. Description 0-905-0 Grease Fitting 3-009-2 Shaft Sleeve 0-909-0 Washer 3-015-9 Shaft Sleeve Nut 0-910-7 Pipe Plug 1/4 NPT Sstl 3-025-3 Housing, Inboard Bearing 0-910-8 Pipe Plug 3-025-5 Bearing Bracket...

-

Page 46: Series 8200 Horizontal Split Case Fire Pump

Series 8100/8150/8200/9100 Fire Pump 12.3 Series 8200 Horizontal Split Case Fire pump Fig. 25 Exploded view of 8200 Horizontal Split Case Fire Pump AC6102 Rev 05... - Page 47 Table 18 List of components 8200 Horizontal Split Case Fire pump Cat. No. Description Cat. No. Description 1-952-0 Bleed Line 3-026-4 Bearing, Outboard 1-952-0 Flush Line 5-050-4 Split Ring 0-910-9 Pipe Plug 5-421-4 Retaining Collar 1-013-9 Seal Cage 3-169-9 Deflector 1-014-9 Gland 3-177-9...

-

Page 48: Series 9100 Horizontal Split Case Fire Pump

Series 8100/8150/8200/9100 Fire Pump 12.4 Series 9100 Horizontal Split Case Fire pump Fig. 26 Exploded view of 9100 Horizontal Split Case Fire Pump AC6102 Rev 05... - Page 49 Table 19 List of components 9100 Horizontal Split Case Fire pump Cat. No. Description Cat. No. Description 0-901-0 Valve 3-015-9 Shaft Sleeve Nut 0-910-0 Pipe Plug 3-018-3 Bearing Housing Cover (Inboard) 0-950-0 Pipe Nipple 3-018-4 Bearing Cover (Outboard) 0-952-0 Tubing 3-025-2 Bearing Housing 1-013-2...

-

Page 50: A Appendix

Series 8100/8150/8200/9100 Fire Pump Appendix AC6102 Rev 05... -

Page 51: A1 Coupling Guard Removal - Non Ce Version

Coupling Guard Removal and Installation (Non CE version) NOTE: Do not spread the inner and outer guards more than necessary for guard removal or installation. Over- spreading the guards may alter their fit and appearance. A1.1 Removal Remove the two (2) cap screws that hold the outer (motor side) coupler guard, (item 1); to the support bracket(s), (items 3 (and item 6)). -

Page 52: A2 Changing Pump Rotation

Series 8100/8150/8200/9100 Fire Pump Changing Pump Rotation Every series Horizontal Split-case Centrifugal Fire Pumps can be operated clockwise or counter-clockwise when viewed from the coupling end of the pump. If you wish to reverse the suction and discharge nozzles, this can be accomplished with the same pump as follows: NOTE: Refer to the disassembly and assembly procedures in section 10 of this manual for proper disassembly and assembly techniques. - Page 53 COMMERCIAL WARRANTY Warranty. For goods sold to commercial buyers, Seller warrants the goods sold to Buyer hereunder (with the exception of membranes, seals, gaskets, elastomer materials, coatings and other "wear parts" or consumables all of which are not warranted except as otherwise provided in the quotation or sales form) will be (i) be built in accordance with the specifications referred to in the quotation or sales form, if such specifications are expressly made a part of this Agreement, and (ii) free from defects in material and workmanship for a period of one (1) year from the date of installation or eighteen (18) months from the date of shipment (which date of shipment shall not...

- Page 54 8200 N. Austin Avenue Morton Grove, Illinois 60053 © 2021 Xylem Inc. AC Fire Pump is a trademark of Xylem Inc. or one of its Tel: (847) 966-3700 subsidiaries. Fax: (847) 966-1914 www.xylem.com/acfirepump...

Need help?

Do you have a question about the AC Fire Pump 8100 Series and is the answer not in the manual?

Questions and answers