Table of Contents

Advertisement

Advertisement

Table of Contents

Summary of Contents for Motorline professional SIGMA X

- Page 1 SIGMA X SIGMA X USER / INSTALLER'S MANUAL v1.0 REV. 08/2020...

-

Page 2: Table Of Contents

00. CONTENT 01. SAFETY INSTRUCTIONS INDEX ATENTION: 01. SAFETY INSTRUCTIONS This product is certified in accordance with European Community (EC) safety standards. 02. AUTOMATISM TECHNICAL CHARACTERISTICS This product complies with Directive 2011/65/EU of the KIT COMPONENTS European Parliament and of the Council, of 8 June 2011, on LIGHT FLASHLIGHT the restriction of the use of certain hazardous substances in MANUAL OPENING / CLOSING... - Page 3 01. SAFETY INSTRUCTIONS GENERAL WARNINGS • Children shouldn’t play with the product or opening devices to avoid the motorized door or gate from being triggered involuntarily. • This manual contains very important safety and usage information. very important. Read all instructions carefully before beginning the WARNINGS FOR TECHNICIANS installation/usage procedures and keep this manual in a safe place that it can be consulted whenever necessary.

- Page 4 01. SAFETY INSTRUCTIONS RESPONSABILITY September 2009. • Attach the permanent label for the manual release as close as possible • Supplier disclaims any liability if: to the release mechanism. • Product failure or deformation result from improper installation • Disconnect means, such as a switch or circuit breaker on the electrical use or maintenance! panel, must be provided on the product’s fixed power supply leads in •...

-

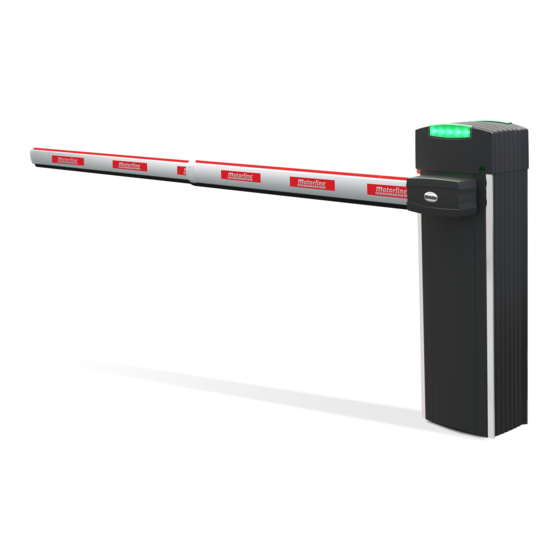

Page 5: Automatism

TECHNICAL CHARACTERISTICS KIT COMPONENTS You should check if the following items are in the automatism package before you start the installation. SIGMA X is an electromechanical barrier designed to control vehicle access to private, industrial or commercial areas. • MC61BR control •... -

Page 6: Light Flashlight 5A

02. AUTOMATISM 02. AUTOMATISM LIGHT FLASHLIGHT MANUAL OPENING / CLOSING This barrier has two RGB flashlights integrated in the top cover, for emission of red, green and blue In an emergency or during the barrier installation / adjustment phase, it may be necessary to move colors. -

Page 7: Installation

03. INSTALLATION INSTALLATION MAP 1 • SIGMA X 9 • Barrier Cover 2 • Bar 10 • Transformer 3 • Bar Extension 11 • Manual movement handle 4 • Photocell support column (not included) 12 • Motor 5 • Photocell 13 •... -

Page 8: Remove Cover And Profiles 7A

03. INSTALLATION 03. INSTALLATION REMOVE COVER AND PROFILES SHOE CREATE SHOE This barrier allows free access to the interior to facilitate the product installation and maintenance • process. To do so, remove the aluminum cover and profiles from the barrier. Drill a hole of 355x470mm and 400mm (or greater) deep to create the fixing shoe. -

Page 9: Automatism Installation

7B (not supplied in the kit). *Once fixed at the ground, the SIGMA X is ready to allow a position adjustment of a few millimeters. Adjustment is made by rotating the barrier in relation to its center. -

Page 10: Spring Direction

If you order the SIGMA X without specifying the position of the rod, it will be mounted on the If you order the SIGMA X for a 6 meter rod (SIGMA - X6) it will be mounted with 2 springs. -

Page 11: Exchange 2 Springs For 1 Spring

03. INSTALLATION EXCHANGE 2 SPRINGS FOR 1 SPRING If the springs are on the wrong side for the desired stem direction (see diagram on page 9A), the position of the springs on the rotation lever must be reversed. To do this, you will need to: 1 ·... -

Page 12: Bar Mounting

03. INSTALLATION BAR MOUNTING Fit the remaining pieces in the order shown in the picture. Route the cable that comes out of the barrier shaft through the hole REVERSE BAR SUPPORT • in the assembly you assembled. Secure the parts to the stem clamping plate with screws and bolts provided in the package. -

Page 13: Fix Bar Supports

03. INSTALLATION FIX BAR SUPPORTS SET EXTENDING BAR LENGTH ADJUSTING SUPPORT (FIXED) HEIGHT • • If the height of the support arm is misaligned to the height of the bar you will have to adjust the arm You should now set its length so that you can then place the support as shown in the image below. height. -

Page 14: Adjust The Springs

03. INSTALLATION ADJUST THE SPRINGS Before adjusting the springs, manually place the stem in a vertical position so that the springs are in the Hold the threaded bar with pliers so that it lowest tension position (see page 5B). does not rotate, and then tighten the adjusting female until each spring is stretched the distance mentioned in the table on page 14. -

Page 15: Adjusting Tables

03. INSTALLATION ADJUSTING TABLES LEVER HOLES • Hole 2 Hole 1 Hole 1 Hole 2 SIGMA - X6 SIGMA - X4 HASTE SIMPLES HASTE SIMPLES 4000 3500 3000 6000 5500 5000 4500 Amount Amount 1 spring 2 springs Adjustment Adjustment 55mm 30mm 70mm... -

Page 16: Testing Spring Adjustment

03. INSTALLATION 03. INSTALLATION TESTING SPRING ADJUSTMENT POWER CABLE * The barrier structure has a tube located on the inside so that it can lead the supply wiring to the connectors The motor must remain unlocked to perform the tuning test. (top of the barrier). -

Page 17: Adjust Stops

03. INSTALLATION 03. INSTALLATION ADJUST STOPS FINE-TUNING THE LIMIT SWITCHES The stops in the barrier are visible in the image of the ceiling. The SIGMA-X has limit switches to complete the opening and closing maneuvers, located on the • Constan of 2 adjustment screws (one on each side of the barrier) fastened to the base as well as its 2 rotation lever. -

Page 18: Apply Profiles And Cover

03. INSTALLATION APPLY PROFILES AND COVER APPLY PROFILES • Position the BACK PROFILE in the correct location (profile previously placed for rod application). Holding the BACK PROFILE so that it does not dislocate, fit the SIDE PROFILES into the barrier frame. -

Page 19: Connections

24AC LOCK FCH PUL + BAT - LAMP • Control board MC61 BR (Barrier Interior) • Transformer • Limit Switch • SIGMA X • MP106 module Barrier LGHI 12V+ GI RGI • Barrier cover • LED Strip (Flashing Light) MOTOR WIRES | CONNECTION... -

Page 20: Photocell Connections And Safety Band

04. CONNECTIONS PHOTOCELL CONNECTIONS AND SAFETY BAND WITHOUT SAFETY BAND WITH SAFETY BAND (SERIAL CONNECTION) • • • LED strip (bar) • Security Band (Optional) • Control board LOCK FCH PUL 24AC LOCK FCH PUL • Control board MC61 + BAT - LAMP MC61 BR (Barrier BR (Barrier Interior) -

Page 21: Troubleshooting

05. TROUBLESHOOTING INSTRUCTIONS FOR FINAL CONSUMERS / SPECIALIZED TECHNICIANS Anomaly Procedure Behavior Procedure II Discovering the origin of the problem 1 • Remove the barrier top cover; • Barrier • Make sure you have • Still not working • Consult a qualified 2 •...

Need help?

Do you have a question about the SIGMA X and is the answer not in the manual?

Questions and answers