Table of Contents

Advertisement

Quick Links

®

SPM

Well Service Pumps & Flow Control Products

®

Safety Iron

Operating and Maintenance Instructions

Copyright © 2016, S.P.M. Flow Control, Inc.. All rights reserved. S.P.M. Flow Control, Inc. is the owner of the copyright and all confidential information in

this document, which must not be copied in whole or in part, in any form or by any means, and the information in it must not be used for any purpose

other than the specific purpose for which it has been provided without the prior written consent of the copyright owner. SPM, SAFETY IRON, SAFETY

HAMMER, SUR-DROP, DESTINY, STAMPEDE, DURALAST and GLADIATOR are trademarks and/or registered trademarks of S.P.M. Flow Control,

Inc.. WEIR and WEIR (logo) are trademarks and/or registered trademarks of Weir Engineering Services Limited. Certain features of some of the products

disclosed in this document may be protected worldwide by patents pending and registered in the name of S.P.M. Flow Control, Inc..

Document P/N:

2P42520

Release Date:

07/11/2016

Revision:

D

Advertisement

Table of Contents

Summary of Contents for Weir Safety Iron

- Page 1 SPM, SAFETY IRON, SAFETY HAMMER, SUR-DROP, DESTINY, STAMPEDE, DURALAST and GLADIATOR are trademarks and/or registered trademarks of S.P.M.

- Page 2 Document P/N: 2P42520 Release Date: 07/11/2016 Revision: ® PRODUCT SAFETY GUIDE WARNING: IMPORTANT SAFETY INFORMATION ENCLOSED. READ THIS OPERATING AND MAINTENANCE INSTRUCTIONS MANUAL BEFORE OPERATING PRODUCT. WARNING: THIS INFORMATION MUST BE AVAILABLE TO ALL PERSONNEL THAT WILL OPERATE AND MAINTAIN EQUIPMENT. FAILURE TO READ, UNDERSTAND AND FOLLOW THE OPERATING AND MAINTENANCE INSTRUCTIONS MANUAL COULD RESULT IN SERIOUS BODILY INJURY, DEATH, OR PROPERTY DAMAGE.

- Page 3 1. Modifications to or unauthorized repair of any part of a SPM product, or use of components not qualified by Weir Oil & Gas , can lead to damage or failure resulting in SERIOUS INJURY OR DEATH! ® 2. All SPM threaded components are right hand threaded unless specifically designated otherwise.

-

Page 4: Table Of Contents

Document P/N: 2P42520 Release Date: 07/11/2016 Revision: TABLE OF CONTENTS SECTION I: GENERAL INFORMATION ......................5 : ........................... 5 HIS SERVICE MANUAL COVERS : ..............................5 : ................................. 6 VERVIEW ® – E ........................7 AFETY XPLODED : ..............................8 AINTENANCE : .............................. -

Page 5: Section I: General Information

Document P/N: 2P42520 Release Date: 07/11/2016 Revision: SECTION I: General Information This service manual covers: Parts List Item Size Pressure (PSI) Assembly Bolt Bolt Clamp Soft/Hard Clamp (in) Retainer (Plain) Seal (Threaded) 4&5 2” 15,000 2A25919 2P25242 2P25243 2P25918 2A39288 2P25916 3”... -

Page 6: Overview

® the oil and gas industry. Safety Iron products eliminate the safety hazard of swinging a hammer to make up and break down a connection while providing stronger, more durable connections that are less fatiguing for the user. -

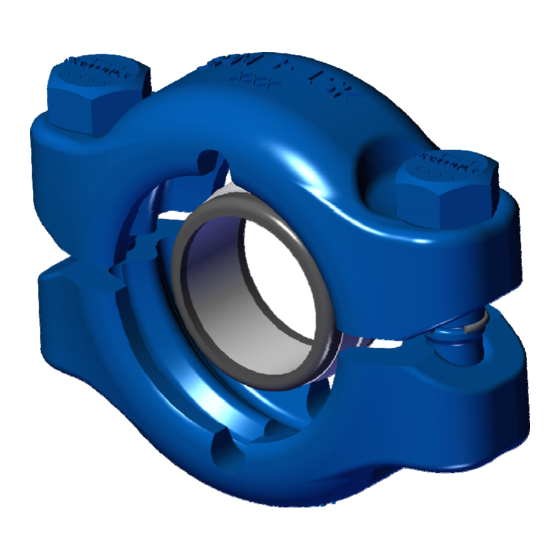

Page 7: Exploded View

Document P/N: 2P42520 Release Date: 07/11/2016 Revision: ® ® Safety Iron – Exploded View Parts List Description Bolt Bolt Retainer Clamp (Plain) Soft Seal Hard Seal Clamp (Threaded) 7 of 22... -

Page 8: Maintenance

All metal components have full material traceability and are identified by their VENDOR ID (SPM), PART NUMBER, SIZE, PRESSURE RATING, HEAT CODE. ® Top View – Non Threaded Safety Iron Half (Showing identification markings) Inspection: ®... -

Page 9: Engineering Reference Documents

Engineering Reference Documents ® ® The following list of SPM Engineering documents serves as guidelines when working with Safety Iron products. It is important that all are adhered to and are completed by a qualified technician. ® ® ENG-051 Safety Iron Clamp Assembly &... -

Page 10: Section Ii: Installation And Operation

This manual torque wrench should be periodically calibrated to verify accuracy in the field. Failure to follow Weir Oil & Gas suggestions for equipment, methodology, and verification may result in ®... -

Page 11: Impact Wrench Specifications

4" 300 to 1000 Impact Wrench Specifications C) Torque Regulating Bar (TRB) - Safety Iron® bolts must be properly tightened during assembly to preserve ® the pressure and structural integrity of the joint. SPM requires that all bolts be torqued such that they fall within ®... - Page 12 Document P/N: 2P42520 Release Date: 07/11/2016 Revision: Installation Equipment, Accessories & Specifications continued This device appears like a simple hex drive extension but is actually an engineered product that limits the torque that an impact wrench can impart to a bolt. This functionality is achieved by a specific combination of physical geometry and material properties of the steel.

-

Page 13: Safety Iron ® Bolt Torque Values

Please note that over- or under-torqueing the bolts outside of the indicated range is detrimental to the performance and safety of the assembly and may lead to leakage or even failure. DO NOT USE TRB TO REMOVE BOLTS - FAILURE MAY OCCUR. ® Safety Iron Bolt Torque Torque Safety Pressure Capacity ®... - Page 14 Torque Regulating Bar. If this extension is not available, the manual torque wrench must be ® used on each assembled Safety Iron connection in order to verify the proper torque. Each manual torque wrench has a 1/2" drive (or larger) in order to more easily match sockets used for the ®...

- Page 15 ® ® G) Socket Size – SPM Safety Iron comes with specified bolt-hex head sizes. Sockets to tighten these bolts are required to match perfectly. The following sockets should come (at a minimum) with a 1/2" drive: Bolt Hex Head Sizes...

-

Page 16: Section Iii: Assembly Of Components

2P42520 Release Date: 07/11/2016 Revision: SECTION III: Assembly Of Components Repeated assembly testing has given Weir Oil & Gas the opportunity to determine the safest, fastest, easiest, ® ®. and most repeatable way to (dis)assemble SPM Safety Iron The below instructions detail the suggested ®... - Page 17 ® 4. Slide the threaded clamp half underneath the SPM Safety Iron flanges, pulling it snugly against the flange outer faces. In the interest of eliminating a pinch point, it is best if the clamps are oriented at a 45 degree angle (see bottom right photo).

- Page 18 Document P/N: 2P42520 Release Date: 07/11/2016 Revision: Assembly of Components continued 7. Attach the Torque Regulating Bar to an approved power wrench. Care must be taken that bar has the appropriate rating for the intended application. This is clearly indicated on the large end of the extension. 8.

-

Page 19: Flow Line Inspection

Revision: Flow Line Inspection Weir Oil & Gas strongly recommends performing a flow line inspection to verify that each clamp has been assembled prior to pressurizing the line. This will require physically inspecting the underside of each clamp to verify that bolt is within approximately 1/4" of the opening in the bottom threaded clamp. This action will provide additional verification that any clamps that may have been loosened to allow for adjustment during the installation process were properly re-tightened. -

Page 20: Section Iii: Disassembly

Document P/N: 2P42520 Release Date: 07/11/2016 Revision: SECTION III: Disassembly Disassembly of components is roughly the reverse of the assembly. Do not use Torque Regulating Bar to remove bolts - failure can occur. Care should be taken to loosen the bolts in a gradual manner. The "two step"... -

Page 21: Troubleshooting Guide

Excessive overpressure Warped Safety Iron® Replace bolts (and all other parts) immediately. bolts Excessive torque on Safety Iron® bolts may warp them. Excessive over tightening Replace bolts and clamps immediately. Excessive overpressure may warp a metal seal ring. Replace seal Excessive overpressure ring (and all other parts) immediately. -

Page 22: Section Iv: Service And Support

SAFETY IRON, SAFETY HAMMER, SUR-DROP, DESTINY, STAMPEDE, DURALAST and GLADIATOR are trademarks and/or registered trademarks of S.P.M. Flow Control, Inc.. WEIR and WEIR (logo) are trademarks and/or registered trademarks of Weir Engineering Services Limited. Certain features of some of the products disclosed in this document may be protected worldwide by patents pending and registered in the name of S.P.M.

Need help?

Do you have a question about the Safety Iron and is the answer not in the manual?

Questions and answers